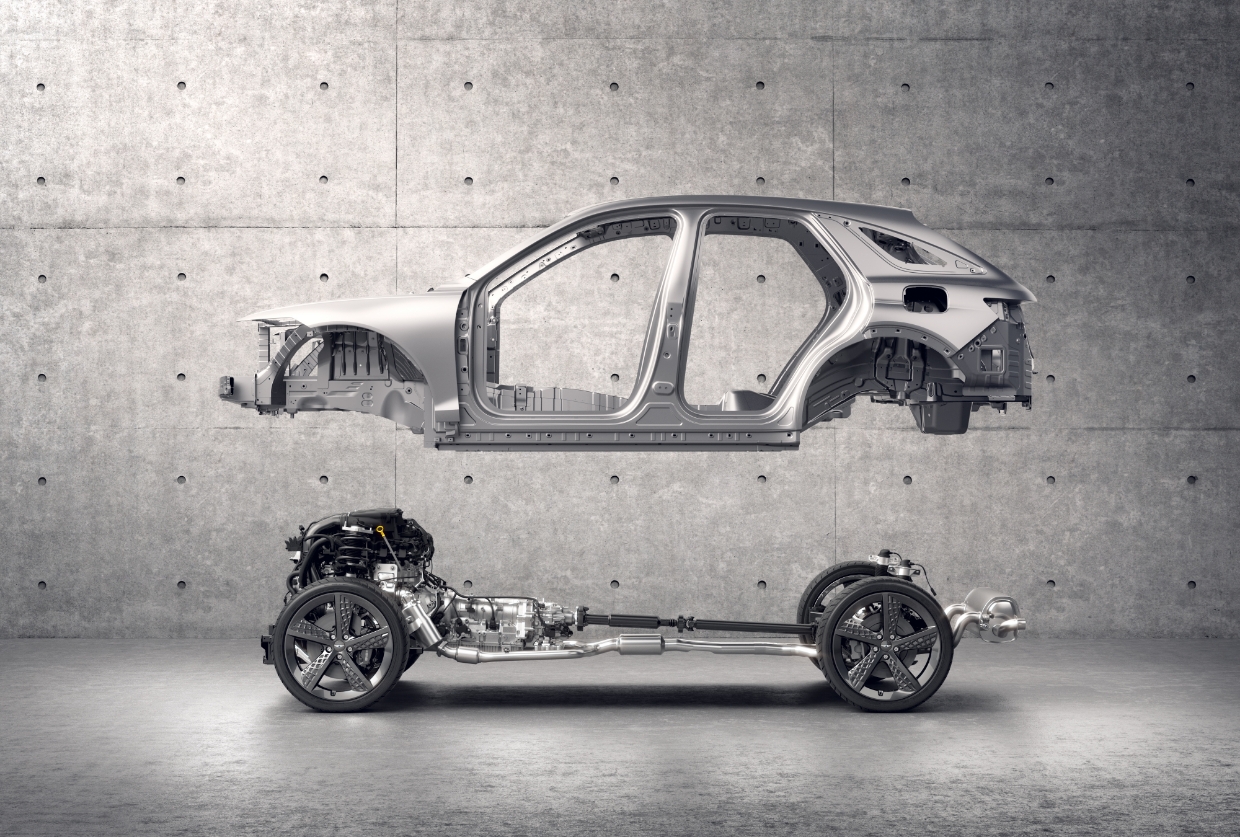

A car is a combination of many parts. A lot of parts are needed to make one car. Of course, there are many different types of molds used to manufacture parts. You can’t even get a small plastic part for the cabin unless there is the right mold. A mold is a frame made to mass-produce products in the same shape. It is divided into plastic molds, die casting molds, press molds, etc., according to the material and construction method.

Plastic molds are made using heated plastic-like materials. A typical example is the bumper cover of a car. After melting a metal material such as aluminum, it is poured into a die-casting mold to make a product. The cylinder block or cylinder head of the engine is also manufactured in this way. Press molds are mainly used to make automobile chassis, exterior panels, etc.; The product is manufactured by pressing a metal plate with strong force.

So, if you have a mold, you can get most of your auto parts as well as parts of cars that have been discontinued for a long time. Therefore, automakers are responding to the demand for discontinued models by keeping molds - so is the Hyundai Motor Group. They supply parts for discontinued models through Hyundai Partecs.

Hyundai Partecs is Korea’s first company specializing in discontinued vehicle parts. For reference, global automakers are separating finished car manufacturing companies from parts manufacturing companies to improve production efficiency. However, Hyundai Motor Group took one step further and established a company specializing in discontinued vehicle parts. Thanks to Hyundai Partecs, which has a dedicated supply team for discontinued parts, Hyundai Motor Group can supply the parts it needs at any time.

The continuous supply of discontinued vehicle parts is also for customer satisfaction. This is because, as the quality of automobiles has improved, the lifespan of automobiles has also greatly increased. According to data from the Ministry of Land, Infrastructure and Transport, a total of 24,365,979 cars were registered in Korea in 2020, of which 7,705,205 cars that were over 10 years old. That means at least 3 out of 10 cars are over 10 years old.

As the lifespan of cars increases, the supply of parts after discontinuation becomes even more important - because the customers will be disappointed if the automaker can’t find the parts to fix their beloved cars. In recent years, however, there has been a significant decrease in the number of cars getting shredded just because they couldn’t get the parts needed for repair. The reason is that automakers predict the demand for parts before discontinuing the car and produce additional parts.

Hyundai Partecs was established in November 2005 through a joint investment of Hyundai Motor Company, Kia Motors, and Hyundai Mobis. They produce various parts such as bonnets, roofs, rear quarter panels, fenders, doors, and trunk lids for discontinued cars, and supply these to domestic as well as overseas car assembly plants.

Discontinued models for which Hyundai Partecs manufactures parts are very diverse - Hyundai Motor 1st Gen Tucson, 5th Gen Sonata (NF), 4th Gen Grandeur (TG), 2nd Gen Santa Fe (CM), Kia 1st Gen Sorento, Forte, 1st Gen K5 , and Granbird Bus, to name a few. They are also producing parts for Kia’s first-generation Karens and Hyundai’s first-generation Verna, which were introduced in 1999 (as of May 2022). It’s been over 20 years since its release, but it’s still a model you’ll often see on the streets.

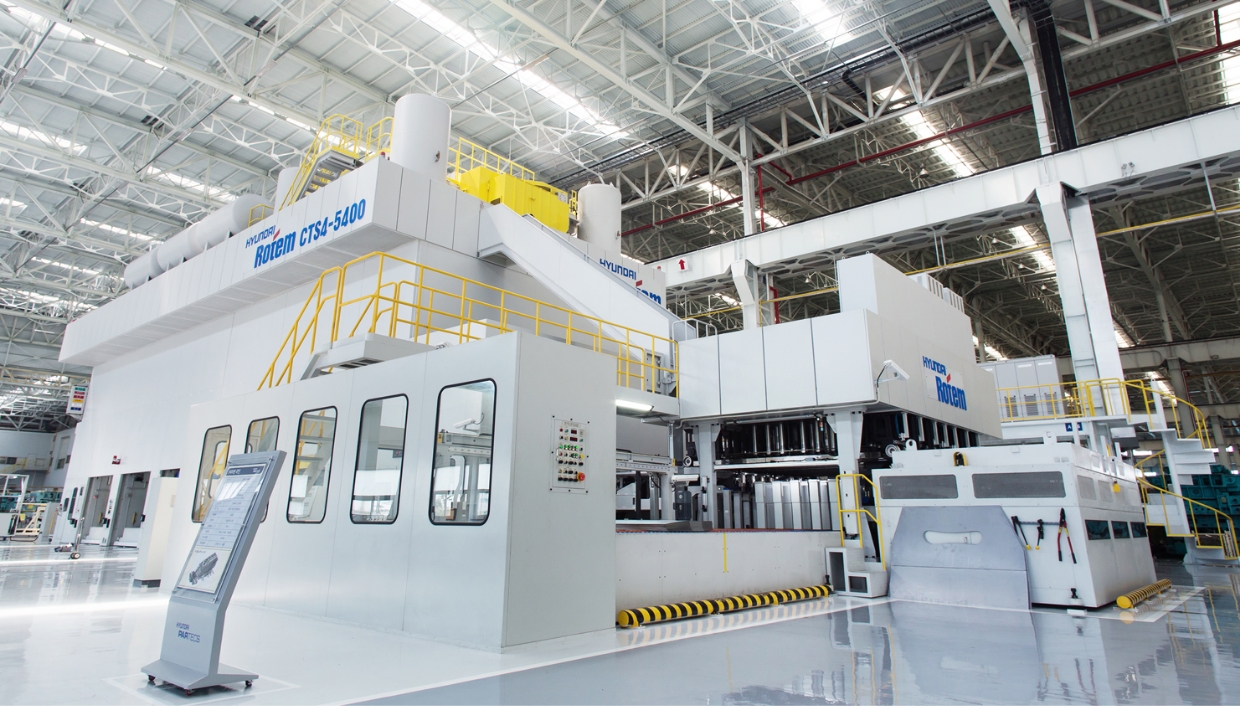

Hyundai Partecs has an integrated production system from press to bodywork to painting and packaging. The body assembly line is divided into two types: the press line, an automated line using a hemming press and a robot, and a manual line where robots and workers work together. Both lines make mass production and small-volume production possible.

All parts produced are thoroughly inspected and electrodeposited on the painting line. After that, they go through quality inspections such as shape and film thickness before moving to the packaging line. In the packaging line, air cap shrink packaging and carton packaging are carried out to protect parts. For parts delivered to overseas car assembly plants, they are fixed on a steel packaging pallet, sprayed with rust-preventive oil, wrapped in rust-preventive plastic, and moved to containers.

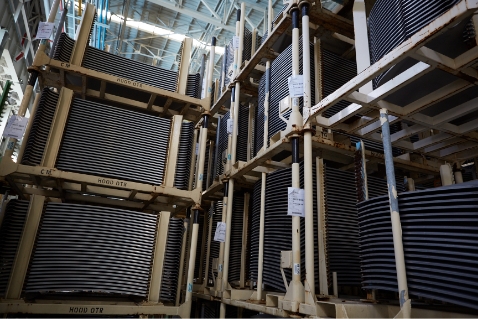

Hyundai Partecs currently has a total of 5,043 molds, capable of manufacturing 1,340 parts for a total of 128 vehicle models. It also serves as storage for various molds that Hyundai Motor Group has produced. Of course, it is important to keep the molds in perfect condition for part reproduction. This is because, if a mold is damaged, it can cause problems for the entire part made using that mold.

Therefore, Hyundai Partecs regularly inspects the condition of the mold to prevent wear or damage to the mold. They replace old parts through regular inspections, and carry out repairs immediately if structural foams or molded parts are damaged. In addition, the molds are kept in indoor storage rooms for protection. This maximizes the durability of the mold and lowers the probability of defects associated with foreign substances.

When Hyundai Partecs manufactures discontinued vehicle parts, it goes beyond just making old parts. They use the latest materials and processes that have been improved by technological advances. It looks the same as before, but it is a high-quality part with the latest technology. Of course, there are items that use old materials or methods because of mold and welding issues.

A car is more than just a means of transportation. Your long-loved car feels like family. This is why Hyundai Partecs tirelessly produces parts for discontinued models. Owners want to be with their cars for a long time, so Hyundai Partecs is always striving to produce high-quality parts.