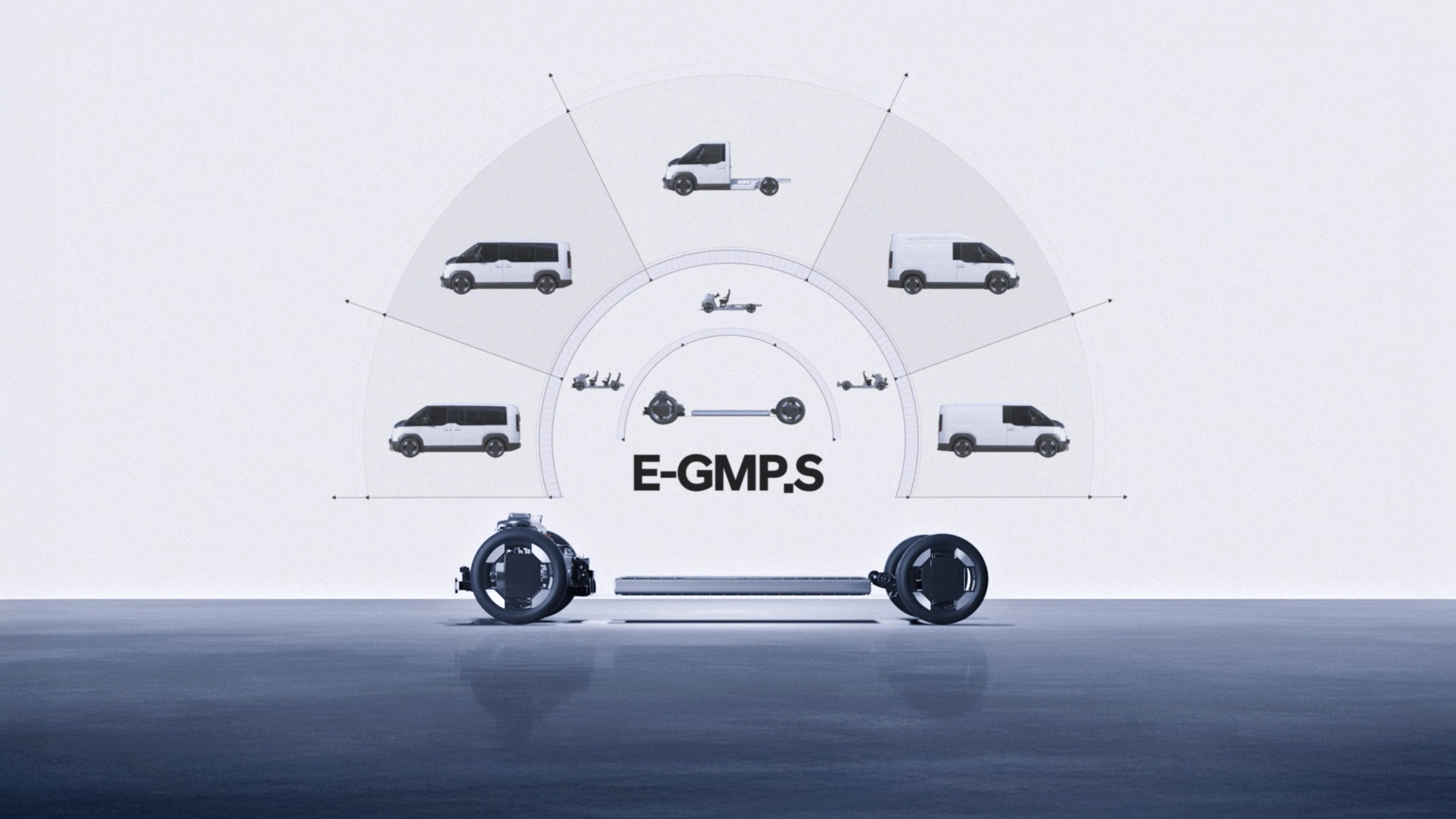

Hyundai Motor Group has introduced the E-GMP.S (Electric-Global Modular Platform for Service), a PBV dedicated platform, developed based on the excellence of the E-GMP. The E-GMP.S is the technological foundation for developing PBVs optimized for various business purposes such as car-hailing, delivery, and living space on a single platform. It is supported by a range of innovative technologies, including advanced electrification, spatial optimization, driving safety features, and PBV software.

Hyundai Motor Group closely researched the PBV market in the early stage of developing E-GMP.S. Customer requirements were carefully identified and actively integrated into the design of E-GMP.S.

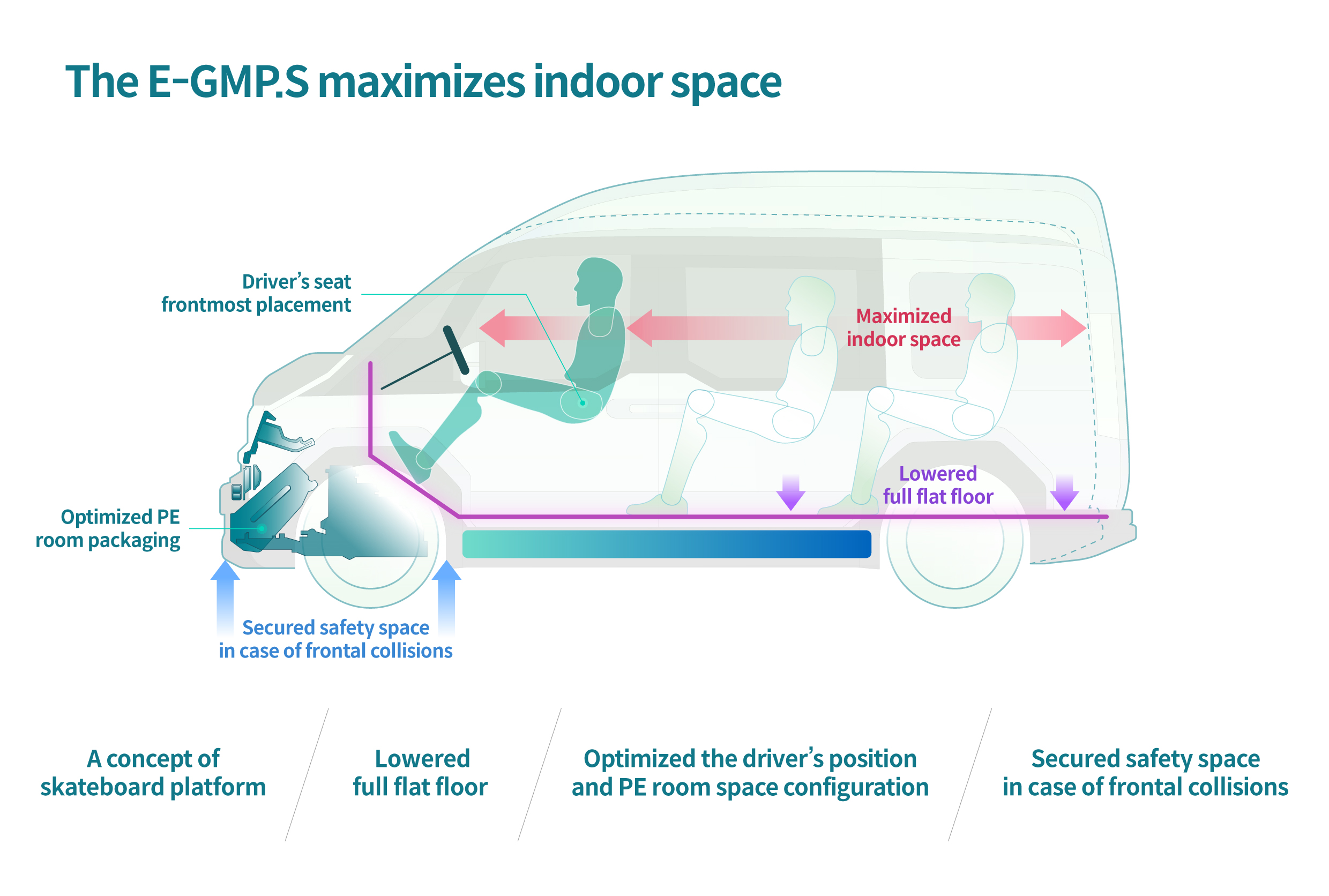

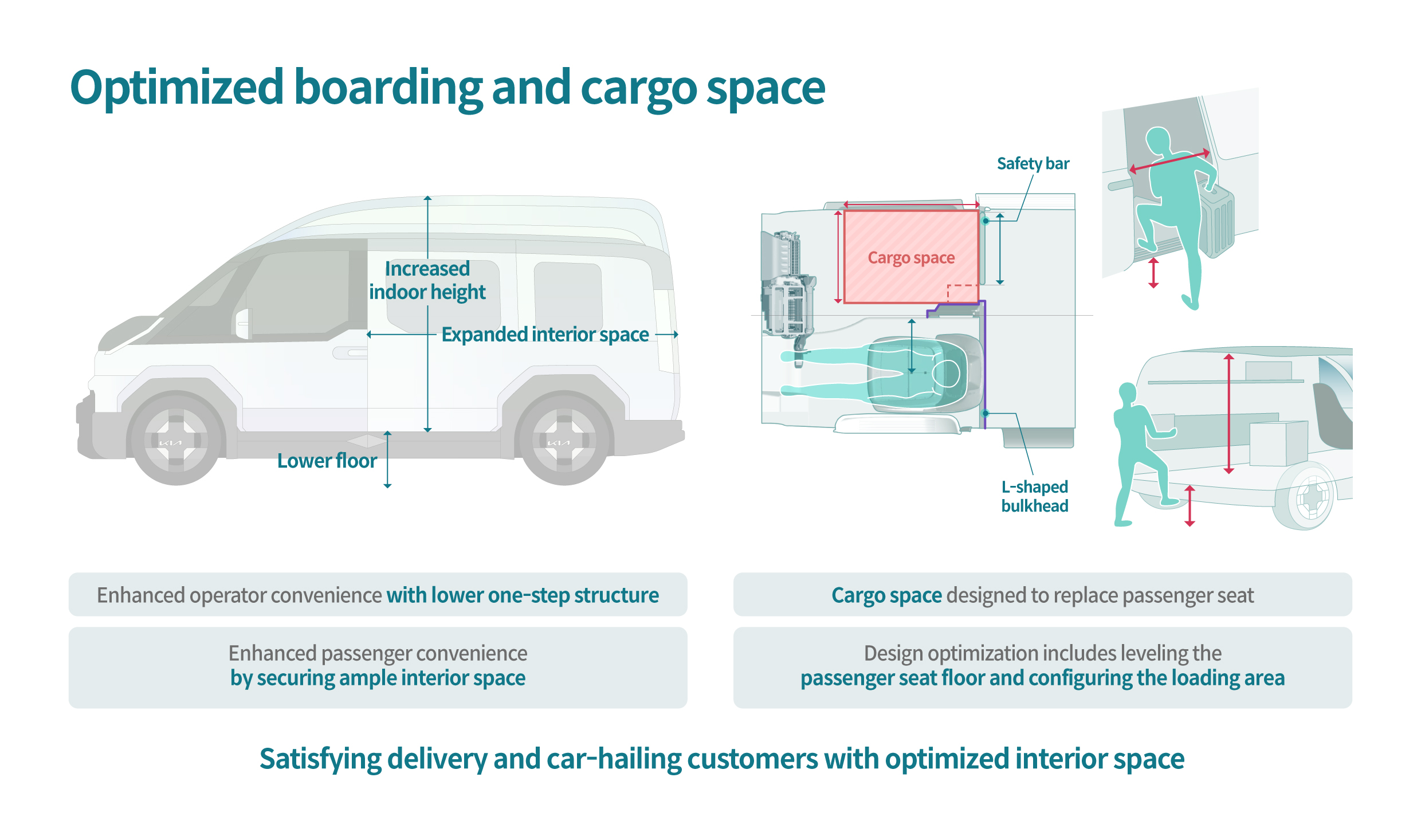

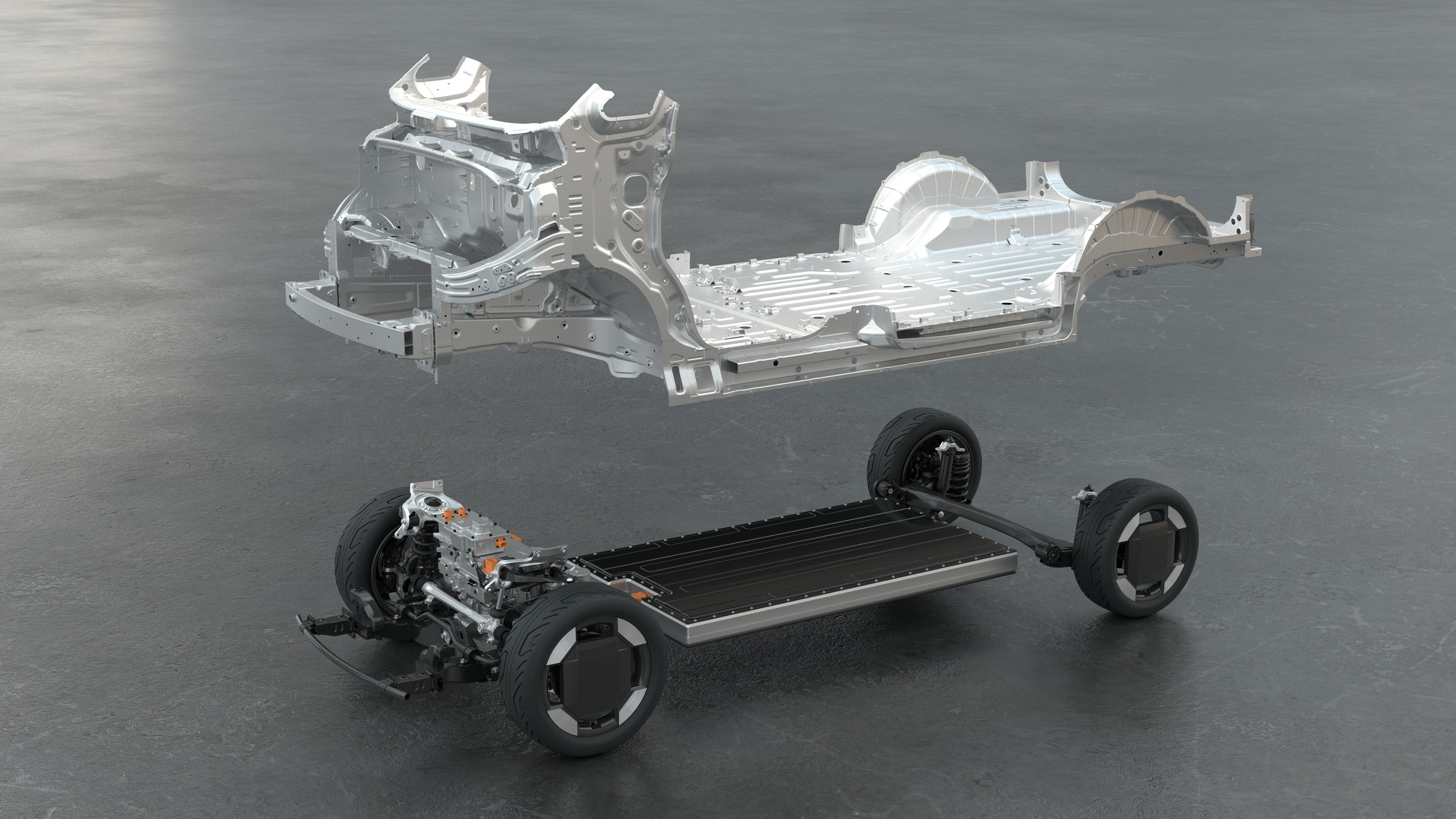

First, E-GMP.S was applied with a skateboard-type platform concept that can be versatile to a variety of upper bodies depending on the purpose. It was the foundation for Hyundai Motor Group to offer a wide product lineup ranging from small to large PBVs. In addition, the driver’s seat has been placed at the forefront and the compact PE (Power Electric) room design ensures ample interior space and enlarge cargo space throughout the second and third rows. In addition, the full-flat floor up to the third row was lowered to enhance space utilization.

The E-GMP.S has been designed with body floor as low as possible so that passengers can get on and off the vehicle more conveniently and cargo drivers can transport goods without bending their backs in a large interior space. In addition, it was flexibly designed to accommodate various types, such as flattening the floor so that the passenger seat space can be used as a cargo loading space and designing the area around the driver’s seat by considering the installation of a partition to separate the interior space.

The E-GMP.S incorporates a number of EV technologies optimized for urban business environments. First, the PE system of the E-GMP.S is a 3-in-1 integrated structure that combines the motor, inverter, and reducer which shrinks the volume and weight of the system. In addition, the hairpin winding technology and silicon carbide (SiC) power semiconductors were applied to the system and secured the world’s highest level of efficiency for driving performance.

E-GMP.S's PE system integrates a motor, inverter, and reducer into an all-in-one structure, providing optimized power for city driving

We have applied a design that satisfies both spatial innovation and driving performance. The front module combining an integrated PE system and suspension provides the driving power and ride comfort required for urban business. The center module is also equipped with a high-voltage battery that considers the PBV’s usage, providing a driving range suitable for business driving. The rear module has applied the suspension structure that is most suitable for space use and loading capacity depending on the vehicle segments. It could also be expanded to allow all-wheel drive system compatible to the PBV lineup to be introduced in the future. Meanwhile, the high-voltage battery was designed for urban driving and price competitiveness. Hyundai Motor Group has applied a 400V high-voltage system to the Kia PV5 with the E-GMP.S and plans to provide a diverse PBV lineup to meet customer demands, including considering expanding to an 800V system in the future, depending on the market and vehicle class.

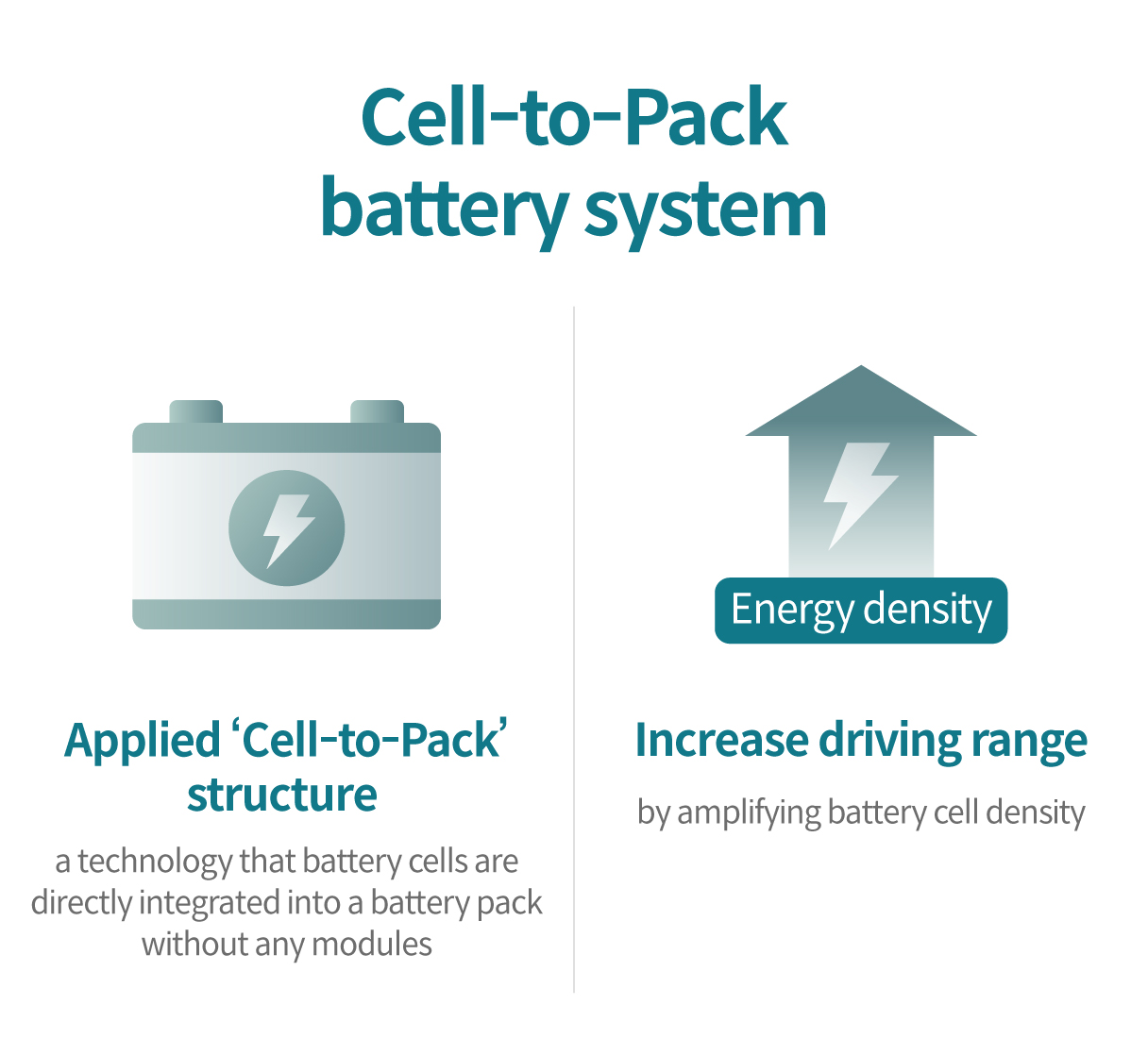

E-GMP.S has applied Cell-to-Pack battery system to optimize PBV performance. Cell-to-Pack battery is a technology that assembles battery cells directly into a pack, omitting the modules that are an intermediate step in the traditional cell-to module battery pack production process. By diminishing the empty space inside the battery pack, more cells can be packed into the pack to improve energy density, which can increase the vehicle’s driving range.

Cell-to-pack battery systems with increased energy density

Hyundai Motor Group is making significant investments to strengthen its battery development capabilities to improve electric vehicle performance, safety, and cost competitiveness. The Group is actively developing next-generation batteries by securing key material technologies and plans to continuously strive to improve customer confidence and convenience by advancing safety technologies.

BV customers, who uses the vehicle for business purposes, are also concerned about the total cost of ownership (TCO). With this in mind, Hyundai Motor Group has designed the E-GMP.S to improve maintenance and further reduce TCO for customers. For example, the module bracket makes it easy to install and remove complex units for maintenance, reducing the difficulty of servicing the vehicle and enabling quick repairs.

In addition, consumables that require regular maintenance, such as coolant and washer fluid, are accessible directly from the hood of the vehicle. This minimizes the PBV’s downtime for maintenance while improving operating efficiency.

module bracket structure that makes parts easily removable

Hyundai Motor Group also focused on enhanced durability, considering the characteristics of PBV customers who drive frequently. By applying highly durable parts and a robust body structure to key areas, the frequency of visits to the repair shop for maintenance or replacement of consumables has been reduced.

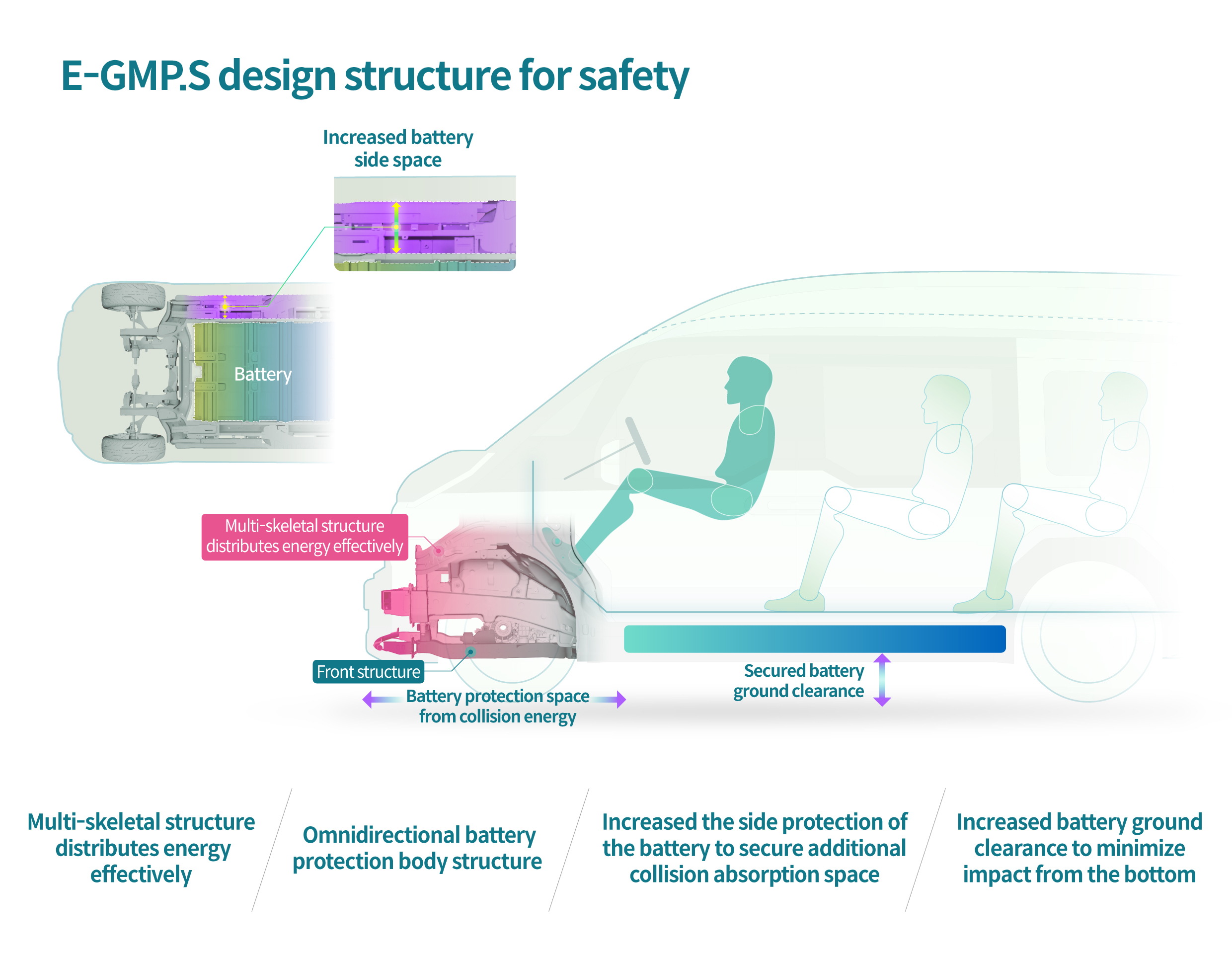

The E-GMP.S features a best-in-class safety design that prioritizes passenger and battery safety. Safety technologies are in place to effectively dissipate collision energy and minimize physical damage to the battery in case of an accident. The front space of the E-GMP.S is equipped with a multi-skeletal structure that can effectively absorb collision energy. The structure is a design that implemented *load paths in the front section, including the front side members, A-pillar members, and front structure, to distribute the impact generated if there’s a crash. Rear collision safety has also been enhanced. Sufficient collision-absorbing space is provided at the rear of the platform to effectively absorb collision energy and minimize interior space deformation.

* Load path: The shortest path along which the load is applied

No detail was overlooked to enhance battery safety. Not only has the vehicle’s side space was secured to protect the side of the battery pack and to minimize damage to the battery in the event of a collision, but the vehicle subframe is placed at the same level as the battery to prevent any frontal impacts. While the platform was designed to be flat, the battery ground clearance is raised to avoid unexpected downward impacts. The functional safety enhancements of E-GMP.S are expected to escalate passenger protection.

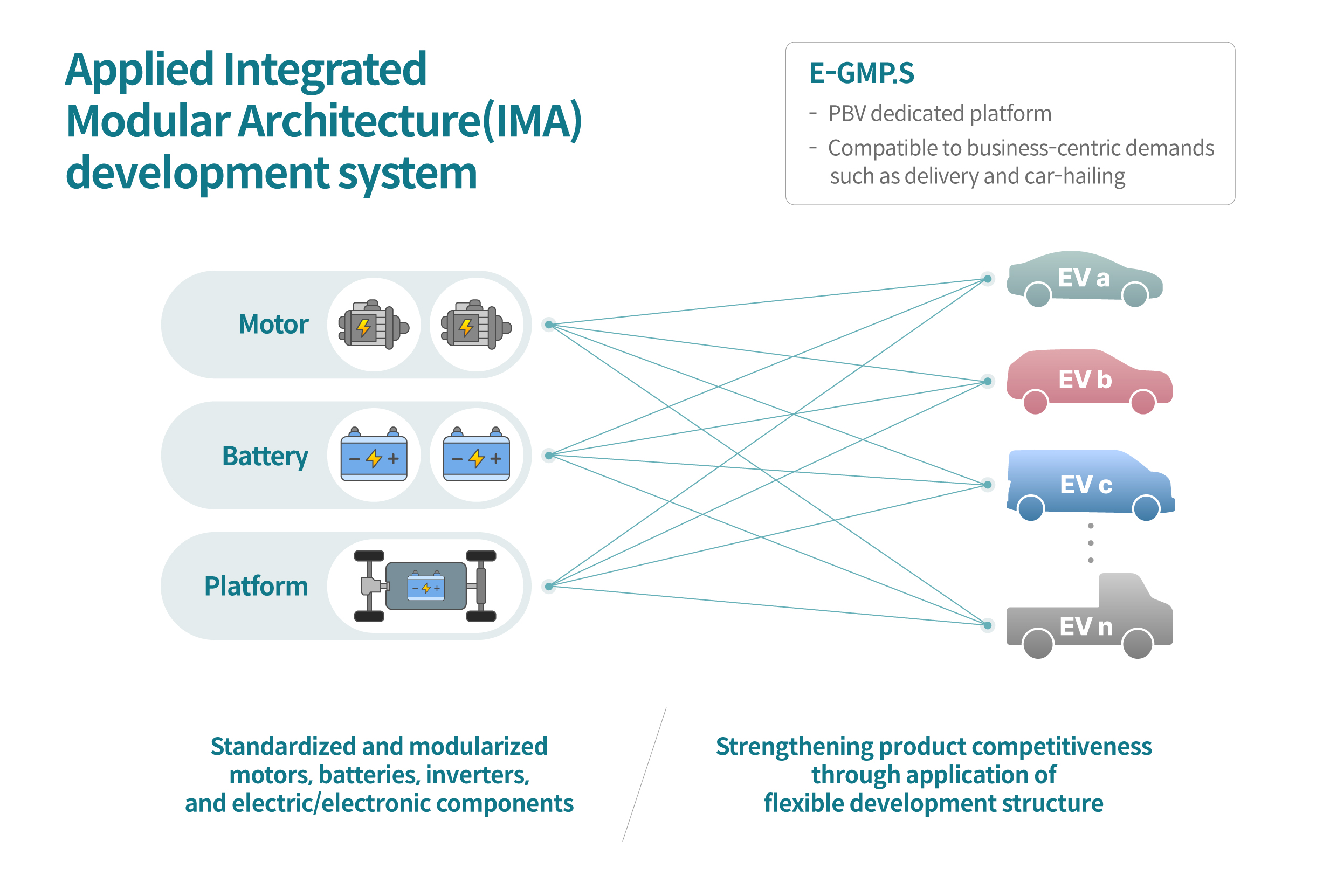

Hyundai Motor Group developed E-GMP.S by adopting the Integrated Modular Architecture (IMA) development system for the first time. IMA standardizes core modules such as motors, batteries, inverters, electricity/electronics, and autonomous driving and develop vehicles regardless of vehicle class or segment. There are benefits from adopting the IMA development system.

First, it simplifies the complex vehicle development process by utilizing common parts and decreases the development period, thereby increasing the efficiency of the development process. Second, it enables horizontal deployment and further increases product competitiveness and productivity. Hyundai Motor Group continually plans to introduce competitive vehicles with high technical reliability under the IMA development system.

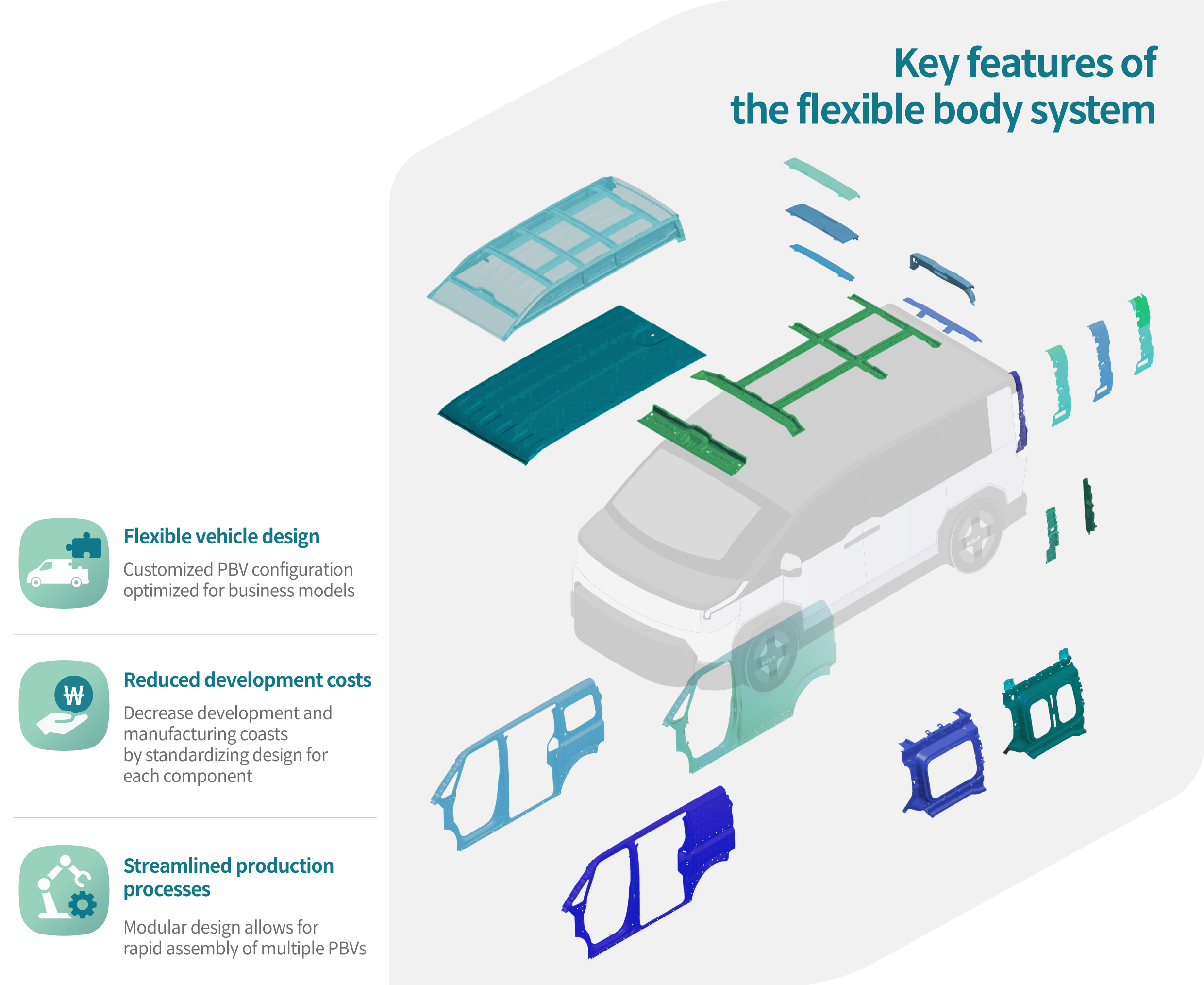

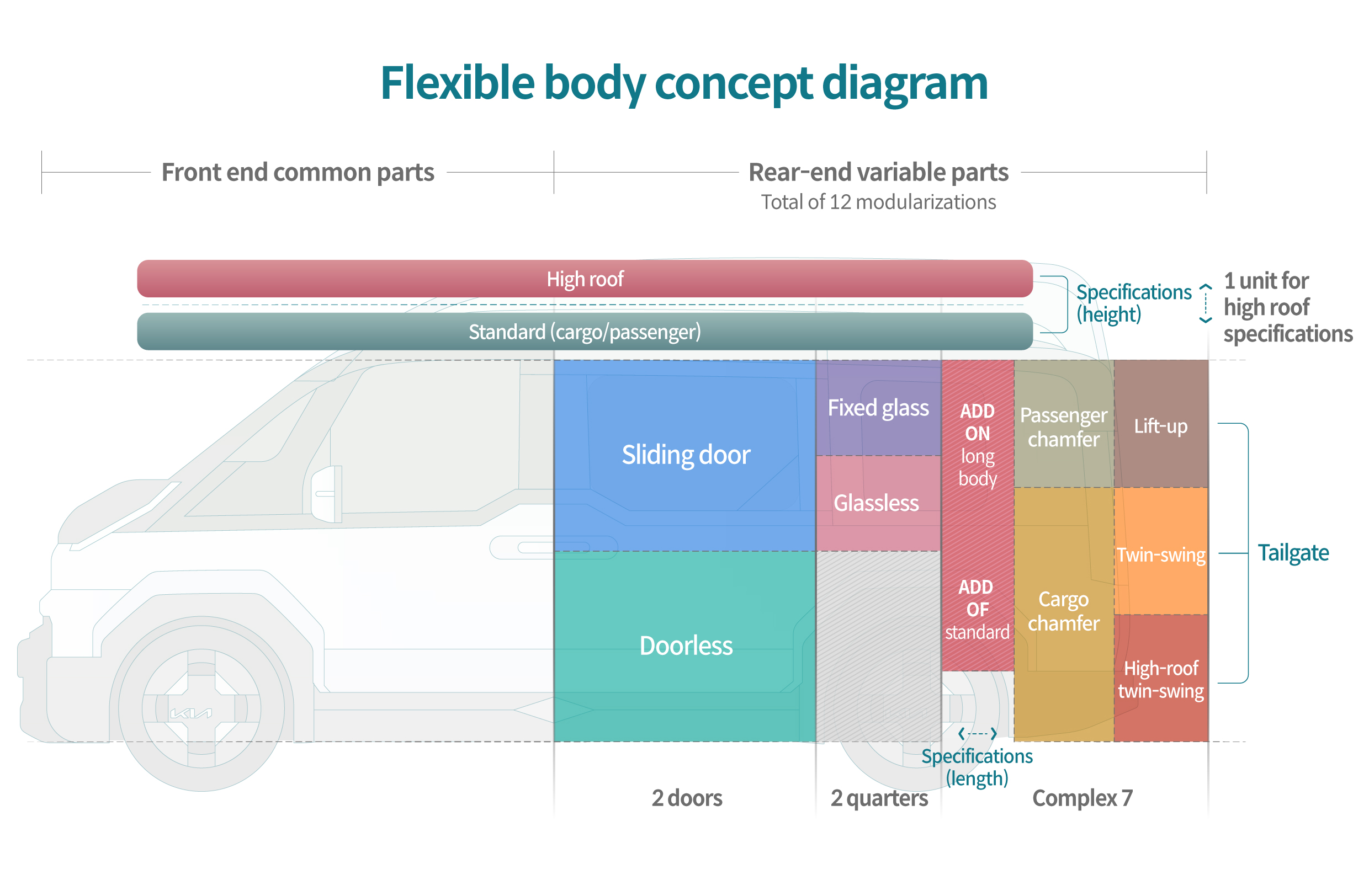

A variety of body specifications in PBVs are essential as they are to introduce vehicles optimized for various business customers. However, with conventional vehicle production methods, increasing the number of body specifications can lead to duplication of development resources and reduced productivity. Hyundai Motor Group introduced the Flexible Body System in the E-GMP.S to enable flexible and efficient development of diverse specifications.

The Flexible Body System is a cutting-edge technology that modularizes the body parts such as roof (standard, high-roof), door panels (sliding door, doorless), rear overhang (standard, long body), and tailgate (lift-up, twin-swing, high-roof twin-swing) and provides customized PBVs to meet customer needs.

Above all, the flexible body system is highly competitive technology as it can reduce various costs in the production process such as design, verification, and molds, and is also excellent in terms of maintenance. Considering that PBVs are often damaged due to the nature of their operation, the rear of the vehicle is composed of an *end garnish module. Accordingly, when the area is damaged, repair time and costs can be reduced by replacing parts instead of expensive sheet metal repairs. Hyundai Motor Group plans to first apply the technology to the Kia PV5 and plans to introduce seven specification combinations.

*End garnish: Body rear part exterior finish

It is also noteworthy that PBVs powered by the E-GMP.S will be equipped with software solutions that increase operational efficiency for business partners. The Kia PV5 based on E-GMP.S is equipped with a Fleet Management System (FMS) and PBV navigation based on the Android OS.

FMS supports vehicle operation and management for companies that operate a large number of vehicles, such as rental car companies and logistics companies. It provides a service that collects and analyzes data required for vehicle operation without a separate device. With FMS, managers can monitor vehicle’s condition such as battery status, maintenance schedule at a glance and operate PBVs more efficiently with remote control system.

PBV navigation provides optimal routes and charging station locations in consideration of the vehicle’s driving schedule or driving range. Android-based OS facilitates the configuration of third-party apps with developers and expand the mobile ecosystem. It may lead to performance enhancement of PBV and contribute to improving the convenience and profitability of business owners.

As we have seen, E-GMP.S is a PBV dedicated platform based on Hyundai Motor Group’s innovative technological features. In particular, its space utilization, electrification technology, and business efficiency, all of which are essential for PBVs, helps Hyundai Motor Group to stand out in the global PBV market. Customers are looking forward to Hyundai Motor Group’s diverse PBV lineup, starting with the Kia PV5.