The most noticeable change in the redesigned Genesis Electrified G80 is its roomier and more luxurious rear seat. However, hidden beneath the surface are a host of performance upgrades: recalibrated driving dynamics to maintain the owner-driven sedan's strengths despite the longer and heavier body, finely tuned R&H to ensure rear-seat comfort befitting a chauffeur-driven sedan, and advanced NVH performance to match.

Genesis applied these performance improvements not just to expand space but to perfect the Electrified G80 as a flagship EV sedan that fully represents the brand’s technical prowess and sophistication. To understand how they achieved this level of refinement, we spoke with Jung-woo Lee, research engineer of the Genesis R&H Test Team, and Munsun Yoo, senior research engineer of the Genesis NVH Test Team.

Q: What was the primary focus in developing the R&H performance for the redesigned Electrified G80?

Research Engineer Jung-woo Lee: When we first saw the elongated wheelbase and the more luxurious rear seat, we immediately began thinking about how to develop a ride quality that would satisfy both drivers and rear passengers. The previous model was largely for owner-driven car. In contrast, the redesigned model, we aimed the comfort of the rear-seat on G90, while retaining the driving dynamics of the previous model.

To achieve this, we had to provide a smooth ride and controlled vehicle movement that would allow rear passengers to relax or conduct personal business. We developed a robust suspension system to absorb road vibrations and shocks, ensuring comfort even on rough roads.

Q: With the increased overall weight due to longer wheelbase and larger high-voltage battery, how did you address the impact on ride comfort and handling?

Research Engineer Jung-woo Lee: From an engineering perspective, increased weight brings more factors to control when driving. Inertia—the tendency of an object to remain in its state of motion or rest—grows as mass increases.

In the driving process, it's crucial for a vehicle to accelerate, brake, and corner properly. With increased weight, more force (engine power and braking performance) is required to move the car from a stop or to bring it to a halt during driving. Additionally, the ride quality becomes more sensitive to various road surfaces. When it comes to handling, even minor steering adjustments can make the vehicle feel unstable, requiring the driver to be more attentive in controlling it.

The curb weight of the Electrified G80 is 2,365 kg, which is 90 kg heavier than the previous model. To ensure a comfortable ride and stable handling in different driving conditions, we strengthened the suspension. This adjustment allowed for a refined, smooth ride, even on domestic roads with uneven surfaces like speed bumps and potholes.

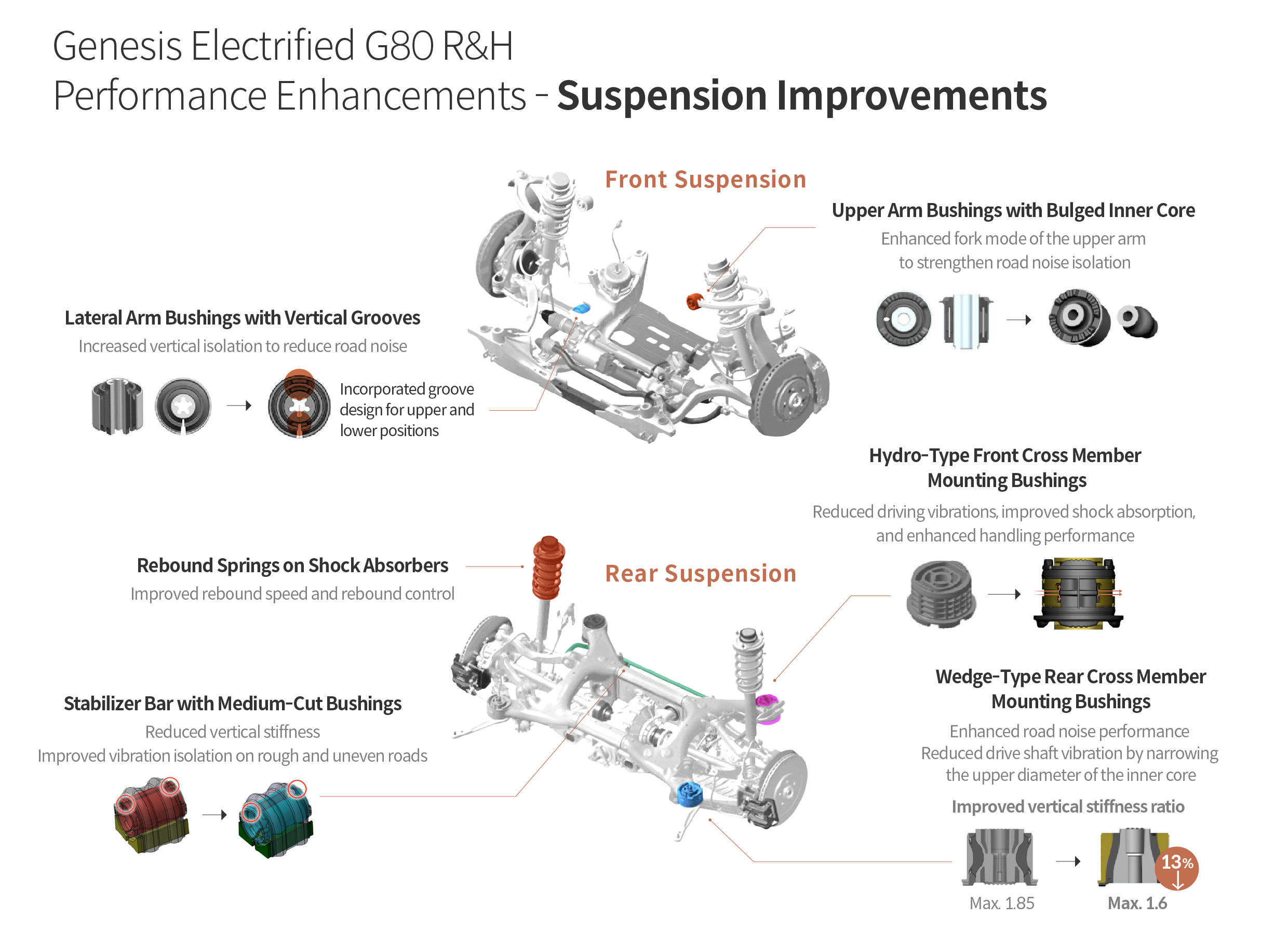

Q: Can you elaborate on the specific improvements made to the suspension?

Research Engineer Jung-woo Lee: The redesigned Electrified G80’s suspension was reinforced with a focus on rear-seat comfort. Among various enhancements, one of the most effective was replacing the front body mounting rubber bushings of the rear cross member with hydro bushings..

Suspension bushings have non-linear characteristics, which means the frequency range that causes resonance changes based on the vibrations from the road. When resonance occurs, it amplifies the noise transmitted into the cabin. Hydro bushings, which contain liquid and a channel for fluid to move through, help dampen external vibrations by setting an appropriate peak frequency, thus reducing road noise, vibrations, and enhancing rear-seat comfort.

The stabilizer bar, which controls the lateral movement or roll of the vehicle, was also upgraded with medium-cut bushings. This reduced vertical stiffness, helping to isolate driving vibrations and improve ride comfort. Additionally, various bushings were applied to the front and rear suspension to minimize road noise, and rebound springs were added to the rear shock absorbers to reduce the impact when the springs compress and rebound over bumps, further improving ride quality.

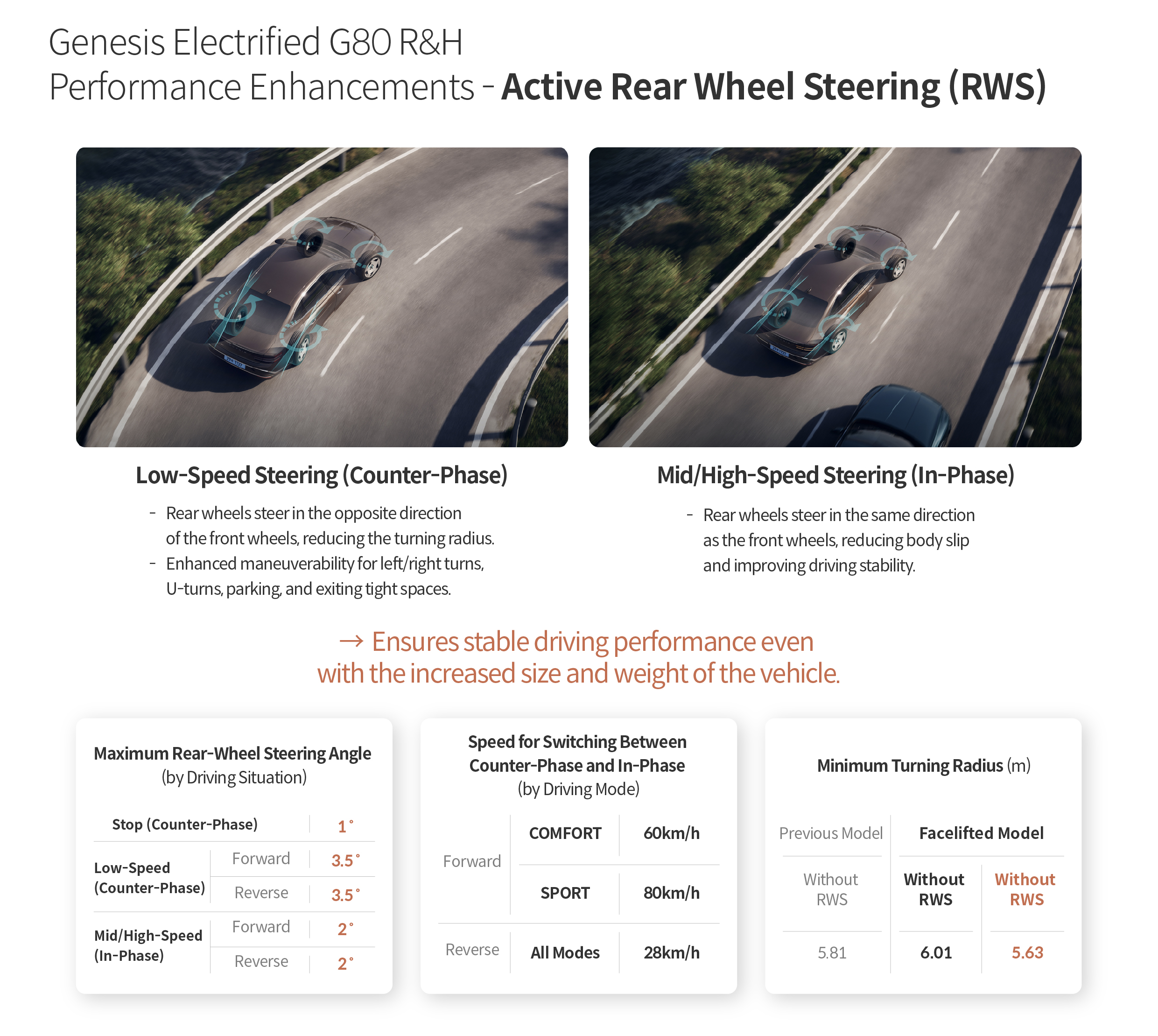

Q: The addition of rear-wheel steering is a noteworthy change. How does it work and what benefits does it offer?

Research Engineer Jung-woo Lee: The Rear Wheel Steering (RWS) system enhances driving convenience by steering the rear wheels in various everyday driving scenarios. It operates in two modes: reverse-phase, where the rear wheels turn in the opposite direction of the front wheels at low speeds, and parallel-phase, where the rear wheels turn in the same direction as the front wheels at higher speeds. While the system is similar to what’s used in the G90 and G80 Sport models, we tuned it specifically for the Electrified G80 to prioritize rear-seat comfort.

The reverse-phase mode, where the rear wheels turn up to 3.5° in the opposite direction of the front wheels, significantly reduces the turning radius. This enhances maneuverability in situations like U-turns, navigating tight alleys, or parking, making the size of the over 5.1-meter car almost forgettable. The previous model without RWS had a minimum turning radius of 5.81 meters, but with the updated model’s 130mm longer body and the addition of RWS, the turning radius is reduced by 0.38 meters. This allows for smoother U-turns and easier handling in parking and tight spaces.

Parallel-phase mode, where the front and rear wheels turn in the same direction by up to 2°, improves driving stability and rear-wheel tracking at speeds over 60 km/h, especially during high-speed cornering and quick lane changes. The speed at which the system switches between reverse-phase and parallel-phase modes varies depending on the driving mode, enhancing the driving experience. For example, in Comfort mode, the system switches to in-phase mode at speeds over 60 km/h, while in Sport mode, the switch occurs at 80 km/h, providing a more dynamic and engaging cornering experience.

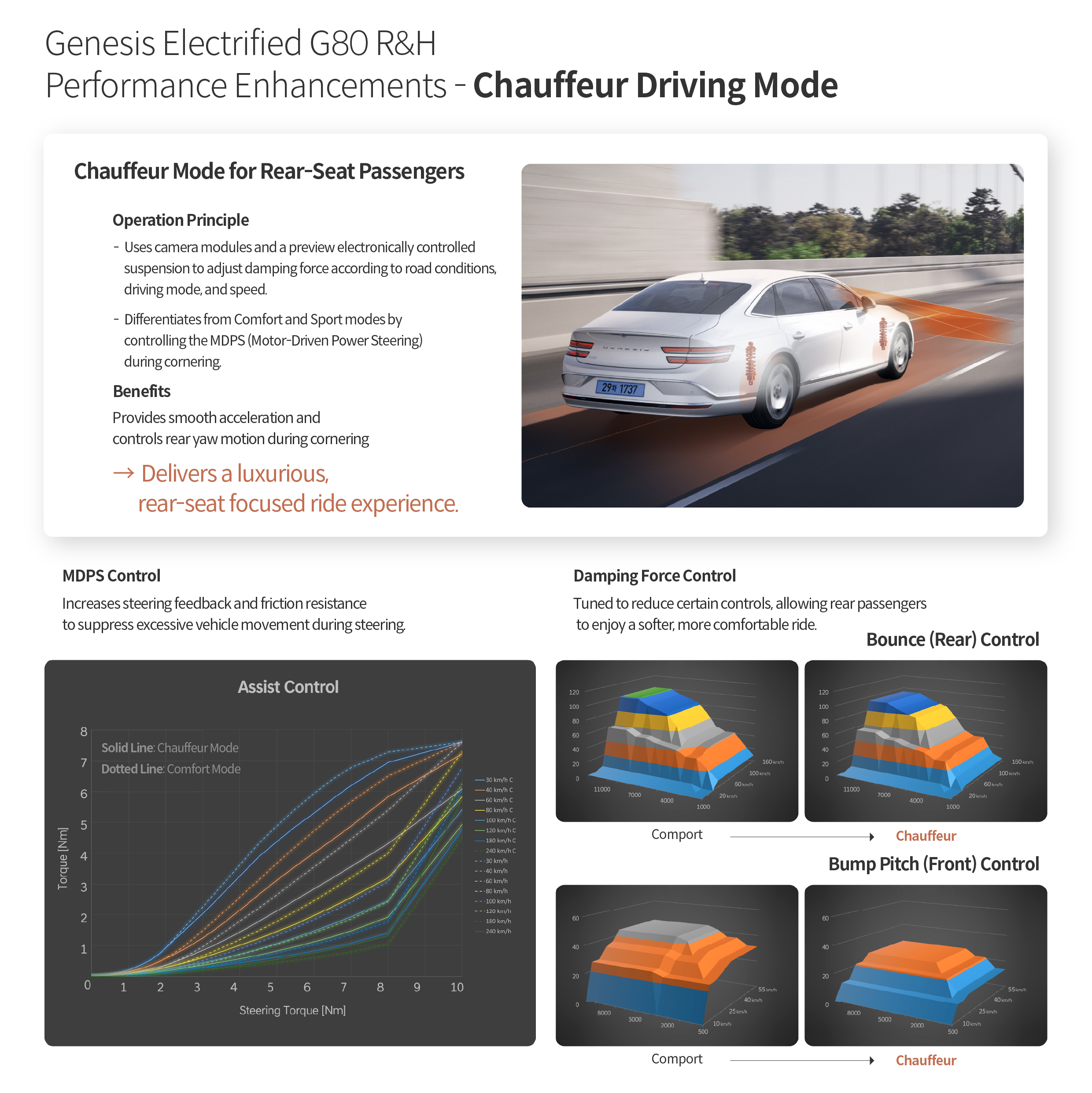

Q: A new Chauffeur mode has been introduced. How does it enhance rear-seat comfort?

Research Engineer Jung-woo Lee: The redesigned Electrified G80 is equipped with a Electronically Controlled Suspension with Road Preview (Preview ECS). Using information from the front camera module and navigation data, the system detects upcoming road imperfections, such as speed bumps, and automatically adjusts the damping force to provide a smoother, more comfortable ride.

Chauffeur mode utilizes the damping control feature of the Preview ECSto minimize movement in the rear of the vehicle, ensuring maximum comfort for rear-seat passengers. It controls the vehicle's bounce (up-and-down motion) and bump pitch (front-to-back tilting) when passing over road bumps, offering a more refined ride. Additionally, during cornering, the MDPS (Motor-Driven Power Steering) is tuned to increase motor torque and friction resistance, suppressing yaw motion (rotation around the car’s center axis) for enhanced stability.

Q: Chauffeur mode has been added to the brake modes as well. Is this also aimed at improving rear-seat comfort?

Research Engineer Jung-woo Lee: The brake mode is a feature that can be individually set through the infotainment monitor, allowing drivers to adjust the pedal stroke and brake pressure differently using the Integrated Electric Brake (IEB) system. This provides a distinct braking feel based on the selected mode.

In the redesigned Electrified G80, we improved the structure of the Integrated Electric Brake to offer pedal operation suitable for a flagship sedan. Additionally, we introduced Chauffeur mode for the brake system, which focuses on smoother and more controlled braking, aimed at providing a more comfortable ride. While the Chauffeur mode in the driving system and the brake system have different functions, both were newly added to enhance rear-seat comfort.

Q: What were the key areas of focus in improving NVH performance?

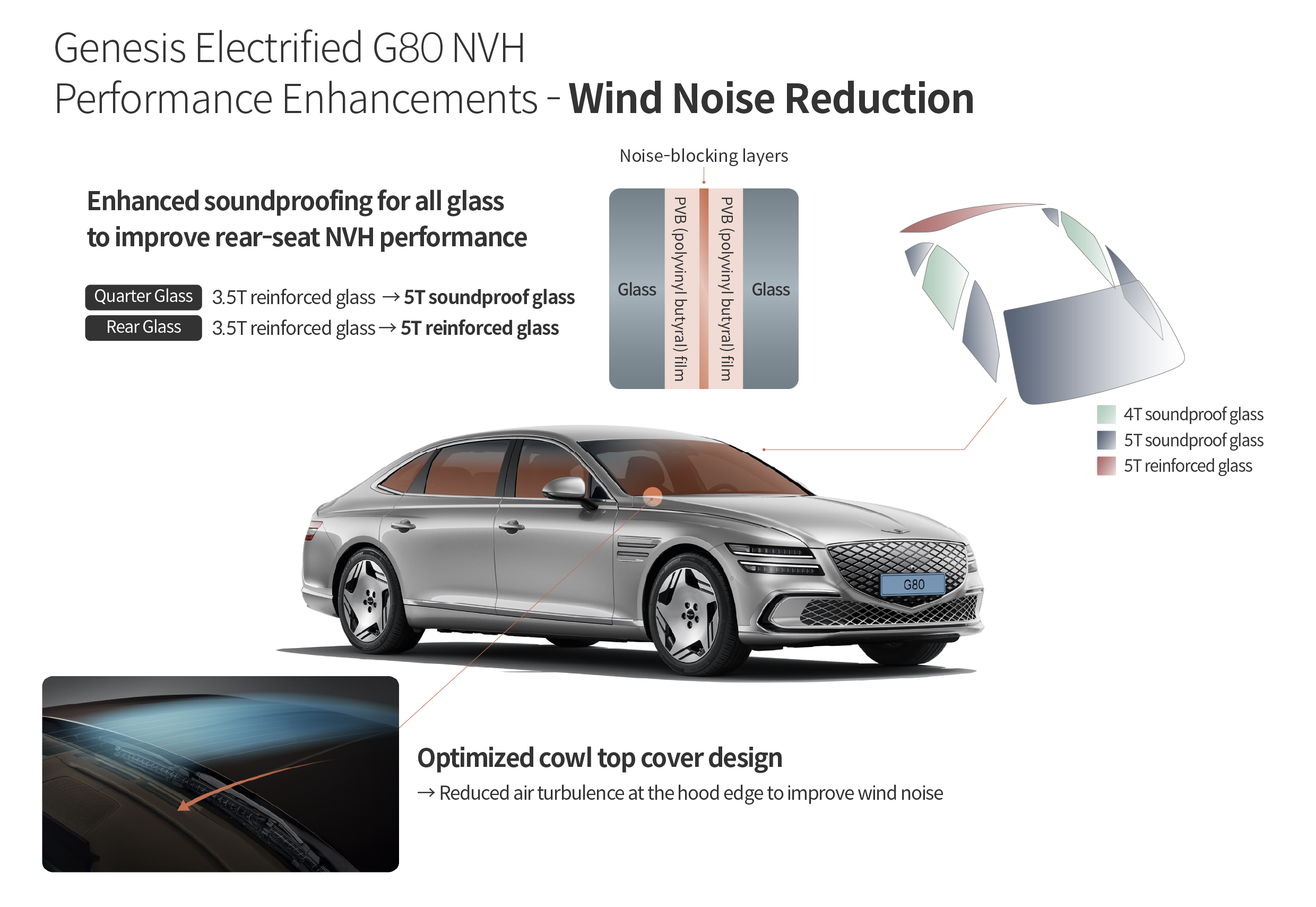

Senior Research Engineer Munsun Yoo: We incorporated many NVH elements from our internal combustion flagship sedan, the G90, to ensure that the Electrified G80 meets the standards of a flagship EV sedan. Since this model is a chauffeur-driven vehicle, we focused on enhancing soundproofing, especially around the rear seats. To achieve this, we significantly reinforced the sound-absorbing materials around the rear seat area, increased the thickness of the quarter glass near the passenger's ear, applied soundproof glass, and added more sound-absorbing materials to the C-pillar trim. Our goal was to provide the best possible quietness and premium feel to our customers.

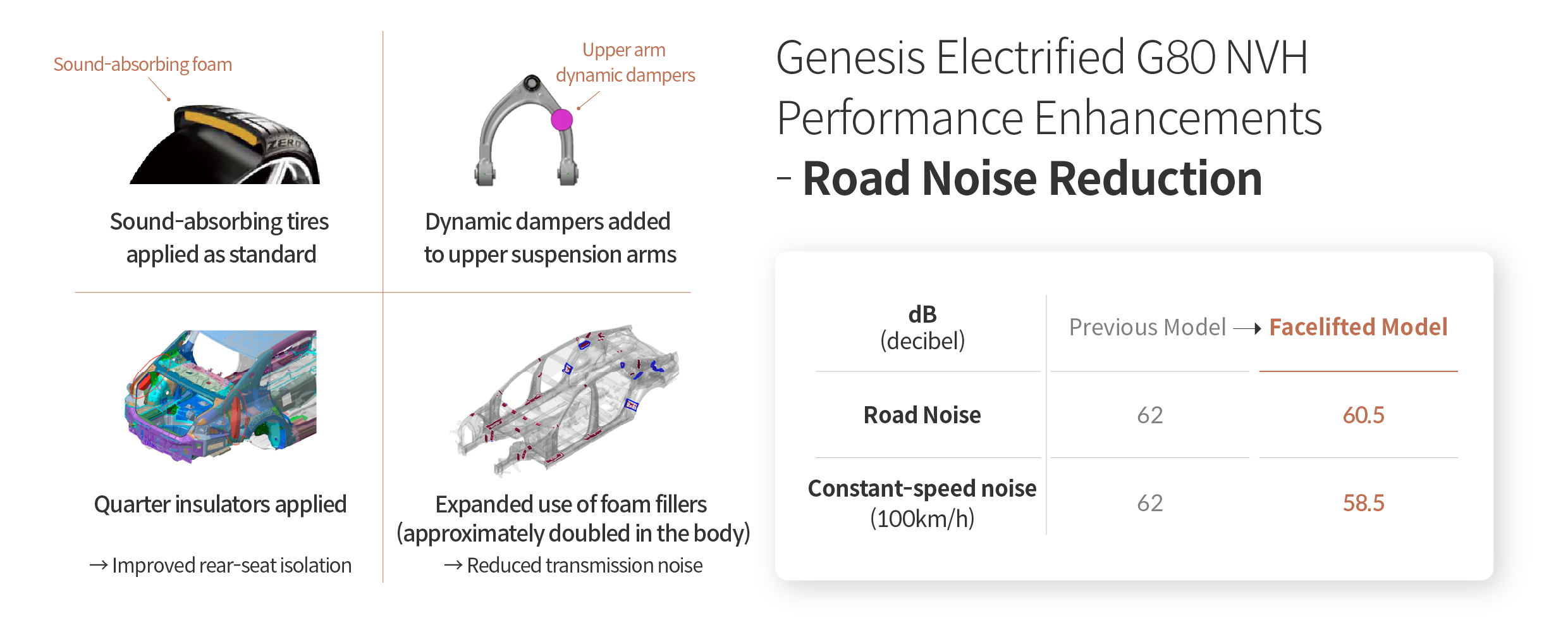

Q: What measures were implemented or enhanced to reduce road noise?

Senior Research Engineer Munsun Yoo: First, we applied sound-absorbing tires to reduce tire resonance. We also added dynamic dampers to the upper suspension arms to absorb vibrations and reduce road noise transmitted from the surface. Additionally, quarter insulators were installed between the inner and outer panels of the rear wheel housing to further block noise and improve the sense of insulation in the cabin.

The body of a car is made up of numerous pressed steel sheets and reinforcements, creating a complex structure with hollow sections where noise can travel. To block these noise pathways, we applied foam fillers, which help reduce noise transmission into the cabin. In the redesigned Electrified G80, we doubled the application of foam fillers, ensuring the quietness expected of a flagship sedan.

Q: With the extended rear seat and additional convenience features, the structure has become more complex. What were the key areas of focus for reducing road noise?

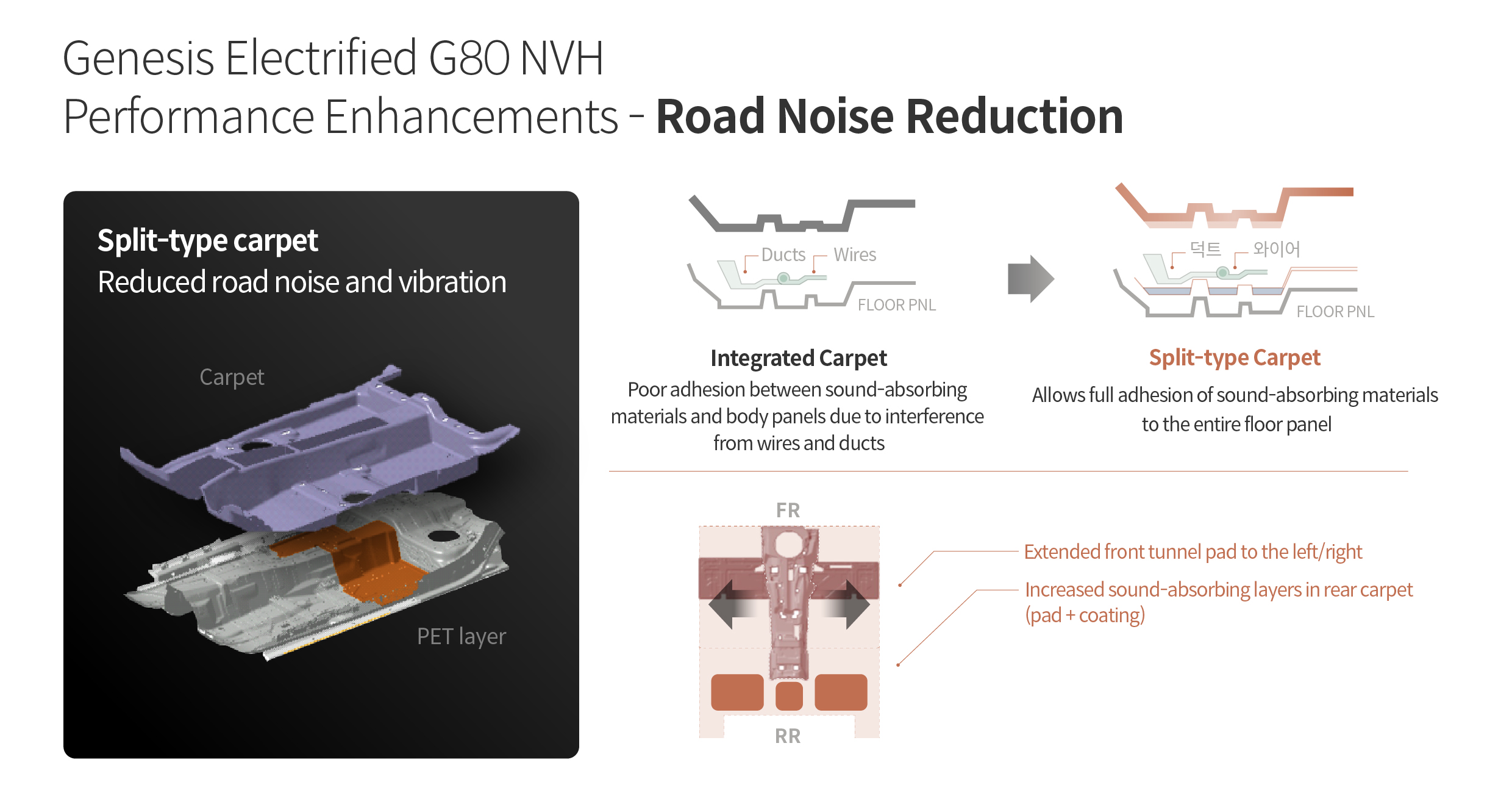

Senior Research Engineer Munsun Yoo: As the wheelbase increased by 130mm, we anticipated that the road noise performance of the floor panel might weaken. Reducing noise from the floor became a critical task, so we significantly improved the structure of the floor carpet, which is the most important sound-absorbing material in the floor panel.

The previous integrated floor carpet had interference issues with components like wires and air ducts, making it difficult to achieve complete adhesion to the floor panel. To address this, we developed a split-type carpet that ensures full adhesion to all areas of the floor. Additionally, we extended the length of the pad attached to the front seat center tunnel and increased the sound-absorbing materials around the rear seat floor, effectively blocking high-frequency noise.

Q: Could you explain the NVH design aimed at reducing wind noise?

Senior Research Engineer Munsun Yoo: First, we increased the thickness of the rear and quarter glass from 3.5T to 5T, applying soundproof glass to the quarter glass near the rear seats. The windshield and front door glass were also upgraded to 5T soundproof glass, and the second-row door glass now uses 4T soundproof glass, significantly enhancing the sense of isolation for rear passengers.

We also optimized the design of the cowl cover, where the hood meets the windshield, to improve aerodynamic performance. This reduced the intensity of turbulence at the hood’s edge, greatly minimizing wind noise at high speeds. Additionally, we optimized the shape and reinforced the stiffness of components around the glass to ensure they fit tightly together, further preventing noise from entering through gaps.

Q: Although there’s no internal combustion engine, what steps have you taken to reduce noise from the PE system and high-voltage battery in the electric vehicle?

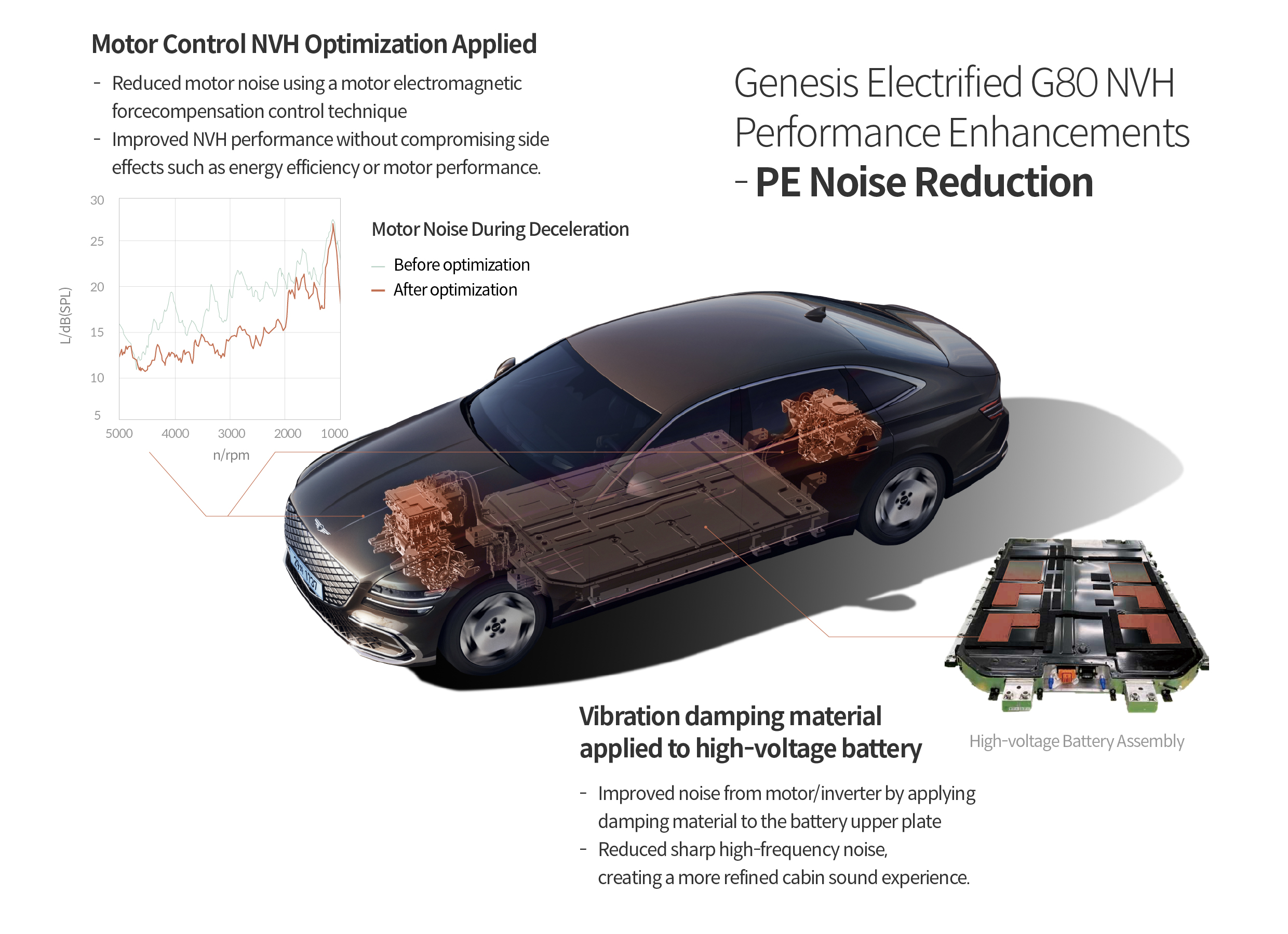

Senior Research Engineer Munsun Yoo: To reduce the noise generated by the electromagnetic force during motor operation, we applied a compensation control technique to optimize motor control. This allowed us to reduce motor noise without affecting efficiency or energy consumption. In addition to the motor, we also focused on reducing high-frequency noise from the high-voltage battery located under the vehicle. We attached damping materials to the upper surface of the battery pack to improve the cabin noise by reducing high-frequency sounds.

Q: Were there any additional measures or improvements made to enhance the NVH performance in the facelifted Electrified G80?

Senior Research Engineer Munsun Yoo: To enhance the rear-seat comfort and living space, we added several new features to the Electrified G80. One of these was the independent electric reclining seats. During this process, motor noise from the rear wheels could potentially enter the cabin and affect the overall comfort. To address this, we optimized the materials around the reclining area and strengthened the sound absorption performance to reduce the noise, ensuring the flagship sedan meets the highest standards of refinement and quietness.

As we've seen, the R&H and NVH performance improvements in the Electrified G80 were not simply about product upgrades. They represent Genesis' commitment to delivering a uniquely meaningful and elevated experience to every customer who chooses this electrified flagship sedan. Genesis will continue to offer a differentiated journey into the electrification era, ensuring its distinct passenger experience remains unrivaled.

Photography by Min-seok Choi