A+A (Arbeitsschutz und Arbeitsmedizin) is the world’s largest industrial safety and health exhibition, held biennially in Düsseldorf, Germany—essentially a global meet-up for the latest tech and trends across occupational safety, health, medical services, protective equipment, human protection, and safety/security systems. This year’s event ran November 4–7 at Messe Düsseldorf under the theme “People Matter (People-Centered),” sparking lively discussion around the newest solutions and trends aimed at creating safer, more human-focused workplaces.

In 2025, 2,340 companies from 70 countries filled 13 exhibition halls, rolling out products and technologies geared toward safer, healthier, and more sustainable work environments—and the show drew attention for both its high international participation and the caliber of attendees.

Over four days, A+A 2025 welcomed roughly 67,000 visitors from 150 countries. Of those, 81% were decision-makers, 52% were international visitors, and 16% traveled from outside Europe—coming to see where industrial safety is headed and to trade insights on cutting-edge safety and health tech.

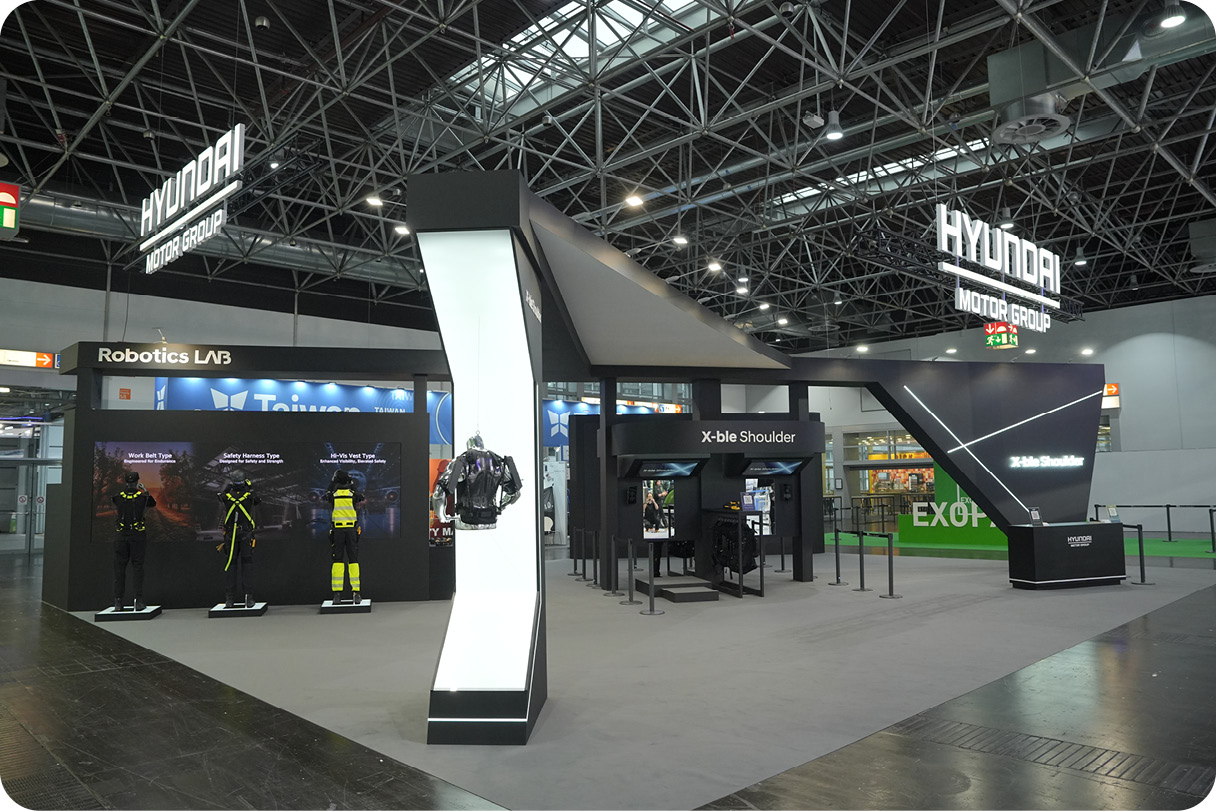

Robotics LAB joined A+A 2025 to formally introduce X-ble Shoulder to overseas markets. With a focus on strengthening X-ble Shoulder brand awareness globally, the team built a differentiated, hands-on booth that leaned into the product’s brand identity—along with a customer experience designed to make the tech feel immediate, not theoretical.

Located in Hall 5 (the Wearable Robot Zone), Robotics LAB efficiently operated a 208 m² space (about 2,240 sq ft) so visitors could naturally move from discovering the product, to trying it on, to learning how it works, and even into purchase consultation. The booth was organized into four main areas: a Hero Showcase for the main product display, an X-ble Shoulder Collection area to preview expanded lineup configurations, a Fitting zone for direct wear-and-try experiences, and a dedicated consultation space.

Robotics LAB also expanded the on-site experience by building a mobile platform called X-ble Hub, designed to handle everything from space guidance and experience support to consultation reservations and satisfaction surveys—all in one place. Visitors who stopped by the booth could scan a QR code provided by booth staff to access X-ble Hub, easily check the booth’s detailed layout, and get more out of the experience.

And by entering their personal X-PASS code in the system, visitors could download photos taken during their trial sessions—useful as a keepsake, and also as a practical reference for reviewing fit and operation afterward.

Developed by Hyundai Motor Group Robotics LAB, X-ble Shoulder is an industrial wearable robot designed to assist shoulder strength—reducing shoulder joint loads across a range of industrial environments while improving workplace safety and efficiency.

Weighing less than 1.9 kg (about 4.2 lb) including the vest, it’s built for extended wear without becoming a burden, and it uses an intuitive magnetic fastening structure that lets users put it on or take it off unassisted in under 20 seconds. A flexible ball joint design that mimics human joints, plus a non-powered torque generator, enables natural movement and long runtime without charging.

The vest uses highly breathable mesh and separates easily from the robot, making washing and hygiene management straightforward. In key components of the torque generator, Robotics LAB applied carbon fiber reinforced plastic (CFRP)—a material tested and proven in vehicles—to secure both lightweight performance and durability.

Because it’s compatible with a wide range of workwear, X-ble Shoulder can be flexibly used across industries including manufacturing, construction, shipbuilding, aviation, and agriculture. After use, the vest can be detached from the toque generator and folded for compact storage, making day-to-day management easy without demanding extra space. In short, X-ble Shoulder is positioned as an innovative technology that delivers comfort and safety at the same time—helping enable a more people-centered industrial site.

After Robotics LAB announced X-ble Shoulder’s commercialization plan at Wearable Robot Tech Day in November 2024, the product has steadily expanded toward real-world deployment. Starting with its first customer, Korean Air, X-ble Shoulder is now being used broadly across industries—including Hyundai Motor Group affiliates such as Hyundai Motor Company, Kia, Hyundai Transys, and Hyundai Rotem, as well as public institutions like the Korea Railroad Corporation.

At the Hero Showcase, visitors could see and experience the product firsthand, taking a closer look at X-ble Shoulder’s functions in detail. Right next door, an expanded lineup—X-ble Shoulder Collection—was displayed in three types.

The Work Belt Type delivers precision fitting across body types, supports attaching modular gear and tools, and is suited for high-temperature work environments. The Safety Harness Type features an industrial-safety-standards-based design compatible with industrial harnesses, making it adaptable across sites including elevated-work scenarios where belt fastening is required. Finally, the Hi-Vis Vest Type is designed to secure visibility for nighttime and low-light operations, helping prevent safety incidents.

Behind the collection, a large screen played a video introducing each type’s strengths and target industries—helping visitors quickly grasp X-ble Shoulder’s advantages and versatility across different industrial and job settings.

In the fitting zone, visitors could wear X-ble Shoulder themselves and directly experience how it supports muscle strength during overhead work. By using tools like paint rollers and sanding machines to rub a ceiling-mounted touchscreen, visitors triggered an effect where the X-ble Shoulder logo appeared—an interactive program that was praised for balancing fun with a clear demonstration of the product’s benefits. The booth also provided additional equipment such as industrial tools and dumbbells, making it easy for visitors to jump into a variety of quick, hands-on trials.

Visitors were also able to receive detailed consultations and purchase guidance on-site. Consultation reservations and schedule management were handled simply through X-ble Hub via QR access, and Robotics LAB used the exhibition as a strong opportunity to expand industry networking and build customer relationships.

A+A 2025 served as a meaningful stage for Robotics LAB to introduce X-ble Shoulder—already recognized in Korea for real-world effectiveness—to a global audience, expanding touchpoints with new customers and creating fresh connections. Built on Robotics LAB’s vision of “Progress for Humanity,” the booth showcased innovation aimed at protecting worker safety and health, and many visitors noted the value of being able to try the product on and experience its effects firsthand.

In particular, the booth’s flow—where hands-on experience, display, and consultation were tightly connected—stood out from the crowd, capturing attention while communicating the value of people-centered technology in an intuitive way. Dong-jin Hyun, vice president and head of Hyundai Motor Group Robotics LAB, said, “Through this exhibition, Hyundai Motor Group Robotics LAB was able to share X-ble Shoulder’s technology for global industrial safety with many leading companies around the world,” adding, “Based on X-ble Shoulder’s competitiveness in performance, quality, and price, we will build a stable supply chain and work even harder so Robotics LAB can contribute to improving the safety and health of customers worldwide.”

Making its first global appearance at A+A 2025, X-ble Shoulder aims to be more than a robot that simply assists strength—it’s positioned as a practical path to reducing shoulder joint loads while balancing safety and efficiency in a more sustainable industrial workplace. And through people-centered robotics innovation, Hyundai Motor Group Robotics LAB says it will continue drawing a future where humans and technology grow forward together.