Hyundai Motor Group's CES 2026 public exhibition greets visitors with six distinct exhibition zones, each centered on a specific theme and showcasing Hyundai Motor Group’s leadership in AI robotics and its practical advantages for human development. Packed with interactive demonstrations, every zone immerses viewers in real-world robotics applications, emphasizing the scalability and the innovative benefits robotics bring to daily life.

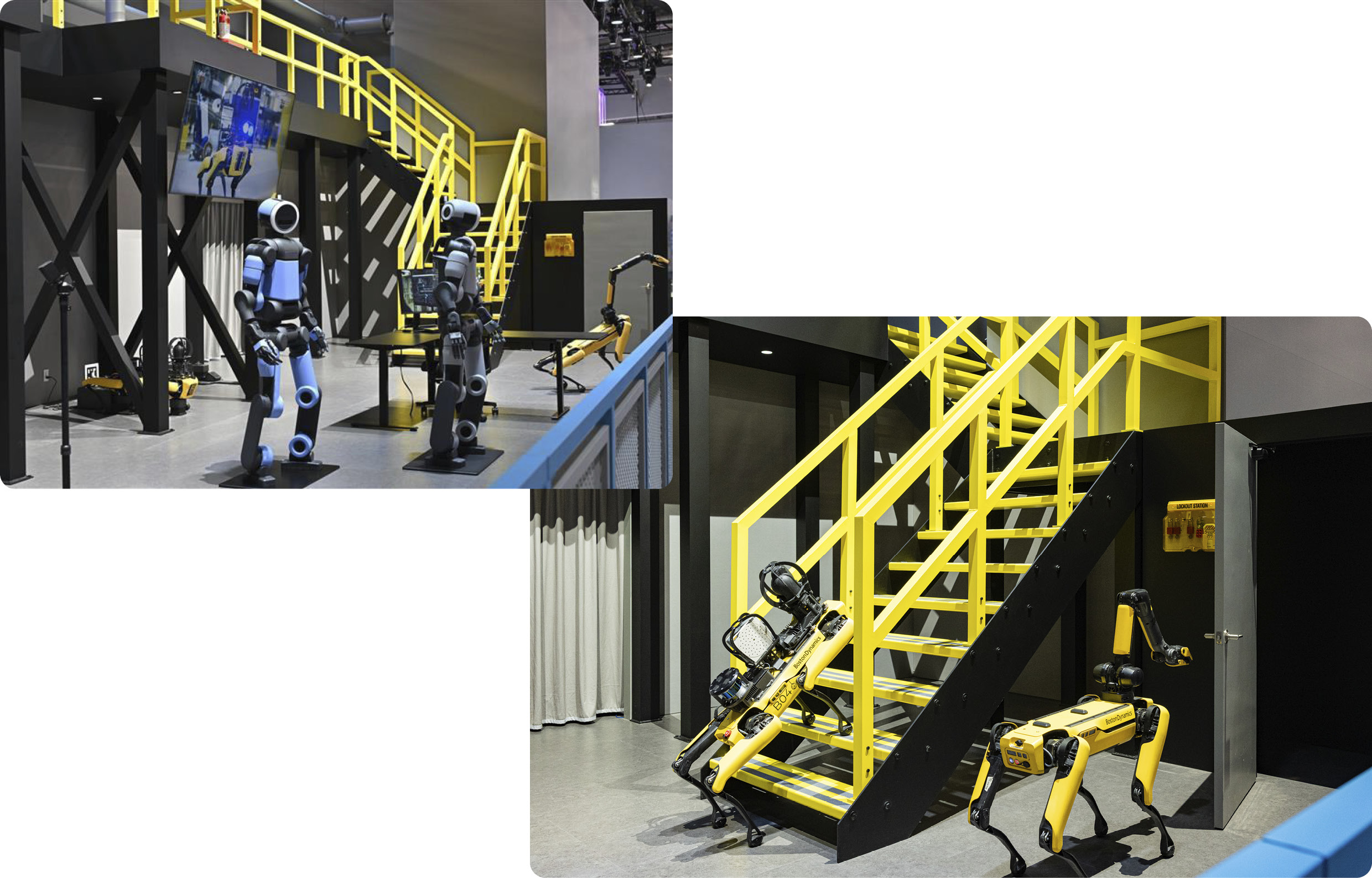

At Tech Lab, center of the booth, visitors can explore Boston Dynamics’ ongoing journey of experiments and challenges to create robotics that contribute to everyday life. Designed as a research lab concept, the exhibition features the humanoid robot Atlas and the quadruped robot Spot, both performing processes of self-learning and testing.

As one of the main highlights, the Atlas Prototype of Boston Dynamics, an early-stage model designed to test the core capabilities required for future products is showcased. Atlas demonstrates exceptional mechanical flexibility, featuring a wide range of motion in its rotary joints, the strength to lift more than 32 kilograms (70 pounds), torso rotation, sophisticated balance control, and dynamic movement execution. The platform is equipped with sensors in its head and hands to leverage AI-based learning by perceiving its surroundings naturally and quickly adapt to new tasks. It becomes the foundation of next-generation robotics technology aimed at performing tasks that are difficult or hazardous for humans. The Atlas demonstrations include the proof-of-concept previously conducted at HMGMA (Hyundai Motor Group Metaplant America), which featured part sequencing—picking components from one shelf and sorting them onto another—to showcase its advanced dexterity and control.

Additionally, Hyundai Motor Group displayed Atlas Product version, the first mass-production model unveiled at CES Media Day. Optimized for autonomous learning in manufacturing environments, Atlas product version combines high performance with efficiency. Built on extensive experience, Boston Dynamics standardized high-performance actuators by reducing more than fifty motors to three core types. The design also features three-fingered gripper which enables dexterous manipulation and field-replaceable limbs and autonomous battery swapping, significantly extending operational uptime.

Atlas product version features 56 DoF(degrees of Freedom), allowing full joint rotation, and offers 360-degree vision with an integrated camera. It also boasts a maximum payload capacity of 50 kg (approximately 110 lbs), water and dustproof, and an autonomous battery-swapping function for more efficient operation. These advancements enable Atlas to learn and adapt to diverse environments and therefore is expected to significantly improve manufacturing efficiency. Hyundai Motor Group plans to mass-produce Atlas and deploy it widely across its global manufacturing sites, including HMGMA and gradually expand its deployment through process-by-process validation.

Another key feature is Spot, Boston Dynamics’s versatile quadruped robot and sensing platform designed for both autonomous and manual operations. Spot’s demonstrations include automated inspections and the precise handling of objects, showcasing its ability to improve safety and efficiency in dynamic work environments. Boston Dynamics’ dedicated Orbit AI software can remotely control multiple Spots, analyze data, and deliver actionable insights to customers.

In addition, Hyundai Motor Group showcased robots archived from Boston Dynamics that provide a comprehensive view of the evolution from the early research models of Atlas and Spot to their current versions. The exhibit includes the first bipedal robot, 3D Biped (1990), Atlas’s precursor Petman-Proto (2007), and the Hydraulic Atlas (2016). For quadruped robots, the timeline features BigDog (2007–2008), Spot V1 “Rusty” (2014), Spot V1 with Arm (2016), and Spot V2 (2016), all displayed in chronological order.

At the Tech Stage, visitors get an exciting and informative look at key technical developments of what Hyundai Motor Group is already making into a reality. Tech Stage features live demonstrations and presentations the latest AI Robotics innovations from Boston Dynamics, including Atlas and Spot, along with MobED. Each presentation puts theme-specific robotics innovation in the spotlight, including its purpose, capabilities, and development backstory. Visitors can enjoy Spot’s synchronized performances, as well as demonstrations of MobED’s autonomous driving and live performance.

Hyundai Motor Group is deeply committed to providing technology that improves the quality of life, across mobility, work, and leisure. In the ‘Enhanced Living Zone’ and ‘Effortless Driving Zone’, guests get an inside look at everything Hyundai Motor Group is designing and creating to improve mobility for more opportunities and possibilities.

In the ‘Enhanced Living Zone’, mass-produced model of MobED (Mobile Eccentric Droid) by Hyundai Motor Group’s Robotics LAB which won the CES 2026 Best of Innovation Award in Robotics showcases how AI Robotics naturally integrates into everyday spaces, making customers’ lives more convenient and enriching. (News: Hyundai Motor Honored with CES 2026 Best of Innovation Award in Robotics for MobED Droid)

As an advanced mobility platform, MobED is equipped with four independently controlled wheels and a unique eccentric mechanism and utilizes DnL(Drive-and-Lift) module to navigate various terrains and remains stable even on uneven surfaces. Driving technology of MobED ensures safe and efficient obstacle avoidance, even in crowded environments.

Hyundai Motor Group plans to provide two types of MobED- Basic model, a standard version, and Pro model that provides autonomous navigation. Both models offer a universal mounting rail and open API, enabling developers and businesses to customize top modules for diverse scenarios—from logistics and delivery to leisure and personal mobility. Concept models of MobED were also showcased in CES 2026 - MobED Pick & Place, MobED Golf, and MobED Delivery are based on the Pro platform model, while the MobED Urban Hopper feature is built on the Basic model.

- MobED Pick & Place: MobED with vision technology for precise object handling and posture-controlled cargo stability, showcasing the platform’s adaptability.

- MobED Golf: An autonomous mobility solution designed for comfort and convenience specialized for golf, featuring swing analysis, weather updates, club drying, and even a mini fridge—delivering a premium leisure experience.

- MobED Urban Hopper: A compact, seated scooter for urban commuting, equipped with zero-turn capability, tilt-assisted boarding, and Hyundai’s “Art of Steel” design philosophy. Its modular “Add Gear” system allows users to personalize their ride for maximum comfort and style.

Guests can experience real-world demonstrations of MobED such as carrying people, delivering goods and navigating various activities. MobED is a robot platform optimized for urban environments and scalable for diverse application needs.

Details for MobED: MobED

In the ‘Effortless Driving Zone’, Hyundai Motor Group presents an experience that brings AI Robotics technology with mobility. Tasks that once required human control are now automated and autonomous, with seamless connectivity extending to charging and parking. As part of this commitment, Hyundai Motor Group presents its latest AI-driven innovations, highlighting the convenience and seamlessness of driving, parking, and charging. The three robotic solutions are Motional’s IONIQ 5 robotaxi, Automatic Charging Robot (ACR) and Parking Robot.

Hyundai Motor Group presents how AI-driven technology enhances the mobility journey with greater flexibility and seamless operations from start to finish. For instance, Motional’s IONIQ 5 robotaxi navigates across the exhibition booth autonomously and conveys how the system seamlessly detects surroundings, predicts the movements of nearby objects, and behaves a safe and reliable driving path. Robotaxi then crawls to a parking space connecting with ACR(Automatic Charging Robot).

When ACR detects vehicle parked, it moves toward the vehicle and automatically begin charging. ACR was designed as water-resistant and dust-proof to minimize everyday inconveniences as it can work in outdoor parking lots and clearly reflects Hyundai Motor Group’s commitment to delivering an inclusive and thoughtful mobility experience—especially for users with limited mobility.

Once the vehicle is fully charged, a pair of parking robots slides under the wheels and lift them to move the car. Visitors can witness how the robot can smoothly and precisely maneuver the vehicle, even within compact space.

Parking Robot carefully moves and positions vehicles even in tight spaces, which relieves stressful parking experience and creates efficient environment. The technology not only makes post-driving experiences convenient but also improves parking efficiency by up to 27% in office buildings.

Details for each product: Robotaxi / ACR / Parking Robot

As a global mobility solution provider, Hyundai Motor Group aims to create safe and collaborative environments by deploying the latest technological developments. Especially in fast-changing industries, AI robotics brings together functionality and innovation to help build more productive and creative industrial environments.

In ‘Collaborative Assembly zone’, Hyundai Motor Group exhibits how AI Robotics helps to make factories more efficient while enhancing the quality of life for workers. Guest are welcome to experience wearable robot, X-ble Shoulder as well as to watch how Spot AI Keeper monitor production quality and how Battery Quick Changer powers Spots.

Spot AI Keeper and Battery Quick Changer (BQC) illustrate how AI-robotics will increasingly contribute to quality detection and management and improve operational efficiency. While Spot AI Keeper, utilizing in HMGICS and HMGMA, maintains optimized manufacturing quality by identifying flaws or failures, BQC automatically replaces Spot’s battery and minimizes downtime effectively.

One of the main highlights of the Collaborative Assembly zone is ‘X-ble Shoulder’, an industrial wearable robot that assists upper body and increases work efficiency by reducing injury risk and fatigue. Even though X-ble Shoulder only weighs 1.9 kg(4.19 lbs), it offers a wide arm range of 0–180° and reduces shoulder joint loads by up to 60% during overhead tasks. Visitors can wear X-ble Shoulders and experience the benefits by standing under an E-GMP platform exhibition and performing the tasks of assembling the parts, similar to actual working environment. Since X-ble Shoulder’s first delivery to Korean Air, Hyundai Motor Group has expanded clients like KORAIL and Group affiliates, including Hyundai Motor, Kia, Hyundai Transys, and Hyundai Rotem—proving its value across diverse industrial settings.

Details for each product: Spot AI Keeper / X-ble Shoulder

Hyundai Motor Group demonstrates how real-world logistics automations will benefit from AI-driven innovation in ‘Streamlined Logistics zone’. With live demonstrations of Stretch, Collaborative Robot (Cobot), and Autonomous Mobile Robot (AMR), Hyundai Motor Group shares the vision of a human-centered robotics ecosystem.

Stretch is an autonomous mobile robot of Boston Dynamics designed for warehouse automation. It demonstrates how AI-driven technology can handle physically demanding tasks, such as unloading floor-loaded trucks and containers, thereby relieving humans of such arduous work. As it was engineered for rapid deployment on-site, it enables efficient and continuous logistics operations and is currently in use at clients’ warehouses such as DHL, Gap.

While Stretch unloads boxes from containers, Cobots, on the opposite side of the conveyor belt, perform palletizing tasks with robot arms. The collaboration of robots helps take over repetitive tasks traditionally assigned to human.

Cobot is an industrial robot engineered to work safely alongside humans in workspaces. Equipped with a 6-axis articulated arm, Cobot performs palletizing tasks to stack boxes or parts on industrial pallets according to a defined pattern. Not only palletizing logistics onto pallets, Cobot can also conducts precise tasks including assembly, packaging, and inspection.

During the demos, Spot patrols the site ensuring safety supervision as monitoring floor conditions and workspace environments.

AMR demonstrates logistics transportation based on SLAM (Simultaneous Localization And Mapping) technology, which utilizes LiDAR sensors and 3D depth cameras. It allows AMR to autonomously recognize the surroundings and obstacles to select the safest and most efficient routes for navigation. These days, AMR are working in HMGMA, ensuring smooth logistics flow along the assembly line.

During CES 2026, Hyundai Motor Group demonstrates AI Robotics innovations that will be even more deeply integrated into our daily lives. From industrial sites and to everyday life, robots powered by safe and validated technologies assist people and drive human progress. Together with leading AI partners, Hyundai Motor Group will continue to shape a human-centered future where AI robotics and humanity collaborate and coexist in harmony.