The recent emergence of automobile technologies has been about more than just improving vehicle performance; it has focused also on external conditions such as weather and traffic conditions that influence driving. The recently released 3rd-gen K5’s themed cluster is one such example: it reacts to the weather and the time of day to change the graphics of the digital display, allowing the driver to more intuitively understand the information on the cluster.

Hyundai/Kia’s recent development of the new transmission system follows this trend as well: the new ICT-connected transmission system reacts to the oncoming road and traffic signal conditions to automatically optimize the gear settings. Thanks to the development of this active transmission technology, automatic transmissions―which used to simply select the gear settings on the basis of vehicle speed and driver pedaling―are expected to see dramatic improvements in both performance and efficiency.

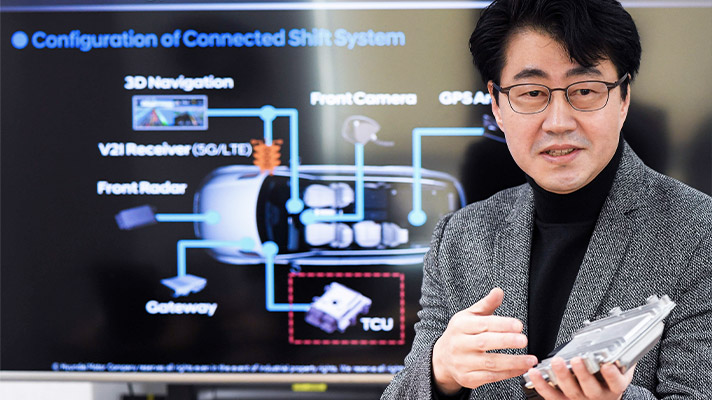

The crux of the ICT-connected transmission system is the TCU (Transmission Control Unit), which gathers and processes the complex array of information from the 3D navigation, forward-facing radar and camera, and V2I communication modem. Using this information, the TCU can establish the optimal gear-shifting logic for the oncoming road conditions. Sometimes aggressive and other times conservative as the conditions necessitate, the transmission system allows for improvements in both driving performance and fuel efficiency.

The ICT-connected transmission system signals the emergence of a new paradigm in intelligent transmission technology. We discussed the tech with its developers, all hailing from Hyundai/Kia’s Intelligent Drivetrain Control Lab.

Q. What is the difference between the ICT-connected transmission and the ‘Smartshift’ technology widely in use for the existing Hyundai/Kia and Genesis models?

Jeon ByeongWook, Research Fellow | There is a concept called “3 elements of driving.” The idea is that for driving to occur, the three elements of ‘driver,’ ‘road,’ and ‘traffic’ are essential prerequisites. Smartshift only used the first element ‘driver’ to execute automatic gear shifting. In order to shift gears, the TCU needs to gather such information as vehicle speed, the force on the acceleration pedal, and so on. Using this, the TCU determines the driver’s tendencies, which in turn determine the transmission’s settings.

The ICT-connected transmission is linked to such external devices as the navigation, radar, and camera. In essence, we’re incorporating the ‘road’ and ‘traffic’ elements into the mechanism. Metaphorically, whereas Smartshift only takes care of in-house affairs, the ICT-connected transmission looks outside-the-house and considers external affairs as well in its decisions.

But the external signals and information at an unprocessed state cannot be used by the transmission. So we need to develop an algorithm that translates ‘sensor signals’ into a kind of road status info―in other words, the TCU can make its optimal gear shifting decisions only when the decoding algorithm has finished its job. This algorithm, of course, includes the aforementioned tasks of Smartshift as well.

Q. Didn’t taking in so much data demand a higher performance from the TCU?

Jeon ByeongWook | The TCU is already an intricate assemblage of a variety of high-level technologies. This means that any upgrade would inevitably entail a high cost increase. Luckily, the current mass-produced TCU is capable enough to smoothly deal with its existing demands from traditional gear-shift algorithms. We believed that a bit more of a burden on it wouldn’t hurt, so we focused on maximizing the capacity of the existing TCU, increasing the algorithmic efficiency and polishing the software.

Q. Any separate control logic for emergency on-road situations?

Jeon ByeongWook | The ICT-connected transmission system is, from the blueprint, built for use in all on-road situations. Naturally, that includes emergency situations as well. For example, the driver may want to manually reduce the speed and/or shift the gears while the vehicle is slowing down; or, a car ahead may suddenly slow down or cut in, while the system’s coasting function is on for fuel efficiency’s sake. In the latter case, the neutral gear set by the function will be revoked, and the transmission’s clutch will be applied to return to the normal driving gears.

Q. Given the differences in many countries’ road and traffic conditions, can the ICT-connected transmission system be useful globally?

Park KwangHee, Senior Researcher | The ICT-connected transmission system is in the main composed of eight functions. Of them, the ‘cornering prediction gear shift’ function should be useful in places with numerous road curvatures, like Korea and Europe; the ‘intersection prediction gear shift’ function should be useful in the United States, where the 4-way stop concept is central to the intersection design.

Speaking of the Korean roads, there are lots and lots of speed bumps, which makes mandatory slowing and re-accelerating common. The ‘speed bump prediction gear shift’ function should be useful there. It facilitates the acceleration after going through a bump, and even minimizes fuel waste by limiting the excessive pressure on a gas pedal.

In the countries where the roads have frequent changes in the speed limit, like Germany’s Autobahn or Korean highways, the ‘speed limit passage prediction gear shift’ function would be useful. But given the often large differences in the countries’ traffic control system, the ‘forward traffic signal linkage’ function, a very important part of the overall system, would require a separate localization process.

Q. Wouldn’t the active intervention from the transmission system cause a degree of awkwardness on the driver’s part?

Jeon ByeongWook | The short answer is not too much, since the ICT-connected transmission system is ultimately limited to the role of performing ‘timely assistance’ to the driver. The operating logic of the control algorithm changes the control mode in accordance with the driving condition, and above all strives to make the acceleration as natural as possible. For example, in places where a sharp acceleration is needed, like a highway entryway, the system’s driving mode can be set to automatically switch into the ‘sports mode’. In our lab’s internal testing, the participating Researchers all remarked that this function made driving quite fun. The function only activates when there is no traffic jam and unhindered acceleration is possible, so the drivers felt no awkwardness from the system intervention.

Q. How does the system function when the driver wants to manually take control of the gear shifting?

Kook JaeChang, Senior Researcher | The very purpose of the ICT-connected transmission is to operate naturally, under-the-surface, without breaching into the driver’s consciousness. The system also adjusts the degree of intervention to match the driver tendencies, so in normal situations we don’t expect the drivers to want to manually operate the gears. But if they want to, they can simply switch the transmission to the manual mode, which would turn off the connected transmission function. We’re currently thinking about an interface that allows the driver to custom-select among the various prediction functions of the system, which we hope will nearly eliminate the need for manual transmission control.

Q. Are there any favorable byproducts of the new transmission system?

Kook JaeChang | We didn’t intend on it, but yes, vehicles with the ICT-connected transmission system have shown non-negligible improvements in parts durability. Limiting the unnecessary gear shifting and breaking means less burden on the relevant parts and a reduction of fuel consumption in all driving conditions. Another favorable byproduct came in comfortability―on winding roads, it’s easy to feel some discomfort at the constant speed changes and gear shifting. The new transmission system’s prediction gear shift function makes the whole ordeal a lot smoother and thus allows for a more comfortable ride.

Q. In what situations was there a noticeable increase in fuel efficiency?

Park KwangHee | The most noticeable improvement came in the coasting function. Most European makers build their cars so that putting one’s foot off the gas pedal will always activate the coasting function. On the contrary, the ICT-connected transmission system’s coasting function activates only when the system judges the neutral gear to be necessary in reaching the speed determined by the predicted driving conditions. This resulted in a pretty dramatic fuel efficiency increase. But it’s difficult to translate that increase into a formal statistic like on-road fuel economy. Unlike a controlled testing ground, real roads come with lots of variables like driver tendencies and traffic conditions. Ultimately, we’d like you to consider the ICT-connected transmission system’s main purpose as improving driving convenience by optimizing gear shifting. Improving the fuel economy is more of an ancillary benefit.

Q. Mass production isn’t far off schedule. What’s your utmost point of concern in preparation?

Jeon ByeongWook | Safety first. To that end, we’re developing various two-layered safety logic for the algorithm. We’re also working on applying the fail-safety technology, which stops the system from making gear shifting errors in the event that one of the data source devices malfunctions. Another factor to consider here is cybersecurity, because the system incorporates connectivity technology. We’re considering all these issues and will embark on mass production only when they are sufficiently resolved. Beyond safety, we’re also trying to link the system to the navigation’s OTA (Over the Air) function, which will help keep the system’s prediction functions up to date and effective.

Q. Could you elaborate on the operation principles of the aforementioned fail-safety technology?

Jeon ByeongWook | While the ICT-connected transmission system is active, the vehicle location data sent by the GPS is always cross-checked with the travelling distance measured by the vehicle’s speed sensor. Likewise, the navigation’s various road information is cross-checked with the road slope and curvature estimates from the car’s internal vertical/lateral acceleration sensors.

The Fail-safety function comes into play during these cross-checking processes. It begins by checking whether the system prediction of the slope and curvature matches the actual data retrieved from the vehicle sensors at the predicted spot. Depending on the level of the disparity, the system judges whether to inactivate the prediction functions. If the disparity is large enough to hamper the driving, the system judges the situation to be a malfunction, reducing the functions to minimum or deactivating them completely. Coming to this decision requires an extremely intricate and precise analysis, which is why we’re employing an advanced AI algorithm.

Q. How will the role of transmissions change in the coming age of electric cars?

Jeon ByeongWook | For the foreseeable future at least, that age will include not just electric cars but also hybrid vehicles (HEV). HEVs come with a complex drivetrain that incorporates an engine, transmission, and electric motor. This complexity makes optimal gear shifting all the more important. For multistage hybrid transmissions, securing a natural feel for shifting gears under the regenerative braking system is another key technology in need of development.

Meanwhile in the EV front, we expect to see significant market demand in the commercial electric vehicle segment, since fuel efficiency is a make-or-break issue for the consumers there. For large commercial EVs, transmissions are a more efficient choice, because they can guarantee both traction at low speeds and performance at high speeds. Applying the ICT-connected transmission technology there would further maximize those EV’s fuel economy.

As for the smaller EVs, opinions vary in both the industry and the academia. I personally think that multistage transmissions will be used well into the age of the electric, mainly as a means to reduce the motor size or to improve fuel efficiency. As the industry sees new entrants, the competition will inevitably veer toward limiting the use of rare earth materials while maintaining fuel efficiency. I think that will naturally result in the emergence of the 2- to 3-stage hyper efficient transmissions.

Q. What was the biggest obstacle in the development of the ICT-connected transmission system?

Jeon ByeongWook | As the system is linked to external devices like the navigation, radar, camera, and V2I modem, we needed to closely collaborate with the Researchers from other teams. Initially, this collaboration was not, well, collaborative. “The navigation is built to give directions, not to link to the powertrain.” For similar reasons, our collaboration requests to retrieve the relevant data from outside were initially met with skepticism.

What’s more, as the older navigation systems often came without any road gradient information, it was a challenge to make the prediction functions work with them. But with the advancements in relevant technology, we saw the rise of navigations with 3D map info with road gradients. The ADAS systems similarly underwent drastic improvements of late. And ‘connectivity’ increasingly became a keyword for everyone, which led the other teams to be more supportive of the development of the ICT-connected transmission system. When the collaboration turned smooth, the development became faster.

I want to stress that this new transmission, in a broad sense, is symbolic of an emerging paradigm of automobile development. Here, the transmission is no longer just doing what a transmission was intended for; its role has expanded, connecting with other parts. The ICT-connected transmission is, as the name suggests, literally connected to other parts to deliver an optimal driving performance. And that ‘connection’ would not have been possible without the interdepartmental ‘connection’ of all the Researchers and researchers involved. That’s what makes this cutting-edge transmission technology particularly meaningful for me: like modern technology ought to be, its development relied on interdisciplinary synergy.