ESG is the business trend the whole world is focusing on at the moment. ESG stands for Environment, Social, and Governance. It’s used to evaluate the non-financial performance of a company. It predicts that a company can make sustainable growth when it protects the environment, prioritizes social values and establish a transparent and ethical governance structure. As it has been confirmed that business performance index reflects environment priorities and social responsibility activities positively, all industries have been carrying out ESG management. Same goes for the steel industry. Steel companies are developing eco-friendly technologies that can reduce contaminants as well as compartments that can be used for eco-friendly mobility. We took a look into an eco-friendly steel mill through the case of Hyundai Steel.

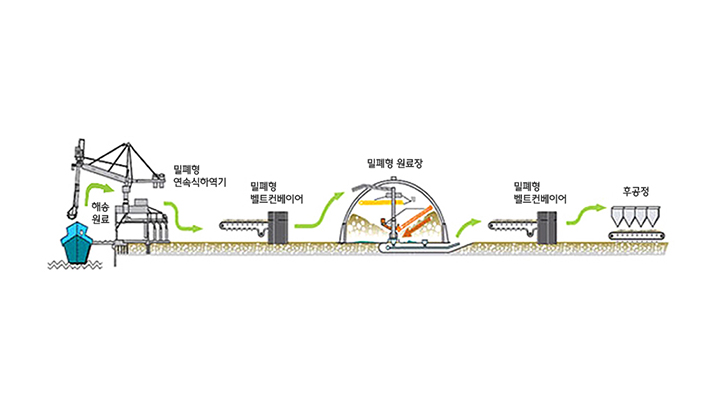

To make an eco-friendly steel mill, Hyundai Steel implemented the ‘closed-type raw material processing facility’ in 2009 for the first time in the world. Iron ore and coal are mostly in powder form; when the wind blows, it will scatter and affect the local environment negatively. To prevent this, Hyundai Steel came up with a closed-type raw material processing facility. When raw materials such as iron ore and bituminous coal are delivered via large ships, they are transferred on the closed-type continuous unloader and belt conveyer without being exposed to outside. This facility became a great case that effectively reduced the scattering dust from steel mills by the windy seashores. Also, compared to the existing open-type raw material processing facility, it is less prone to limitations caused by weather conditions and can store much raw materials, which allows reducing the raw material management cost as well.

Hyundai Steel recently has been developing various technologies for eco-friendly steel mills. In March, they uploaded a video that shows such endeavor and vision on their official YouTube. They used a motion graphic method, which is a video creating method that makes use of illustration and animation technology so that laymen can easily understand the eco-friendly iron manufacturing technology. The recent motion graphic video released is the ‘shaft furnace breather’ episode. Shaft furnace is a tower shaped heating furnace used to make iron from iron ore. It creates pure molten metal by melting iron ore at a maximum temperature of 2,300 degrees and high pressure.

When the shaft furnace gets too hot, it could explode; so, 8 times a year, the upper most safety valve, breather, on the shaft furnace is opened. There is a chance of letting out contaminants, but it has to be done for safety, hence there are a lot of concerns over this matter. All steel companies around the world were concerned with shaft furnace breathers. Hyundai Steel took the lead in solving this problem. They cooperated with a world-renowned engineering technology company to develop a ‘gas cleaning valve’ that could reduce the contaminants emitted from the shaft furnace. They came up with a method to create clean iron while keeping it all safe.

Gas cleaning valve is world’s first facility that can reduce the harmful gas emitted from a shaft furnace. It makes use of a steam inserting facility that prevents outside air from getting in when the shaft furnace is in operation. Originally, the shaft furnace is made to insert gas from the outside storage in the form of steam through the dehumidifying facility (a facility that reduces moisture in gas) and dust collecting facility (a facility that collects any impurities in gas) to adjust internal pressure and prevent outside air from getting in. The gas cleaning valve facility takes this facility and uses it to process shaft furnace contaminants: the shaft furnace contaminants are purified through the dehumidifying and dust collecting facilities, and the purified materials are exhausted through the additionally installed gas cleaning valves. The gas cleaning valves are currently installed at the Dangjin steel mill 1~3 shaft furnaces. As it is an environment related facility for shaft furnace, technology support will be actively provided if any Korean or foreign steel mills wish to install such facility for themselves.

More motion graphics that inform people of Hyundai Steel’s endeavors for the environment will be released, through the episodes of ‘Hydrogen society Hyundai Steel dreams about’ and ‘iron recycling.’ Go see them on the Hyundai Steel official YouTube channel!

▶ Go watch Hyundai Steel motion g shaft furnace breather’ episode raphic, the ‘

There are even more eco-friendly technologies here and there. Hyundai Steel developed and implements a technology that can re-use more than 50% of strong waste water that much contains highly concentrated non-degradable organic and inorganic ion materials and thus couldn’t be re-used as process water. Also, a material called ‘FerroPhalt’ is utilized for the roads in the Hyundai Steel’s plants. FerroPhalt is an eco-friendly road packaging material Hyundai Steel developed by recycling the steel slag. Steel slag is non-metal materials and metal oxides created when making steel from a high temperature electric furnace. With the development of FerroPhalt, the steel slag, which was regarded as waste in the past, now has a wider scope of recycling. If FerroPhalt were to be used for regular roads, more than 1 million ton of natural aggregate would be saved, contributing much to environment protection. A concrete product ‘FerroCon,’ which makes use of shaft furnace slag, was also developed and is used for water pipes and manholes. Applicable product range will be expanded through continuous research and development.

Hyundai Steel is also actively developing new technologies that can be used on eco-friendly mobility. They released their own brand ‘H-SOLUTION’ for eco-friendly automobiles. H-Solution, which shows their will to realize ultra-high-strength & light auto body, provides automobile materials such as high tensile steel as well as various services including the property of matter/forming/welding/stamping/modularization, which can enhance quality.

Eco-friendly automobiles have different driving system compared to that of diesel locomotives and thus have great difference in their car frame structure. Hyundai Steel is trying to swiftly provide optimum car materials for each client by developing materials for electric car’s own platform and acquiring modularization technology through the H-Solution. For example, when the self-driving cars become commercialized and we no longer need handles, the concept of automobile interior space will change, and thus seat and center pillar structures will inevitably change. To acquire collision safety function for the changed automobile structure, we will need a different reinforcement design than the one we have now. H-Solution specializes in technologies that implement ultra-high-density materials for car body, doors, etc. to prepare for such future mobilities.

So, we’ve looked into Hyundai Steel’s eco-friendly endeavors. As steel industries around the world are transforming quickly into eco-friendly industries, Hyundai Steel has also taken part in saving the Earth by developing scattering dust reducing technology, shaft furnace contaminant purification technology, materials for future mobility platform, etc. Hyundai Steel will continue to carry out various eco-friendly campaigns to keep our Earth healthy. Keep an eye out for Hyundai Steel to surprise us with technologies that will accelerate the transformation of eco-friendly steel mills.