Hyundai Motor Group has announced its full-fledged entry into the PBV market with the launch of the Electric-Global Modular Platform for Service (E-GMP.S), a platform dedicated to PBVs. As the name suggests, the E-GMP.S is a platform optimized for the PBV market based on the E-GMP, Hyundai Motor Group’s well-known dedicated EV platform with innovative technology. In the developing phase of E-GMP.S, Hyundai Motor Group took time to analyze the characteristics of the PBV market thoroughly and reflected the opinions of customers and business partners to create a platform tailored to the business purpose.

The changing landscape of the consumer market, which has been transformed by e-commerce, and the mobility market, which is shifting from ownership to sharing, is driving rapid growth in ride-hailing and last-mile delivery services. According to Mordor Intelligence, a global market research firm, the global market for ride-hailing services is expected to soar from $185.6 billion in 2024 to $294.1 billion in 2029, while Fortune Business Insights, another global market research firm, estimates that the last-mile delivery market will grow from $20.5 billion in 2024 to $134.9 billion in 2032.

As the market grows, so does the demand for new mobility. This is why there is a growing need for business-specific vehicles, such as delivery vehicles that can be loaded quickly and easily, and ride-hailing vehicles with spacious and comfortable interiors. In fact, the light commercial vehicle (LCV) market has been on an upward trajectory as the mobility business market has expanded.

Hyundai Motor Group has taken note of this shift in the mobility market. As vehicles have become more versatile than simple transportation, consumers have begun to focus on the value of space, and mobility providers recognized the necessity to offer new concepts of mobility to customers with different needs. To proactively introduce vehicles specialized for the PBV market, Hyundai Motor Group focused on developing a dedicated platform that would serve as the technological foundation for vehicles suited for various purpose.

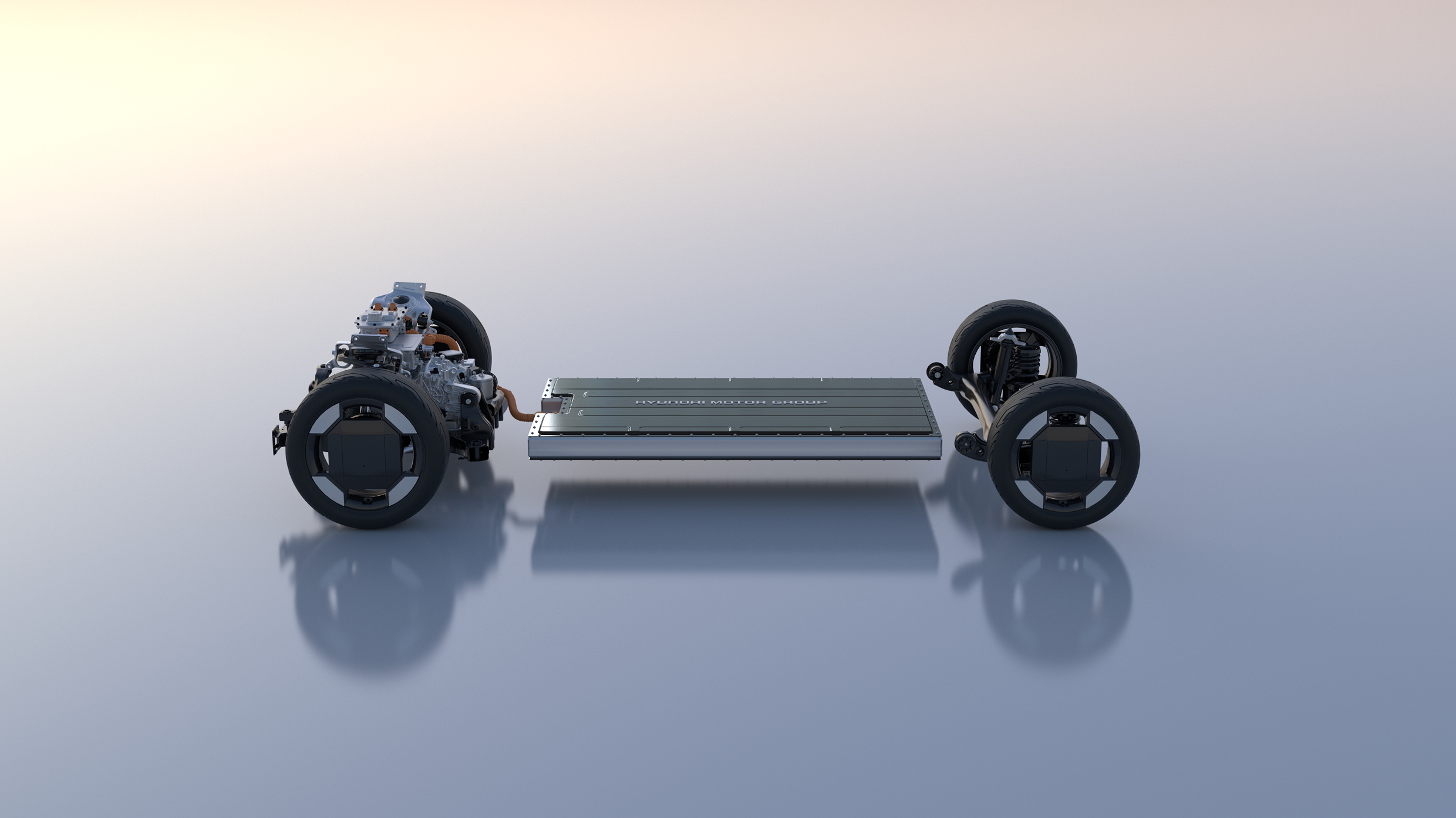

Hyundai Motor Group’s dedicated PBV platform, the E-GMP.S, is based on the globally acclaimed electrification technology of the E-GMP. Hyundai Motor Group has incorporated the unique characteristics of E-GMP into E-GMP.S, including a spacious and flexibly configurable interior, a power electric (PE) system that maximizes efficiency, and a driving range optimized for business environments. In addition, Hyundai Motor Group has developed the platform’s key specifications and enhanced product quality by closely analyzing the market and customers and adapting consumers’ feedback. The result is the EV platform optimized for the PBV business by securing versatility and spatial flexibility that can be used in a wide range of businesses.

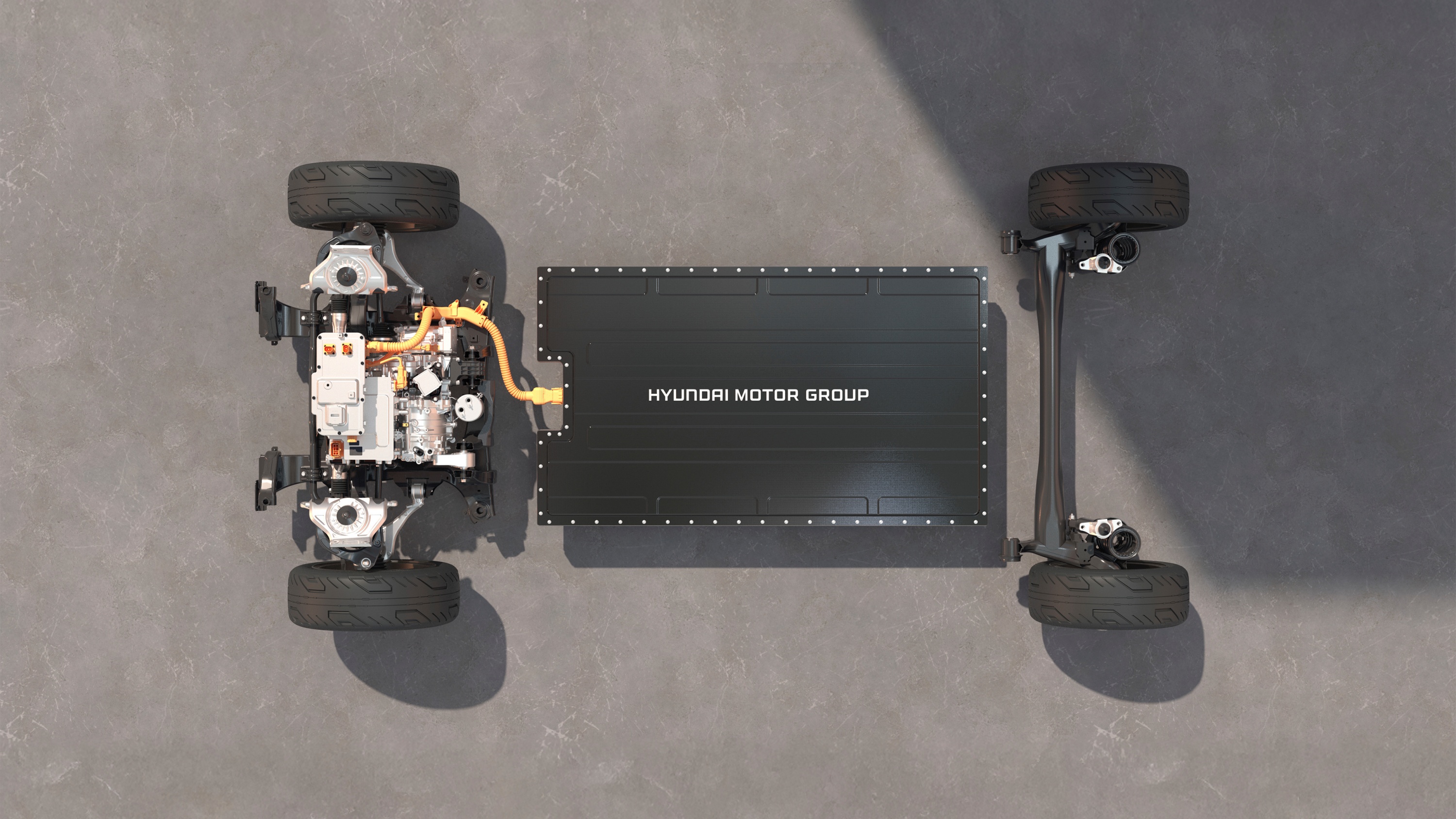

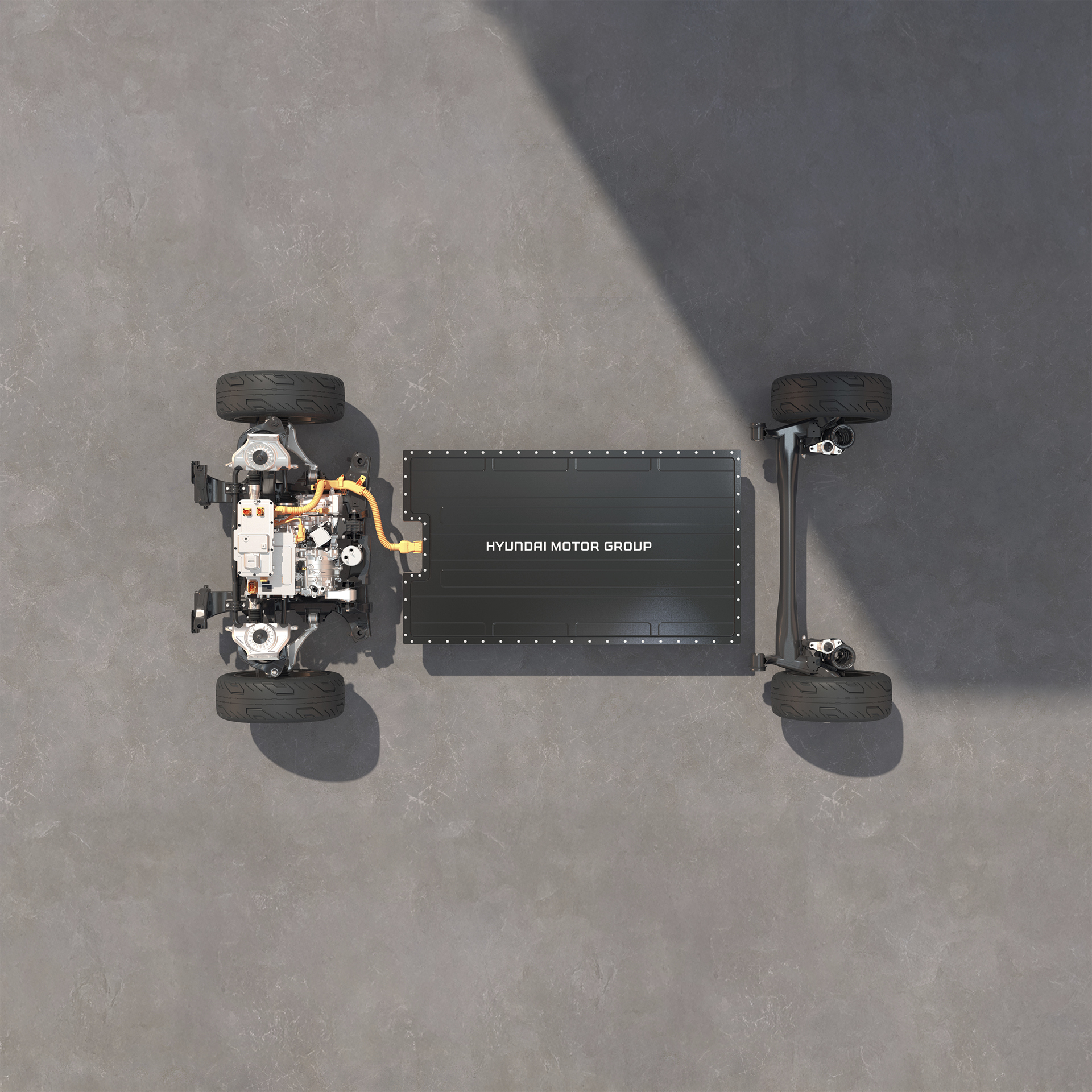

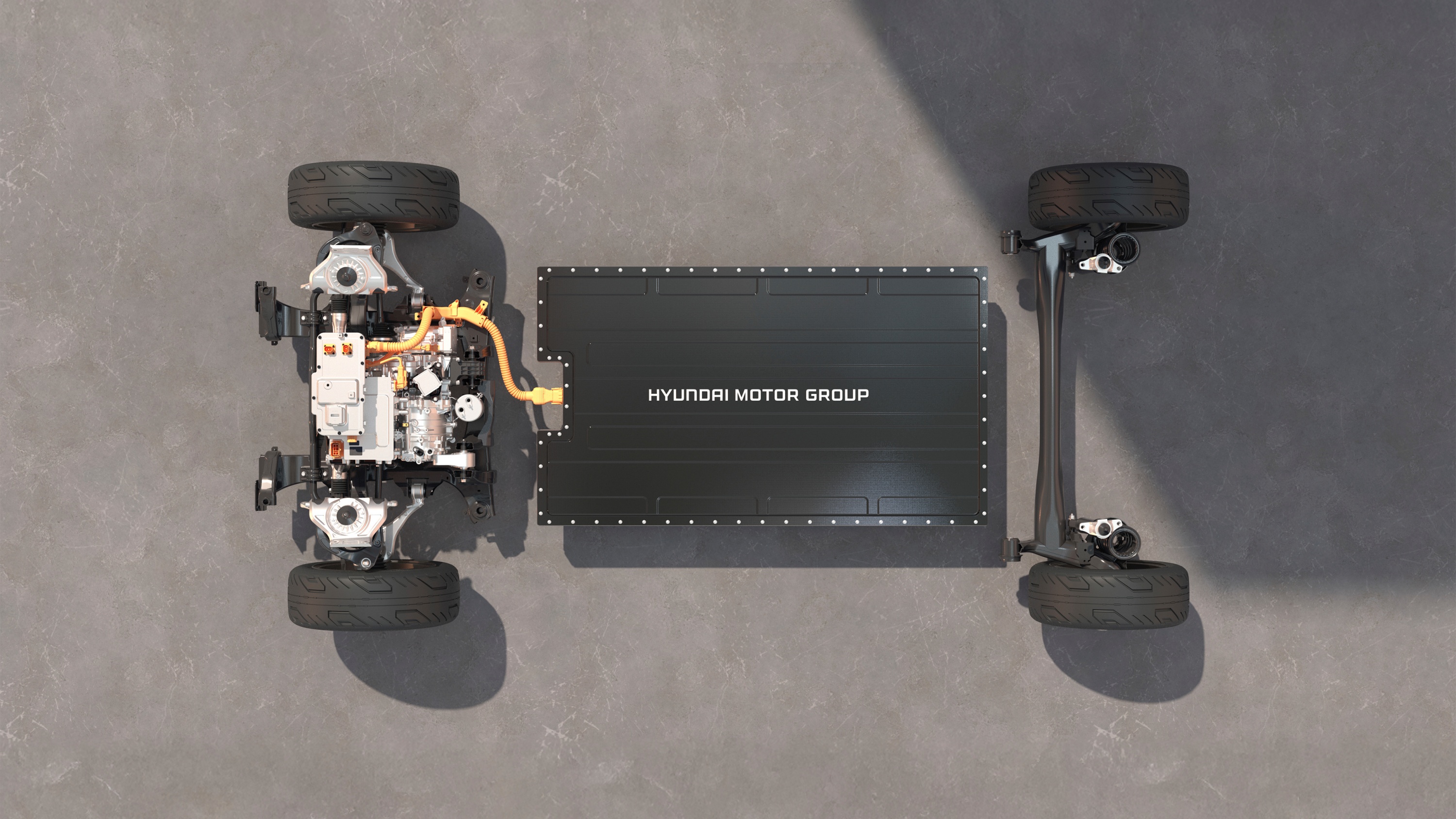

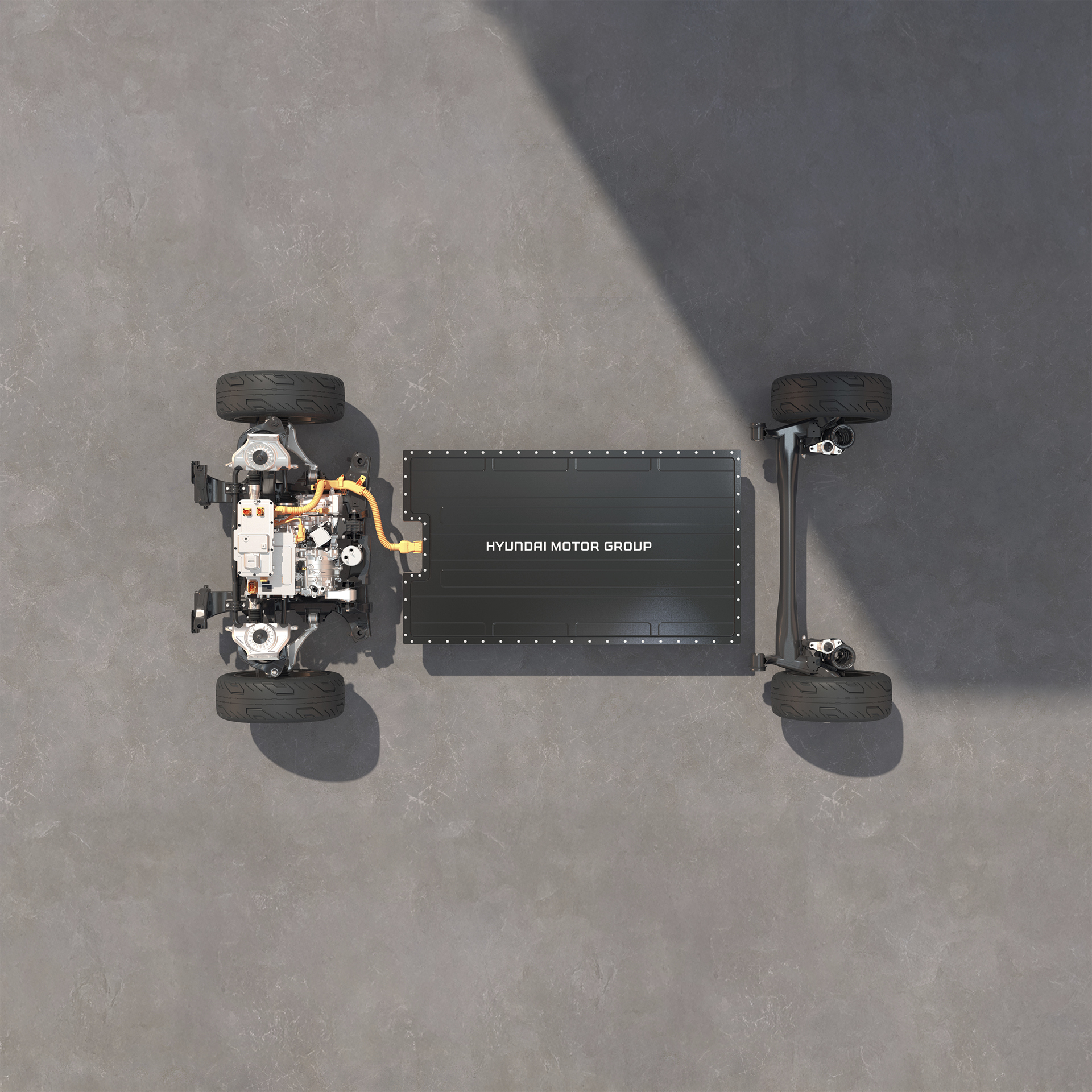

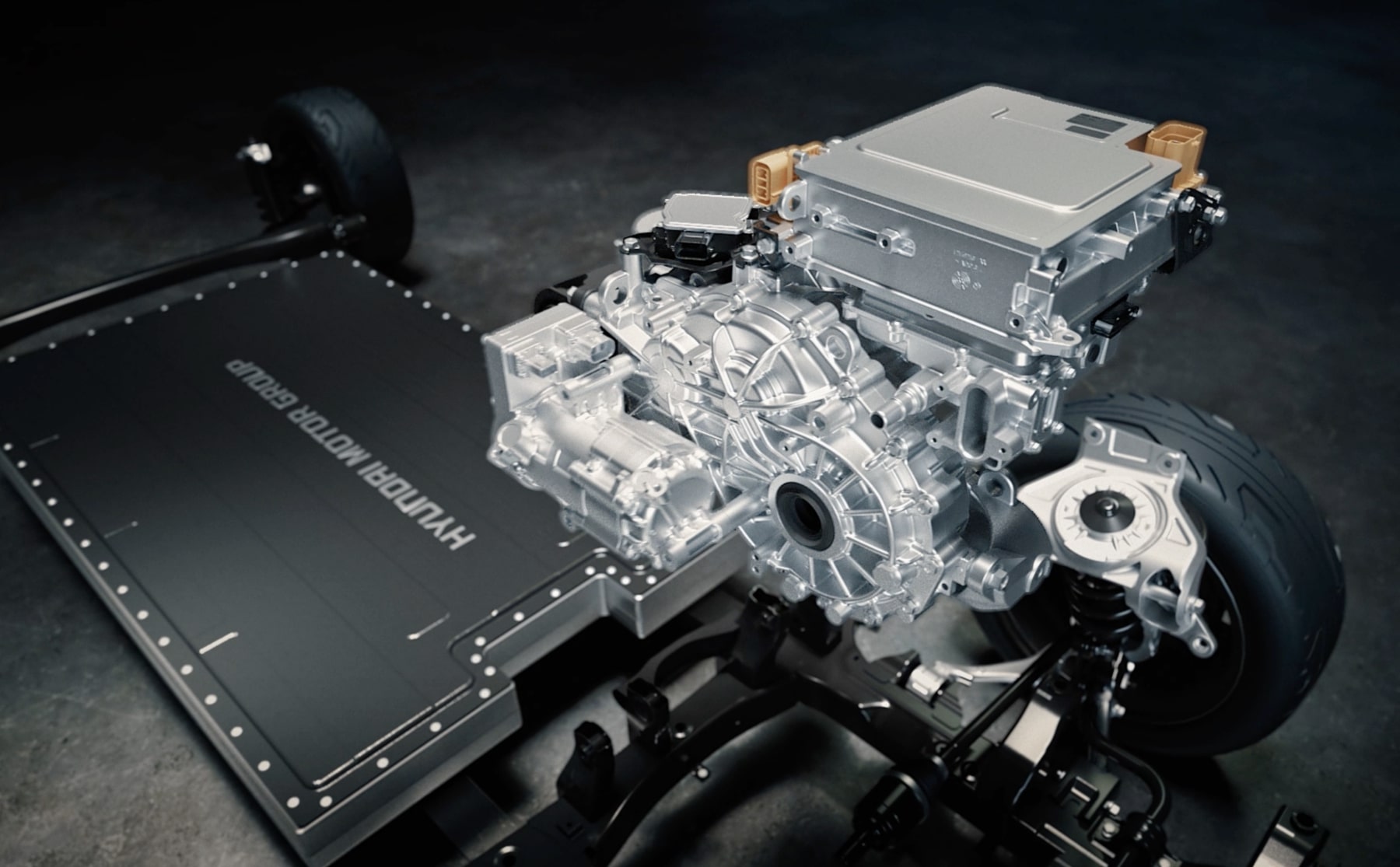

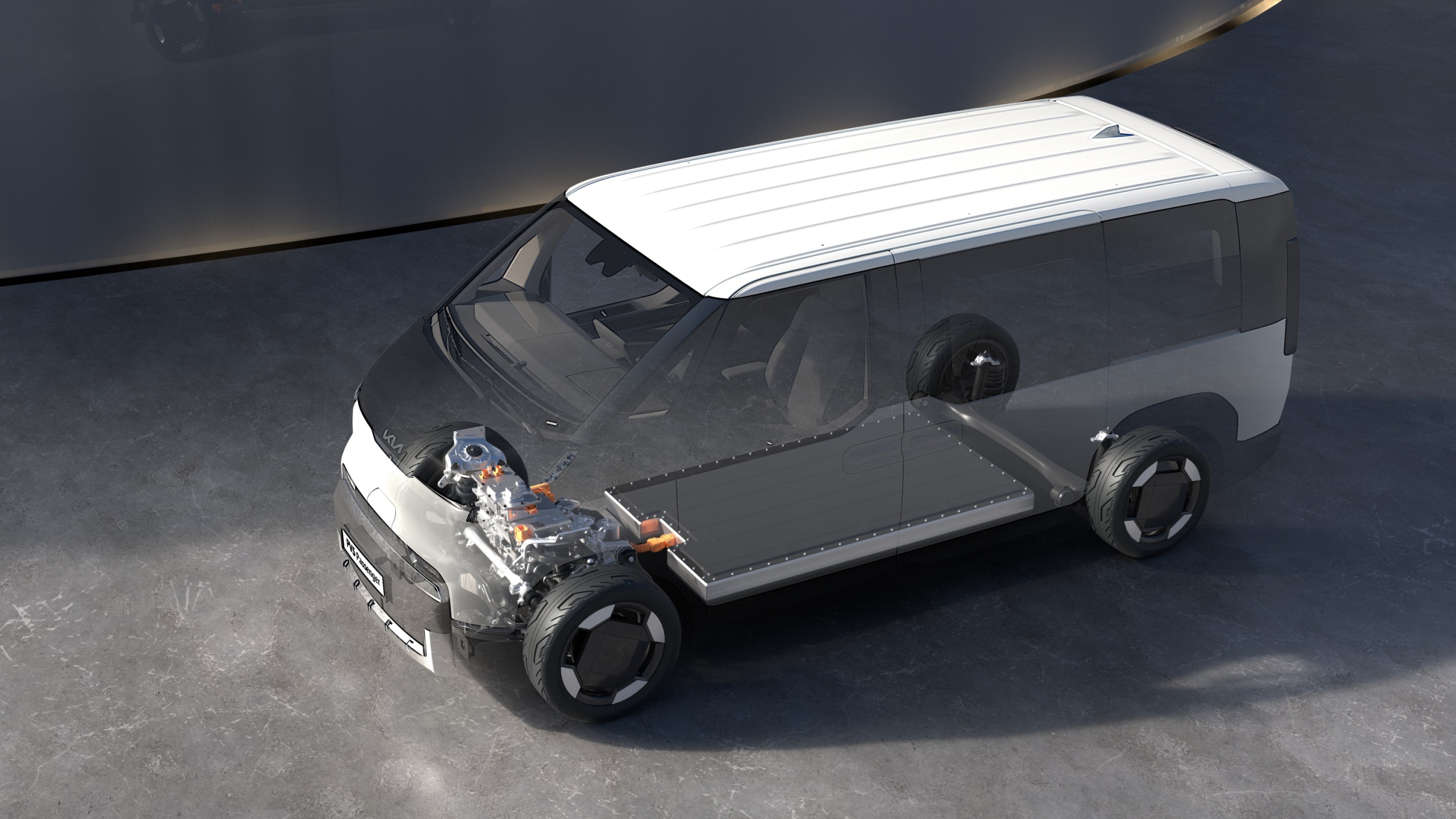

Hyundai Motor Group introduced the skateboard platform concept to the E-GMP.S with the goal of developing PBVs for various businesses. The skateboard platform is a structure that allows the upper body to be applied on a flat platform with the motor, battery, drivetrain, etc. placed at the bottom of the body. As a result, it responds to businesses such as ride-hailing services with multiple seats inside the upper body and delivery services focused on cargo loading, and implements a wide vehicle lineup from small to large.

One of the main features of the E-GMP.S is the application of the Integrated Modular Architecture (IMA) development system, which standardizes core components such as batteries and motors. Standardizing a large number of components that vary from vehicle to vehicle reduces development complexity and is the basis for increasing the vehicle’s technical reliability. In addition, cost reduction through economies of scale makes vehicle production more efficient and productive, and enables better mobility for customers.

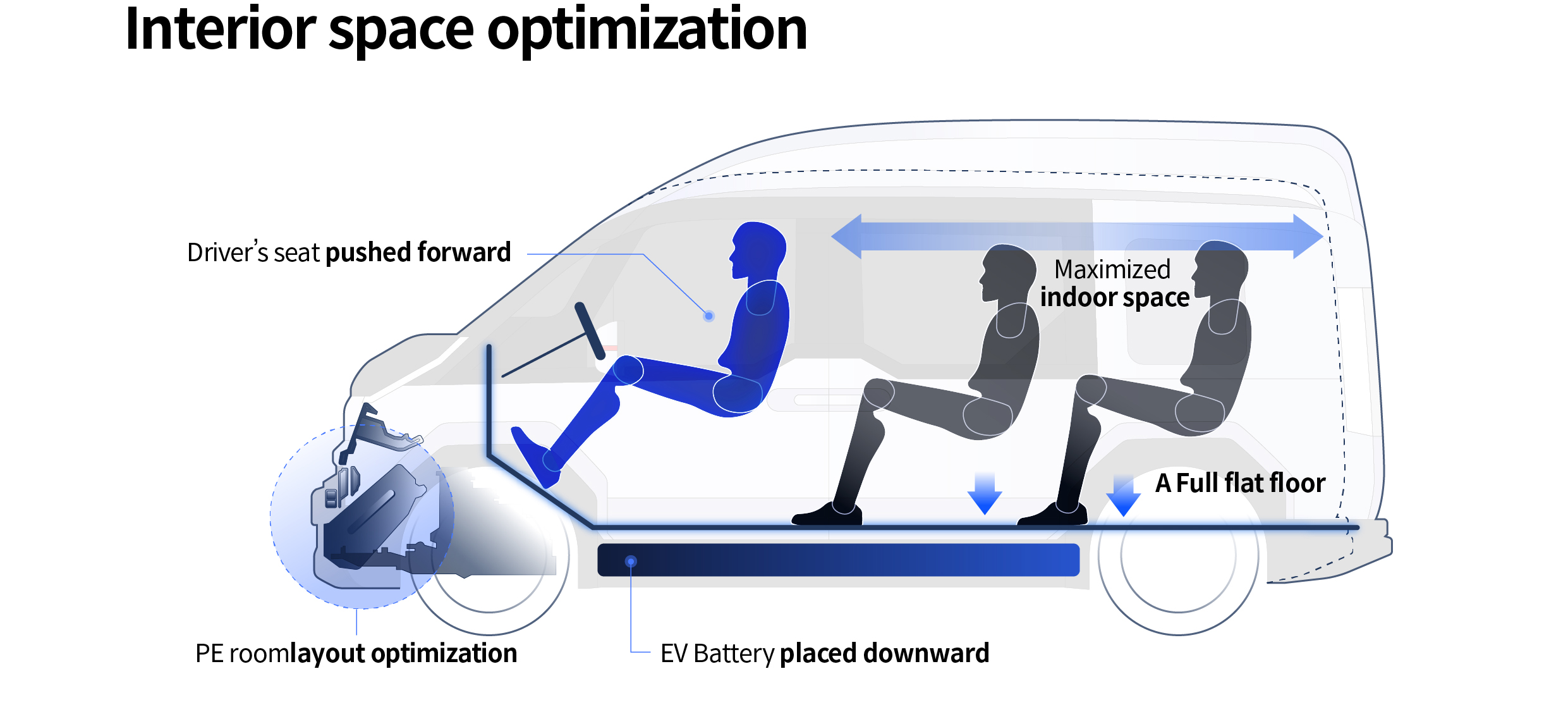

In the PBV business, it is no exaggeration to say that the interior spaciousness is a key factor in elevating business efficiency. For example, ride-hailing services require flexible seating configurations and ample passenger space, while delivery services rely on cargo space which is directly related to business profit. Hyundai Motor Group listened to actual PBV customers in these different industries and prioritized a spacious interior from the very beginning of the E-GMP.S’s design.

In addition to the structural benefits of the skateboard platform, which places the battery at the bottom of the vehicle, Hyundai Motor Group optimized the layout of the PE (Power Electric) module by integrating the motor, inverter, and reducer while positioning other systems with the module in the front. The driver’s seat was also moved forward as far as possible to create a spacious, passenger-oriented interior with maximized cargo space. In addition, the space between the floor above the battery pack was eliminated and a full-flat floor structure was designed from the first row to the third rows, allowing for more flexible space.

As a result, E-GMP.S offers a number of benefits in real-world vehicle operation. For example, the height of the step floor was lowered for passengers to easily get in and out of the vehicle. It also makes a driver to easily load and unload cargo from the bay, which improves business efficiency. By placing the units at the bottom of the vehicle also naturally lowers the center of gravity, making driving more stable.

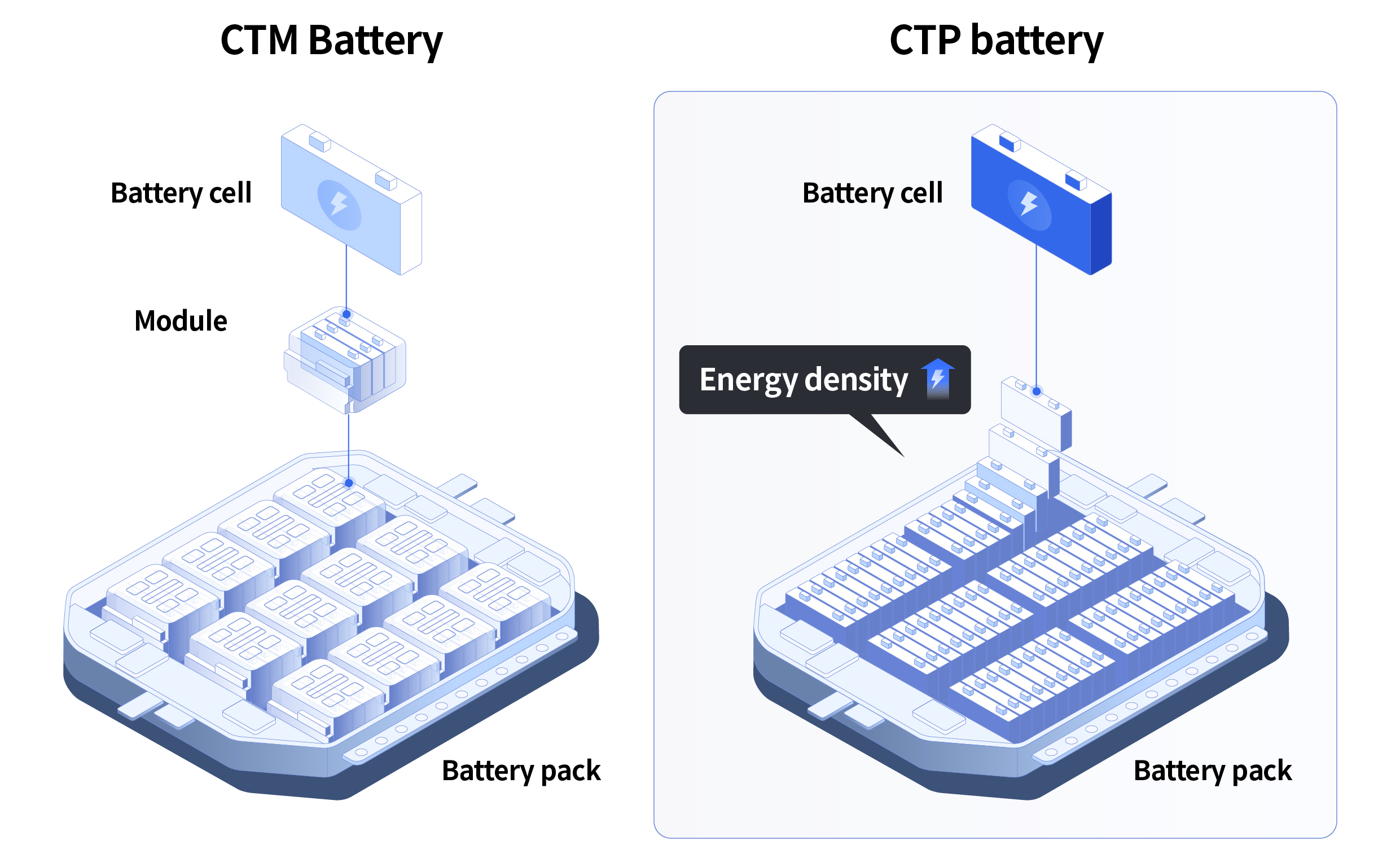

One of the design features of the E-GMP.S is the use of the Cell to Pack (CTP) system, a next generation battery technology. While the conventional Cell to Module (CTM) batteries require cells to be modularized to form a pack, the CTP process makes battery cells directly into packs without modules. This allows for a higher energy density by filling more battery cells in the space which was previously occupied by the module casing. This is why PBVs with the E-GMP.S can travel longer distances compared to other vehicles with the same size of CTM battery.

Furthermore, the E-GMP.S can be installed with either the front or rear wheel drive module, depending on the vehicle class, in order to meet market demand and affordability. Hyundai Motor Group has equipped E-GMP.S with a 400V high-voltage charging system and plans to expand to an 800V system, offering a diverse range of products tailored to market demands. (※ Front wheel drive motor and 400V high voltage system applied to Kia PV5)

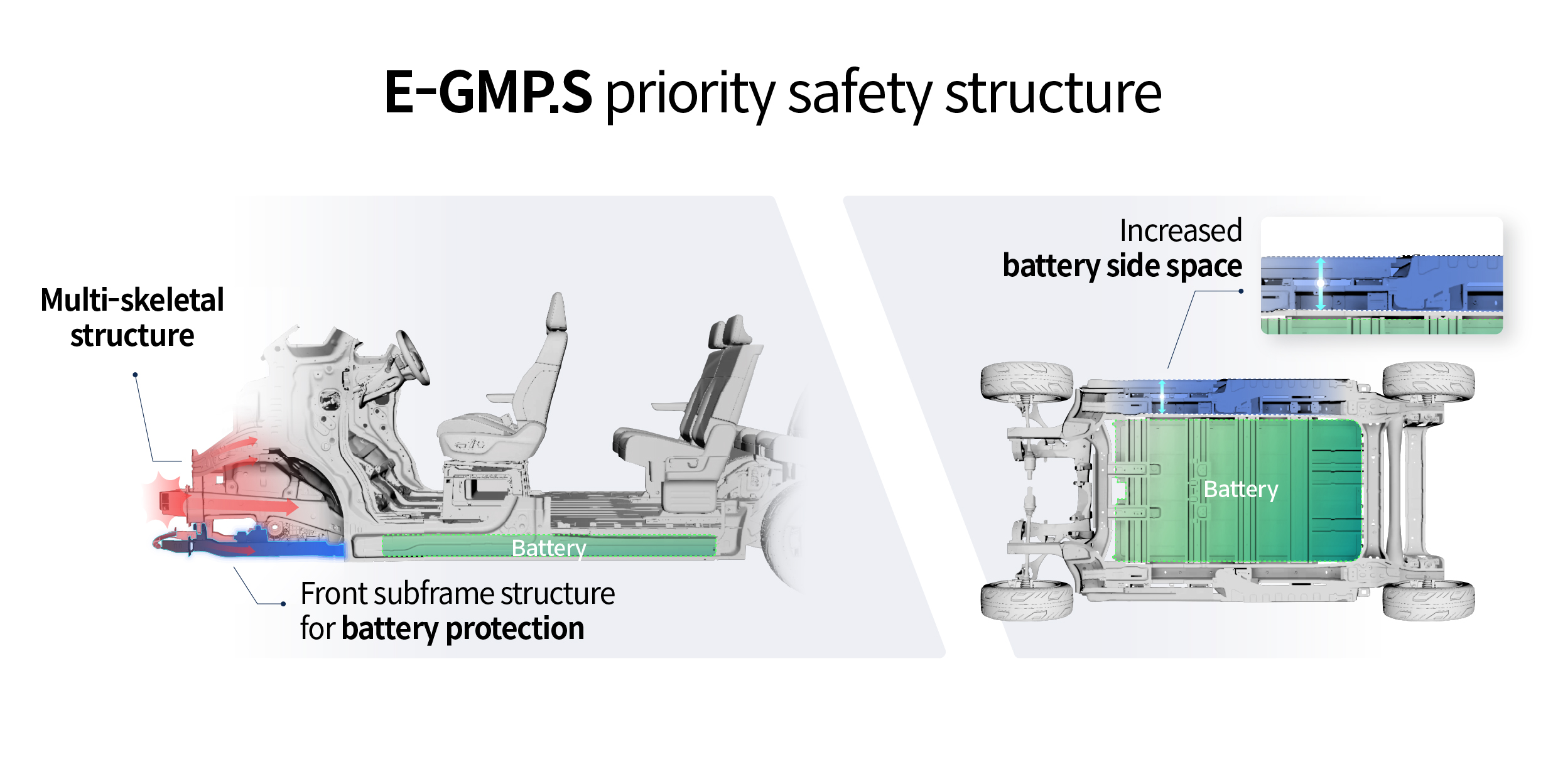

Hyundai Motor Group has prioritized creating a safe and reliable business environment for customers. For example, E-GMP.S features a multi-skeletal structure to prevent the impact of a collision from being concentrated in one place. This structure effectively reduces collision impact by distributing energy to the side members with various paths such as the subframe and fender apron. In addition, the PE room protection structure in the Crumple zone absorbs crash energy to minimize impact transferred to the passenger area.

Hyundai Motor Group also focused on protecting the battery pack from external impacts while keeping the low platform design. To protect the battery from unexpected impacts while driving, the battery pack was elevated as much as possible to avoid any damage and the subframe was located at the front to protect the battery pack. Finally, ultra-high tensile steel members with a strength of 180K were applied to the periphery of the battery to ensure the safety of the battery.

Meanwhile, business vehicles tend to be driven more frequently and longer distances than passenger vehicles, so vehicle owners are more concerned about safety and durability. The total cost of ownership (TCO) in operation was also considered when developing the platform.

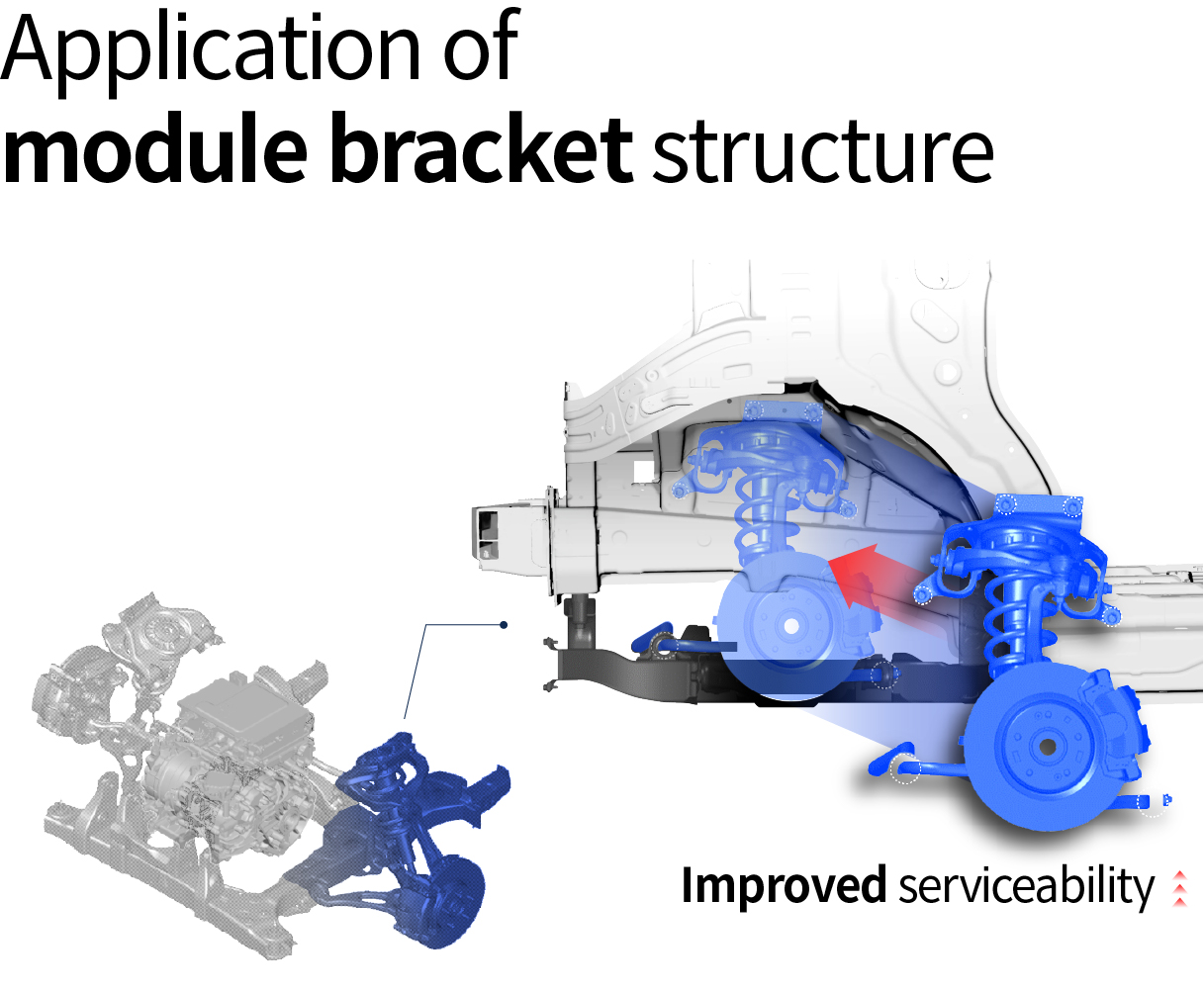

Some of major factors that increase a customer’s TCO include vehicle damage and unnecessarily prolonged repairs, which lead to additional expenses. To alleviate these customer concerns, Hyundai Motor Group applied a ‘system-based module structure’ to E-GMP.S that enables quick and easy maintenance of only the damaged parts. In addition, module brackets were applied to the front wheel suspension so that each part can be easily removed and attached from under the vehicle when PE module requires maintenance. In addition, consumables that require frequent replacement, such as coolant and washer fluid, were placed in the front or upper part of the PEoom to reduce maintenance time.

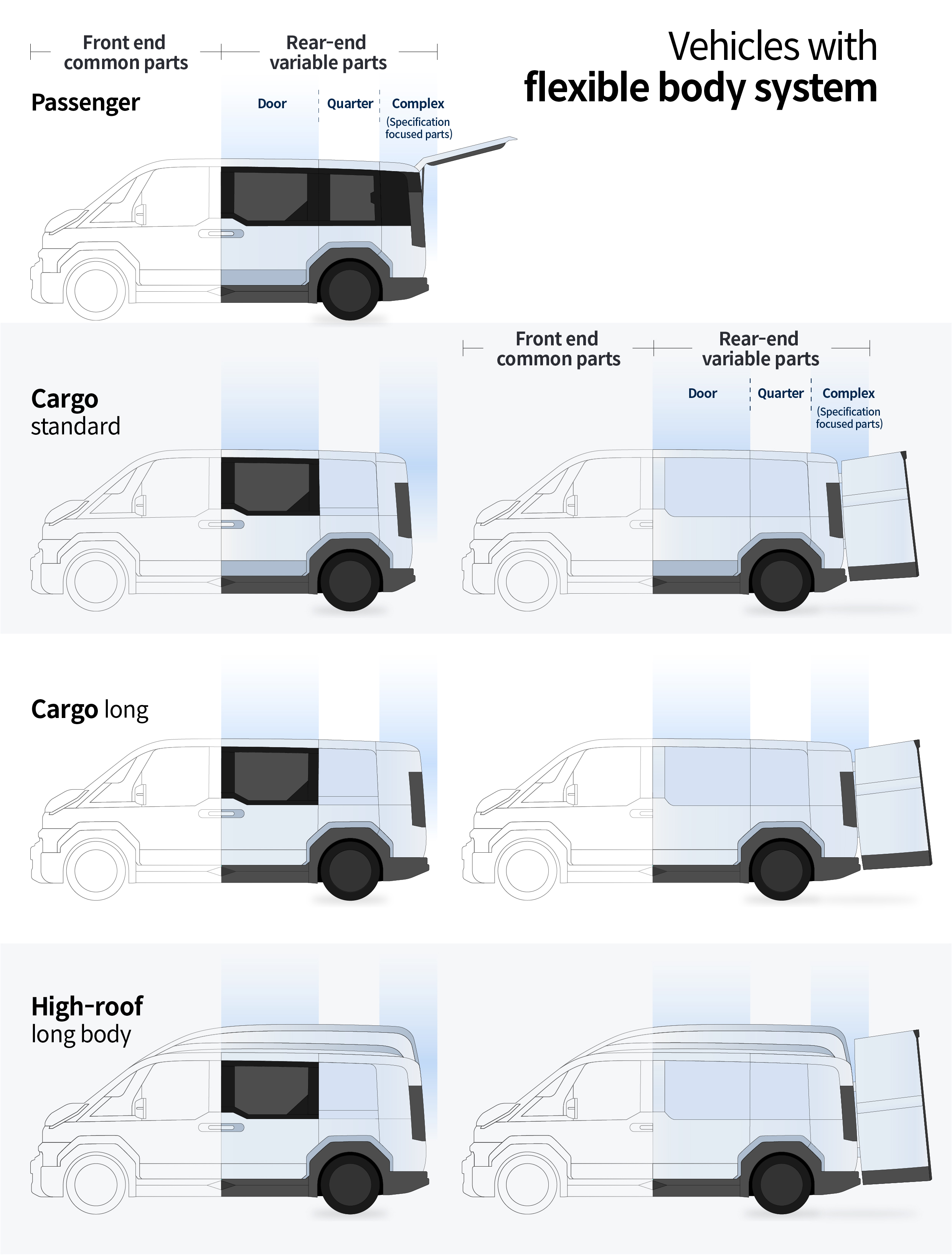

Considering the diverse PBV models, Hyundai Motor Group has introduced a new technology called ‘Flexible Body System’, which allows for modular combination of the exterior panels and rear body frame. This technology moves away from the conventional production method of creating a new mold for each body type. Instead, Flexible Body System enables Hyundai Motor Group to efficiently and quickly provide various vehicle types by dividing body parts into modules and assembling them like puzzle pieces based on customer demand.

As described earlier, Flexible Body System allows E-GMP.S-based PBVs to be transformed into a variety of sizes and shapes with the combination of body parts. For example, passenger vehicles which can accommodate a large number of passengers, can be equipped with sliding door panels to facilitate easy entry and exit for the mobility impaired, while the cargo can be configured with a high roof and twin-swing tailgate to support walk-through access. Hyundai Motor Group will first apply Flexible Body System to the Kia PV5, and will initially introduce seven specifications that are expected to be in high customer demand.

Another feature of the E-GMP.S to increase business efficiency is customized software. Hyundai Motor Group is launching Fleet Management System (FMS) to help business customers with PBVs to manage their vehicles more efficiently. With the FMS, customers can monitor vehicle status, such as the vehicle’s charging status and current location, and immediately identify unusual situations, such as accidents or maintenance, to optimize vehicle and workforce schedules. The system helps business owners minimize operational losses and reduce their TCO.

In addition, the E-GMP.S supports a PBV infotainment system, which specializes for business purpose vehicles. The infotainment system is based on the Android OS and is highly compatible with the mobile ecosystem. Thanks to AAOS, business customers can utilize the functions required for PBV business in real time through various service applications. Furthermore, OTA updates keep the vehicle’s infotainment system always up to date.

As seen so far, the E-GMP.S is a platform that is the technical foundation of PBV, Hyundai Motor Group’s remarkable business vehicle with optimized electric vehicle performance. Hyundai Motor Group plans to expand its PBV lineup based on the E-GMP.S continuously, starting with the Kia PV5, so that the market can experience technological competitiveness. It is expected that E-GMP.S, which was created based on the voices of PBV partners, will provide a valuable business life for various customers.