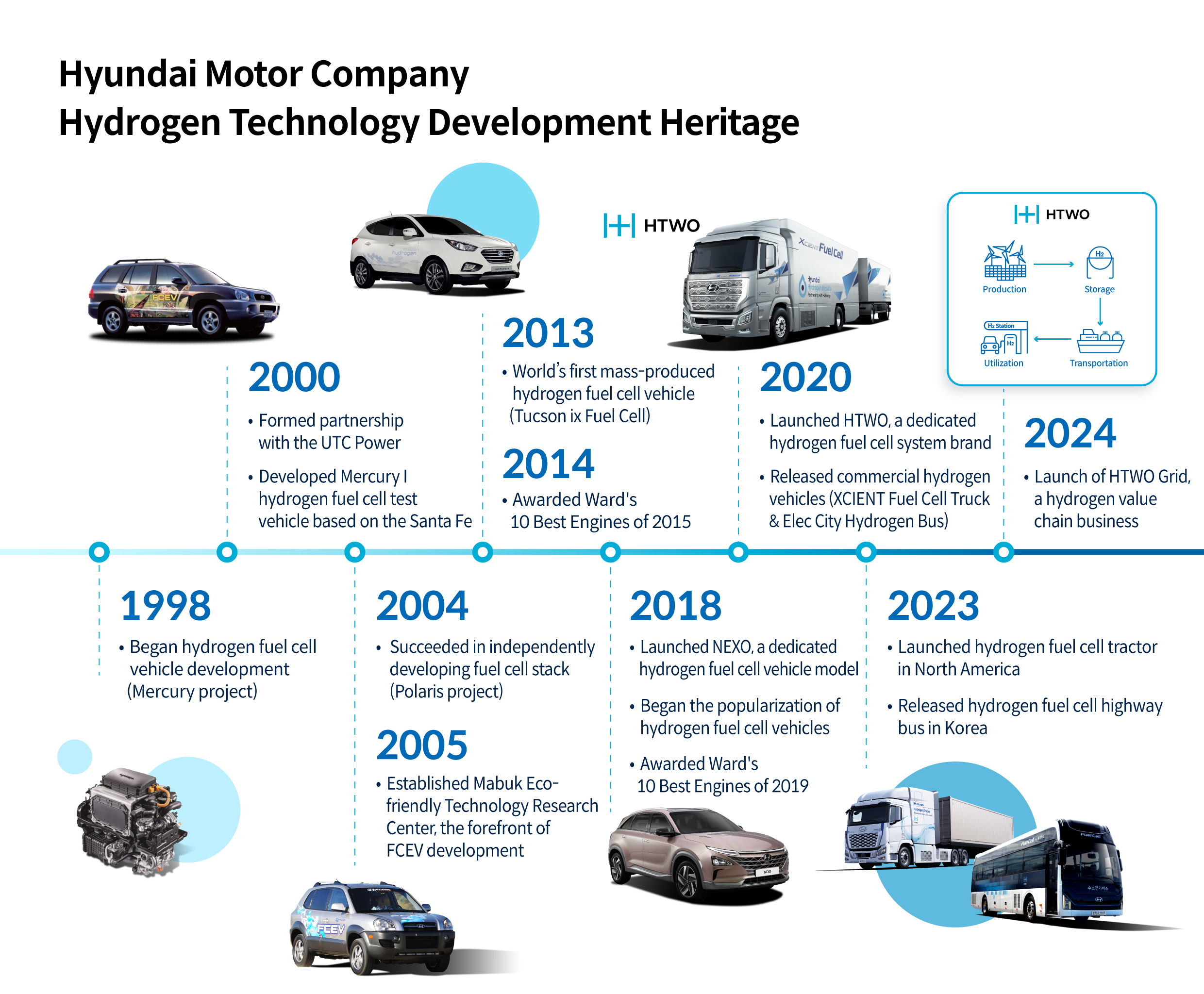

Despite uncertain success and no immediate financial gains, Hyundai decided in 1998 to pursue hydrogen fuel cell vehicle development, driven solely by the mission to build a sustainable world for future generations. This commitment empowered Hyundai to become a ‘first mover’ in the hydrogen sector, achieving milestones like the world’s first hydrogen fuel cell car and large-scale hydrogen fuel cell trucks.

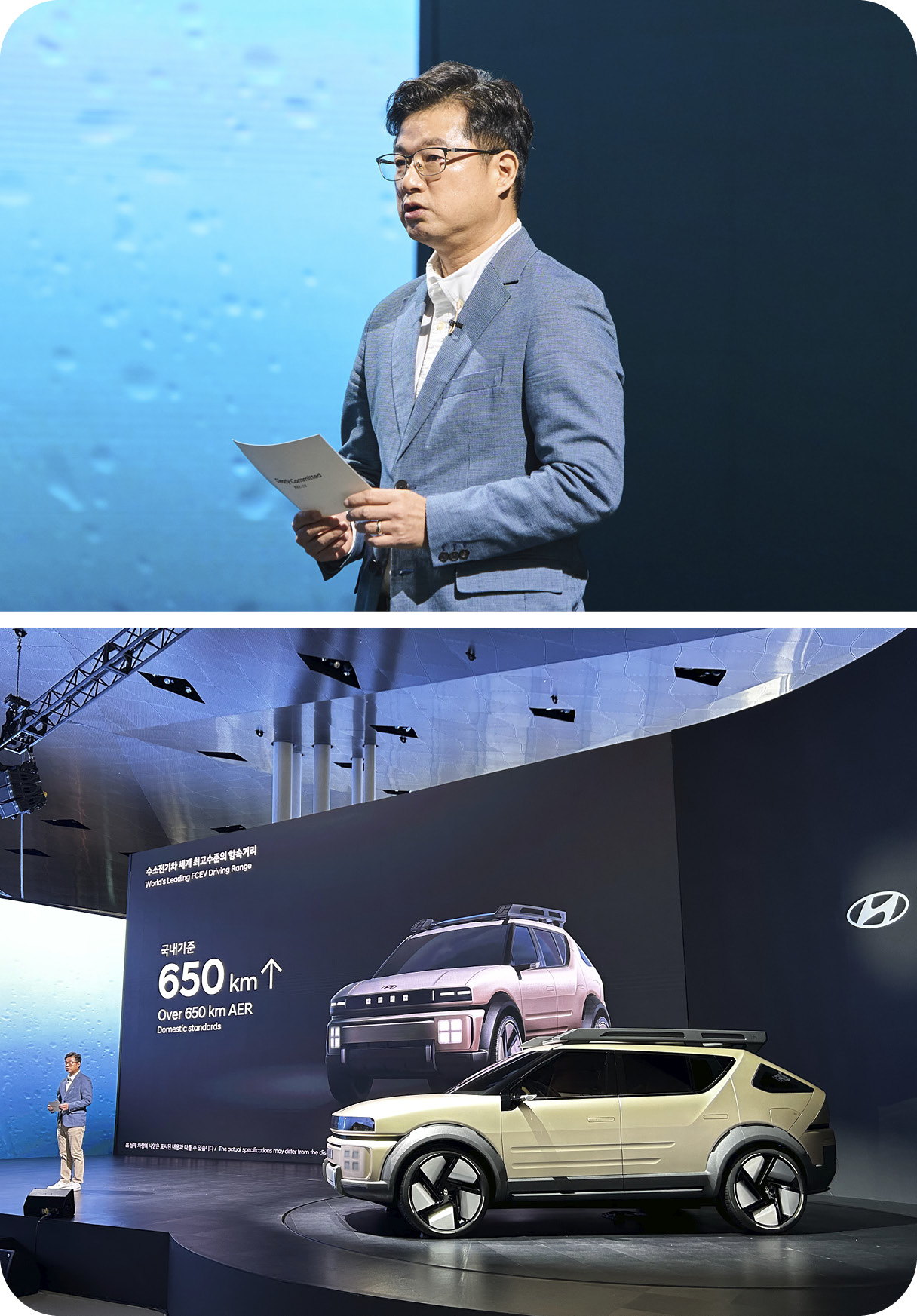

The INITIUM concept car reflects the clear and unwavering commitment Hyundai has cultivated toward hydrogen technology over the last 27 years. On October 31, Hyundai held an unveiling event titled "Clearly Committed: Unwavering Commitment" at the Hyundai Motorstudio in Goyang, South Korea. Named after the Latin word for "beginning," INITIUM symbolizes Hyundai’s aspiration to launch a prosperous future and lead the world toward a hydrogen society. The INITIUM gives a preview of design and technological features of the hydrogen fuel cell vehicles Hyundai plans to reveal next year.

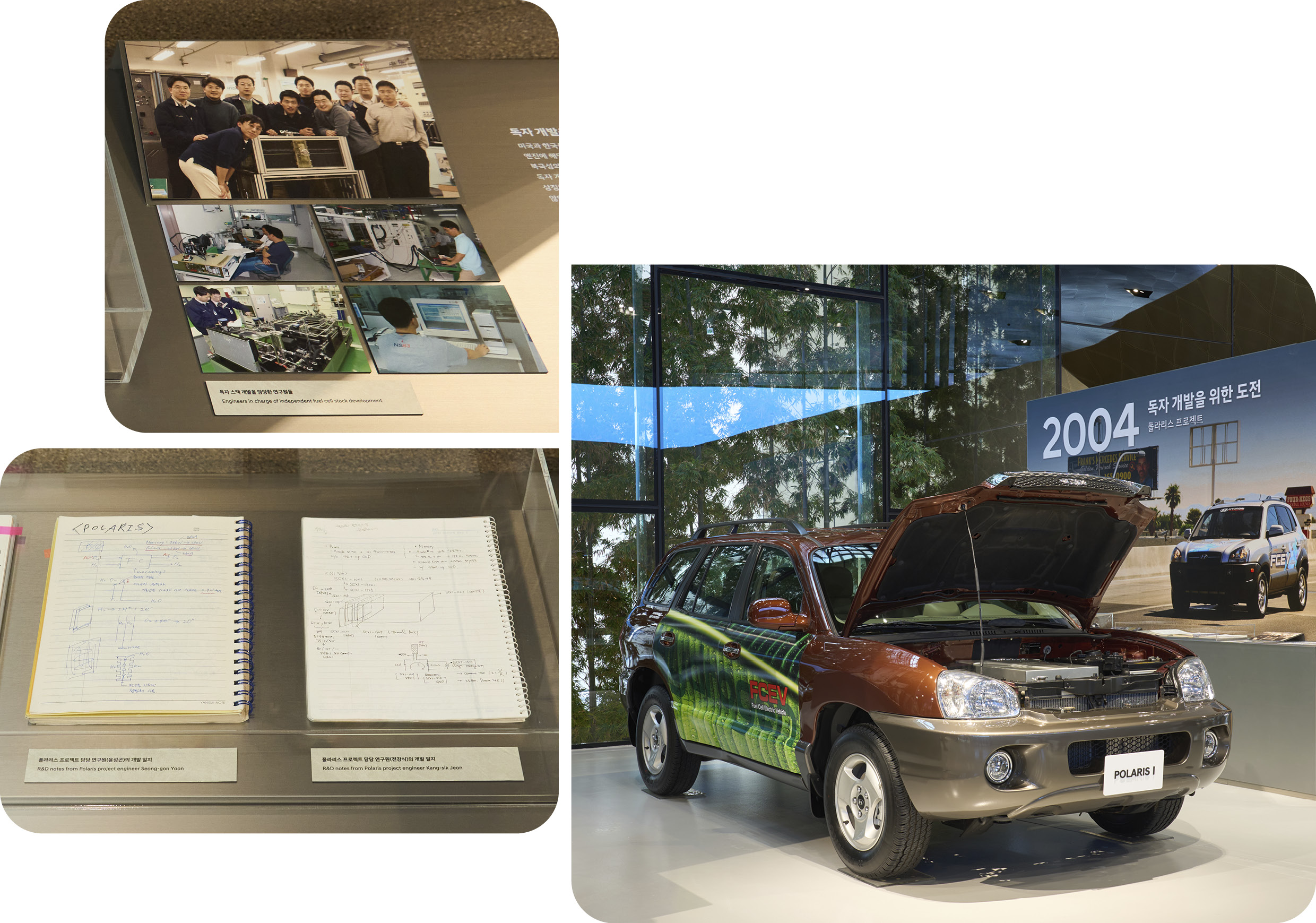

Alongside the unveiling of INITIUM, Hyundai showcased a rich exhibition illustrating its hydrogen technology journey. Photos, records, and blueprints from the time when Hyundai embarked on the hydrogen vehicle development to the actual launch of the first mass-produced FCEV NEXO—the first dedicated hydrogen fuel cell model—provided a comprehensive view of Hyundai’s 27-years of unwavering commitment to hydrogen. Hyundai’s President & CEO, Jaehoon Chang welcomed automotive media from around the world with the following address:

Hyundai’s 27-year history of hydrogen technology can be defined as a time of ‘unwavering commitment, bold moves, and unyielding resolve.’ During the Asian financial crisis and global financial crisis, we made bold moves to push forward, achieving the world’s first hydrogen fuel cell vehicle mass production. Hydrogen, as the most abundant resource on universe, is a highly accessible and fair source of energy. Hyundai believes that technological progress should improve people’s lives. With today’s concept car and our ongoing efforts, we will show you a world where hydrogen is used by everyone, for everything, and in everywhere, with all of Hyundai Motor’s capabilities and commitment.

Typically, concept cars offer a preview of upcoming models, showcasing design or technological features. The INITIUM also hints at the design and technological innovations planned for Hyundai’s next hydrogen fuel cell vehicle. “While preparing the new hydrogen fuel cell vehicle’s design for the first time in seven years, we focused on designing with the customer’s experience in mind and on aligning with our customers’ lifestyles,” said Lee as he introduced INITIUM’s design.

The INITIUM’s design incorporates a lifestyle that transitions seamlessly between urban and outdoor environments, blending ruggedness and sophistication to highlight its SUV characteristics. The EVP Lee further explained Hyundai’s new design identity, Art of Steel, developed to capture hydrogen’s dual qualities of purity and strength as an energy source:

"With INITIUM, we sought to embody the pure and resilient nature of hydrogen. We found these qualities in steel, a material central to automotive history, and approached the manufacturing process with the goal of maximizing the material’s inherent beauty. The ‘Art of Steel’ emphasizes the natural elasticity of steel, celebrating its beauty through form—a source of INITIUM’s essential aesthetic.”

As EVP Lee explained, INITIUM’s design conveys purity along with strength and ruggedness, leveraging the material properties of steel across the vehicle’s structure. The thick bumpers, voluminous fenders, large 21-inch wheels, and grooved door patterns underscore the powerful SUV appeal, while the sturdy roof rack emphasizes its versatility for both city and outdoor settings.

The hydrogen identity of the INITIUM is also evident in its seamless lamp design, achieved through cut-less technology. The iconic design incorporates the HTWO symbol, Hyundai’s hydrogen value chain business brand, reinterpreted with four dots representing the letter "H" in Morse code on the front and rear lamps and other exterior elements.

This design approach enhances INITIUM’s futuristic, high-tech appeal and highlights Hyundai’s identity. The vehicle is finished in the brilliant gold matte shade, a modern interpretation of Hyundai’s 27-year-old hydrogen heritage that symbolizes the permanence and energy of metal.

Following the design introduction, the senior vice president Jinhwan Jung discuussed INITIUM’s key technological features. He summarized the main development goals as 'extended driving range and enhanced power performance,' 'spacious interior and cargo areas for family use,' and 'unique convenience and safety features exclusive to hydrogen fuel cell vehicles.'

The SVP Jung explained that by incorporating an improved PE system, hydrogen tanks with increased storage density, hydrogen fuel cell-specific aerodynamically designed wheels, and low rolling resistance tires, Hyundai achieved a top-tier range of over 650 km (408 miles in North America). Additionally, they enhanced fuel cell and battery performance, increasing motor output to 150 kW (up from NEXO’s 113 kW), enabling acceleration from 0-100 km/h in under 8 seconds and passing acceleration from 80-120 km/h in under 6 seconds.

He also elaborated on the interior and cargo space improvements: “We enhanced second-row living space by extending legroom and headroom and increasing seat reclining angles, while adjusting rear door angles for easier entry and exit.” The trunk now accommodates up to four golf bags, thanks to an extended rear overhang and redesigned trunk space compared to the NEXO.

The INITIUM includes newly introduced convenience and safety features specifically optimized for hydrogen fuel cell vehicles. A notable feature is the hydrogen fuel cell route planner, which provides information on charging stations along the route for long trips, suggesting the optimal route. The infotainment system displays real-time information on the operational status, waiting times, and availability of charging stations.

The vehicle also incorporates V2L (Vehicle-to-Load) capability, allowing its power to be used by external electronic devices. SVP Jung explained, “A fully charged INITIUM generates about one-third of the electricity consumed by a typical household in Seoul for a month. The external power outlet is designed to directly connect to a standard 220V home outlet.”

Additionally, the INITIUM features a multi-frame front structure to protect passenger space during collisions, reinforced B-pillar construction, and nine airbags, achieving world-class collision safety performance. Advanced ADAS (Advanced Driver Assistance Systems) technologies, including a driver monitoring system using an internal camera (In Cabin Camera, ICC), and Highway Driving Assist 2 (HDA 2), have also been incorporated to enhance safety in various driving scenarios.

The event also featured a Hydrogen Heritage Zone, showcasing Hyundai’s journey in hydrogen fuel cell vehicle development, which began in 1998. Senior Vice President Changhwan Kim of Electrification Energy Solutions Tech Unit, Vice President Seoho Choi, one of the first-generation key players in Hyundai’s Hydrogen and Fuel Cell System Development Group, and research engineer Jihyun Lee born in 1998. from the FC System Design 1 Team at the Fuel Cell Development Center, conducted a heritage talk session. Their stories enriched the heritage exhibit, adding depth to the displayed artifacts.

In 1998, Hyundai turned its attention to hydrogen, a clean energy source, forming a dedicated hydrogen R&D team and launching the Mercury project. In 2000, Hyundai partnered with UTC Power, the fuel cell supplier for NASA’s Apollo 11 lunar lander, to co-develop hydrogen fuel cell vehicles. The first test vehicle, MERCURY I, co-developed with UTC Power, competed in the 2001 Michelin Challenge Bibendum and won an award, showcasing Hyundai’s hydrogen vehicle development capabilities on the global stage. A restored MERCURY II, the successor to MERCURY I, was also displayed at the event.

Vice President Choi looked back on the situation at that time: “Our goal was to complete a Fuel Cell Electric Vehicle (FCEV) within six months of starting the project. Seven researchers have been dispatched to the U.S, working day and night to build the test vehicle.” This led to the creation of MERCURY I, Nation’s first hydrogen fuel cell vehicle based on the Santa Fe, introduced domestically in 2000.

The two speakers explained that while partnering with UTC Power, Hyundai also embarked on the Polaris project, an independent initiative to develop its own hydrogen fuel cell stack. “The fuel cell stack requires high humidity for optimal hydrogen ion conductivity. UTC Power’s stack had limitations in internal humidification, which also affected its cold-start capabilities. So, Hyundai began developing a stack using external humidification. Without specialized facilities for temperature and humidity control, we used humidifiers and stacked fuel cells for over three days.”

The Mercury project used UTC Power’s hydrogen fuel cell system, with Hyundai overseeing power and vehicle control. However, Hyundai realized that mass production of hydrogen fuel cell vehicles would require independent development, prompting the Polaris project. In 2004, Polaris I was completed as Hyundai’s first vehicle with a self-developed fuel cell stack.

In 2005, Hyundai established the Environmental Technology Research Institute (Mabuk Eco-friendly Technology Research Center), accelerating hydrogen fuel cell vehicle development. It was in the same place where Hyundai’s first Independently developed engine, the α-Engine, was created. Polaris test vehicles won awards at the 2007 Michelin Challenge Bibendum and successfully completed cross-continental road tours in North America in 2008 and 2009, enhancing Hyundai’s reputation in hydrogen fuel cell technology.

Despite the 2008-2009 global financial crisis and the shift toward battery electric vehicles, Hyundai’s dedication to hydrogen research continued. SVP Kim explained:

“With a well-established ecosystem for fuel cell components in Korea, we couldn’t stop our research. Driven by a commitment to future generations who will benefit from hydrogen energy, we continued developing the metal separator stack for mass production. The result was the Tucson ix Fuel Cell. At the time, Europe was Hyundai’s FCEV technology was recognized in Europe, which still saw potential in hydrogen vehicles, so our researchers knocked on doors at public offices, ultimately selling around 1,000 units.”

Unlike the more complex graphite biopolar plates, the metal biopolar plates can be mass-produced using pressing, making it better suited for mass-production vehicles. Moreover, the system’s performance improved with a more precise flow design, generating electricity by combining hydrogen and air and releasing water as the byproduct. Control technology, honed and refined since the Polaris project, reached new heights, resulting in the world’s first mass-produced hydrogen fuel cell vehicle, the Tucson ix Fuel Cell.

Hyundai, the first automaker to mass-produce hydrogen fuel cell vehicles, unveiled the NEXO in 2018 as its first dedicated hydrogen fuel cell model, marking the beginning of widespread hydrogen adoption. The NEXO became an iconic model, integrating Hyundai’s second-generation hydrogen fuel cell system, enhanced hydrogen tank storage and durability, and a range of advanced technologies.

Hyundai’s expertise in hydrogen technology has earned high praise worldwide. The Tucson ix Fuel Cell’s 100kW fuel cell system was selected by Wards Auto as one of the 10 Best Engines of 2015, and in 2018, the NEXO’s 113kW fuel cell system was again named among the “2019 Ward’s 10 Best Engines.” Additionally, the NEXO received the highest safety rating in the Euro NCAP, underscoring its outstanding product quality.

Guided by an unwavering commitment to future generations, Hyundai’s journey in hydrogen fuel cell development continues. In 2020, Hyundai launched the HTWO brand for its fuel cell business, introducing hydrogen-powered trucks for long-distance logistics and buses for urban transit. The world's first commercialized hydrogen fuel cell electric truck, the XCIENT Fuel Cell Truck, now contributes to decarbonization efforts in Europe and the U.S., while the ELEC CITY Fuel Cell for urban use and the UNIVERSE Fuel Cell for long-haul travel operate in Korea.

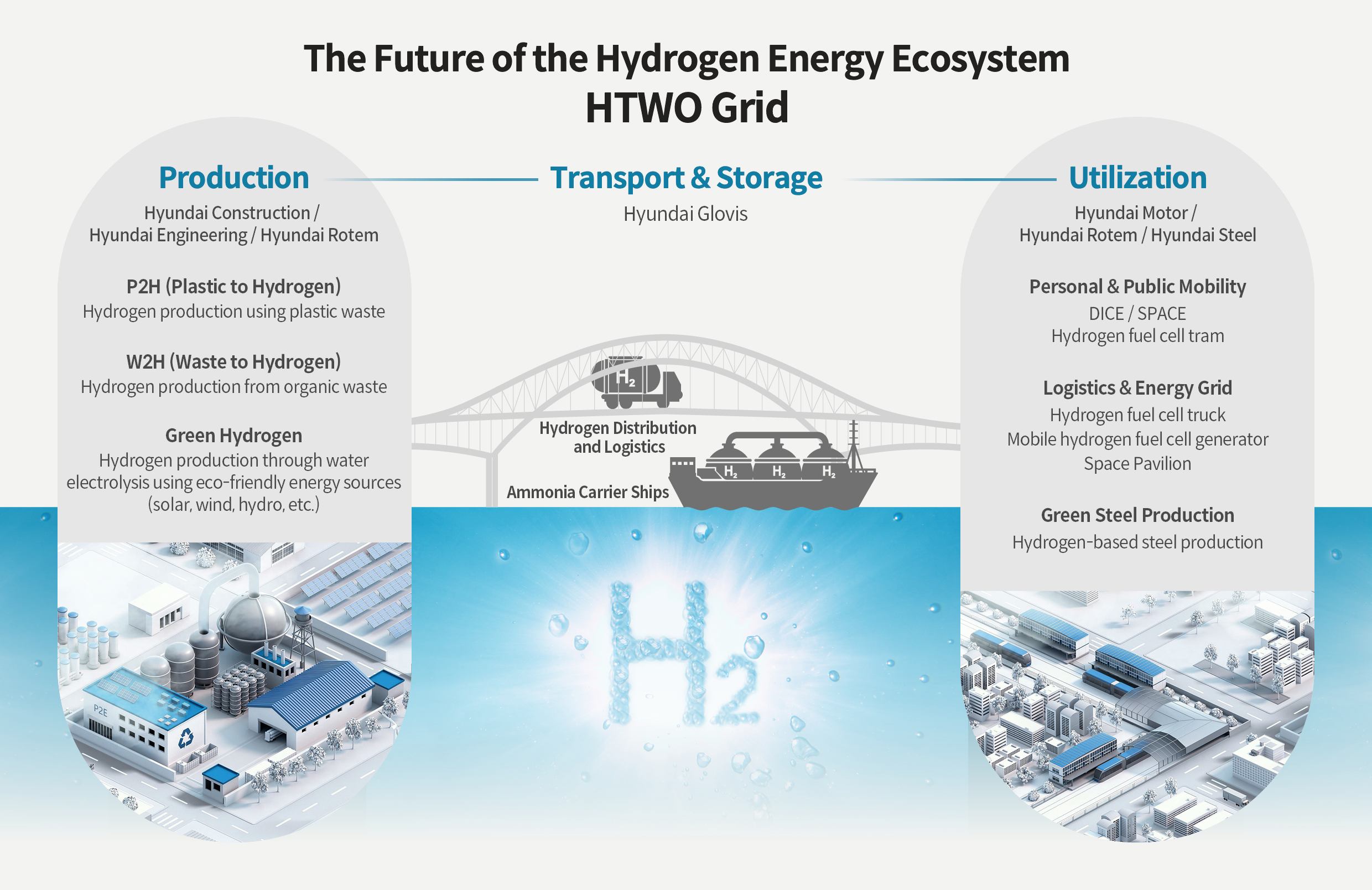

Earlier this year, at CES in the U.S., Hyundai unveiled the HTWO Grid, a customized solution applicable across the entire hydrogen value chain, from production and storage to transportation and utilization. This initiative underscores Hyundai Motor Group’s commitment, alongside Hyundai Construction, Hyundai Engineering, Hyundai Rotem, Hyundai Glovis, and Hyundai Steel, to build a robust hydrogen energy ecosystem. At the event, Hyundai displayed a model of the HTWO Grid, showcasing their comprehensive hydrogen vision from production to utilization.

The INITIUM represents Hyundai’s 27-year journey of unwavering commitment and heralds a new beginning. While the NEXO led the way in popularizing hydrogen fuel cell vehicles, the INITIUM serves as Hyundai’s declaration of leadership in ushering in a hydrogen society. The design and innovative technologies presented in INITIUM will carry forward into the hydrogen fuel cell vehicles Hyundai plans to launch next year. Many eagerly anticipate the next generation of hydrogen fuel cell vehicles, as Hyundai continues to build hydrogen society infrastructure around the world.

Photography by Hyuk-su Cho