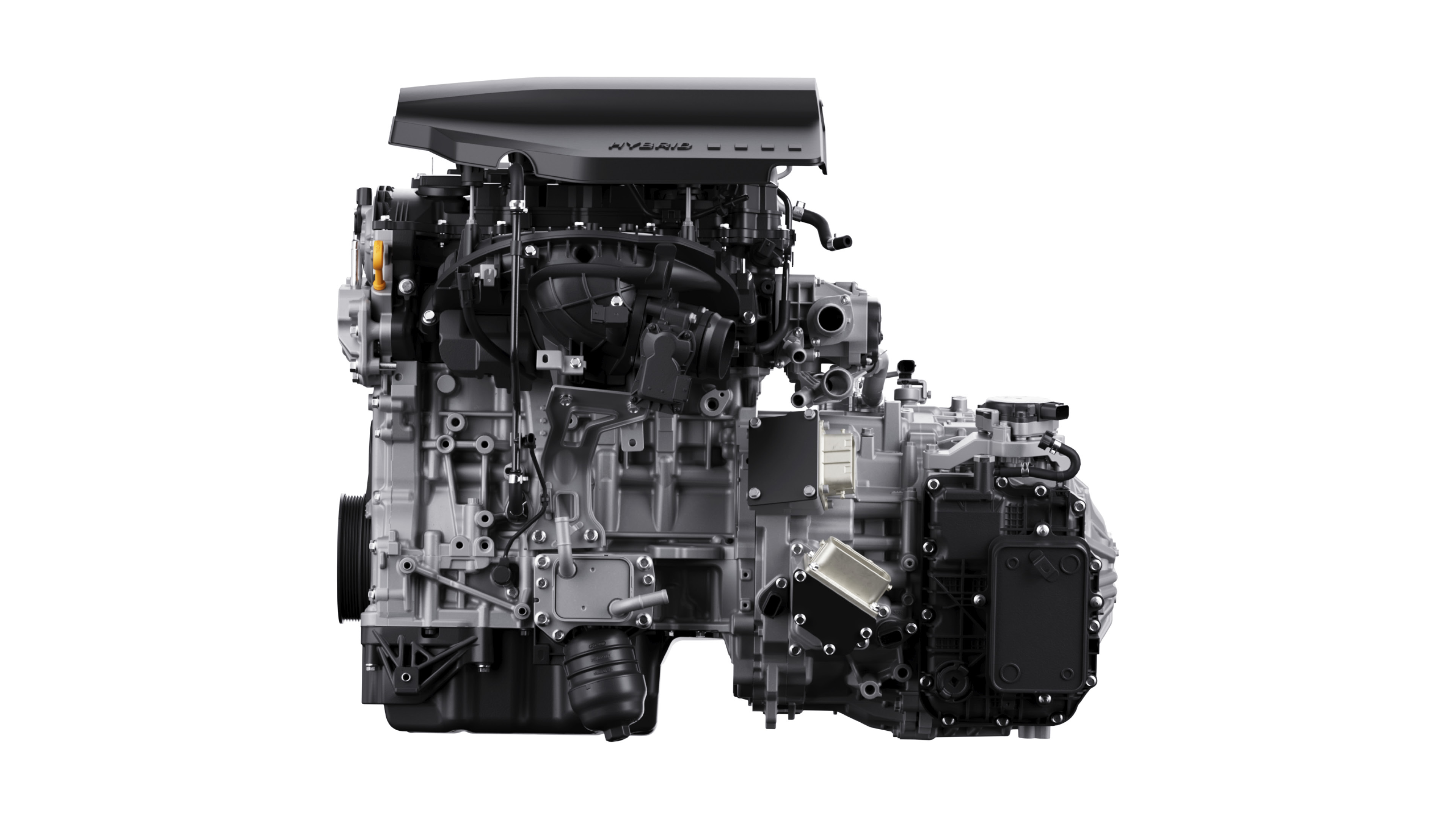

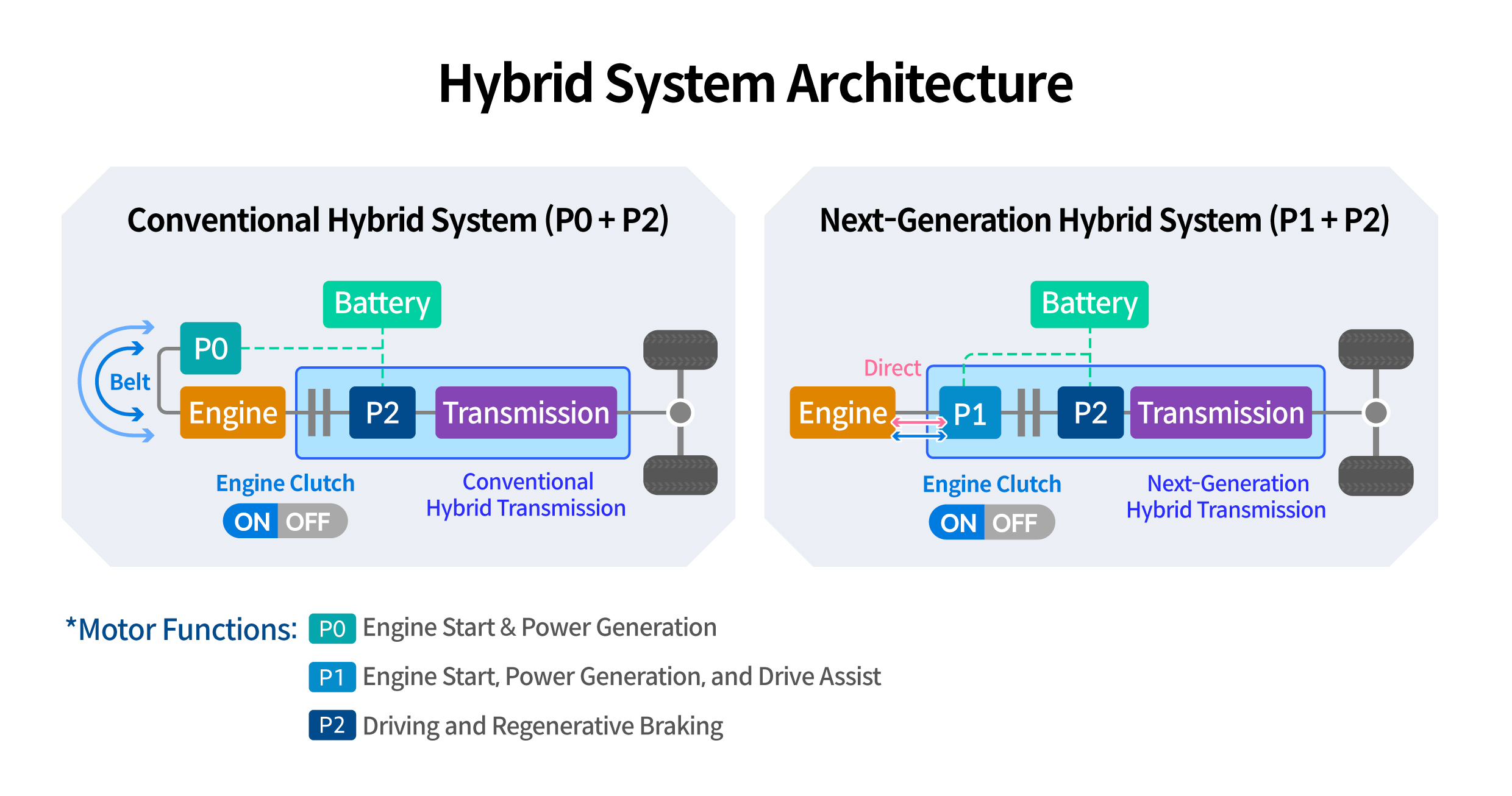

HMG has unveiled what may be a new milestone in powertrain technology: its next-generation hybrid system. Leveraging its extensive hybrid experience, HMG has evolved from the traditional ‘P0+P2’ setup to a ‘P1+P2’ configuration. This shift, paired with a newly developed hybrid-specific engine and transmission, results in a fuel economy improvement of over 4% (based on the Smartstream 1.6 Turbo Hybrid).

The new system is scalable across a wide range of powertrains, from over 100 horsepower to more than 300 horsepower, offering five different configurations to serve everything from compact to full-size models. The goal? Delivering stronger performance and enhanced product value in the age of electrification. The first model to debut this system is the Palisade Smartstream 2.5 Turbo Hybrid, and senior research engineers Hong-sik Yu (Electrified Drivetrain Design Team) and Jong-guk Park (Electrified Drivetrain Testing Team 1) provided deep insights into its development.

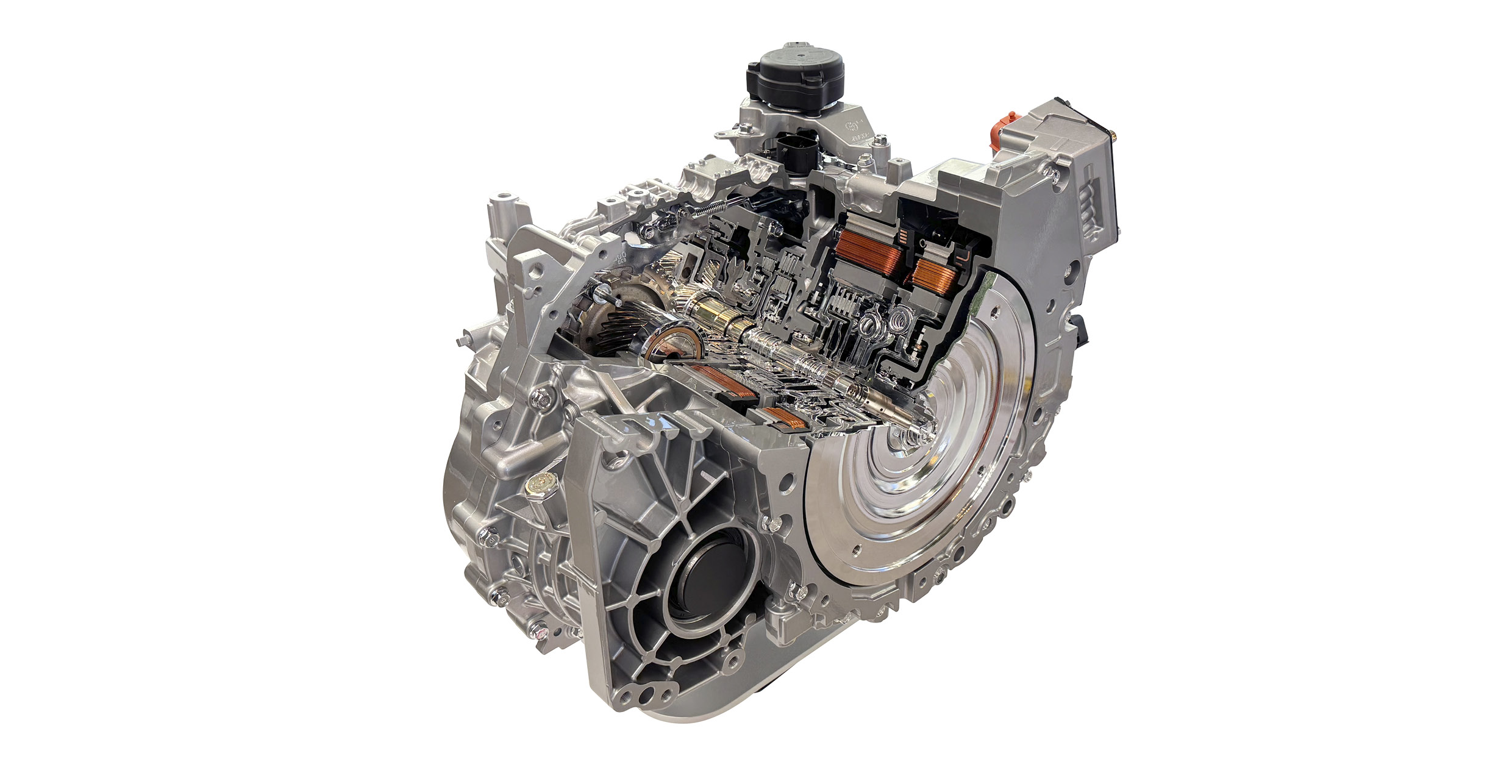

One of the core elements of this new hybrid system is its all-new transmission. Traditional hybrid transmissions integrated a P2 motor for drive and regenerative braking. The new version takes it a step further by also incorporating a P1 motor within the same unit—responsible for engine starting, power generation, and torque assist. As a result, the transmission’s role has expanded significantly. We spoke with Hong-sik Yu for a technical breakdown.

Q. What defines this next-gen hybrid system?

senior research engineer Hong-sik Yu | The ‘P1+P2 parallel’ structure minimizes the limitations of the previous ‘P0+P2’ layout. To clarify: hybrid systems are categorized by motor placement—P0 through P4. P0 is belt-driven for engine start/generation. P1 is directly attached to the engine crankshaft, assisting in both starting and drive. P2 and P3 motors are positioned at the input and output shafts of the transmission respectively, enabling EV drive and regeneration. P4 powers the rear axle for AWD applications.

In previous setups, the P0 motor’s belt connection introduced frictional losses, and only the P2 motor handled drive, limiting performance. The new P1 motor, being directly coupled, eliminates belt losses and actively assists the P2 motor, significantly enhancing overall system efficiency.

Q. What was your primary focus during development?

Yu | The biggest challenge was fitting the hybrid drivetrain into a front-wheel-drive engine bay. The transmission length had to remain compact, despite adding the P1 motor. That meant optimizing the internal layout and reducing component sizes while still increasing torque capacity—up by 9.5 kgf·m—to match the output of the 2.5 Turbo Hybrid.

Q. How was the packaging strategy executed?

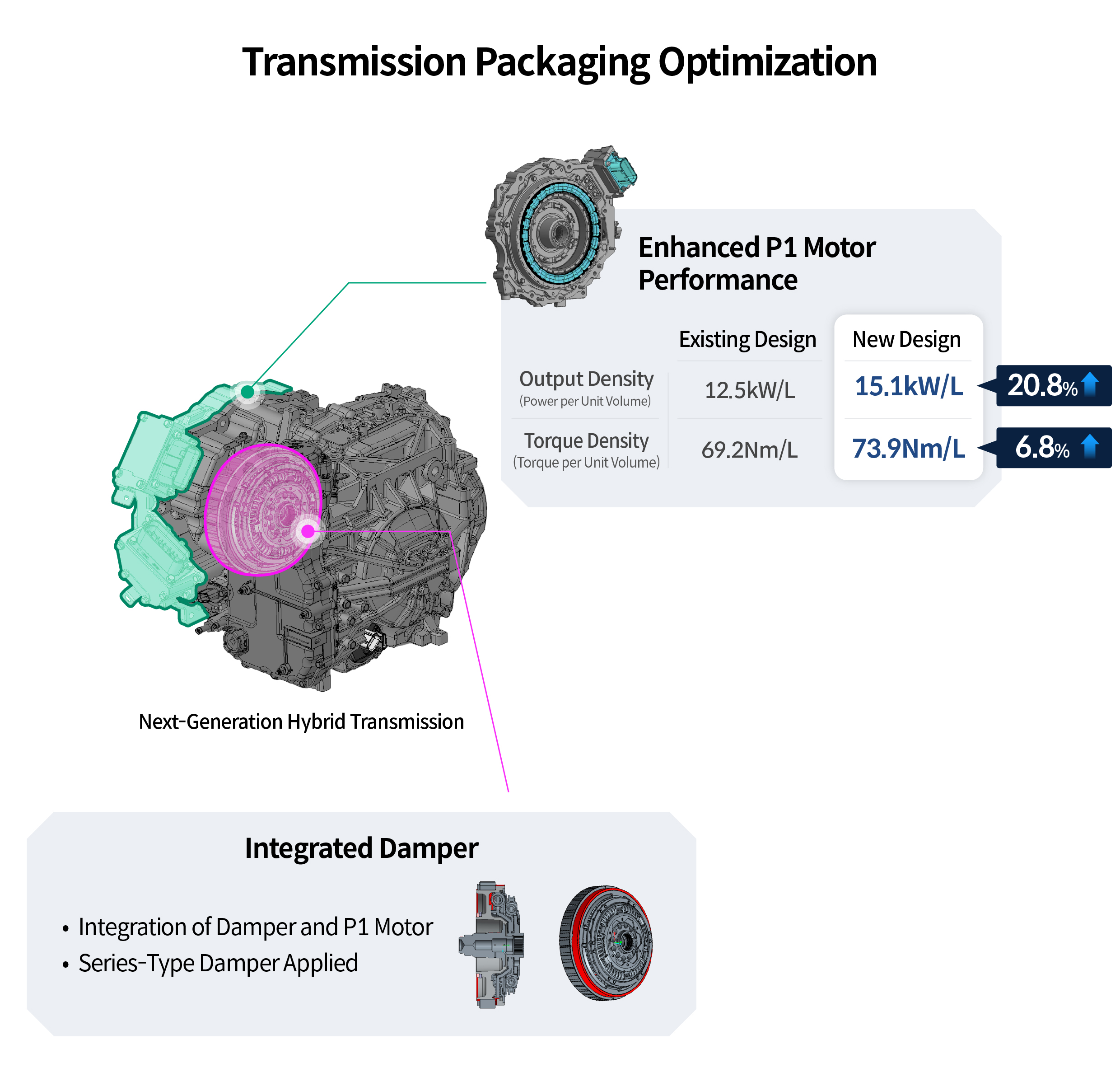

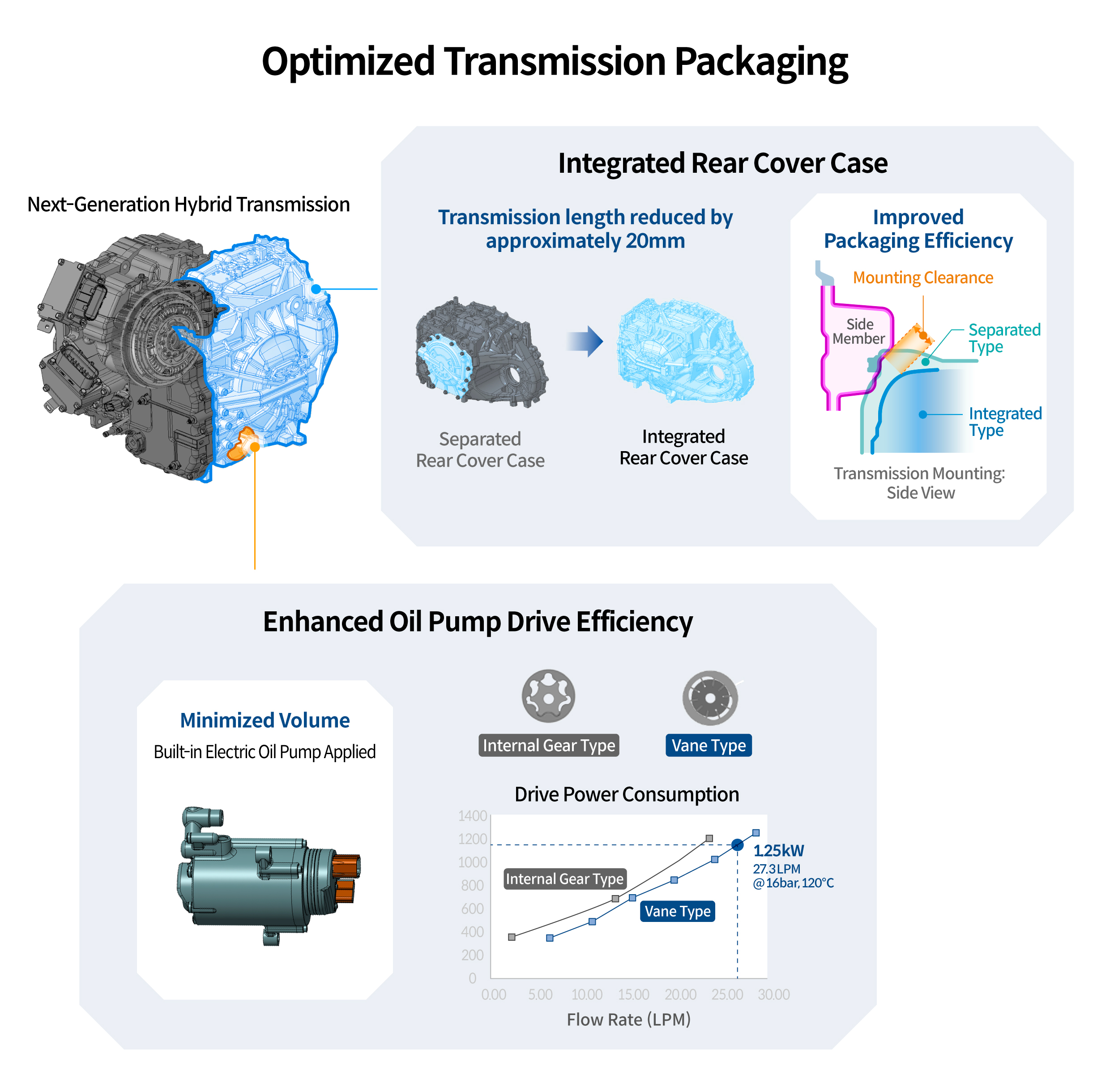

Yu | Minimizing the overall length increase of the new hybrid transmission revolved around four key strategies: optimizing the drive motor packaging, redesigning the transmission damper structure, integrating an electric oil pump, and adopting a one-piece rear cover case.

First, by optimizing the drive motor layout, we secured enough space within the transmission to accommodate both the existing P2 motor and the newly ad-ded P1 motor. This was achieved through the design of an ultra-thin P1 motor, drastically shortening the motor’s stacked length and maximizing packaging efficiency. Additionally, we enhanced the P1 motor’s cooling structure and flow rate to minimize performance degradation due to heat buildup, improving power density by 20.8% and torque density by 6.8%. These improvements allowed us to meet the packaging requirements without sacrificing performance.

We also developed an entirely new transmission damper. The transmission damper, which reduces vibration when engine torque is transmitted to the gearbox, was repositioned within the newly available space created by the P1 motor layout. Furthermore, since the damper’s outer diameter became smaller compared to previous systems, it was critical to enhance its structural rigidity. To solve this, we designed a new series damper that uses two springs to absorb shocks, delivering higher performance than the previous single-spring design.

An integrated electric oil pump also contributed to packaging efficiency. Previously mounted outside the transmission, the pump is now positioned internally. We switched from an internal gear type to a vane type, where rotating blades generate oil pressure. This change improved operational efficiency and reduced power consumption.

Finally, the adoption of a one-piece rear cover eliminated unnecessary bolts and joint structures, shortening the transmission section by 16.9mm. Thanks to these thoughtful packaging innovations, even though the addition of the P1 motor would have extended the transmission by 25.4mm, the total length increase was contained to just 8.5mm. We also refined the gear tooth width and increased the number of planetary pinion gears to distribute higher loads, effectively reducing the overall transmission volume.

Q. What is the future outlook for hybrid transmissions?

Yu | Building on Hyundai’s proprietary automatic transmission technology, we've developed the next-generation P1+P2 hybrid system. In a hybrid layout, achieving the perfect balance between the engine and motor outputs is essential. Increasing gear stages in a hybrid doesn’t significantly impact fuel economy, but too few gears can overly restrict the engine's operating range. HMG is continuously exploring various new transmission technologies to further refine the efficiency and completeness of its hybrid systems.

Hyundai's next-gen hybrid system also involved major improvements to the engine itself. The newly revealed Smartstream 2.5 Turbo Hybrid engine features hybrid-optimized design elements that boost combustion efficiency, achieving up to a 2.9% improvement in fuel economy while also cutting emissions. Senior research engineer Jong-guk Park, who led the engine development, explained the key technologies behind it.

Q. What makes the Smartstream 2.5 Turbo Hybrid engine unique?

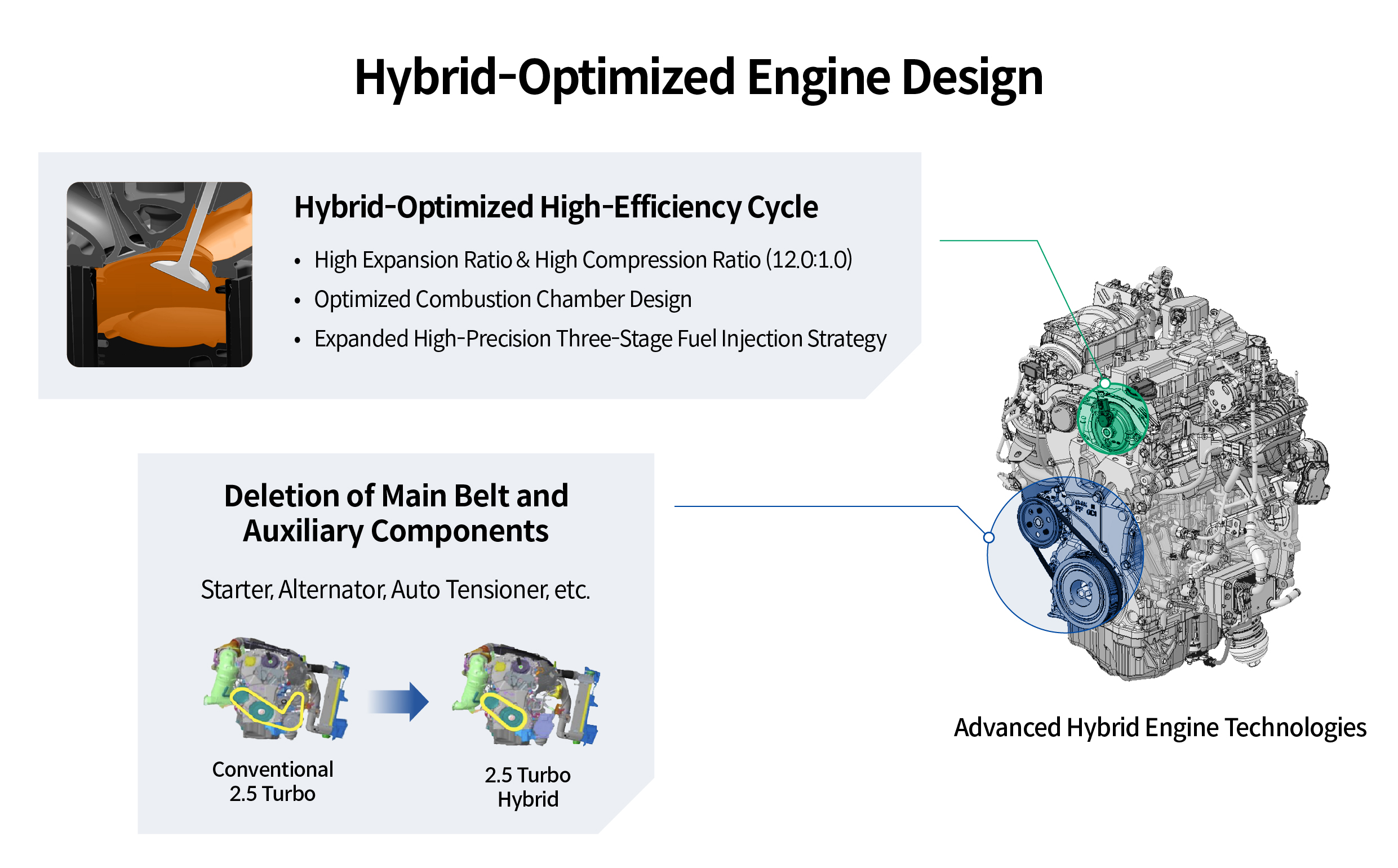

Park | Since hybrid vehicles benefit from motor assistance, we intentionally reduced the base engine’s peak power and torque to optimize it for hybrid application. Balancing dynamic performance, fuel economy, and strict emissions compliance wasn’t easy, but we achieved it through hybrid-optimized engine design, the application of the high-efficiency hybrid combustion cycle, and refinement of multi-stage fuel injection strategies.

Q. How did changes in the hybrid system architecture affect engine design?

Park | In the new system, the P1 motor is directly connected to the engine crankshaft. Therefore, components like the belt, alternator, and A/C compressor—previously driven by the engine—were removed and replaced with on-demand electric accessories. This reduced parasitic losses, cut weight, and improved the overall energy management of cooling and air-conditioning systems.

Q. How does the hybrid high-efficiency cycle work?

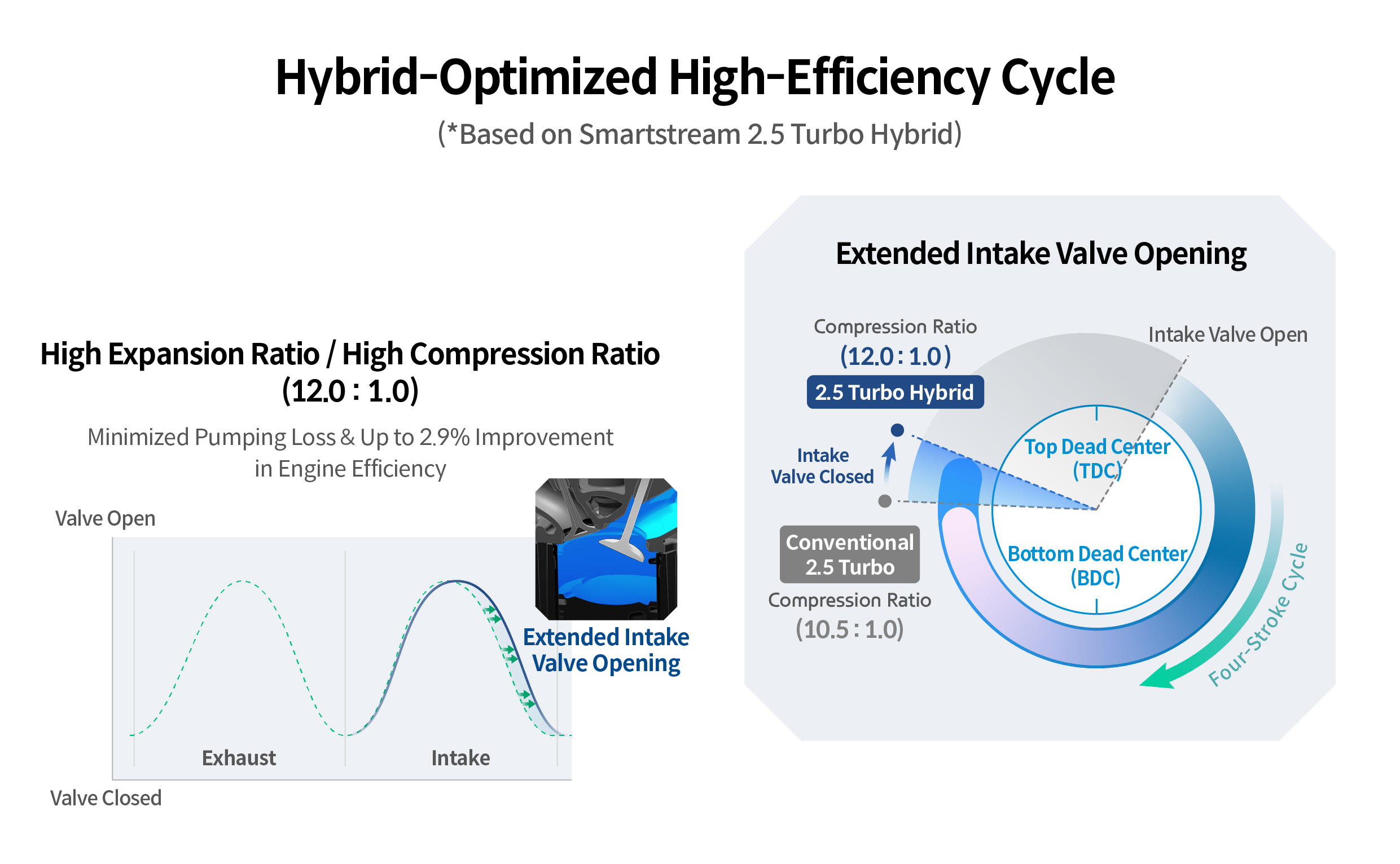

Park | Typically, internal combustion engines generate power through four strokes: intake, compression, combustion, and exhaust. Increasing the compression ratio enhances efficiency by generating more usable power from each combustion event. However, higher compression also raises the risk of abnormal combustion, or knocking. To counter this, we delay the closing of the intake valve during the compression stroke. This ‘Late Intake Valve Closing’ (LIVC) strategy reduces the effective compression ratio while still allowing a high expansion ratio—a principle called the ‘over-expansion cycle.’

In the Smartstream 2.5 Turbo Hybrid, we raised the mechanical compression ratio from 10.5:1 to 12:1. By delaying intake valve closure, the engine achieves a reduced effective compression ratio while maximizing the expansion work during combustion. The result: minimized energy loss during compression and maximized energy output during combustion, boosting both performance and efficiency. Additionally, by optimizing the multi-stage injection strategy of the GDI system, we enhanced the air-fuel mixture’s flow inside the combustion chamber, accelerated combustion speed, and suppressed knock tendency. This significantly improved high-load power delivery, fuel economy, and cold-start emissions.

Q. What additional improvements support the hybrid high-efficiency cycle?

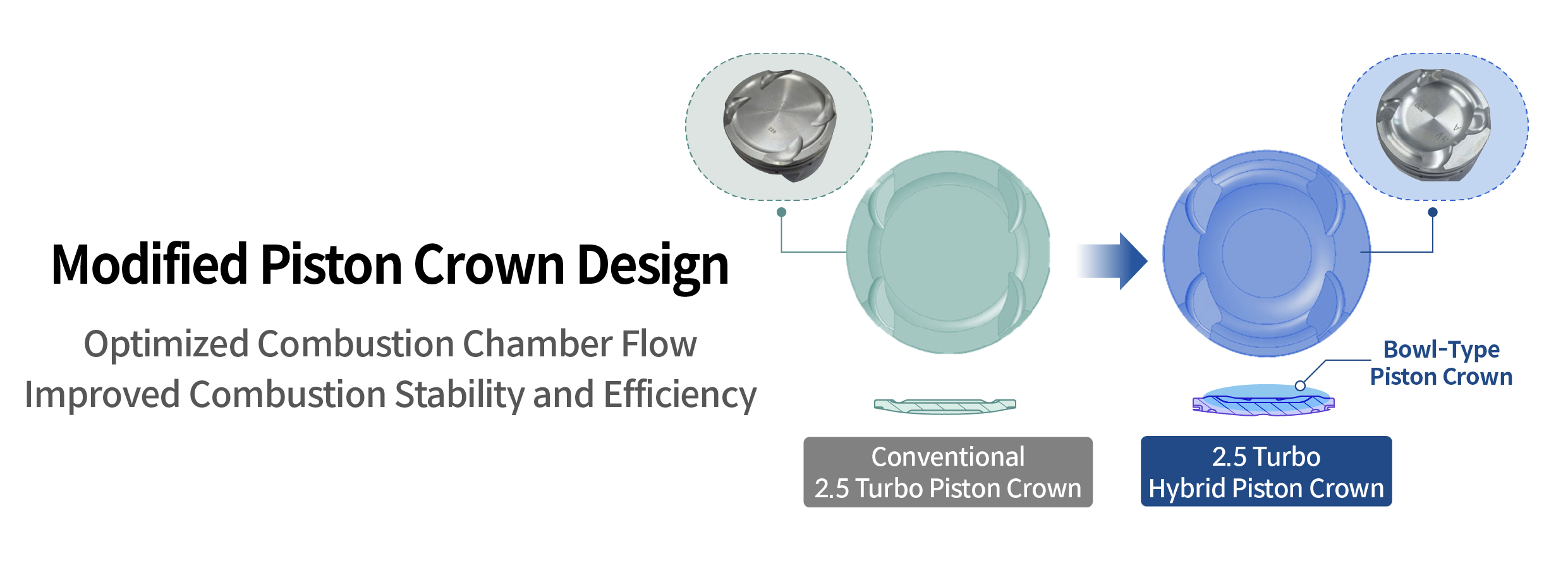

Park | To fully realize the Hybrid High-Efficiency Cycle, we focused on enhancing airflow within the combustion chamber. In a gasoline engine, efficient mixing of air and fuel — and complete combustion — hinges on strong ‘tumble flow,’ where the air-fuel mixture rotates vertically inside the cylinder. A powerful tumble flow enables faster, more stable combustion, which in turn suppresses knocking, boosts combustion efficiency, and helps lower harmful emissions.

However, as mentioned earlier, delaying the closing of the intake valve — a key part of the hybrid high-efficiency cycle — can weaken tumble flow. This happens because some of the intake mixture flows backward, disrupting the smooth airflow inside the chamber. To solve this, we redesigned the piston's crown with a concave ‘bowl’ shape, reinforcing tumble motion and restoring efficient internal flow. As a result, combustion became more stable and efficient, improving overall engine performance. It also enhanced catalyst light-off during cold starts, helping the engine meet even stricter emissions regulations with ease.

Q. How was the fuel injection strategy optimized for combustion?

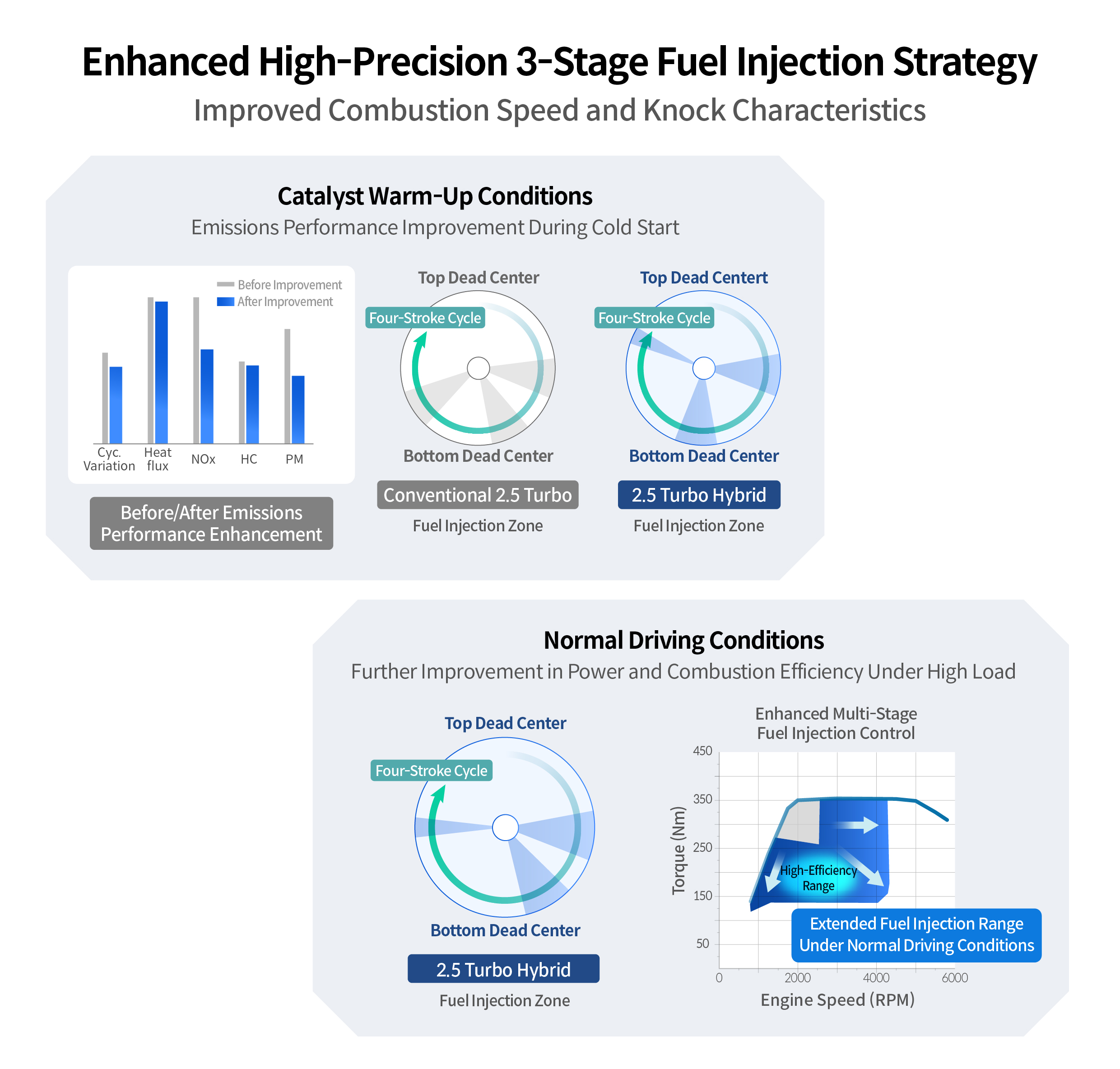

Park | The previous 2.5 Turbo engine utilized a two-stage fuel injection strategy during the intake stroke. In contrast, the Smartstream 2.5 Turbo Hybrid advances this with a three-stage multi-injection strategy, especially critical while the catalyst warms up before it becomes fully active.

Here’s how it works: Fuel is injected in three carefully timed bursts depending on intake airflow intensity. In the early and mid-intake phases, fuel is dispersed rapidly to promote quick vaporization. Then, a small additional amount is injected during the late compression stroke to sustain strong mixture motion inside the cylinder.

At the same time, we improved injector quality to reduce the risk of knocking caused by additional injections. This refinement not only enhanced power and combustion efficiency under high-load conditions but also expanded the range where the engine operates at peak efficiency. As a result, the system achieves better fuel economy even during heavy-load driving and significantly cuts down nitrogen oxides (NOx) and particulate emissions, meeting tougher global emissions standards.

As we’ve seen, HMG’s engineers have made major strides in internal combustion innovation — pushing the Smartstream 2.5 Turbo Hybrid engine to maximize performance, efficiency, and emissions control all at once. The next-generation hybrid system — featuring a dedicated transmission and optimized engine — will debut in Hyundai’s flagship Palisade 2.5 Turbo Hybrid, finally offering customers the large hybrid SUV they’ve been waiting for. Moving forward, HMG remains committed to pushing the boundaries of powertrain technology, delivering even greater performance, value, and sustainability for tomorrow’s drivers.

Photography by Hyuk-soo Cho