In a hydrogen society, FCEVs are more than just eco-friendly vehicles. Hydrogen fuel cells mounted on FCEVs require stable performance, robust durability, and strong power. Hence, providing an opportunity for automakers to test new technologies. It also plays an important role in promoting the growth of related industries such as energy, steel, chemical, and new materials needed for infrastructure, considering that the hydrogen required for FCEVs is stored infinitely and the production process is eco-friendly.

Hyundai Motor Group has been developing related technologies through mass-producing FCEVs for the first time in the world in 2013 and constantly unveiling a number of FCEV concepts. The Group continuously developed and supplied hydrogen buses through collaboration with the central and local governments. Also, Hyundai Motor Group mass-produced large-sized hydrogen trucks for the first time in the world, exporting them to Europe. In the future, Hyundai Motor Group plans to utilize hydrogen fuel cells in Urban Air Mobility (UAM), large vessels, and railways. We are actively creating hydrogen charging infrastructures to expand the FCEV market.

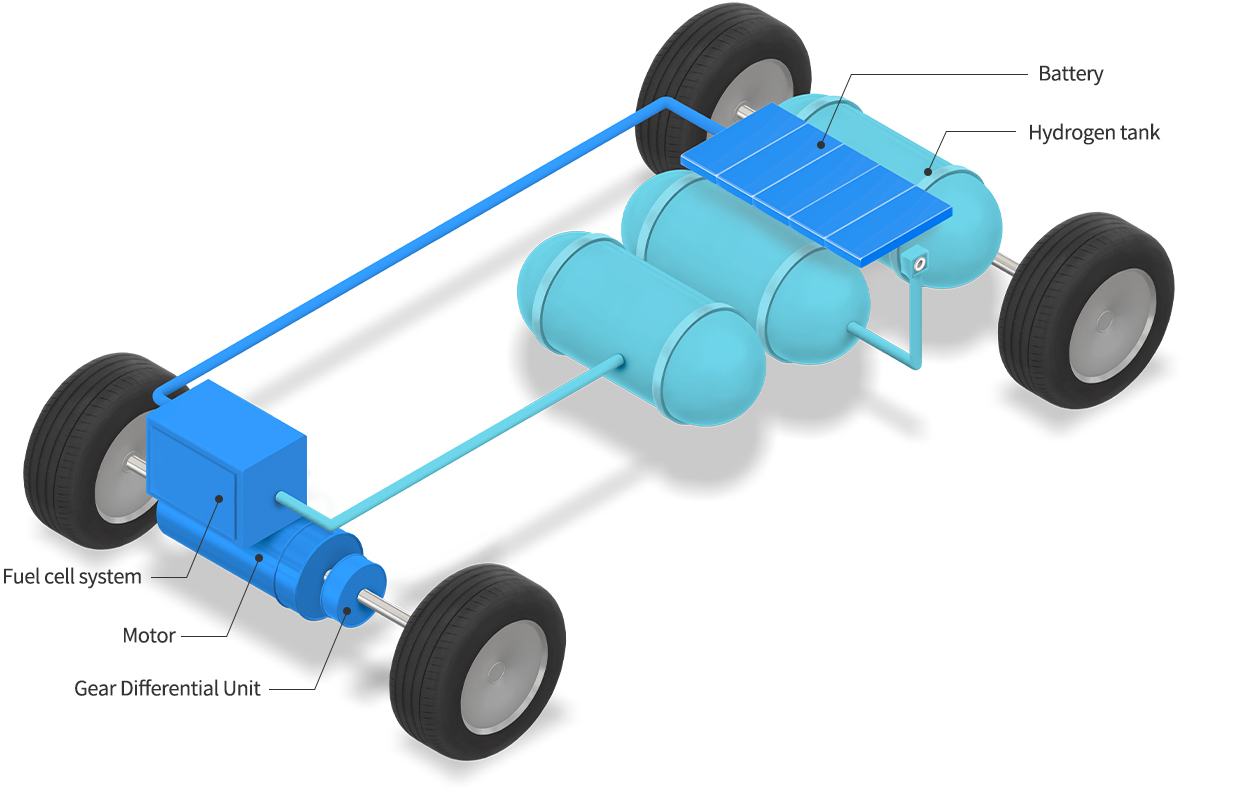

FCEV is powered by electricity generated from the electrochemical reactions between hydrogen dispensed into FCEV hydrogen tanks, and oxygen. Because FCEV is powered by electricity generated from the electrochemical reactions between hydrogen and oxygen, the only byproduct is pure, distilled water.

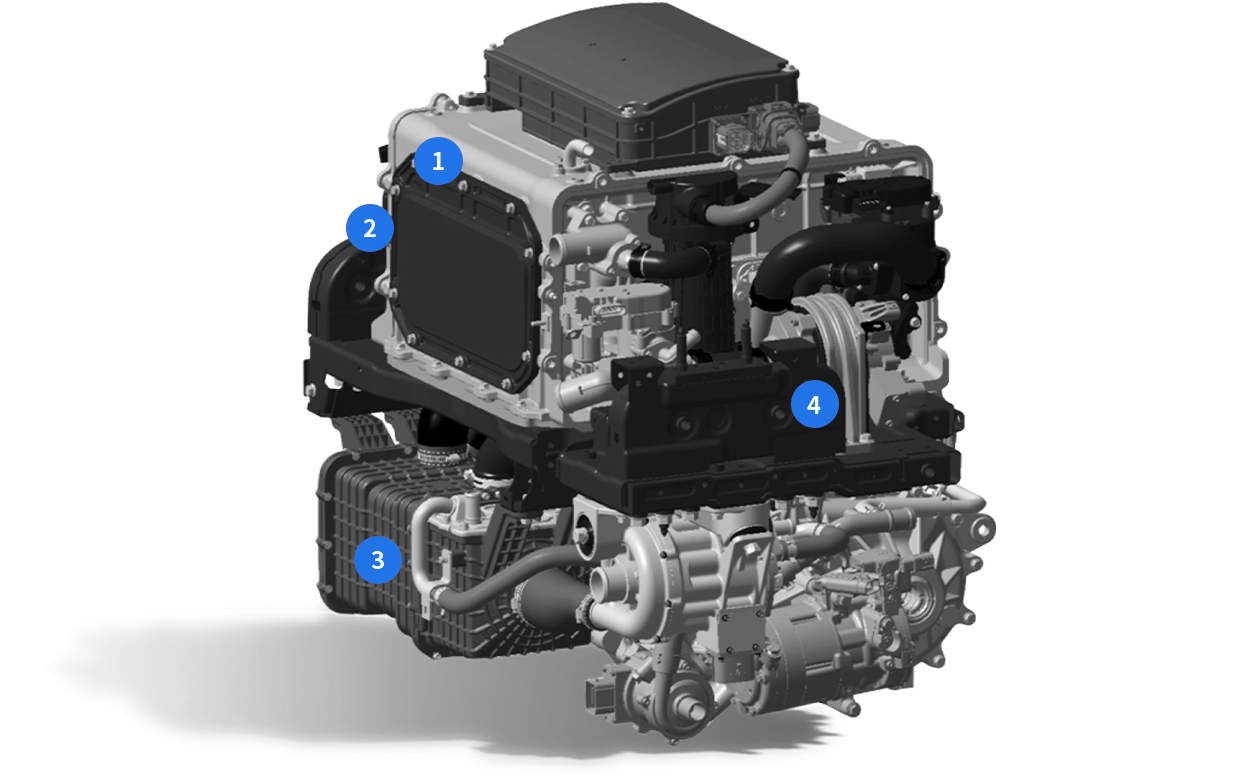

Fuel cell system that generates the electricity needed to drive is also called a ‘tertiary battery’. Fuel cells convert thermal energy into electrical energy, using the chemical reaction between oxygen and hydrogen. This electrical energy generated is the result of a pure chemical reaction, which, unlike fossil fuels, does not produce emissions such as carbon dioxide. There are various types of fuel cell systems such as PEMFC, SOFC, and MCFC, depending on operating temperature or main purpose. The system comprises a fuel cell stack, fuel processing system, air processing system, and thermal management system.

A fuel cell stack of an FCEV is one of the most essential – and the most expensive – compartments because FCEVs need to generate their own electricity using a fuel cell stack system that uses a chemical reaction between stored hydrogen and atmospheric oxygen. Fuel cell stacks consist of hundreds of cells, and each cell consists of an electrolyte membrane, separator and catalyst, a fuel electrode and an air electrode.

To generate efficient electrical energy for fuel cell stacks, a certain device is necessary. The fuel processing system is responsible for transferring hydrogen safely stored in the hydrogen tank from high pressure to low pressure and moving it to the fuel cell stack. It also improves the efficiency of the hydrogen supply through the recirculation line.

The oxygen necessary to react with hydrogen is drawn from the atmosphere. Such air drawn into the FCEV passes through an air purification system that cleans it of particulates and other unwanted matter, leaving the air cleaner. This is necessary for keeping the fuel cell stack from pollutants.

Fuel cell systems require a thermal management system to manage the temperature of the fuel cell stack. This is to prevent the electrolyte membrane within the fuel cell stack from being exposed to high heat, as that would curb optimal performance and lifespan.

The Global Technical Regulation (GTR) is regularly revised to ensure FCEV safety internationally. Every market with FCEVs either has or is developing localized safety regulations and laws based on international standards. They generally include specifications to ensure electrical safety and hydrogen safety. Hyundai Motor Group is in full observance of standards and regulations through very robust testing and evaluation. The fuel cell system in the NEXO, for example, comes with a 10-year 160,000km durability guarantee, but Hyundai Motor Group set engineering standards far exceeding that guarantee.

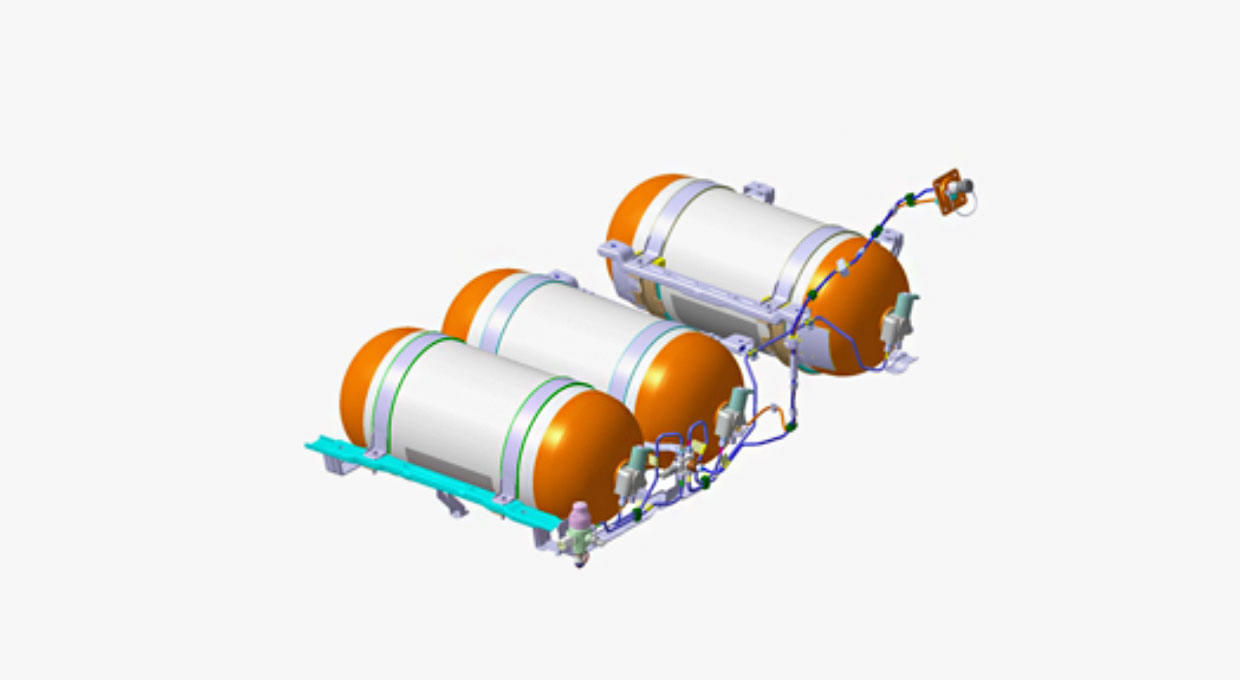

The storage system for high-pressure hydrogen is also very important. Hydrogen is low in density per volume, so it takes a lot of space to store it. Hydrogen gas is pressurized at about 700bar of pressure and stored in a tank. The safety and reliability of hydrogen fuel tanks concerning their high-pressure storage have been thoroughly engineered and tested, achieving a sufficient level of safety. Hyundai Motor Group’s hydrogen tank is made of carbon fiber reinforced plastics, and the inner surface of the hydrogen fuel tank is made of a thin polyamide liner (nylon) that minimizes hydrogen permeation. The NEXO houses three total hydrogen fuel tanks for maximizing cargo space, which is the first in the world.

A motor converts electricity from the fuel cell stacks and battery to kinetic energy; and an energy-saving idea is applied when the car is reducing its speed, culminating in the so-called ‘regenerative braking system.’ Then the system stores the electrical energy back in the high-voltage battery, which improves the fuel economy.

Unveiled in 2018, the Hyundai FCEV NEXO houses advanced technology developed by Hyundai Motor Group and boasts the best performance among the other current FCEVs available.

NEXO boasts an outstanding 611km range(certified in the U.S.) and 5-minute refueling capability(6.33 kilograms of hydrogen per time). In addition, Hyundai Motor Group has advanced technology features such as Advanced Driver Assist System (ADAS), Remote Smart Parking Assist (RSPA), and Lane Follow Assist (LFA).

NEXO houses a three-layer hydrogen fuel tank made of high-strength carbon fiber, and is controlled by various safety devices. NEXO won the first maximum five-star overall rating as an FCEV from Euro NCAP, the European car safety performance assessment program.

Hyundai Motor Group has expanded its Fuel Cell Electric Vehicle (FCEV) line to include commercial vehicles; the company has unveiled XCIENT Fuel Cell, the world’s first mass-produced heavy-duty fuel cell truck line. Since its manufacture in 2020 and export to Switzerland, it is playing a vital role in European commercial FCEVs. But Hyundai Motor Group’s efforts do not end with mere production here; it has also been involved in the development of the nascent FCEV infrastructure in Europe, cooperating with Switzerland’s many hydrogen solution firms, power plants, charging stations, and retail logistics chains.

| Year | History |

|---|---|

| 1998 |

|

| 2000 |

|

| 2004 |

|

| 2005 |

|

| 2010 |

|

| 2013 |

|

| 2018 |

|

| 2019 |

|

| 2020 |

|

| 2025 |

|

| 2030 |

|