Hyundai Motor Group announced its plan to popularize hydrogen energy, at “Hydrogen Wave.” It has taken a step closer to its vision of building a hydrogen society for the future by announcing a plan to install hydrogen fuel cells in all its commercial mobility systems by 2028 for the first time worldwide, and by releasing various forms of future eco-friendly mobility.

Hyundai Motor Group is the most active “first mover” in building a hydrogen society. It started the era of hydrogen electric vehicles with Tucson ix FCEV (2013) and NEXO (2018), and announced its mid/long-term hydrogen roadmap, called “FCEV Vision 2030,” at the end of 2018 to launch a full-fledged hydrogen popularization strategy. As part of the strategy, the Group started mass production of XCIENT FCEV, the world’s first heavy duty hydrogen fuel cell truck, in July last year and began exporting it globally.

The Hydrogen Wave is a more concrete form of Hyundai Motor Group’s vision to lead the realization of a hydrogen society. This includes not only the bright future of eco-friendly commercial mobility using hydrogen technology, but also the possibility of hydrogen energy that can be commonly used in our daily lives. Let’s explore the Group’s future mobility and eco-friendly hydrogen technology unveiled at Hydrogen Wave.

There are seven types of hydrogen commercial mobility unveiled by Hyundai Motor Group at Hydrogen Wave. What stands out most among them is a trailer drone that combines hydrogen fuel cell technology and fully autonomous driving technology. This trailer drone is an unmanned transport system for long-distance logistics. It has a structure that supports the front and rear parts of a long trailer using two e-Bogies, minimizing the turning radius of a long trailer exceeding 15 m. Each e-Bogie produces 120 kW and is under development with the goal of a 1,000-km driving range on a single charge. The trailer drone e-Bogie has numerous potential applications. It can be used for various purposes such as firefighting, and at construction sites, airports and ports.

The rescue drone unveiled along with the trailer drone is the concept of mobility that is capable of being controlled remotely and autonomously. It can be used for firefighting, rescue and patrol. A flying drone and a firefighting water gun are combined at the top of the rescue drone. A four-wheeled independent steering system is applied so that it can be driven in various environments, such as on narrow, rough roads. The driving range of the rescue drone on a single charge is 450 to 500 km. Since the top part of the e-Bogie can be easily modified, it is expected that it will accommodate various uses in the future.

Another means of mobility for disaster relief purposes is also attracting attention. It is a disaster relief vehicle being developed to supply power using hydrogen fuel cells in emergency and crisis situations. Apart from the rescue drone, which is an unmanned autonomous driving mobility system, this is an off-roader concept mobility system that can be driven by a person and run on remote, rough roads. Its four-wheel drive system allows a maximum climbing angle of 60%, and it can cross water up to a depth of 760 mm. It is equipped with a 50 kW hydrogen fuel cell power generation system to provide emergency power to disaster zones. In addition, it can charge an electric vehicle in urgent situations.

The emergence of eco-friendly commercial mobility also stands out as we expect to experience it relatively easily in our daily lives. These are the M.Vision POP, a small urban shared mobility concept, and the M.Vision 2GO, a short-distance delivery mobility concept. The M.Vision POP is an electric vehicle-based urban shared mobility system that can travel 180 km with a 30 kWh battery. The M.Vision 2GO is a mobility system optimized for short-distance urban logistics. It is equipped with a 30 kW hydrogen fuel cell power pack and can travel up to 200 km. Both mobility systems feature an e-corner module that rotates 180° on all four wheels independently, making it possible to drive and park in tight spaces through its capability to turn in all directions while staying in one spot.

In addition, Hyundai Motor Group also introduced the latest model of XCIENT FCEV, the world’s first mass-produced heavy duty hydrogen fuel cell truck, as well as a hydrogen-powered tractor for the North American market. The European-style hydrogen fuel cell truck is a large 34-ton cargo truck, and consists of a 180 kW hydrogen fuel cell system and a 350 kW driving motor. Its driving range on a single charge is about 400 km. The performance and durability of the major parts such as fuel cells, motors and batteries have been improved, and advanced driver assistance systems are applied in various ways.

On the other hand, the XCIENT hydrogen fuel cell tractor, developed out of the hydrogen fuel cell truck, is an American model that has been improved so that it can travel about 770 km on a single charge by applying a large-capacity tank that can charge 68.6 kg of hydrogen. The Group is developing a mass-production model by accommodating the needs of the US market, and is in the process of local optimization.

In the near future, the “H Moving Station,” a mobile hydrogen charging station, will also become available to increase convenience. The H Moving Station is a charging truck that can easily move to areas where hydrogen charging stations are not available, or where existing charging stations have been out of service for a long time. 80 kg of hydrogen can be stored per unit, and up to 25 NEXOs can be charged per day with a charging pressure of 350 bar (based on 50% of the charging capacity). It is expected that hydrogen charging will become much more convenient for drivers thanks to the H Moving Station, which is scheduled to be distributed to Seoul and Jeju Island by early next year.

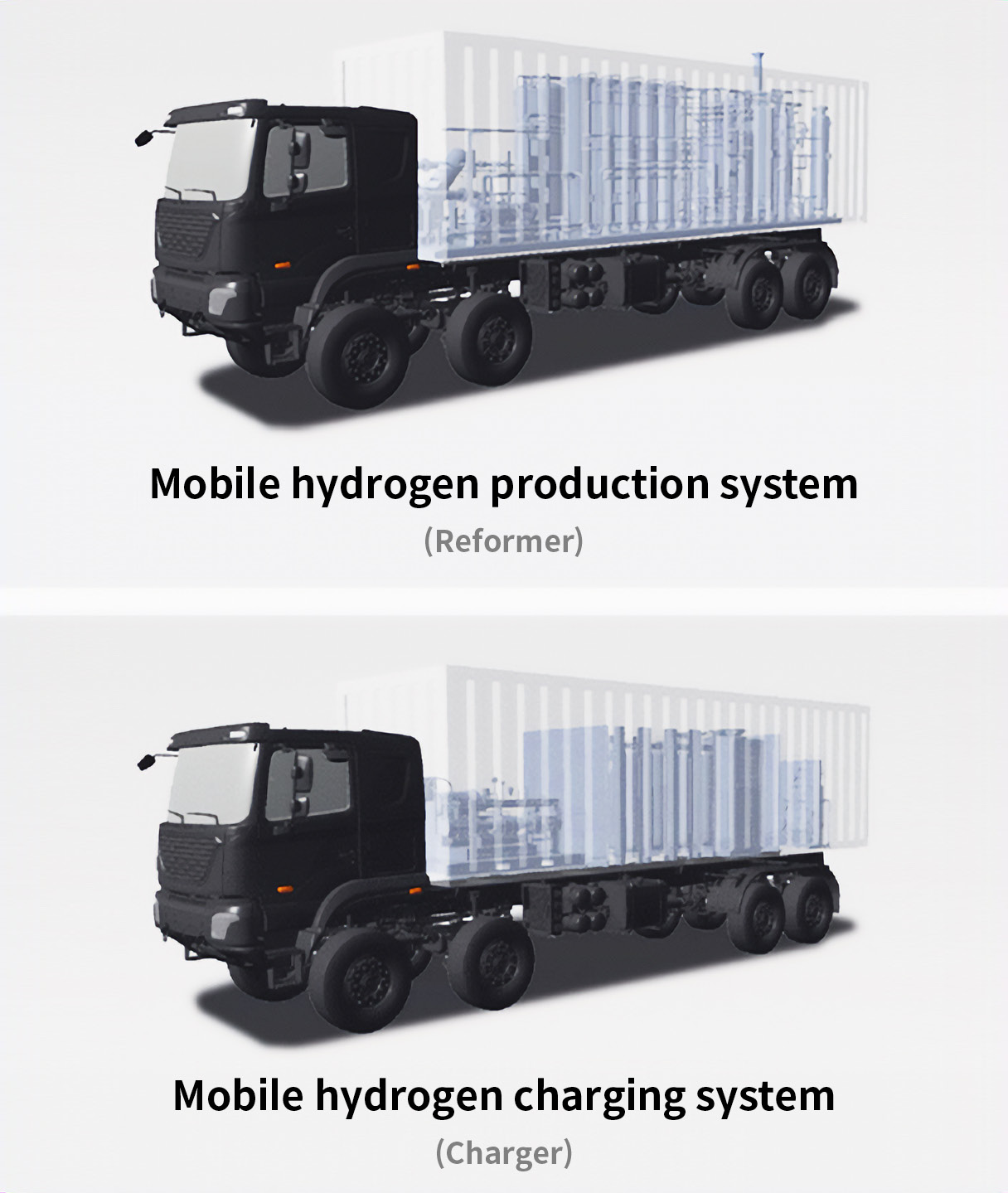

The mobile hydrogen production system (reformer) and hydrogen charging system are mobile systems that can directly produce and supply hydrogen in remote areas where hydrogen charging infrastructure is lacking. The mobile hydrogen production system can produce up to 150 kg of hydrogen per day using diesel or ammonia, which is easy to store for a long time. The mobile hydrogen charging system supplied with the hydrogen produced by the production system supplies hydrogen to other hydrogen mobility systems or hydrogen generators by going through the process of hydrogen compression-storage-cooling-supply. Both systems are easy to move and store because they have a detachable/attachable structure to a large truck in the form of a container.

As such, Hyundai Motor Group’s journey toward a hydrogen society encompasses hydrogen mobility for various purposes and charging infrastructure technology. It also includes a grand vision of realizing a healthy, eco-friendly future by utilizing hydrogen energy in industries and facilities that affect our daily lives such as houses, buildings, factories and power plants. We hope that the eco-friendly hydrogen society that Hyundai Motor Group envisions can become a reality as soon as possible.

A Paradigm Shifter, Shifting Towards a Hydrogen Society

2022.01.17 12min read