Those of you who have ever sprinted will appreciate the importance of shoes. Shoes with enhancement added to the feet accurately transmit the strength of the legs to the ground and reduce foot fatigue. Tires, which are the shoes of a car, do the same thing. Transmitting the car’s power to the ground, it changes direction and stops exactly where you want it.

As such, tires play a very important role in the performance of a car. In particular, fast cars need tires that can fully support their performance; So, it would be correct to say that new model development starts with tires. Automakers go through a meticulous development process to achieve the target tire performance. Seong‒su Kim, Senior Researcher, Tire Design Team, Hyundai Motor Company, responsible for the design and development of wheels and tires, explains the importance of tires as follows:

“Tires are the only parts of a car that touch the ground. Therefore, it has a great impact on ride comfort, handling, vibration, noise, and efficiency, which are the basic elements of a car. In particular, the effect of tires on handling and braking accounts for more than 50%. In other words, the drivability of a car varies depending on the tire. Therefore, there are quite demanding conditions and goals in the manufacturing and selection process of tires for shipment. And to meet these requirements, automakers work closely with tire manufacturers to build and validate the tires they want. Of course, performance isn’t everything; Tires are used for a long time, so manufacturing quality is also important. We carefully check various aspects because it can affect the vibration or tilting of the vehicle.”

Just as running requires different shoes for different weights, internal combustion engines and electric vehicles also use different tires; This is because the conditions the tires must meet must change to match the characteristics of the electric vehicle. Electric vehicles generate instantaneous power compared to internal combustion engines, so tires must be able to fully withstand this power. Slipping or pulling, which makes the driver uneasy, is also unacceptable. In addition, electric vehicles are heavier than internal combustion engines because of their batteries. So it has to withstand more weight than internal combustion engines, while at the same time ensuring wear resistance and durability.

The tires of electric vehicles wear 20% faster than those of internal combustion engines, which is due to the acceleration of electric vehicles that generate strong instantaneous power. Accordingly, the tires of early electric vehicles focused on abrasion resistance. In addition, as a result of developing not only this aspect but also reinforcing the tread material, the tread material of the latest electric vehicle tires has more than 30% higher wear resistance compared to the tires of current internal combustion engines.

Of course, efficiency is also very important in electric vehicles. We continue to research various technologies that can run as long as possible with limited energy, and tires are no exception. It is also necessary to reduce the rolling resistance coefficient (RRC) that occurs when the tire rotates. However, it is necessary to reduce the rolling resistance and create a rigid structure at the same time. The EV‒only platform mounts heavy batteries on the floor to lower the center of gravity. As the wheelbase increases, the interior space becomes larger, but the weight on the rear wheels also increases. Therefore, it must be able to withstand the forces and loads applied to the tire when changing direction. Seong‒su Kim, Senior Researcher, explains this as follows:

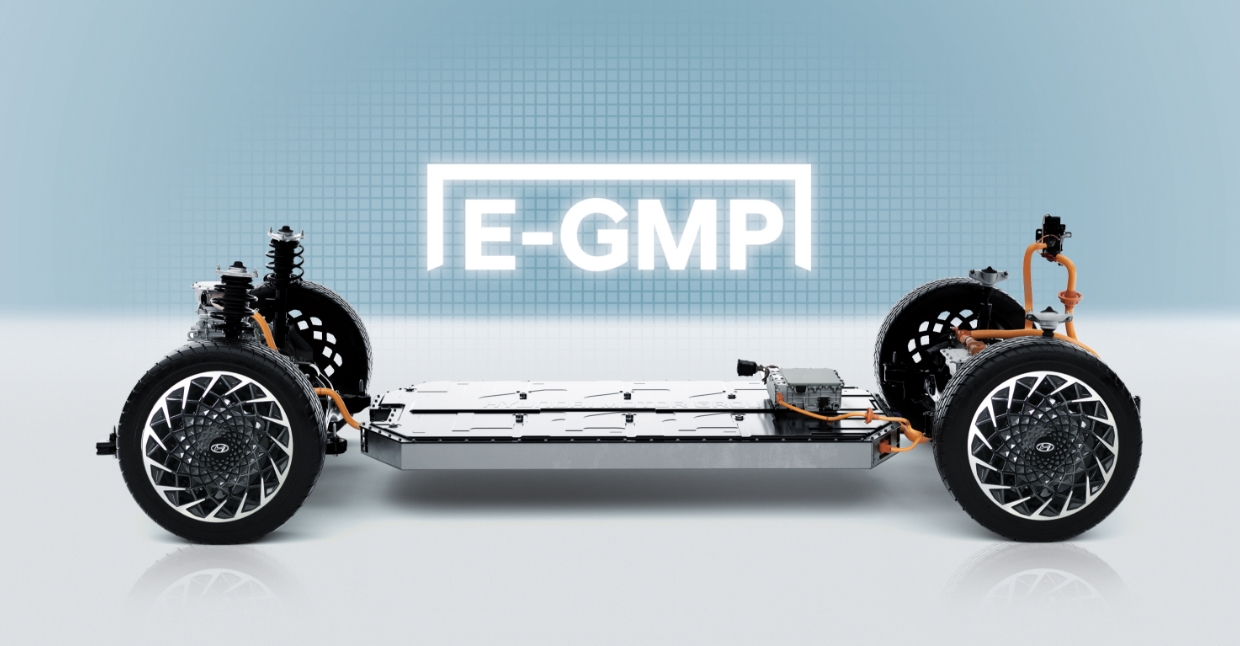

“For electric vehicles, fuel efficiency and mileage on a single charge are very important, and we are developing tires with this in mind. For example, if the rolling resistance rating is reduced by 1.0, the driving range of an electric vehicle on a single charge can be increased by 5%. In other words, tire technology development is an important factor in raising fuel efficiency and has an impact on EV technology development plans. When developing the tire of the IONIQ 5 using the E‒GMP platform, the goal was to keep the rolling resistance below 6.5. However, models equipped with the E‒GMP platform have a long wheelbase and a lot of load is placed on the rear wheel. Therefore, it was necessary to create a tire with low rolling resistance and excellent driving stability.”

The tires of electric vehicles are full of irony. Reducing the rolling resistance of the tire will reduce its grip. In addition, tires that emphasize driving performance increase rolling resistance and deteriorate fuel efficiency. In the past, it was considered important to find the right point between these opposing conditions. However, the tires of IONIQ 5 broke this stereotype, innovated the tires of electric vehicles, and showed an overall performance improvement by strengthening the characteristics of each part of the tire.

The automaker reduced the rolling resistance of the tires and emphasized cornering forces for their E‒GMP platform‒based models. This is thanks to the development of separate roles for each component of the tire. First, the company improved handling and braking performance by increasing the traction of the tire tread, and reduced rolling resistance by reducing the deformation of the tire side. The tread increases the grip as much as possible, while the pattern groove improves the longitudinal rigidity through shape optimization such as angle/depth. This has been a huge help in preventing skidding when accelerating. In addition, the depth of the pattern groove was made shallower to reduce rolling resistance and increase pattern rigidity, and a wear‒resistant compound was utilized to compensate for the reduced wear resistance.

The story does not end here. The IONIQ 5’s tires are equipped with sound‒absorbing materials. Electric vehicles have no engine and no transmission, so their mechanical noise is relatively low. Instead, you can hear the outside noise better. The same is true for tire friction noise while driving. So EVs need quieter tires than internal combustion engines. That’s why the IONIQ 5 has a lightweight sound‒absorbing material inside the tire.

In addition, materials that lower rolling resistance are used in the sidewall rubber or inner liner to lower the rolling resistance. In addition, the high‒stiffness material keeps the top surface of the inner tire thin. This not only helps to optimize the traction of the tire, but also reduces rolling resistance and increases contact patch. In addition, thanks to the change in the molding and curing process, the rolling resistance of the tire was lowered to 6.5 or less, while the traction was improved.

Nothing can be done right the first time. Equally, it takes time to develop electric vehicle tires. The development process was also not easy. Seong‒su Kim, Senior Researcher, says the following regarding the development of E‒GMP. “Starting to develop a model using the E‒GMP platform, Hyundai Motor Group and Michelin signed new MoU to collaborate on R&D for innovative tire technologies. First of all, together with Michelin experts, we decided to maximize tire performance with the goal of lowering tire rolling resistance and securing driving performance at the same time. And what the tires couldn’t cover, we decided to overcome it through chassis and motor control.”

“Of course it wasn’t easy. Acceleration performance, general road driving performance, and fuel efficiency were all improved, but traction on wet and snowy roads was relatively low. However, the dynamic driving test team and the electric vehicle performance test team confirmed the tire’s limit performance on a road with low friction, and by optimizing the control of the chassis and motor, driving stability and braking performance were improved.”

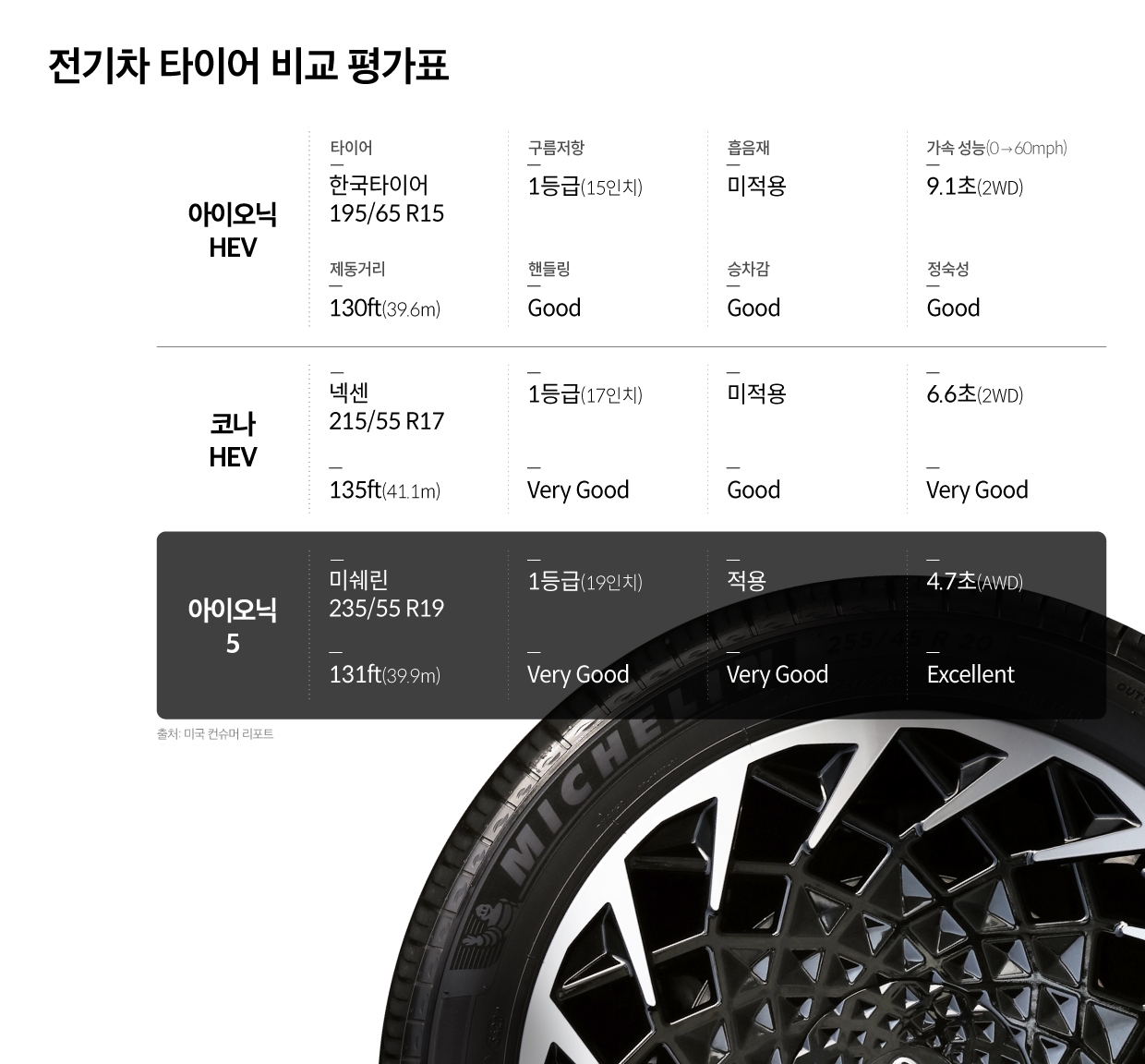

The IONIQ 5 outperformed its competitors in test drives conducted by various auto magazines around the world. It also scored 91 points in Consumer Report’s Road Test Score, recording the best driving performance among electric vehicles. As such, tires play a large role in receiving good reviews. Based on the IONIQ 5 tire development experience, the tire design team completed the tires for the Kia EV6 and IONIQ 6. Of course, this time the automaker took a step further.

The tires of the IONIQ 6 use high‒strength *carcass to further reduce weight and reduce rolling resistance to 5.9 thanks to the introduction of all new processes available. This is thanks to the low rolling resistance among the existing all‒season tires and the high level of driving performance.

*carcass: refers to the basic skeleton that maintains the shape of the tire. it is a structure in which metal cords are placed in parallel, and a layer of rubber stacked around them.

Currently, the number of electric vehicles is growing rapidly. High‒performance electric vehicles such as the Kia EV6 GT and Hyundai Ioniq 5 N are also on the way. A new car model will need new tires. For example, the EV6 GT, Kia’s first high‒performance electric vehicle, uses the Michelin Pilot Sport 4S, which can accelerate from 0 to 100 km/h in 3.5 seconds. This is a tire hitherto only used for high‒performance internal combustion engines. In addition, dedicated tires are required for mobile platform MobED and Plug & Drive (PnD) modules.

This is because, as we enter the era of autonomous driving, the weight of electric vehicles increases as we need to provide various convenience specifications to our customers, and high‒load responsive tires must be applied accordingly. In particular, for purpose‒built vehicles (PBVs) that would provide ride‒hailing or delivery services, it is important to reduce maintenance costs, and to help this, tires with emphasis on wear resistance will be needed. As the times change, the conditions required for tires will continue to change. “The tire design team is developing future tire technologies including electric vehicles in advance. We will conduct secondary technical cooperation with Michelin and prepare various tires such as heavy‒duty electric vehicles, electric pickups, and European all‒weather by 2025 in cooperation with related departments. We are also preparing to develop tire technology using eco‒friendly/reusable materials, and are also reviewing tires that can respond to UAM,” explains Seong‒su Kim, a senior researcher who is developing future mobility tires.

What will the electric car of the future look like? There is no set shape, but tires will still be needed, even if the electric car can fly. That’s why Hyundai’s tire design team is constantly developing and preparing useful technologies in the future mobility era. The same goes for technologies for autonomous driving and a carbon‒neutral era. Like a humble tire that silently rolls while supporting the vehicle in the lowest place, Hyundai Motor Company’s tire design team will silently continue to develop technology for the safety of customers.