Wearable robot technology will allow us to overcome our physical limitations, while service robots will interact with us and bring innovative changes to our future lifestyles. Meanwhile, mobility technologies will broaden the definition of mobility that once has been limited to automobiles. Hyundai Motor Group hopes that its robot technology, utilized in several industries and our daily lives, will create a better future. Here are some of our key technologies.

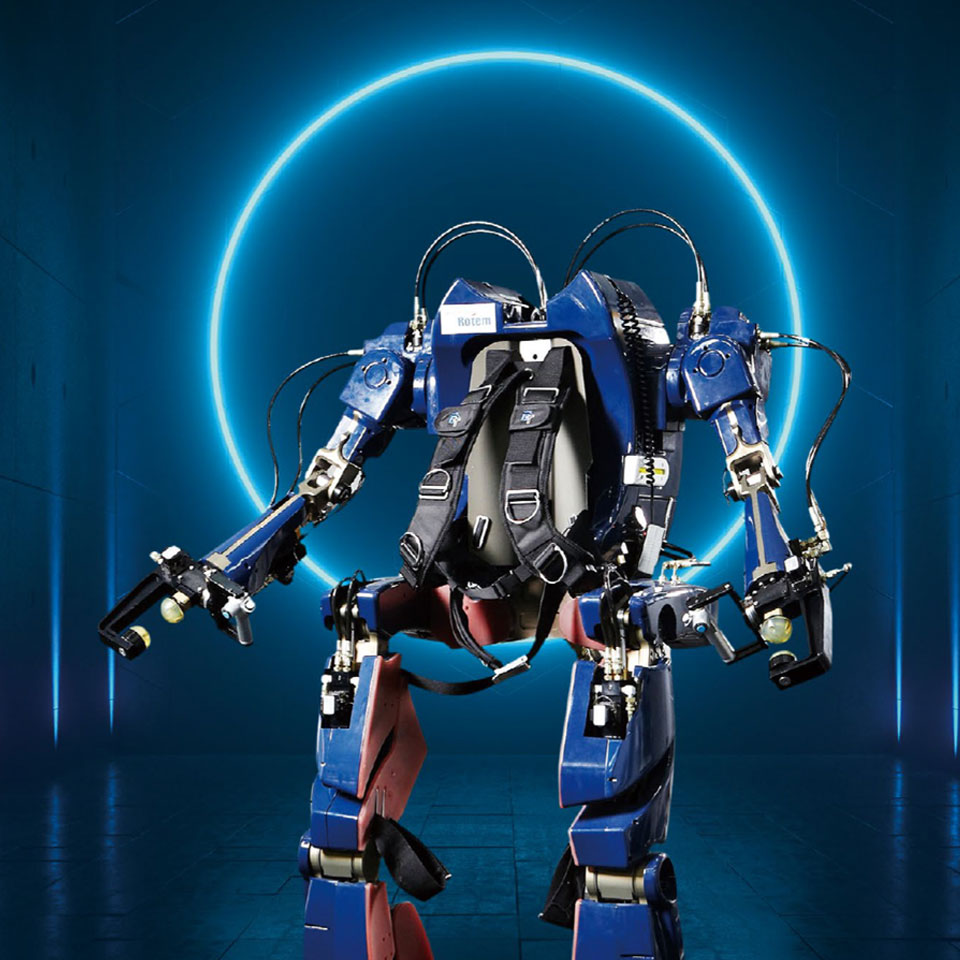

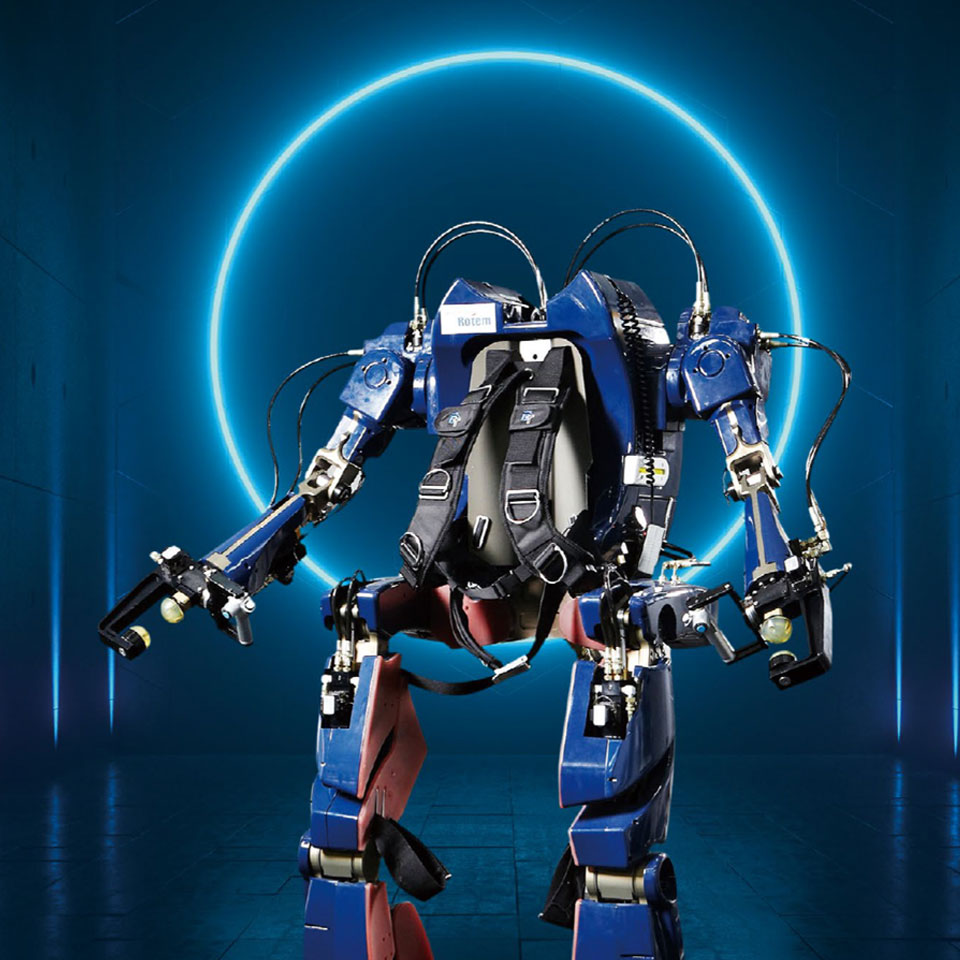

Wearable robots complement physical limitations by becoming an extension of the human body. There are the medical wearable robot MEX, which helps the weak to walk freely as others do, and industrial wearable robots CEX and VEX, which reduce the risk of muscle or joint injury in manufacturing processes where simple tasks are repeatedly done. CEX and VEX are scheduled to become utilized in North American factories and are expected to play a major role in creating smart factories where humans and robots coexist without alienating one another.

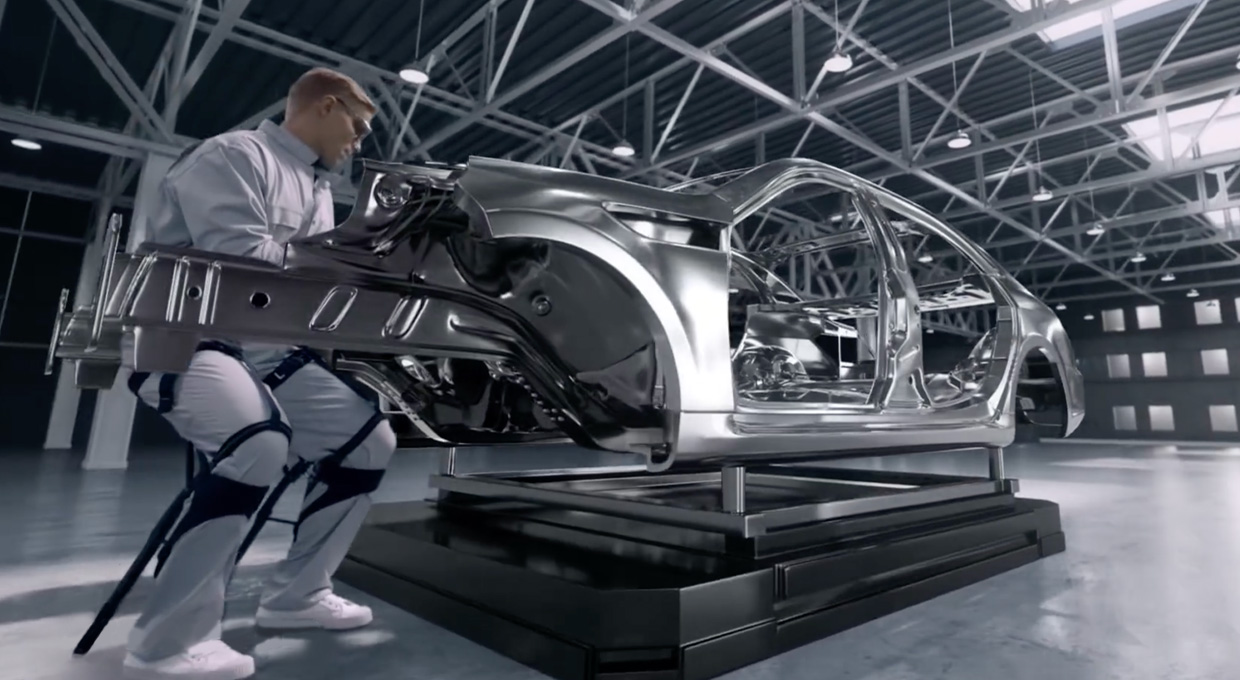

CEX: Chairless EXoskeleton

It is the first wearable robot developed for industrial applications and is made in the form of a chair to protect the knee joints of workers who remain seated for a long time. Although it only weighs 1.6kg, it is strong enough to support up to 150kg and is easy to wear. What is notable about the CEX is that the length and angle of the robot can be adjusted depending on the user’s height and sitting posture, and the portability of the ‘engineering plastic’ material is remarkable.

Hyundai Motor Group conducted a test pilot of CEX in Hyundai and Kia North American factories back in September 2018. As a result, it has been proven that reducing the user’s waist and lower body muscle activity decreases the risk of injury and significantly improves work efficiency.

VEX: Vest EXoskeleton

While the CEX is for supporting the lower body, the newly developed VEX is for production-line workers whose job is primarily focused on overhead works; it enhances productivity and reduces fatigue of industrial workers by imitating the movement of human joints and boosting load support as well as mobility. The wearable vest features a polycentric axis – combining multiple pivot points with quadruple-link muscular assistance – to function.

If you wear a VEX and raise your arm while holding a tool, it will provide an additional 6kg of force to prevent musculoskeletal disorder and improve work efficiency. The latest model features better neck support, enhancing safety with a smoother surface.

MEX: Medical EXoskeleton

Hyundai Motor Group brand campaign film unveiled back in January drew the public’s attention as para-athlete/archer Park Jun-beom, with the help of Hyundai’s Medical Exoskeleton H-MEX, miraculously stood up from his wheelchair.

The H-MEX helps patients with lower spinal cord injuries regain their ability to walk. By utilizing a wireless clutch with an on-board motion control system, the equipment fully supports the paraplegics. Currently, we are preparing for FDA clearance in the U.S., including Korea MFDS, since it will be for medical usage, not industrial.

Robots were once used to simply take on tasks too difficult or dangerous for humans; however, now, using AI technology, interactive robots are being produced. Hyundai Motor Group is developing advanced service robots that can move similarly to a vibration-free vehicle, provide contactless services such as information, guidance, or delivery, while even communicating with other people.

H2D2: Hyundai Hotel Delivery Droid

H2D2 is a robot specialized for room service at a hotel, recognizing and avoiding all emergencies or obstacles during the task. When a hotel customer asks for room service, the hotel staff will enter the room number and authentication code on the touch display attached to the robot, load the item to be delivered, and then the robot will take the parcel to the requested destination. H2D2 is an IoT technology that allows users to exchange information with various facilities in the hotel, so it is also possible to move between floors of the hotel using the elevator. After successfully completing the H2D2 pilot operation at Rolling Hills in 2019, Hyundai Motor Group is further planning to improve the robot’s performance and diversify its service criteria.

DAL-e: Drive you, Assist you, Link with you – experience

These are the service robots based on certain sales hubs, that can guide and communicate with customers directly. Back in June 2019, Hyundai Motor Group conducted a pilot operation at Hyundai Motorstudio Seoul. While H2D2 simply focused on moving between two points, DAL-e, with a more complex software, can avoid any sudden obstacles on the way and optimize route calculation.

DAL-e’s biggest feature is that it can read customers’ emotions just by searching from its vast database of various facial shapes and expressions. Not only can the robot understand verbal elements, but it can also understand non-verbal elements such as gestures, posture, facial expressions, eye contact, intonations, and voice. It is also designed to recognize and respond to the voice of the commander among many others in the store and it can distinguish between the faces of the visitors and staff. These robots can even have small conversations with others.

ACR: Automatic Charging Robot

It is an arm-shaped automatic charging robot, designed to be installed on the side wall of an electric vehicle charging unit. The way it works: When an electric vehicle is pulled up in front of the charger, the robot arm automatically inserts a connector into the electric vehicle and charges it rapidly. Image recognition and control software that can run this operation has been developed, and the pilot operation began in 2021 at the Hyundai Motor Group headquarters.

In addition, Hyundai Motor Group is also studying self-driving cars, so that when the self-driving cars are done charging, they would autonomously drive back to their individual parking space. In the era of eco-friendly and fully autonomous cars, Hyundai Motor Group’s electric vehicle auto-charging robots are expected to greatly improve charging efficiency.

Besides wearable robots and service robots, Hyundai Motor Group is also conducting research and development on future mobilities, such as built-in scooters and delivery robots. Among them, the E-Board, Hyundai Motor Group’s last-mile mobility, is about to be mass-produced and we are devoting our time and effort in developing the next-generation mobility concept.

Last-mile mobility E-Board

After Hyundai Motor Group unveiled the mini-sized last-mile mobility concept ‘Ioniq Scooter,’ at CES 2017, the company showcased its successor in 2019 as a built-in form. It is easy to carry as it can be folded in three stages and is known to be chargeable inside vehicles. After commercialization, E-Board is expected to meet the customer’s diverse needs, such as being able to navigate along narrow urban streets where vehicles are not allowed to enter or for purely recreational purposes.

Self-driving Delivery Robot TarGo

What if a robot can directly deliver your parcels to your home or to your office? The process will no longer require manpower, and you would be able to get your parcel anytime, anywhere you want. Hyundai Motor Group plans to develop self-driving delivery robots, collaborating with the autonomous-driving robot developer. The robot will be able to carry loads as heavy as 60 to 100kg. It will not only be capable of logistics delivery services but also capable of carrying personal beverages to each house. Its pilot operation began in 2021 at the new Hyundai Glovis building, and in the future, Hyundai Motor Group plans to utilize self-driving delivery robots at logistics centers and apartment complexes in the city center.

Smart Parking Systems & Parking Robots

Everyone with a driver’s license would have experienced – looking for empty spaces in buildings or public parking lots or trying to remember where they had parked their own car. Hyundai Motor Group is developing smart parking systems and parking robots to solve these problems. If you park your car in front of the parking lot entrance, the parking robot would drive your car to an empty space and let you know where it is when you’re back. Hyundai Motor Group will start conducting pilot operations of the parking robot in 2022 at Incheon International Airport to verify its performance and operation method, and use the parking robot technology in industrial sites such as logistics centers in the future.

Hyundai Motor Group acquired Boston Dynamics to develop technologies for humanity through a new business in robotics and to provide customers with a better experience. The acquisition of Boston Dynamics is expected to keep Hyundai Motor Group at the forefront of robotics and accelerate its strategic transformation into a smart mobility solution provider.

Boston Dynamics

Boston Dynamics is an American robotics company with world-class core technologies in areas such as self-driving and walking, robotic arms, and recognition and judgment that can aid our entry into logistics robot, guide and support robot, and humanoid robot markets. Their robots include “Spot,” a four-legged walking robot, “Atlas,” a two-legged robot that can walk upright, and “Stretch,” a robot specialized for use in warehouses and logistics facilities.

We plan to apply the capabilities developed by Boston Dynamics to manufacturing, logistics, and construction in the future. We will also create a new robotics-based value chain, which includes manufacturing robot parts and building smart logistics solutions, and support Boston Dynamics’ global sales, service and product line extension.

Factory Safety Service Robot

Hyundai Motor Group has started a pilot operation of the factory safety service robot at AutoLand Gwangmyeong, to detect risks and enhance safety on industrial sites. The robot was completed by combining Boston Dynamics’ Spot, the four-legged robot, with an AI processing service unit equipped with AI-based software from Hyundai Motor Group’s Robotics Lab. This robot moves around autonomously and inspects a designated area at dawn when workers are gone, helping early morning patrols with monitoring safety in a comfortable environment.

The AI processing service unit developed by Robotics Lab is capable of recognizing whether a door is opened or closed, detecting a high temperature risk and unauthorized intrusion by using sensors, such as 3D LiDAR, thermal imaging camera and front camera, and conducting real-time data processing based on deep learning. It autonomously moves within the designated patrol area on the industrial site through AI-based navigation. We plan to optimize the robot’s system based on the data obtained from pilot operations and introduce the robot to a wide range of industrial sites by adding new features.