Hyundai Motor Group plans to accelerate AI Robotics business by leveraging its global mass-production capabilities and a robust value chain across Group affiliates. Through collaboration between Boston Dynamics—home to the world’s most advanced robotics technology—and global AI leaders, Hyundai Motor Group will integrate cutting-edge AI Robotics across all manufacturing sites worldwide, and subsequently expand into logistics, energy, construction, and facility management sectors.

Through CES 2026, Hyundai Motor Group reveals how human-centered AI Robotics can go beyond the laboratory to become an integral part of human life—and how to make this vision a reality.

Many companies develop robots, but bringing them into real-life applications involves countless trials and errors. The key competitiveness of Hyundai Motor Group’s AI Robotics lies in its ability to apply and validate these technologies on a scale, backed by the one of the world’s largest manufacturing capabilities.

Hyundai Motor Group’s manufacturing facilities helps to develop reliable robots with a number of tests and training. Utilizing capabilities within the Group, Hyundai Motor Group can supply robot parts, mass-produce robots, and provide one-stop Robotics-as-a-Service (RaaS). Working with affiliates like Boston Dynamics, the Group can expand its mass-production expertise from automotive to robotics, increasing overall value for customers.

Each affiliates play a crucial role in development and testing robots by bringing their own expertise:

- Hyundai Motor Company and Kia provide manufacturing infrastructure, processing control and large-scale production data.

- Hyundai Mobis works closely with Boston Dynamics to develop high-performance actuators, standardizing key components and optimizing designs for manufacturability.

- Hyundai Glovis optimizes logistics and supply chain management.

Hyundai Motor Group integrates all areas of expertise and offer ongoing customer support after deployment, including regular software updates, hardware maintenance, repairs, and remote monitoring and control. It to oversee the process from start to finish, helping to bring AI Robotics solutions to market.

Hyundai Motor Group’s robotics solutions are already operational across several industries, with partners including DHL, Nestlé, and Maersk. As Hyundai Motor Group strives toward the ambitious goal of achieving 9.8 million annual vehicle sales by 2030, Atlas will move beyond its pilot stage and enter full-scale production, seamlessly integrating into global manufacturing value chain. The it will expand its applications to logistics, energy, construction, and facility management.

AI Robotics services tested at the development site would ensure the companies to receive comprehensive, customized solutions backed by reliable data and support, regardless of their specific needs.

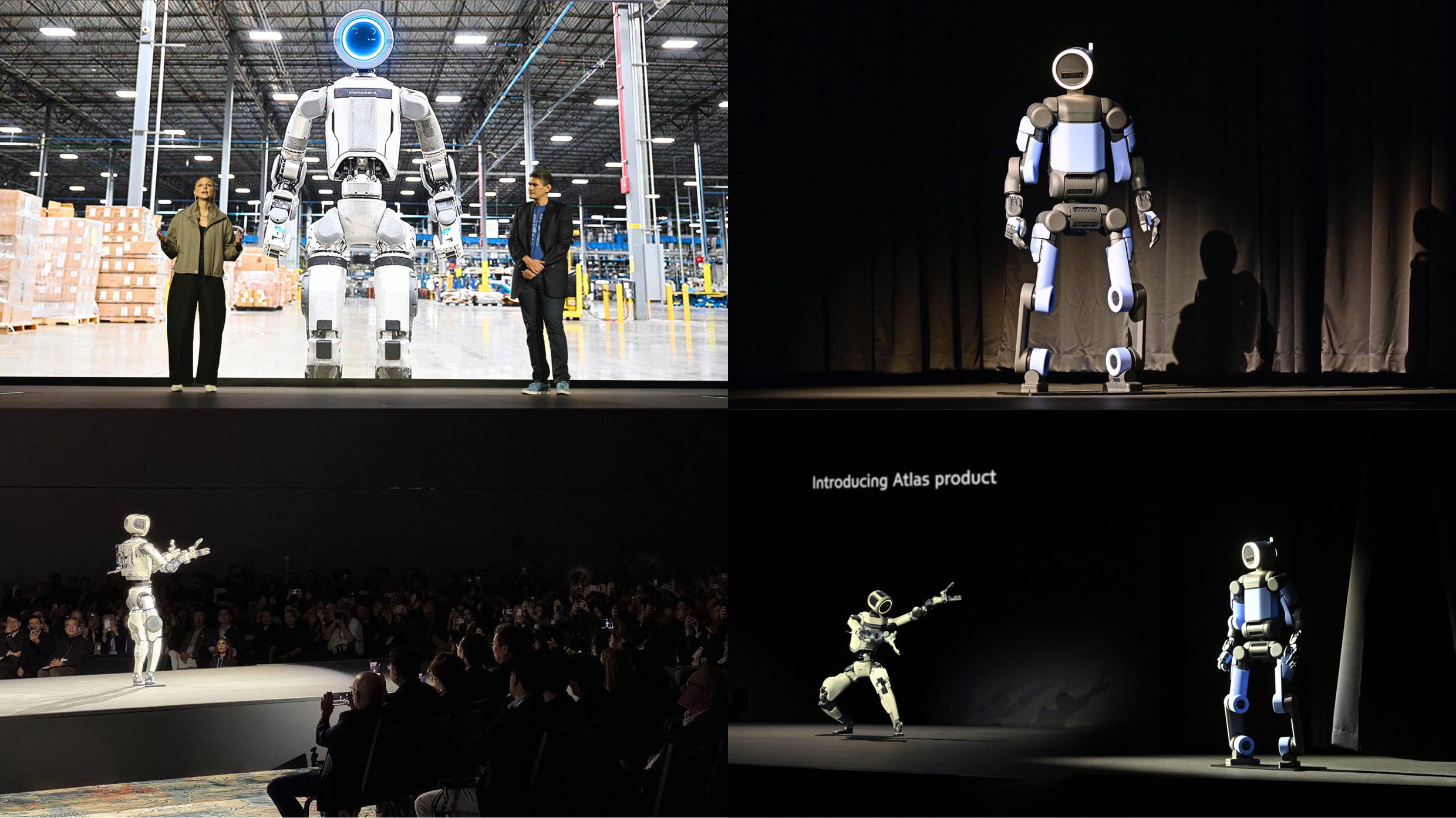

Boston Dynamics has long demonstrated the tangible success and real-world value of advanced robotics in the industry, notably with Spot and Stretch. Building on this foundation, Atlas product model is taking the next major leap.

When imagining a robot, the Atlas product model checks every box. Created by Boston Dynamics as a product-ready robot designed for industrial work, it is conceived to operate alongside humans, especially in dangerous or challenging environments. Updated with technology designed to assist people, Boston Dynamics’ AI Robotics support people by easing their workload for a number of tasks.

Carrying heavy objects that were once the duties of humans is just one example of its promise and potential. Aside from relieving humans of physically demanding or repetitive tasks, Atlas can learn and adapt in its role as a workplace partner, becoming a trusted and dependable robotic colleague. This is what Hyundai Motor Group approaches to human-centered AI Robotics: robots working for and with people as support.

This vision is becoming a reality through the development of the Atlas product, with plans to integrate the models into the manufacturing system of the Group.

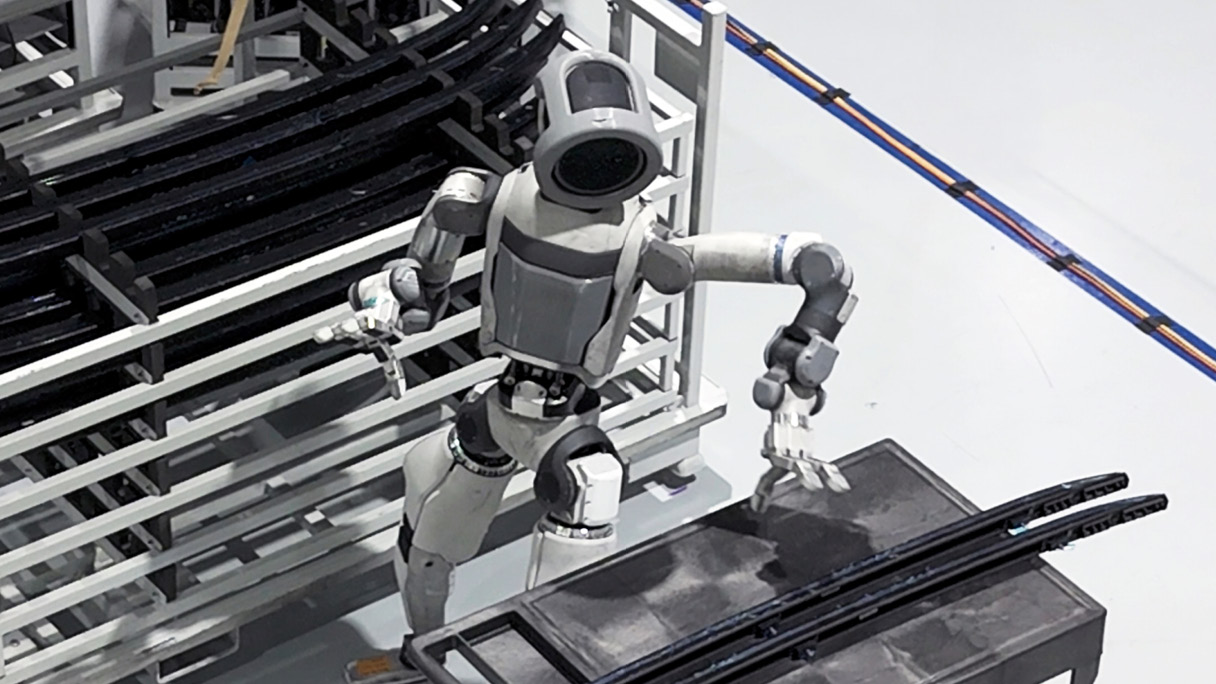

Creating and offering optimal human-centered AI Robotics solutions requires the right facilities for constant training, testing, and improvement. Hyundai Motor Group’s Software-Defined Factory (SDF) and Robot Metaplant Application Center (RMAC) are responsible for training and validating its AI Robotics solutions to ensure they meet the highest performance and quality standards.

While most factories today have evolved to remain hardware-focused, Hyundai Motor Group is leading the transition towards SDF. The advantages of SDF are operation based on a software and data-driven manufacturing model and enabling greater agility and flexibility, while creating safer work environments by integrating AI software at the heart of manufacturing. Compared to hardware, software is simpler to update, offers more features, and promotes knowledge sharing across the global network. Through the SDF model, Hyundai Motor Group aims to better serve customers, respond quickly to market changes, improve product quality, and reduce costs through greater efficiency. Additionally, SDF fosters better collaboration between humans and robots, supporting reliable deployment and ongoing improvement across all plants.

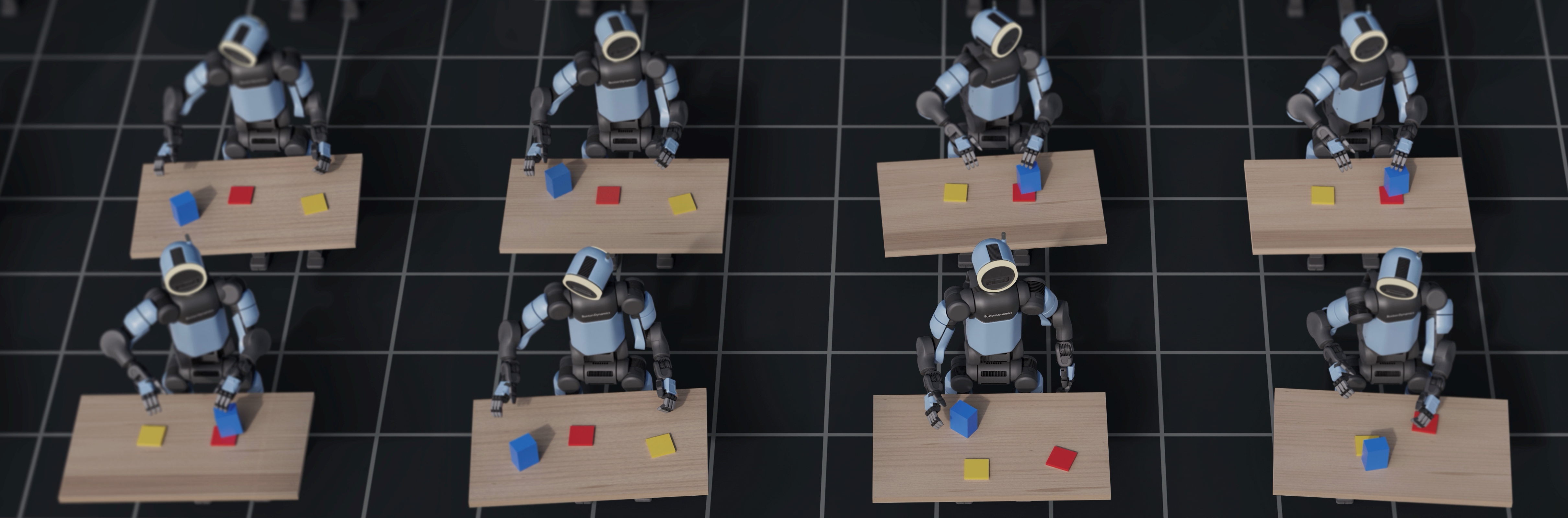

Before deployment in SDF, robots first undergo learning and training at the Robot Metaplant Application Center (RMAC), a facility that serves as a hub for robot training and validation. Providing robots with a technical training environment allows them to learn and adapt through every lift, turn, and recovery in authentic factory conditions. This process enables robots to become faster, smarter, and safer. Data collected from real-world operations in SDF flows back to RMAC where they are used for retraining, creating a continuous cycle of improvement.

The RMAC is set to open in 2026. Atlas robots trained at RMAC will start sequencing tasks at HMGMA(Hyundai Motor Group Metaplant America) by 2028, with more complex operations like assembly beginning by 2030. Their deployment and integration into the manufacturing landscape not only improve product quality but also emphasize the collaborative relationship among SDF, RMAC, and robots like Atlas.

Hyundai Motor Group envisions a future of manufacturing driven by human-centered AI Robotics. It requires robots to be more than just physical intelligence. They must be equipped with advanced foundational skills to reason and respond to real-world environments to optimally support people across various work situations.

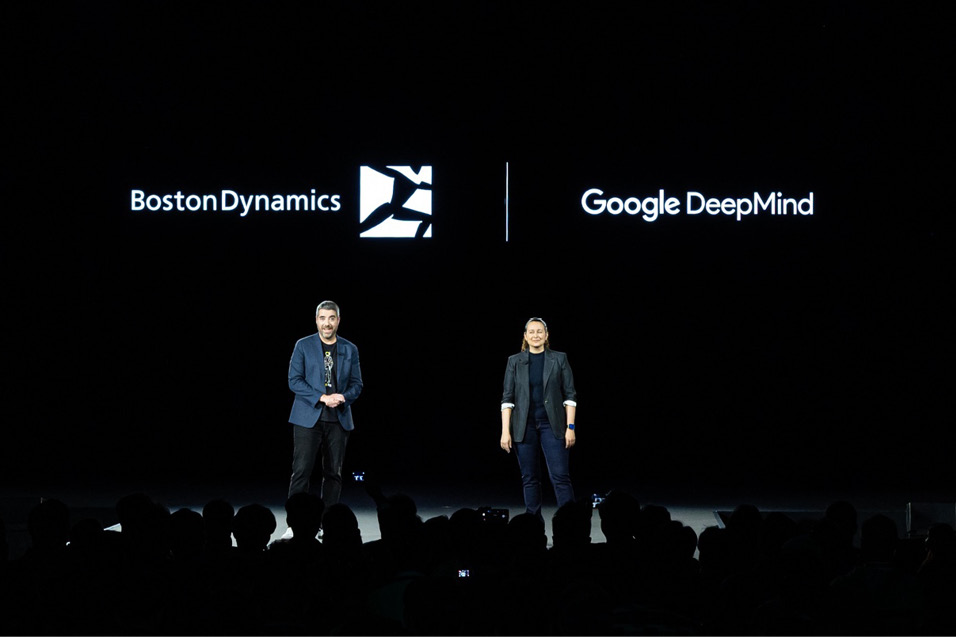

Thus Boston Dynamics is partnering with Google DeepMind. This collaboration is founded on a powerful idea that a general purpose brain is most powerful when combined with a highly capable generalist body. By combining Boston Dynamics’ humanoid robots with Google DeepMind’s leading Gemini Robotics AI foundation models, Hyundai Motor Group aims to create new opportunities for AI Robotics beyond manufacturing to a much larger set of complex, real-work tasks. It will pave the way for the successful large-scale deployment of robots as trusted and helpful partners to people.

At Hyundai Motor Group, AI Robotics is not about concept robots confined to laboratories — it’s about robots that step into our lives and provide real, practical help. Transformative change doesn’t happen with only words of “we can do it”; it happens when we take real action.

That’s why Hyundai Motor Group doesn’t keep robots in the lab. But instead, deploy them first in the most demanding and precise environments—global manufacturing sites. Here, robots collaborate with people, and only AI Robotics that have been tested and proven in harsh conditions can become trusted partners in everyday lives.