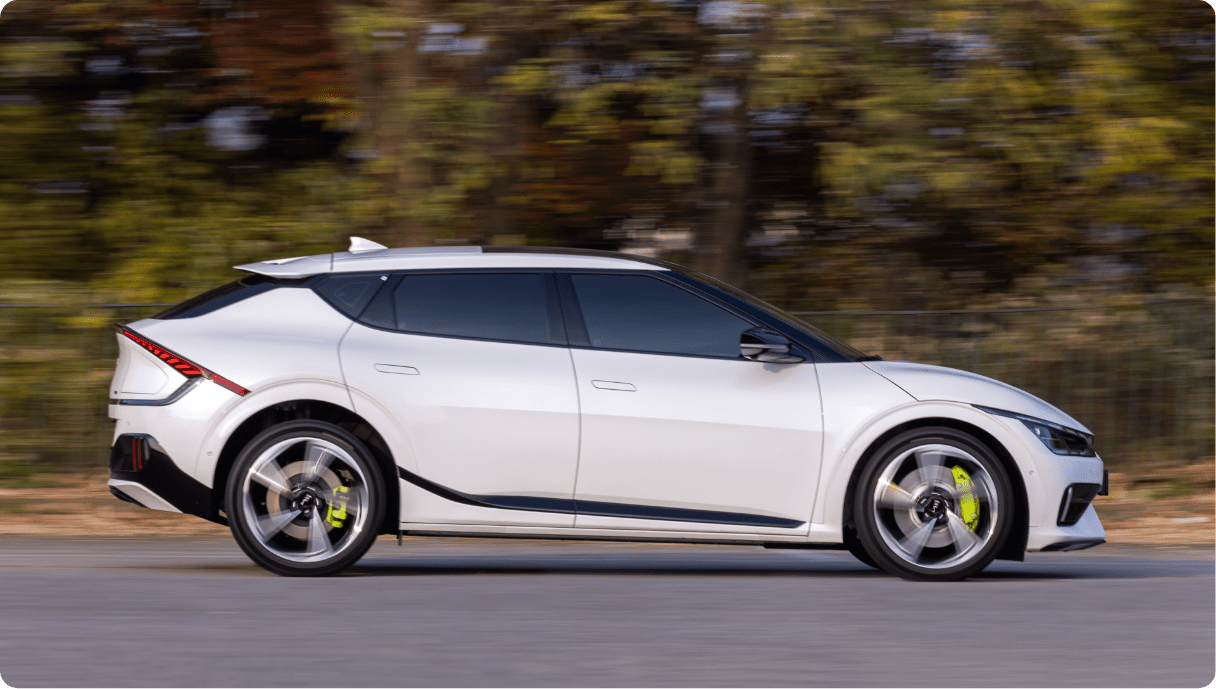

Eco‒friendliness, electric motor, battery, and sleek design are the words that describe the latest electric vehicle. However, as Kia introduced the EV6 GT, it added a new term ‒ high performance. With a maximum output of 585 horsepower and a maximum torque of 75.5 kgf m, the EV6 GT, with stronger performance than that of current sports cars, won the title of ‘the fastest car in Korean automobile history’ as soon as it emerged. Hyundai Motor Group’s electrification technology opened the era of true high‒performance electric vehicles.

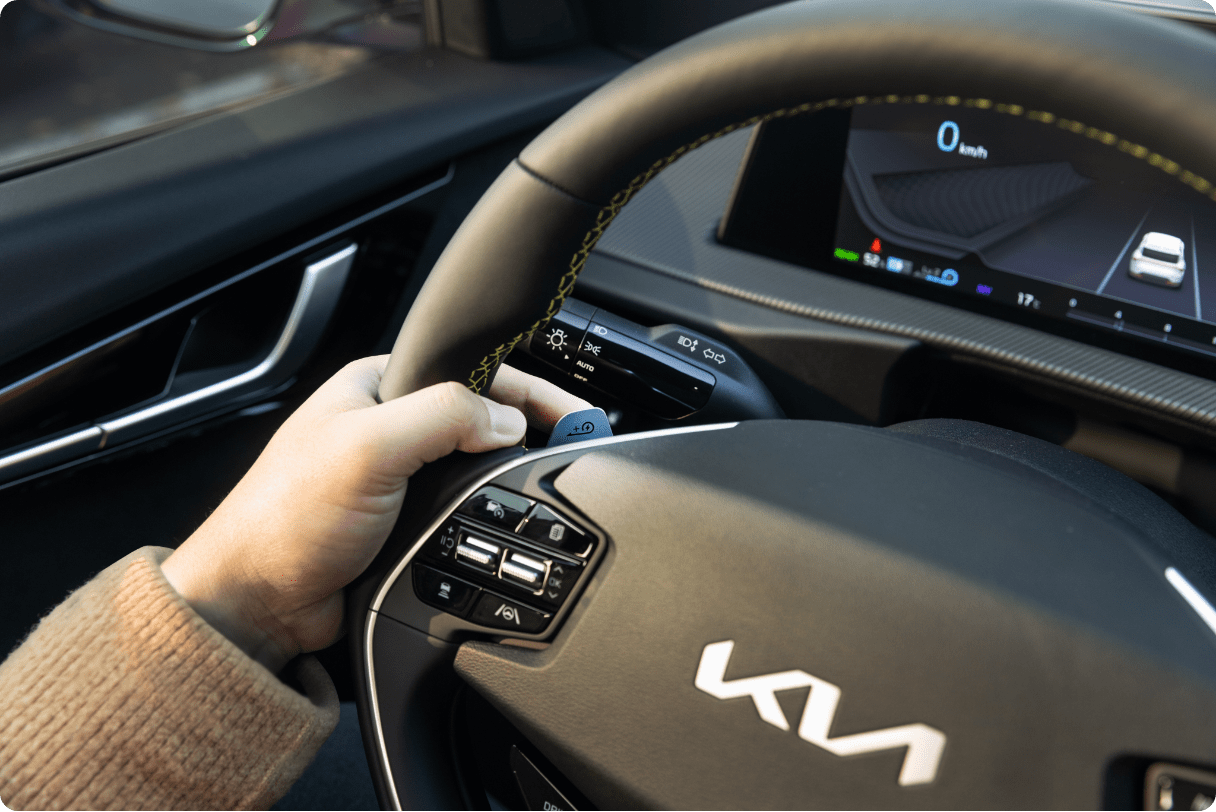

The EV6 GT accelerates from a standstill to 100 km/h within four seconds. However, fast acceleration alone cannot perfect a high‒performance electric vehicle; Other necessary elements for the vehicle, such as braking and steering, must be supported. Kia successfully developed ‘Regenerative Braking Maximization (RBM)’, dedicated to high‒performance electric vehicles that maximizes regenerative braking for the sports‒car‒like EV6 GT, satisfying both drive quality and safety. Researcher Kyung‒ho Yoon of the Hyundai Motor Group R&D Headquarters Braking Test Team, who was in charge of developing the RBM of the EV6 GT talks about the characteristics of RBM.

Q. Why developed a dedicated brake system for the high‒performance EV6 GT?

The EV6 GT features the highest output of 585 horsepower among EVs not only made by Kia but also by Hyundai Motor Group. Therefore, it required a brake system to respond to such strong performance. Competitors utilize carbon ceramic discs or high‒capacity brake systems when developing high‒performance electric vehicles. However, this also increased development cost, weight, and even maintenance cost. Considering this, the automaker developed an RBM that maximizes regenerative braking performance to tackle all these problems.

Q. What was the most important when developing RBM?

Our goal was to develop a braking system that suits high‒performance electric vehicles. The most important thing is to maintain a stable braking force even in harsh driving environments. The EV6 GT is a high‒performance electric vehicle with a grand tourer concept. Therefore, consistent braking capability was important even during a long trip. Enhancing the familiarity of control during ‘fun driving’ was also one of the key development goals.

Q. What makes the EV6 GT RBM different compared to the current electric vehicle brake system?

The brake system configuration is not much different from the usual models. To improve braking response, the automaker utilized discs with a diameter of 380 mm and 4‒piston monoblock calipers. This configuration has already been introduced in several models. What makes this stand out is that logic that maximizes regenerative braking that can only be implemented in electric vehicles. To put it simply, RBM expands the range of regenerative braking and uses cooperative control technology to most actively use regenerative braking among models currently mass‒produced. The EV6 GT is the world’s first and only RBM that delivers a large amount of regenerative braking torque to the front, rear, and high deceleration areas. Furthermore, the EV6 GT RBM enables variable control of the regenerative braking ratio of the front and rear wheels. Basically, regenerative braking is performed at a ratio of 50:50 to the front and rear wheels, and the regenerative braking ratio is variably controlled up to a maximum of 70:30 for the front and rear wheels, depending on the driving environment, such as the steering angle and brake operation. More stable braking is possible through variable control.

Q. How does regenerative braking cooperative control technology work?

The EV6 GT’s regenerative braking cooperative control technology has a different amount and range of regenerative braking compared to conventional electric vehicles. For example, Hyundai Motor Company’s IONIQ 5 and IONIQ 6, Genesis GV60, and Kia EV6 general models used inverters with different power efficiency for the front and rear wheels. Therefore, rear‒wheel regenerative braking with high power efficiency is used first, followed by front‒wheel regenerative braking. In this case, regenerative braking is used as a technology to assist braking power for fuel economy.

In the case of the GT mode, which is used when driving in a harsh environment with a lot of acceleration and deceleration, it will be able to replace hydraulic braking rather than assisting the braking force. Regenerative braking plays the role of the main braking device. The amount of regenerative braking is optimized for both the front and rear wheels to maximize regenerative braking. In addition, a large amount of regenerative braking is used, but the load movement is minimized, and it is implemented to match well with the hydraulic brake system. At an EV6 GT test drive event held at the HMG Driving Experience Center, many participants said that regenerative braking only seemed to intervene when they took their foot off the accelerator. It proved that the hydraulic brake system and regenerative braking were harmonized. In addition, it used a unique coordinated control method that can maintain braking performance by maximizing the brake recovery rate in consideration of the overall condition of the high‒voltage battery and drive motor.

Q. What are the effects of the new regenerative braking system?

In the GT mode where RBM is available, simultaneous cooperative control is performed on the front and rear wheels, rather than the conventional rear‒wheel priority regenerative braking. In addition, by improving the torque response of the motor where regenerative braking operates, braking stability and energy recovery rate have been improved at the same time. Through this, hydraulic brakes are used to a minimum compared to conventional models. Because fewer hydraulic brakes are used, regenerative braking does all the braking when the driver routinely uses the brakes. It also uses less brake discs and brake pads. Thanks to this, less friction material dust is emitted, and the durability of brake‒related consumables has increased. It is also safer than current regenerative braking.

Q. What was the improvement over the general brake system when driving in severe conditions such as circuit driving, and what were the results of the verification of braking power and durability?

When driving in a harsh environment such as a circuit, the GT mode optimizes the ratio of regenerative braking between the front and rear wheels while recovering as much deceleration as possible as regenerative braking energy. Even on rougher terrain, regenerative braking doesn’t stop working. Durability verification was conducted at circuits such as Yeongam, Inje, and Taean in Korea, and the Nürburgring in Germany. At the Inje Speedium, the most visited circuit in Korea, the *brake pedal fade did not occur even after driving five laps. In addition, the temperature of the brake disc is also reduced compared to the general brake system. This is easy to understand when looking at the Yeongam circuit driving results. Before applying RBM, the maximum brake temperature during lap driving was 640℃, but after applying RBM, the maximum temperature was lowered to 475℃. In addition, it was confirmed that the braking energy recovery rate increased from 0.7% to 40.5%.

*Brake pedal fade: When the brake pedal is used excessively, the friction coefficient between the brake pad and the disc decreases, and thus the braking force is weakened.

Q. Compared to the brake system of ordinary EVs, how much has the regenerative braking been enhanced?

The amount of regenerative braking of the EV6 GT RBM has increased by 50% compared to that of general electric vehicles. The instantaneous charging ratio to the amount of braking has also been improved. To understand this easily, compare it to the quick chargers used by average EV drivers; A typical fast charger in Korea charges at a level of 100kW to 200kW. In the case of an RBM, it is possible to instantly recover more than 320kW of energy at a gravitational acceleration of 0.6G during rapid deceleration. Because it recovers more energy than a rapid charger does, it helps increase range.

Q. As the regenerative braking performance is strengthened, the durability of hydraulic brake‒related parts increases, which is expected to have a positive impact on the environment as well as maintenance costs.

When a hydraulic brake system is used a lot like a general internal combustion engine, brake pads generate a large amount of dust. This kind of dust has a lot of impact on environmental deterioration, and also damages brake system performance due to deterioration. As the regenerative braking range widens, the hydraulic brake usage decreases, so the brake pad and disc replacement cycle becomes longer. This naturally leads to maintenance costs. Of course, even if the amount of regenerative braking is increased, disk replacement is necessary depending on driving habits and driving environment, so to minimize maintenance costs, the automaker did not use new materials or increase the size only for the EV6 GT.

Q. How was the braking test conducted during the RBM development process? And how does it compare to the hydraulic brakes of similarly powered internal combustion engine sports cars?

Since the EV6 GT is a high‒performance electric vehicle with high output, the braking test was also conducted under severe conditions. Braking systems have to deal with high thermal energy per unit time. That’s why we started braking at 215 km/h on the high‒speed main circuit, then decelerated to 70 km/h, and then re‒accelerated again over 10 times. Although it is not a vehicle designed for circuit driving, it has also undergone driving tests at Yeongam and Inje circuits. Let’s assume that we conducted a harsh driving test at high deceleration under the same conditions using a high‒performance sports model with an internal combustion engine with similar output. If so, it would have been difficult to achieve consistent braking performance due to brake pedal fade and deterioration due to its high dependence on hydraulic braking.

Q. How will the brake system for electric vehicles develop in the future?

Following the RBM concept in the EV6 GT, the range of regenerative braking is being expanded to enable active control. In the future, we expect that the brake system for electric vehicles will actively use regenerative braking to become more simplified and highly efficient to suit the purpose of the vehicle. And in the near future, a system that controls the braking force from the wheel without hydraulic brake transmission lines is likely to be developed. Furthermore, through the tri‒motor system, regenerative braking will be maximized on the front wheels, and independent motor control will be performed on the rear wheels to assist in body posture control. In addition, it is expected that a system without a hydraulic braking device using an in‒wheel motor mounted on each wheel can be implemented.

Photography by Geun‒jae Lim