Following the reveal of the Kia EV3’s specific performance details, consumer interest and reactions have been overwhelmingly positive. The anticipation is that the EV3, with its advanced electrification technology and best-in-class features, will offer a significantly enhanced electric vehicle experience. Held in Gwangjin-gu, Seoul, on the 16th, 'The Kia EV3 Tech Day' was designed to provide detailed insights into the EV3’s various technologies to a broader audience, attracting numerous journalists and influencers.

The event included explanations and Q&A sessions with research engineers, along with a separate technology exhibition booth, to broaden the understanding of the EV3's key technologies. New electrification technologies such as i-Pedal 3.0, Smart Regeneration System 3.0, THIN HVAC, next-generation thermal management system, new electric vehicle power control, driving range guide, and fourth-generation batteries were introduced, along with R&H (Ride & Handling) and NVH (Noise, Vibration, Harshness) technologies, PE system NVH, and aerodynamic performance improvements.

The superior electrification features of the EV3 are based on Hyundai Motor Group's advanced electrification technology. MSV Electric Vehicle Performance Testing Team's research engineer Woo Ha-young kicked off the presentation with the development of i-Pedal 3.0. i-Pedal 3.0 is a one-pedal driving mode that supports acceleration, deceleration, and complete stops using the accelerator pedal only, utilizing the regenerative braking system. It features significantly improved user convenience compared to i-Pedal 2.0, including optimized regenerative braking levels and the ability to use i-Pedal when reversing.

Additionally, enhancements such as supporting forward/reverse shifting without pressing the brake, activating i-Pedal upon restart, and improved usability have been implemented. Research engineer Woo Ha-young stated, "Unlike before, where i-Pedal only operated at the strongest regenerative braking level, now drivers can enjoy one-pedal driving with their preferred deceleration rate, and the previously set i-Pedal level is maintained when restarting the vehicle, improving convenience from the user’s perspective."

The Smart Regeneration System 3.0 applied to the EV3 supports more economical and convenient driving. It helps to automatically decelerate according to driving conditions by utilizing various navigation information such as inter-vehicle distance, left/right turns, corners, speed limit zones, speed bumps, and roundabouts. This system has evolved to be much more detailed compared to the previous system, which only utilized speed camera information.

The use is also straightforward. Pressing the right paddle shift on the steering wheel for about one second activates the Smart Regeneration System 3.0. Shim Kyu-bin summarized the advantages of the system by stating, "The system automatically controls driving speed according to driving conditions using only regenerative braking, offering both economic driving and excellent convenience."

The interior usability of a vehicle directly impacts its marketability. The EV3 features the world's first THIN HVAC, which dramatically reduces the size of the HVAC system for excellent interior packaging. THIN HVAC is characterized by the horizontal stacking of the evaporator and heat exchanger, which were previously arranged vertically, resulting in a slim overall package. Additionally, the actuator door's operation method was changed from rotary to sliding, and the air passage to the rear seats was moved from the interior to the PE (Power Electric) room side.

By shortening the vertical length by 33% compared to the existing HVAC system, the space occupied by the HVAC system under the crash pad was minimized, and 6cm of additional legroom was secured for the passenger seat. Moreover, the simplified internal air flow path increases airflow, reduces wind noise, and lowers power consumption. Lee Yoon-hyung confidently explained, "THIN HVAC is one of the keys to the EV3’s revolutionary interior usability enhancement."

For electric vehicles, thermal management is crucial to maximize performance, as battery charging and discharging performance remains high at optimal temperatures. The next-generation thermal management system of the EV3 has improved thermal management efficiency and heating performance compared to existing systems. The modularization of cooling water and refrigerant-related components reduced the number of parts by 44% and weight by 4.5%.

In particular, the simultaneous heat absorption method, which simultaneously utilizes the heat from external air and the PE system, maximizes heat pump performance, improving heating performance and minimizing energy consumption during the winter seasons. Park Chang-min explained the detailed technical principle: "Previously, only one heat source, either external air or the PE system's waste heat, was utilized. However, the next-generation thermal management system of the EV3 allows for more efficient thermal management by simultaneously utilizing both."

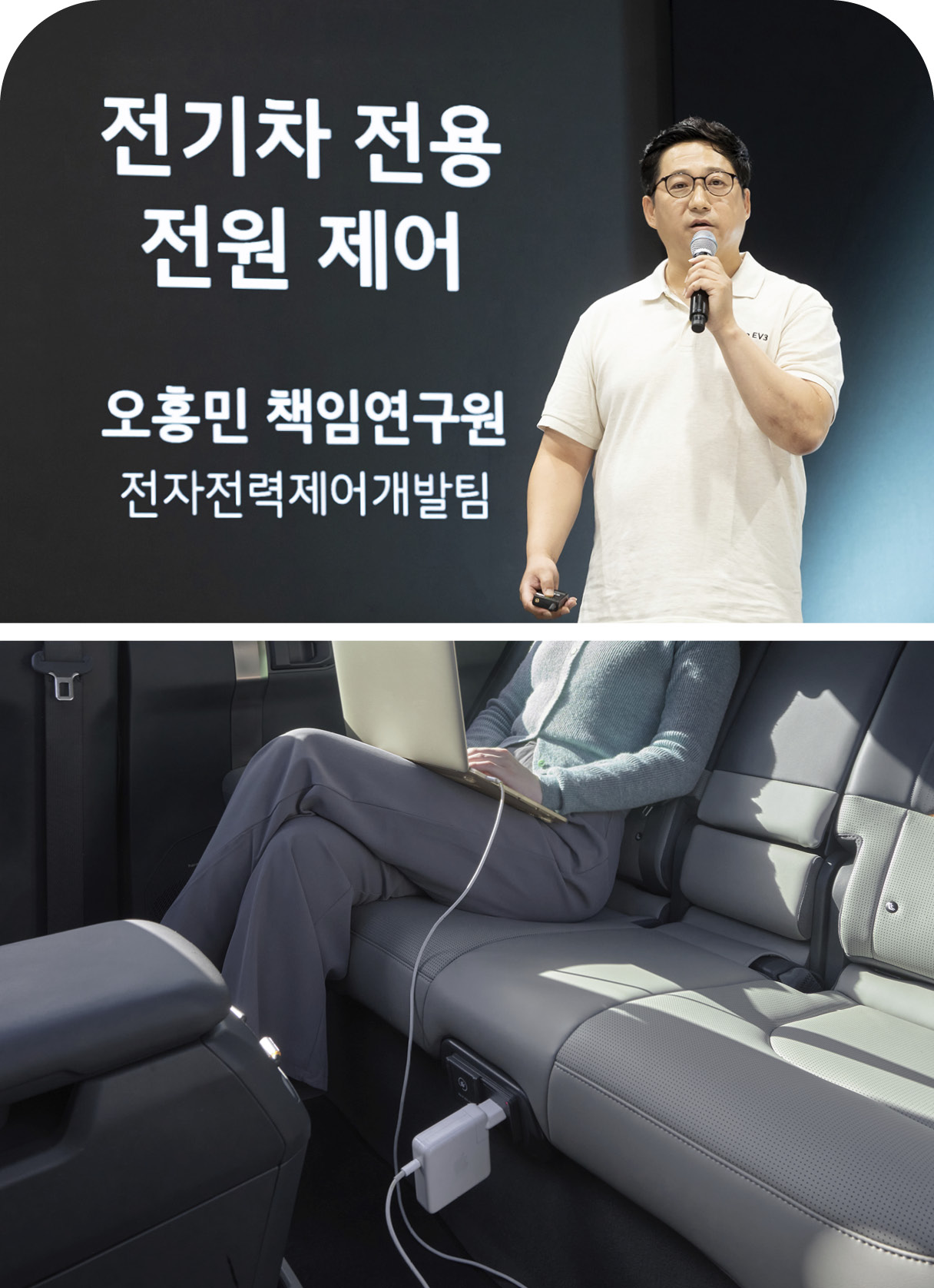

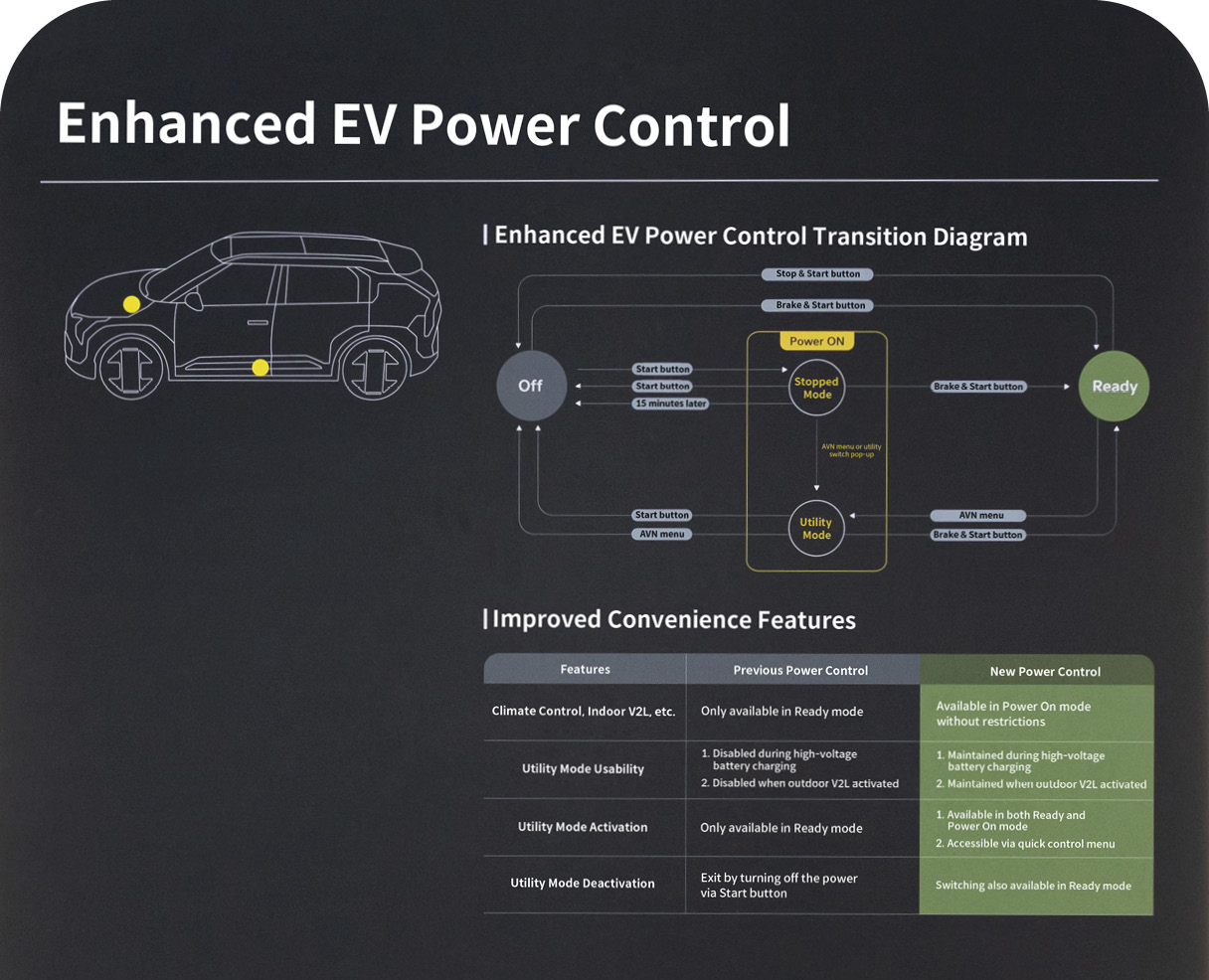

Previously, just like internal combustion engines, EVs required the engine to be running to use the electrical systems. The EV3 has rationalized this power control, enabling the use of specialized electric vehicle features such as utility mode and V2L (Vehicle-to-Load) without starting the engine. By pressing the start button without stepping on the brake pedal, the vehicle activates 'POWER ON' mode, allowing the operation of utility mode, climate control system, and interior V2L.

The power control configuration has been simplified from the traditional four-step process (OFF – ACC - IGN – READY) to a three-step process (OFF – POWER ON – READY). High voltage batteries can now be utilized in both READY and POWER ON states. Senior research engineer Oh added, “We pursued convenience by adding utility mode to the quick control menu. This also supports utility mode activation during battery charging or using outdoor V2L.”

The EV3 employs various technologies to achieve optimal driving performance and best-in-class driving range. Hyundai has introduced a 'Driving Range Guide' for the first time, assisting drivers in efficient driving. This guide analyzes driving patterns and displays the calculated driving range, maximum, and minimum possible distances on the cluster based on the driver’s style.

If a driver maintains driving habits that positively impact energy efficiency, the maximum driving range will be indicated with a green gauge on the display, encouraging more efficient driving. Conversely, if driving habits deteriorate, an orange gauge will appear, showing how current habits are negatively affecting the vehicle's efficiency. Kim Yong-chan, Project Leader of the EV Performance Testing Team, explained, “This feature allows drivers to not only enjoy a new driving experience but also drive in a way that benefits energy efficiency.”

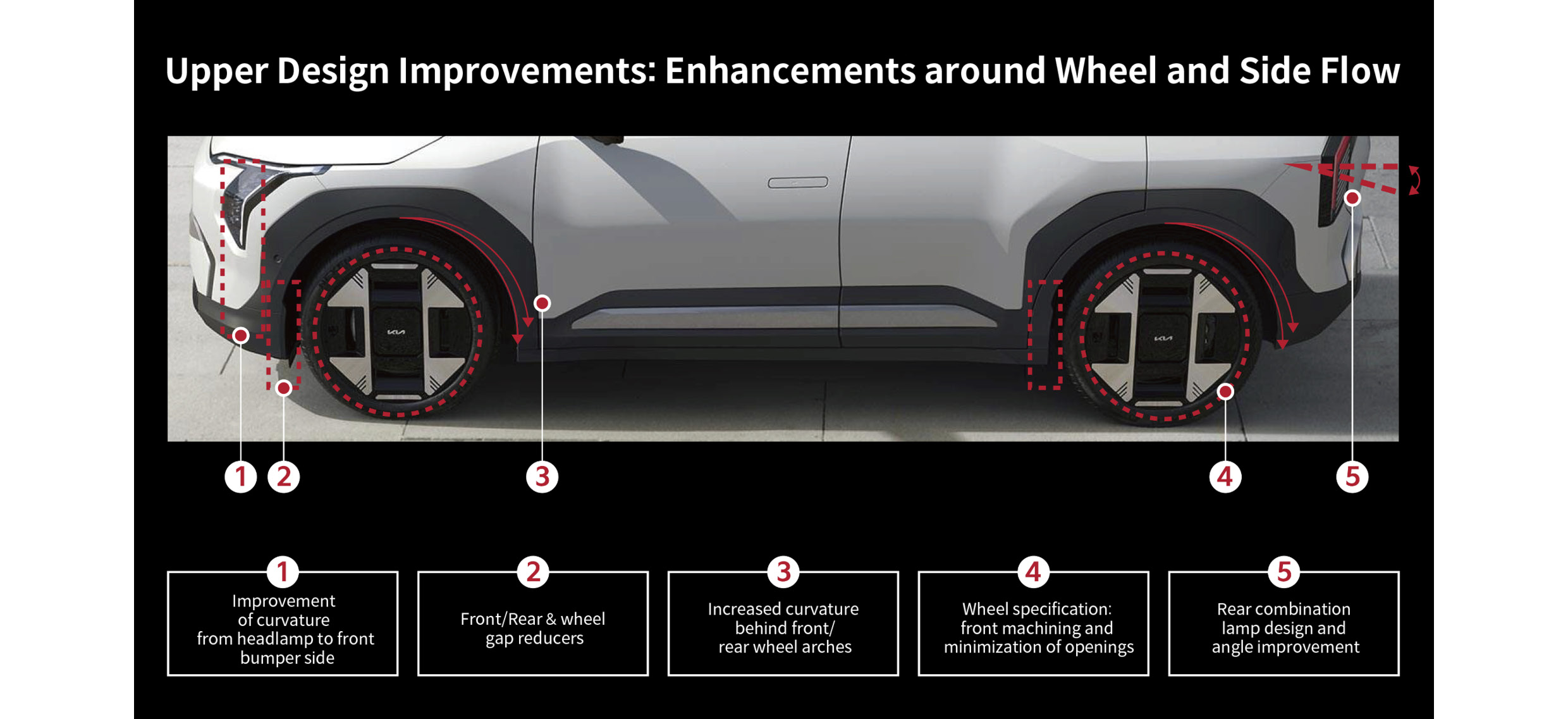

Aerodynamic performance is crucial for electric vehicles since overcoming wind resistance at high speeds consumes significant power. Improving aerodynamic performance is essential to increase the driving range of electric vehicles.

The EV3 achieves a class-leading drag coefficient of 0.27 through improvements in headlamp and front bumper curvature, wheel gap reducers, increased curvature of front and rear wheel arches, optimized wheel shapes, and enhanced design and angles of the rear combination lamps. Additionally, the EV3 optimizes airflow balance with features like a lowered roof spoiler angle, a spoiler shape applied to the lower rear bumper, and a boat-tail shape that reduces the width of the rear wheel arches by about 10mm compared to the front.

Son added, “The underbody of the EV3 features side sill undercovers applied for the first time in Hyundai Motor Group, with a total of eight components covering 79.1% of the area. This, combined with the three-dimensional layout from the front undercover to the rear undercarriage and the lower rear bumper, has achieved optimized airflow.”

The fourth-generation battery is a critical element of the EV3’s impressive electric performance, enabling a driving range of up to 501km (for the long-range model with 17-inch wheels). The energy density per cell has increased by 22% compared to previous models, and the battery pack packaging has been optimized to accommodate more cells. Additionally, the thermal management system has been improved to mitigate the temperature rise that slows down charging speed during rapid charging.

As a result, the EV3’s rapid charging time (from 10% to 80% SoC) has been reduced by about 12 minutes, now taking approximately 31 minutes (for the long-range model using a 350kW charger). Kang stated, “The enhanced cell energy density, optimized battery pack packaging, and superior thermal management system enable the EV3’s impressive driving range.”

The EV3 employs various technologies to deliver a luxurious driving feel and handling performance. One such technology is the third-generation Smart Frequency Control Damper (SFD3), which adjusts damping to effectively counteract vibrations transmitted from the road surface. These vibrations, primarily in the high-frequency range, can cause significant fatigue to passengers.

The EV3 also features hydro G-bushings, typically used in mid-to-large vehicles. These bushings, which contain fluid inside, offer up to ten times better shock absorption than regular bushings, contributing to a luxurious ride. Koh further explained, “In addition to the third-generation Smart Frequency Control Damper and hydro G-bushing, we have added reinforcements connecting the rear member and the body to better handle lateral stress, thereby enhancing vehicle response and unity during cornering.”

Ensuring a quiet interior is a key focus for electric vehicles like the EV3. Various technologies have been employed to minimize vibrations and noises from entering the cabin. Enhancements include the front member frame stay bracket, rear member dynamic damper, improved member bushing characteristics, reinforced cowl, roof corrugation pads, rear wheelhouse stiffness enhancements, tailgate dynamic damper, rear crossmember mount stiffness improvements, floor-separated sound-absorbing pads, perforated sound-absorbing bags made from recycled materials, hollow sound-absorbing materials inside the rear wheel guards, and laminated acoustic glass.

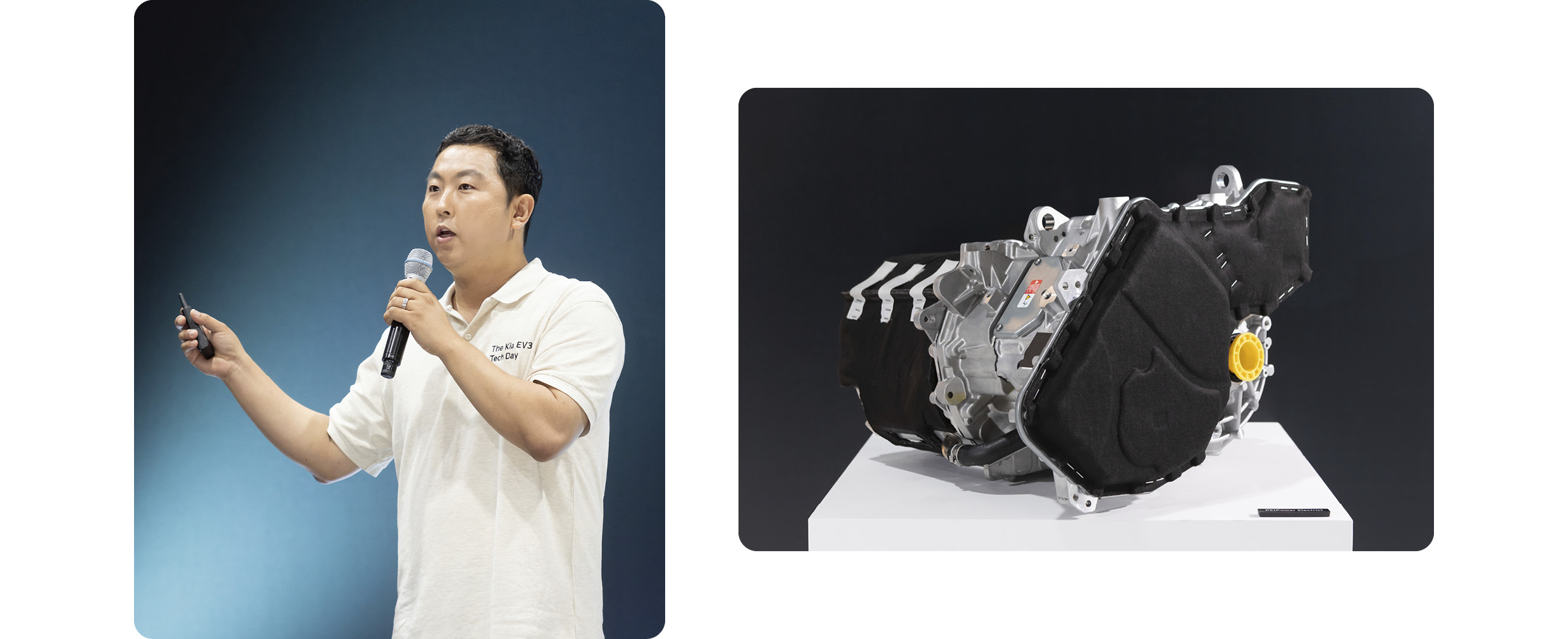

Then the noise reduction technology housed in the PE system was introduced; the system includes measures such as minimizing motor and gear vibrations, applying sound-absorbing materials to the motor and inverter covers, and reinforcing the PE case structure to reduce high-frequency motor noise transmission. These fundamental approaches effectively reduce noise and vibrations, which were thoroughly explained by Lee Sung-won and Lee Jong-byung during the presentation.

Following the presentations, there was a Q&A session where journalists and influencers could directly engage with the research engineers and ask detailed questions about the new technologies, aerodynamic improvements, ride comfort, and handling of the EV3. This session provided valuable insights into the cutting-edge innovations introduced in the EV3.

Attendees showed great interest in the development direction of the EV3, which achieved impressive product value beyond expectations. Yoon Kiwan, Senior Research Engineer from the MSV Project 5 Team, explained, “The EV3 is a dedicated electric vehicle that incorporates the common characteristics of E-GMP technology. By focusing on weight reduction and improved transmission efficiency, we developed a new motor that enhances performance compared to existing compact electric vehicles, meeting customer performance requirements.”

Following the Q&A session, attendees were given the opportunity to freely explore the vehicle and technology exhibition booths, engaging directly with developers to address any questions. The exhibition showcased 18 different real parts, including the PE system, NVH performance enhancement parts - stay brackets, vacuum sound absorption bags, sound-absorbing wheel guards - , third-generation frequency-sensitive valves, hydro G bushings, aerodynamically improved design wheels, undercovers, fourth-generation high-voltage battery packs, next-generation thermal management systems, and THIN HVAC. This allowed numerous journalists and influencers to examine the related technologies in detail.

The EV3 Tech Day was designed to help automotive media gain a deep understanding of the specialized vehicle technology. The high satisfaction among participants was attributed to the ability to gain detailed technical knowledge beforehand and then verify it during subsequent vehicle test drives.

Meeting the research engineers at this event showcased their passion and hard work to achieve top-tier product quality in their class. Kia will continue to strive to innovate the electric vehicle experience for its customers by presenting excellent electrification product quality. The true popularization of the electrification era is coming closer to us through the EV3.

Photography by Choi Daeil and Kim Beom-seok