Can Hyundai Motor Company Build a Midship sports car? Some might doubt, some might wait for it to be released. But, at least, there will be no one who would say it's just a mere fantasy - and it's because there is the RM20e.

Last year, when the world had to lock every door due to COVID-19, Hyundai Motor Company drew attention by introducing the RM20e, a high-performance electric vehicle prototype. In fact, the RM20e is not for mass production, nor is it a mere concept for futuristic design or brand image. This is the RM project, which collects data and verifies advanced technologies through test drives.

Hyundai's RM project is a 'rolling lab' that connects between a racing car and N production model. Its purpose is to test and develop high-performance-related technologies and to showcase the brand's technological potential. In the automotive industry, such a car is often called as a 'Halo Car'. This is because it gives a 'halo effect' to the mass-produced models, and furthermore, spreads a dynamic and positive image for the brand. The RM Project, which started with the RM14 released in 2014, worked as a testbed for various technologies for high-performance sports cars, laying the foundation for ‘Hyundai N Performance’. The RM20e, unveiled last year, is the fifth model. Though it may look similar to the RM19 released in 2019, it has a pure electric drivetrain and has taken a big step towards the era of eco-friendly high-performance cars.

The RM project, which started in 2012, aimed to realize the extreme driving performance that Hyundai had not tried before. RM stands for 'Racing Midship', and it was revealed at the 2014 Busan Motor Show after two years of preparation. The first model, the RM14, looked just like a Veloster, but surprisingly it was a midship model; a 300 HP 2.0L theta turbo engine was sitting where the rear seats used to be, and it was used as a test car to develop and verify new technologies as well as the characteristics of a high-performance car.

Hyundai dubbed the hybrid lightweight body structure - or HLBS - for the RM15, and then the automaker released the RM16 with an electric supercharger with increased responsiveness right after that. Then in 2019, the RM19 was released with the drivetrain of a TCR race car housed in the center of the body. The latest RM20e has the same body as the RM19, but it is the first all-electric vehicle with an electric motor instead of an internal combustion engine.

Where to put the engine or which wheel drive to choose is a very important question to answer that could determine the overall characteristics of a car. Most general passenger cars are FF (Front Engine Front Drive), in which the engine is placed on the front of the body and uses a front wheel drive system. On the other hand, FR (Front Engine Rear Drive) in which the engine is in front and the rear wheels are driven is widely used in luxury cars and high-performance cars. The front wheel is in charge of steering and the rear wheel is only responsible for driving, which is advantageous in terms of performance.

Midship literally means the engine is placed in the center of the body (between the passenger seat and the rear wheel) and is driven by the rear wheels. You can increase the agility when you place the engine - the heaviest part in a car - close to the center of the body; of course, you will have to give up the back seat, then. This is why it is difficult to find a midship layout in a regular passenger vehicle. Nevertheless, sports cars, especially supercars, use midship because it is advantageous for sports driving. The small body plus the midship structure, specially designed for the RM project, will be a perfect choice for Hyundai because it will serve the purpose to test its technologies with the vehicle that could be a bit too sensitive to drive. This is why the project was named Racing Midship, RM.

The RM models are not like the usual mass-produced cars from the beginning. Let's take a look at the R&D process of the most recent works, RM19 and RM20e. These two are the results of collaboration between Hyundai Kia Namyang R&D Center, Hyundai Motor Europe Technical Center (HMETC), and Hyundai Motorsport GmbH (HMSG). Based on the motorsport-related technology gained while developing WRC and WTCR race cars, the HMETC and Namyang R&D Center collaborated to produce high-quality outcome that drew worldwide attention in short time; they indeed developed the model together while working on the other side of the planet, overcoming even the COVID-19 situation.

RM19 and RM20e were conceived together from the planning stage, and the following step-by-step R&D system was introduced to enhance completeness. At the first stage, planning and defining what kind of car to make (concept development and specification definition) for the second and third stages, and the team calculated the time it would take for research and development. Such planning was very important for the efficiency of R&D in each sector.

In the second stage, the team started to produce a prototype based on a race car into a racing car on the road. The Prototype #1 and #2 were first produced based on the race cars Veloster N TCR and Veloster N ETCR. In this process, the passenger seats were re-installed, and the race car parts were modified to be suitable for a regular passenger car. These included the rack-mounted motor-driven power steering (R-MDPS) and partial roll cages. The suspension was also changed to MacPherson struts in the front and double wishbones in the rear. However, the engine and ABS brakes are made up of race car parts for testing the performance to the limit.

In the third stage, prototype #3 is produced with upgraded driver convenience and performance based on the prototype # 1 and # 2. In this process, the RM19 #3 became even closer to a mass-produced car; unlike the past two RM19 #1 and #2, TCR powertrain was replaced with a newly developed 2.3L turbo engine and 8-speed DCT, not to mention NVH and the ECU considering durability. In addition, the aerodynamic performance was refined - installing a front-wheel deflector and a top-mounted rear wing, and improving the undercover (streak), so to speak. In other words, compared to the first two prototypes, which focused on verifying new technologies work in an actual car, the automaker put a lot of effort on the third one to make sure it is suitable for mass production.

RM20e, the 5th of the RM project, is an experimental model that can indicate the direction of ‘Hyundai N Performance’ in the era of EVs, and was inspired by the Veloster N ETCR unveiled at the 2019 Frankfurt Motor Show. As is well known, the Veloster N ETCR is a race car developed for the 'Pure ETCR', the all-electric touring car series that started this year.

The RM20e looks almost the same as the Veloster N ETCR in terms of design and powertrain configuration. This is because it is based on the RM19 originated from Veloster N TCR, which also is the origin of Veloster N ETCR. By inheriting the aerodynamics of RM19 and powertrain of Veloster N ETCR, the team could efficiently develop RM20e to clearly work as both 'the Rolling lab' and racing car on the road as an electric vehicle; they added passenger seats and a brake booster, and also improved steering responsiveness with R-MDPS. In addition, even in the era of electric vehicles, a speaker was added just to make a virtual internal combustion engine sound. A suspension that combines a MacPherson strut in the front and a double-wishbone in the rear with a damper with adjustable damping force is also a unique part of the RM20e. It became powerful as well; unlike ETCR race cars, which have limited power (continuous 410 HP average, peak 680 HP), RM20e does not have to abide by any regulation.

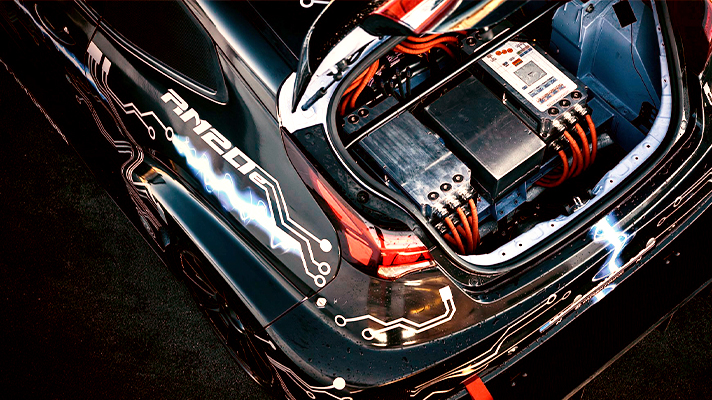

As a result, the RM20e became the most powerful model in the history of the RM project. A four-motor configuration with two 148kW motors mounted on the left and right rear wheels has a system output of 800 horsepower. In addition, a powerful system torque of 960 Nm drives the rear wheels. The brake system is also equipped with Bosch Racing ABS for robust power. Of course, in case of driving on normal roads, the performance was refined so that its rear-wheel drive could successfully handle the maximum output exceeding 800 horsepower. It should be noted that the e-ASD+ for high-performance electric vehicles is very sophisticated, too. E-ASD+ provides exhilarating sounds that attract the driver, such as idling and engine booming, as well as the roaring sound of combustion engines through the speaker.

The RM20e's 60kWh cylindrical lithium-ion battery has a cooling effect through liquid immersion, and thanks to the 800V high-voltage system, it can be charged very quickly and can be charged up to 80% in about 30 minutes. Above all, the most important feature is that it realizes excellent driving stability and agile handling by placing a heavy battery and motor in the center of a car.

The technologies verified through the RM project are applied to various Hyundai models, including the N, to enhance driving performance. The most notable example is the N-Corner Carving Differential (e-LSD), which was first introduced with the i30 N in 2017 and is currently installed in most N brand models. Since the past i30 (GD) prototype, the e-LSD, which has been tested through RM16, is a device that electronically controls the torque of the left and right wheels. It suppresses understeer caused by the turning difference between the left and right wheels when going through tight corners. As a result, it reduces the slip of the driving wheels on extremely slippery roads, helping to accelerate quickly.

The 8-speed wet DCT (Double Clutch Transmission) is also a technology that has been tested through the RM19 for mass-produced models. Among the N lineup, it was first introduced in the Veloster N in 2020, and has since been applied to the i30 N, Kona N, and Avante N (Elantra N). For reference, the 8-speed wet DCT was developed for high-performance engines. Unlike the conventional dry transmission without a high permissible torque limit, a wet clutch with oil cooling can handle higher torque.

ASD (Active Sound Design), which has been continuously tested since RM15, is also a technology housed in Hyundai Motor Group's latest models. Passenger cars usually want to reduce their noise, but in high-performance models, such a sound that excites the driver is an important factor. In the latest N model, Avante N (Elantra N), the technology is applied under the name of N Sound Equalizer (NSE), which even provides TCR race car sound.

In addition, the roll cage used in racing cars was applied to the rear part of the body in the form of a simplified partial roll cage in the RM project. This increases rigidity, minimizes distortion of the vehicle body while driving. The rear brace bar used in the trunk of the Avante N (Elantra N) is derived from this. The rear spoiler, which is a representative aerodynamic part, is also notable. Hyundai Motor Company's aerodynamic performance has been continuously upgraded through the RM project. Although all the rear spoilers installed on the N model might look similar, it is optimized through numerous experiments for each model's performance.

Carbon outer parts, which have been used since RM15, have also been continuously researched and verified for mass production to reduce weight and improve rigidity. As a result, i30 N Project C, which was introduced in 2019, has the hood and bucket seats made with carbon, reducing the weight by about 50 kg. For reference, only 600 units of the i30 N Project C were produced in Europe and sold out for 43,000 euros for the first time in Hyundai Motor's C-segment in Europe.

There are numerous technologies that are derived from the RM project, but the available core technologies are all described above for now. Of course, we can try to predict new technologies to be applied in the future by looking at what's with the RM20e. For example, the RM20e is equipped with e-ASD+, a virtual engine sound technology dedicated to high-performance electric vehicles, and VGS (Virtual Gear Shift) that implements virtual shifting operations. It may be possible someday to meet Hyundai's high-performance electric car with an iconic 'popcorn sound’ of the current internal combustion engine N model.

In addition, a dual-motor system can achieve near-perfect cornering performance that cannot even be compared with an internal combustion engine vehicle through independent traction control. Hyundai is trying to develop its own VCU for RM20e to take advantage of these characteristics. Also, based on the know-hows learned from IONIQ, which is battery output map that depends on the temperature, directions for future technology development can be established such as cooling control optimization, battery pre-conditioning based on drive mode and etc.

As such, the technology used in the RM20e can be used in various high-performance electrified models of Hyundai Motor Group to appear in the future. The use of data accumulated from the RM project and motorsports will continue into the electric vehicle era. Moreover, unlike the existing RM projects, which was used for testing technologies for mass-production vehicle, the RM20e itself opens up the possibility of mass production. This is a story that has the potential to appear in the market as a true Hyundai super sports car beyond a Rolling lab.

Hyundai Motor Company is currently renewing its brand image in the global automobile market thanks to its active role in the motorsports field, boosting this trend through the N brand. There are people enjoying the pleasure of driving Avante N (Elantra N), Veloster N, and Kona N after watching them perform as Hyundai race cars on the weekend.

The RM project, as the 'Rolling lab', has played a very important part in Hyundai's high-performance plan. Various experiments are refining the automaker's know-how, the latest materials, and technologies while making it even more sophisticated and elegant. And new ideas are continuously getting realized even at this moment. Just as quenching and tempering complete great swords, Hyundai Motor Company completed the high-performance N model through the RM project that can act as both a daily car and a sports car. What kind of future will the RM project show in its next phase? The new slogan of the N brand, ‘Never just drive.’, demonstrates the brand's dream and willingness to pursue the fuN of driving at every moment even in the era of electric vehicles. RM Project will continue to play an active role as the forerunner of that dream in the future.

By Sujin Lee, automobile critic

Excited about the 1991 establishment of the first domestic auto mania magazine 〈Car Vision〉, I sent a series of long letters there that led to an unexpected hire. 27 years have passed since then, the years of plowing through the writing struggles of an auto journalist. After becoming an editor for 〈Car Vision〉, I came to my current position as the Editor-in-Chief for 〈Car Life〉. My recent interests include cutting-edge techs like electric cars, connected cars, and autonomous driving, but the ‘otaku’ in me doesn’t want internal combustion engines to disappear either.