As ‘Minimalism’ slowly penetrates the automotive industry, automakers are competing to showcase functionally integrated technologies. And this trend is making designs that are simpler and more sophisticated than before - like the 7th generation Hyundai Motor Company’s The All New Grandeur and the 2nd generation The All New Kona. The seamless horizon lamps on both models show the ultimate minimalism design.

In particular, the seamless horizon lamp of The All New Grandeur not only has an unconventional design, but also includes left and right Daytime Running Lights (DRL), positioning, turn signal lamps, and DWL (Dynamic Welcome Light) functions in one lighting part. Here, Hyundai Motor Group’s accumulated lighting technologies, such as an indirect light optical system and a double inner lens with an optic structure, are integrated. Researchers from the Hyundai Motor Group Lighting Vision Design Team talked about the seamless horizon lamp technology.

Q. The seamless horizon lamp is the main element that creates an unconventional impression of the latest Hyundai models. What technical elements are included here?

Researcher Mi-seon Kong | The styling concept of the Seamless Horizon Lamp follows Hyundai Motor Company’s design philosophy, ‘Sensuous Sportiness’. Later, in the development stage for mass production, we tuned the design to improve the perfection of the exterior and satisfy the performance of the lamp - for example, the structure with the surroundings such as steps, safety in case of collision, and regulations. So we not only implemented the original design concept well, but also improved the quality of the design.

Q. These seem tricky to implement. How did you find harmony between design and technical issues?

Researcher Mi-seon Kong | From the beginning of development, we reviewed various expected issues such as product manufacture, deformation, and conflict, and verified the configuration system more often than other models. Moreover, the design in the form of a single line may look simple, but it was not easy to satisfy the completeness and quality standards because a small flaw ruins the whole look.

Researcher Moon-soo Park | Since it was the first time for parts factories to assemble integrated lamps, errors were inevitable for them as well. Nevertheless, in order to implement a design concept worthy of the flagship model, people in each department worked tirelessly to overcome technical obstacles.

Q. What technical aspects have been added by changing from the current split lamp to an integrated structure?

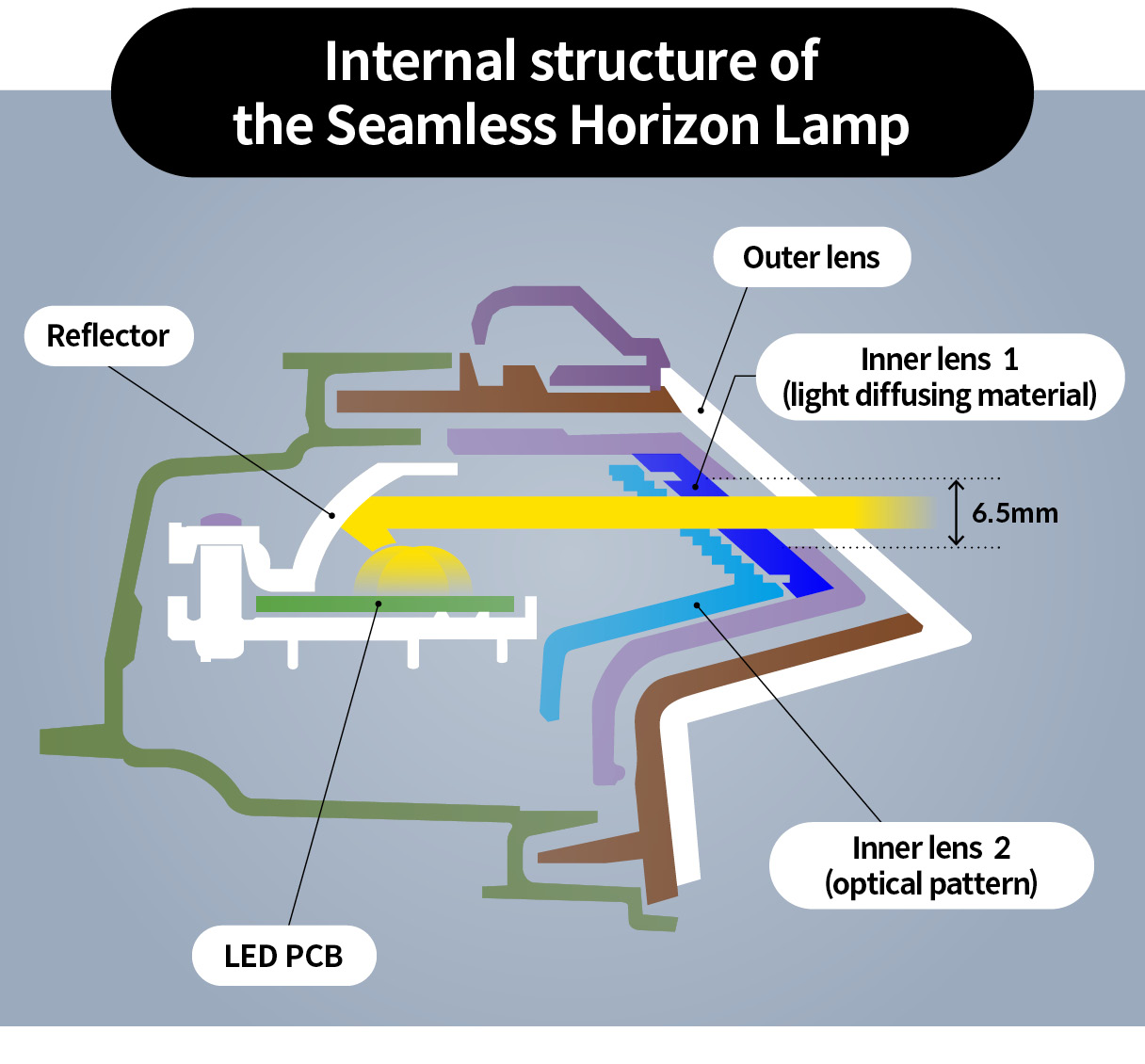

Researcher Moon-soo Park | No certain new optical technology or theoretically special new technology is used in this lamp structure. However, since it is for the brand’s new flagship model, all lamp technology that Hyundai Motor Group has learned so far has been utilized. To convert one 1.8m-long lamp into one thin 6.5mm line, you need both a high-level durability design and an optical system design to meet the required light distribution performance. The concept of’Horizon Lamp’ started in Hyundai Staria, but the technology and effort to change it into an integrated one is special because it gives the flagship model a sleeker and more sophisticated impression.

Q. The length of a single part reaches 1.8m. How do you overcome the disadvantages in terms of durability and quality when producing such long parts as a single piece?

Researcher Moon-soo Park | Compared to the divided lamps like Hyundai Staria, the parts were more than twice as long and there were many difficulties in terms of production - such as product deformation. Therefore, we improved the FEM (Front End Module) structure so that the body can support the lamp more stably, and reinforced the rigidity of the lamp housing to prevent deformation. In addition, defects were minimized by automating most of the production process except for some assembly steps. In addition, when a product is completed, it goes through inspections such as appearance and lighting status for quality management.

Q. It must have been difficult to make a long, thin lamp emit sufficient yet uniform amount of light. Did you face any obstables?

Researcher Mi-seon Kong | We thought about many ways to secure the right amount of light for the regulation and at the same time create uniform light. First of all, the lens inside the lamp is doubled to increase optical efficiency. And several times of verification were carried out to match the color temperature of the DRLs at both ends of the lamp and the positioning lamp in the center. According to regulations, there is a 100 times difference in brightness between the DRL and the positioning lamp, so we had no choice but to use LED units with different capacities. We unified the color temperature between the parts through several tasks of using different LED colors and adjusting the current. In fact, if you look at the seamless horizon lamp, you can see that there are almost no color boundaries for each section.

Q. Could you explain the double lens structure in more detail?

Researcher Moon-soo Park | Basically, the internal structure uses indirect light utilizing a reflector. Here, the inner lens is divided into primary and secondary lenses. The light emitted from the LED passes through the primary lens via a reflector; Here, the front and rear surfaces of the lens have a special optical structure to secure light distribution performance while spreading light. In addition, the secondary lens made of light diffusion material diffuses the light evenly so that the light can be seen more calmly when the lamp is turned on.

Q. LEDs are originally low in heat, but when more than 200 units are gathered, can their performance or durability be reduced due to heat generation?

Researcher Moon-soo Park | Seamless Horizon lamps have heat dissipation solutions optimized for each function; In particular, the side with the DRL and turn signal lights boasts high heat dissipation performance because it requires a high amount of light. On the other hand, since the positioning lamp requires relatively less heat dissipation structure, we paid more attention to the material and size in consideration of weight optimization. By making these design changes efficiently, we were able to maintain optimal lamp performance.

Q. The slim structure of the lamp seems to make it difficult for the other driver to check the lamp status. Were there any special measures to increase visibility?

Researcher Mi-seon Kong | Since it is an ultra-thin structure with a thickness of only 6.5mm, it was important to design the lamp so that it can be seen from various angles. To solve this problem, the lamp’s inner lens was placed as close as possible to the outer lens, so that the light reached the largest possible angle. In addition, in order to make the lamp emit light as clearly as possible, we continuously checked and improved whether there was light leakage from the lamp or a difference in light uniformity depending on the viewing angle.

Q. Hyundai Motor Group continues to take on challenges in the field of lighting technology. What are your thoughts as engineers who realize people’s imaginations into reality?

Researcher Mi-seon Kong | Recently, the lamp designs of Hyundai Motor Group’s models are diverse and show pioneering new technologies. In the future, it is expected that the lamp technology will further develop in line with this future-oriented design. We, too, are continuously thinking and researching not only the purpose of implementing such a design, but also the next-generation lamp technology considering autonomous driving and eco-friendliness.

Researcher Moon-soo Park | From an engineer’s point of view, implementing a new design is challenging, but it has a good effect in terms of motivation. In particular, the various designs attempted by Hyundai Motor Group serve as a starting point for leading technology development and brand development. I think these aspects make us proud as engineers.

Photography by Jo Hyuk-soo