As electric vehicles become more mainstream, consumer interest in them has surged, particularly in areas such as charging performance, driving capabilities, and range. "Range anxiety" is a global concern, especially since EVs, unlike internal combustion engine (ICE) vehicles that utilize waste heat for heating, consume significant power for heating, which can vary greatly depending on external conditions. This necessitates more precise thermal management technology for EVs.

In response, Hyundai Motor Group has been developing various thermal management technologies to ensure a convenient EV experience for consumers. These include heat pumps that use waste heat from the vehicle's electronic systems to improve interior heating efficiency and battery conditioning with battery heaters to reduce energy consumption in winter and enhance charging performance.

The group is also developing new technologies to prepare for the future EV era. One such innovation is a radiant heating system that maintains passenger warmth even with lower interior temperatures while reducing power consumption. Since 2019, Hyundai Motor Group has applied customized infrared knee warmers using carbon fabric heating elements in select models. In 2022, the company further demonstrated the future of mobility heating technology with its mobility Ondol concept.

So, how is the radiant heating system currently being developed? Experts from the Integrated Thermal Management Research Lab, Thermal Energy Vehicle Testing Team 1, Genesis Interior Design Team, and Genesis Interior Design Team explained how the latest radiant heating system differs from previous technologies and the process behind its development.

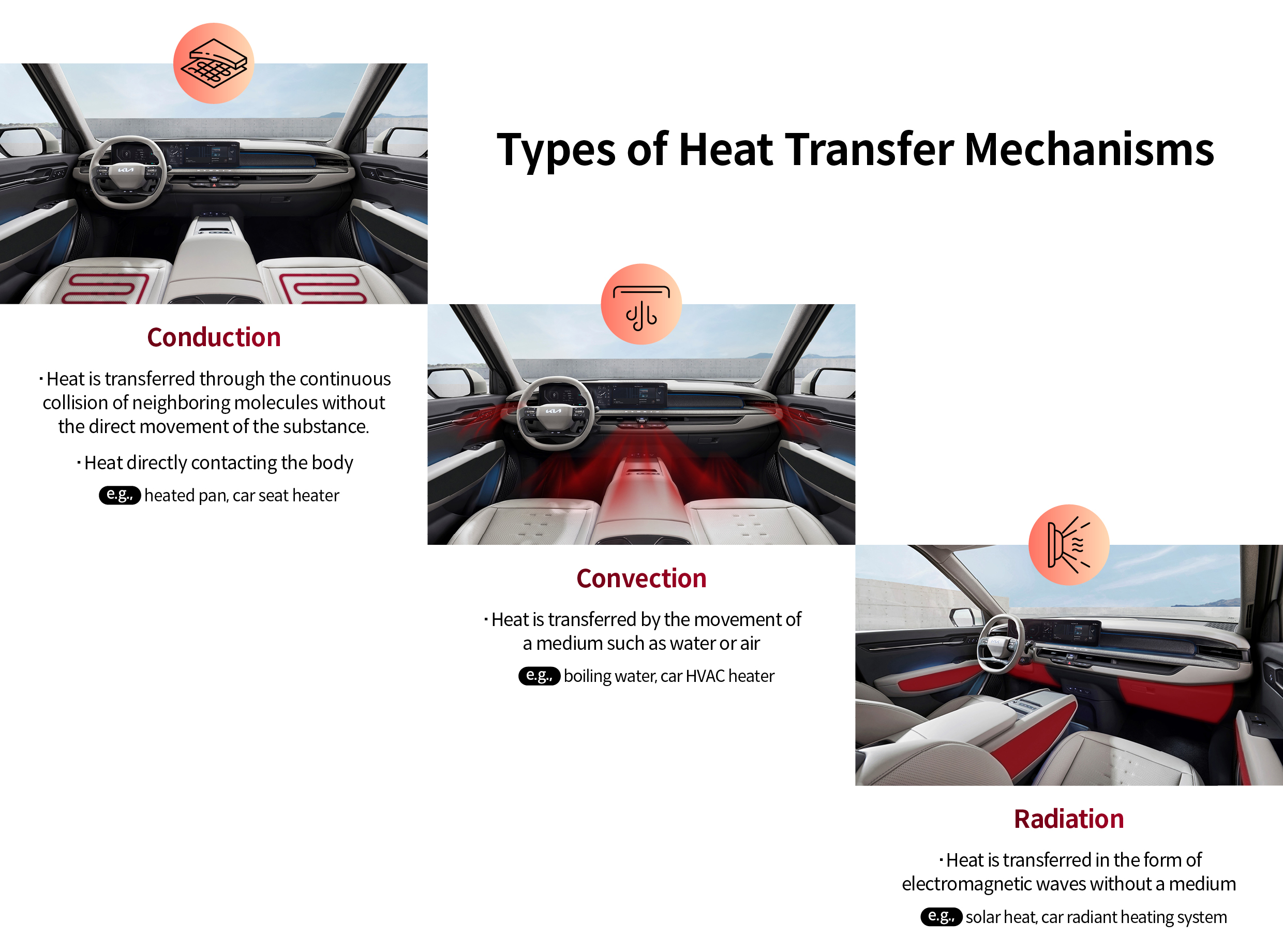

The radiant heating system, as its name suggests, is based on the principle of radiant heat transfer. Heat transfer occurs in three main ways: conduction, convection, and radiation. Conduction involves the transfer of heat through direct contact within a material, such as when one side of a metal object is heated, and the heat travels to the other side. This method is often found in high thermal conductivity metals and is used in car features like heated seats and heated armrests.

Convection occurs when fluids or gases, such as water or air, are heated, causing the heat to spread. An example of this is a car’s climate control heater, which blows warm air into the cabin. Finally, radiation is the process by which heat is emitted from a source in the form of electromagnetic waves. This is how sunlight travels through space to warm the Earth or how a heater can warm you from a distance. Hyundai Motor Group aims to provide a comprehensive heating solution by integrating radiant heat into the vehicle’s interior, complementing conduction (heated seats and armrests) and convection (PTC heater) with radiant heat (radiant warmers).

Radiant heating is widely used in residential heating today, and its principles can be found in Korea's traditional Ondol heating system. In Ondol, when a fire is lit in the stove, the heat travels under the floor slabs, warming the floor (conduction). The heated floor then radiates heat into the room (radiation), which in turn warms the air (convection).

Oh Man-ju, a research fellow at the Integrated Thermal Management Research Lab, introduced a radiant heat system for automobiles inspired by the principles of Ondol. He explained the background of this development: “As we explored the possibility of incorporating radiant heating into vehicles, we considered both energy reduction for EVs and the impact on human comfort. Researching everyday examples of radiant heating, I was inspired by the way traditional Korean houses use Ondol to provide a gentle warmth.”

Oh Man-ju mentioned that the latest radiant heating system embodies advanced technology. Chung So-la, a senior research engineer at the Integrated Thermal Management Research Lab, elaborated on how the new system differs from the first-generation knee warmer used in models like the Hyundai Venue, Tucson, Palisade, and Kia Seltos, explaining its evolution from concept to current development:

“Conventional convective heating systems take time to raise the overall air temperature inside a car. However, a radiant heating system directly transfers heat to the body, providing warmth much faster. Since radiant heating systems had never been properly applied in vehicles, we first developed a knee warmer—a customizable product targeting the body part most sensitive to temperature changes—and it received positive feedback from consumers.”

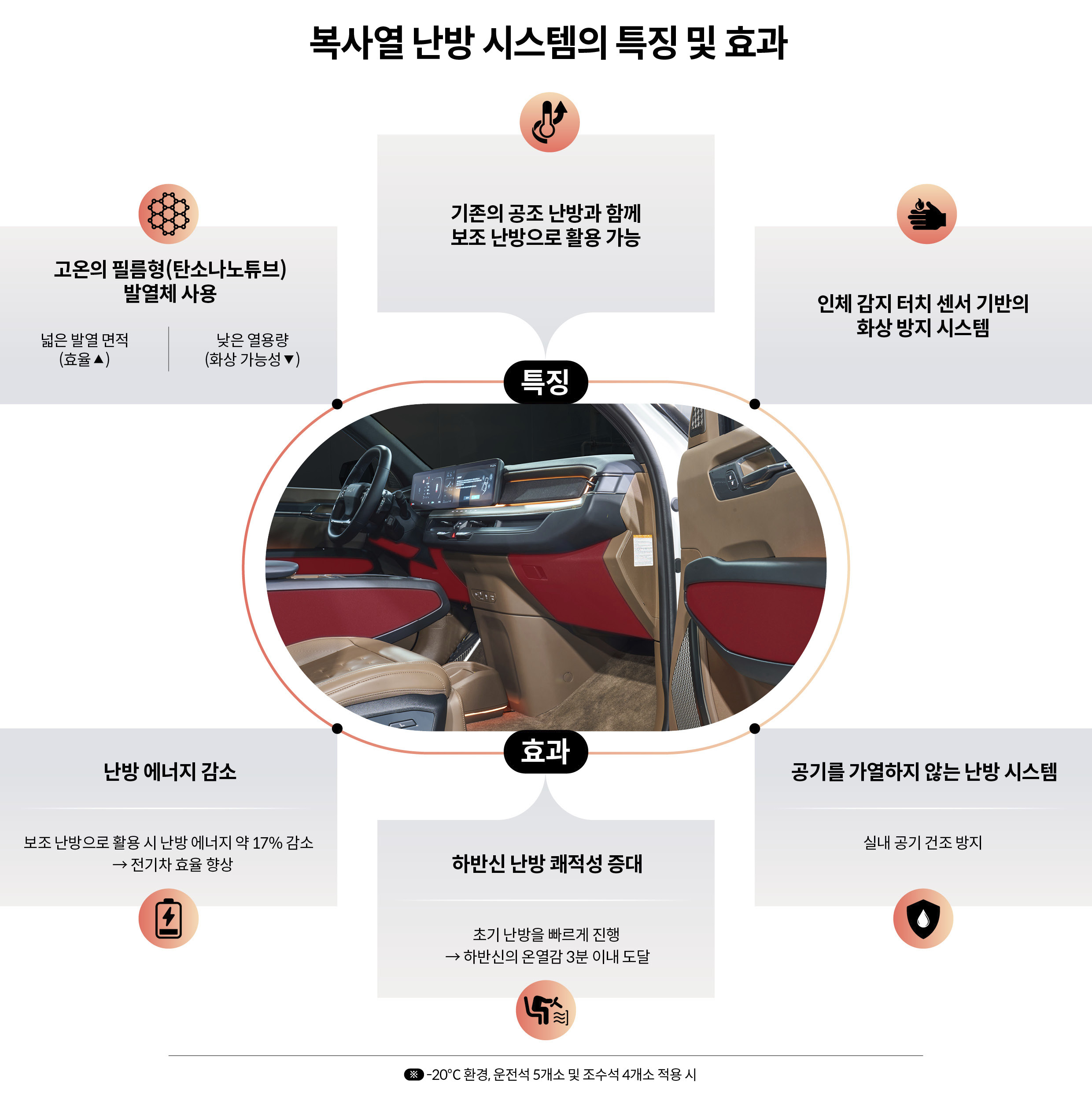

“Following this, we created a study model of a radiant heating system that could provide warmth to all body parts of the occupants. This model underwent evaluation and analysis, establishing a foundation for applying heating elements to optimal locations. Additionally, we developed a new film-type heating element made from carbon nanotube material, which has a larger heating area than the carbon fabric heater used in the first generation, offering a more effective warming experience. We also developed a new 48V power architecture to support this advancement. Moreover, preliminary tests in trial vehicles confirmed reductions in heating energy consumption and improvements in fuel efficiency.”

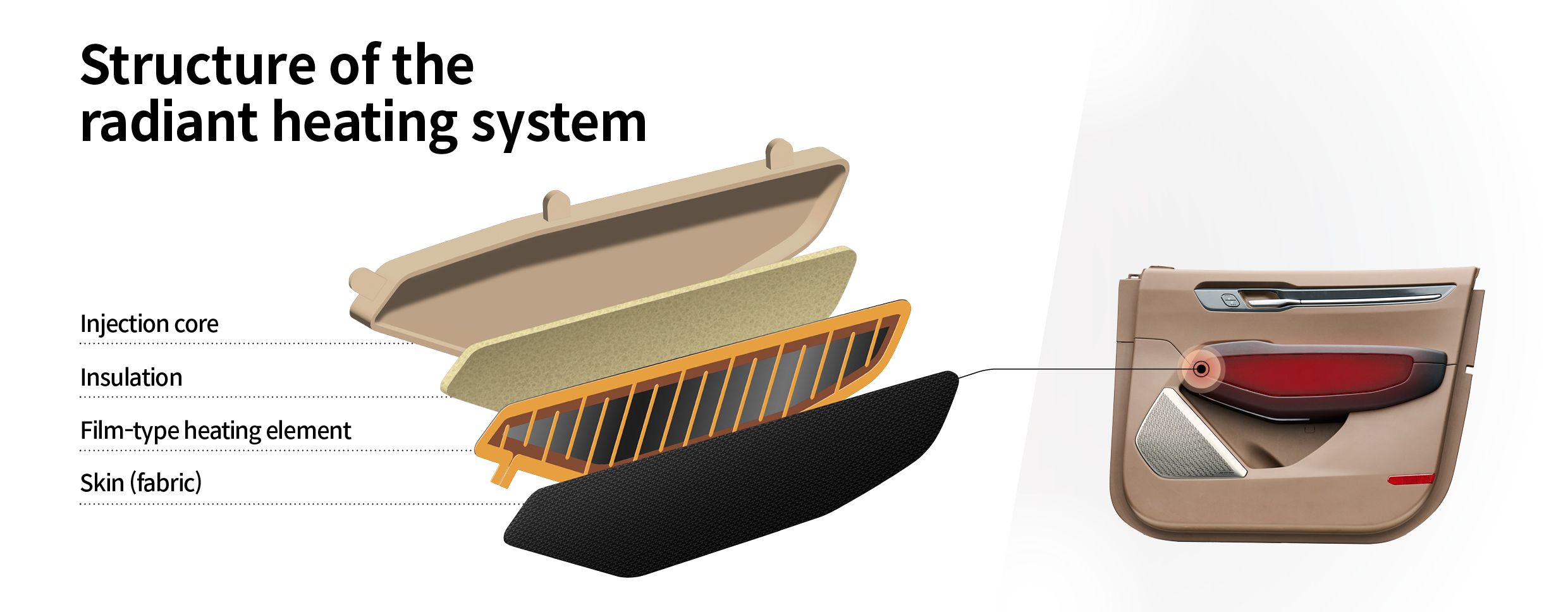

As Chung So-la explained, one of the key features of the new radiant heating system is the application of film-type heating elements that reach high temperatures between 85-110°C. These are superior to the heating elements used in the first-generation system and those introduced by other manufacturers, allowing for quicker heat release and a warmer, more comfortable interior. The switch from wire-based to surface-based heating structures also ensures a more even temperature distribution. The carbon nanotubes used in these film heaters are noted for their excellent electrical and thermal conductivity and are already widely used in various industries such as batteries, semiconductors, automotive, and aerospace.

The radiant heating system can be tailored in shape according to its installation location and interior design. It comprises an injection-molded core to fix the shape of the components, insulation to prevent heat deformation and direct the radiant heat into the interior, the high-temperature film-type heater, and a skin layer that encases the components.

Lee Jae-yong elaborated, “To implement a heating structure that operates at higher temperatures than previous radiant heating systems, we faced significant challenges in securing insulation and flame retardancy around the film heater. Radiant heat intensity decreases with the square of the distance, so the optimal distance for effective warmth is around 10 cm from the body. We needed a solution to maintain the appropriate distance while minimizing the risk of burns to occupants, which led to the development of the burn prevention system, another key feature of this radiant heating system.”

The burn prevention measures were approached from both hardware and software perspectives. On the hardware side, the heating element was made thinner to reduce heat capacity, and a fabric material with low thermal conductivity but high emissivity was used in the skin layer to minimize the risk of burns. On the software side, capacitive touch sensors were integrated into the heating elements to immediately cut off power if the system detects direct contact with the body. Safety features were also included to deactivate the heating function instantly if components are damaged or if there are power connection or software errors, thoroughly preventing any potential risk of burns.

As temperatures drop below freezing, many of us have experienced the discomfort of cold seats when getting into a car that's been parked outside for a while. And radiant heating systems are designed to address precisely this issue. When used alongside traditional convection heating, radiant heating can quickly warm passengers, enhancing their comfort. In milder conditions, the radiant heating system alone can sufficiently heat the lower body.

Researchers conducted extensive tests at the Namyang Technology Research Center to analyze the effectiveness of radiant heating. They applied the system to five areas of the driver's seat, including the shroud beneath the steering wheel, door trim, and center console. For the passenger seat, they equipped four areas, including the glove box, door trim, and center console. The results showed that at -20°C, the system could reach the desired temperature within three minutes, providing noticeable warmth to the lower body.

Kim Sang-hun, a Global R&D Master from the Thermal Energy Vehicle Testing Team 1, highlighted the reduced energy consumption of radiant heating. According to Kim, using radiant heating in conjunction with conventional air systems can reduce heating energy consumption by approximately 17%, although this may vary depending on the vehicle’s interior design.

Senior Research Engineer Chung So-la added that the system also helps maintain better air quality inside the car. According to her, by reducing reliance on traditional air heaters, which can dry out the air, the radiant heating system ensures a comfortable environment. This could be particularly beneficial for consumers who avoid using heaters to protect their skin during winter, offering them both warmth and comfort.

Collaboration among various teams, including the Integrated Thermal Management Research Lab and components design and testing teams, has been crucial for the mass production of these systems. The Genesis Neolun concept, unveiled earlier this year, showcases this collaboration, featuring radiant heating elements integrated into the dashboard, door trim, flooring, seat backs, and console sides.

Oh explained, “The radiant heating system in the Genesis Neolun concept represents a new challenge for designers, balancing aesthetic design, durability, and the ability to deliver heat. We are developing various designs that harmonize with the vehicle’s interior while making radiant heating possible.”

Thanks to the close cooperation and efforts of the development team, the radiant heating system is rapidly moving towards mass production. A recent milestone in this journey was the successful revision of long-standing automotive regulations related to heater components in the European market. Previously, UN R122 heating system regulations stipulated that metal parts in contact with the human body should not exceed 70℃, and non-metal parts should not exceed 80℃. Hyundai Motor Group spearheaded the effort to amend these regulations. Yang Hyeon-kyu, senior research engineer at the Integrated Thermal Management Research Lab, provided insight into this achievement:

“The temperature and burn risk vary depending on the properties and thermal capacity of the heat-conducting medium. To fully realize the heating performance of the radiant heating system, a surface temperature above 80℃ is necessary. However, meeting the existing European regulations made it difficult to achieve the system's full potential. Through deep discussions among the radiant heating system development team, Hyundai Motor Group’s regulatory certification team, European research institutes, and government agencies, we reached a consensus on the safety, heating effectiveness, and energy-saving benefits of the radiant heating system, ultimately leading to the revision of the European regulations this year.”

Radiant heating systems are not a distant future technology. The system is already sufficiently advanced for near-term mass production. While challenges remain regarding design, materials, manufacturing processes, regulations, and certification systems, the passion and persistence of Hyundai Motor Group’s development team suggest that these obstacles will be overcome. Like the Genesis Neolun concept, a radiant heating system with high design and functional quality is set to soon deliver a more comfortable winter driving experience.

Video by Nam Do-yeon and Lim Woo-jin

Photography by Cho Hyuk-su