On September 30, 2024, Hyundai marked its 100 millionth vehicle produced globally, a landmark achieved 57 years after the company’s founding. This milestone underscores Hyundai’s evolution into a leading force in the era of electrified mobility. Hyundai reached 1 million units in 1986, then surged to 10 million by 1996. Rapid growth followed, with milestones at 50 million in 2013, 80 million in 2019, 90 million in 2022, and finally, 100 million in 2024. Hyundai’s journey to this achievement—just 57 years—places it among the fastest in global automotive manufacturing.

To commemorate this milestone, Hyundai held a special event on September 30, 2024 at the Ulsan plant, celebrating the rollout of the IONIQ 5 as the 100,000,001st vehicle. Following this, the exhibition, "One Step Further"

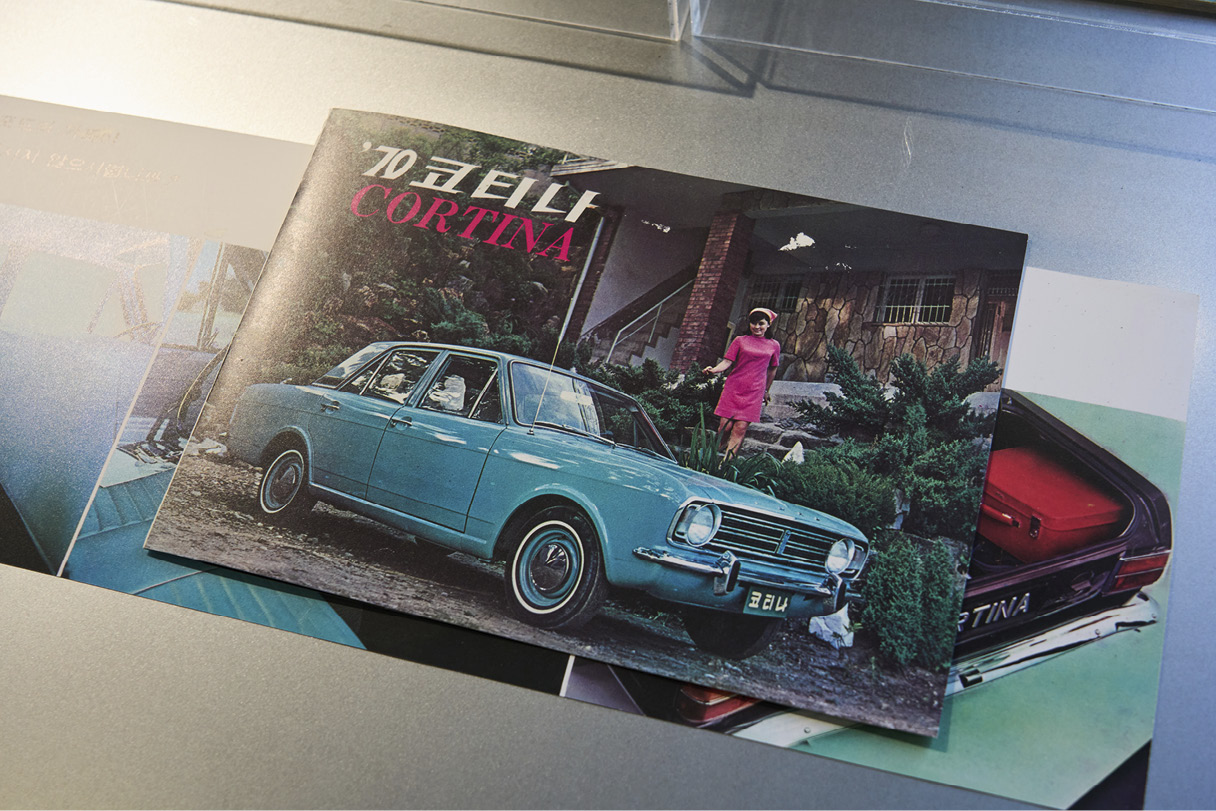

"One Step Further" fills all five floors of Hyundai Motorstudio Seoul with interactive exhibits. On the first floor, visitors are greeted by Hyundai’s earliest models—the Cortina, the first vehicle assembled by Hyundai, and the Pony, its first proprietary model. This floor, themed The First Step, highlights Hyundai’s beginnings as it transformed from an assembly operation to a full-fledged automaker. Surrounding these iconic cars are displays featuring images of the original Ulsan plant, Cortina brochures, and export records of the Pony to Ecuador, offering a look into Hyundai’s early history.

Founded in 1967, Hyundai completed its Ulsan plant in 1968 and began producing Ford’s compact sedan, the Cortina, using the CKD (Complete Knock Down) method. CKD involves importing parts from abroad and assembling the vehicle domestically. However, the Cortina, not suited to Korea’s road conditions, often encountered breakdowns, highlighting the limitations of assembly-based production. This experience spurred Hyundai to develop its first model, the Pony.

In 1976, the Pony’s launch was a pivotal event that firmly established Hyundai as a full-fledged automaker. Designed to suit Korean drivers and road conditions, the Pony was easy to maintain, making it an instant hit. In its debut year, it sold 10,726 units, capturing 43.6% of the domestic market and becoming Korea’s top-selling model. That same year, the Pony was exported to Ecuador and other countries, establishing Korea as a car-exporting nation. The Pony on display at this exhibition was re-imported in 1996 from Ecuador, where it had served as a taxi, in celebration of the 20th anniversary of Pony exports.

Moving up the central staircase to the second floor, visitors find Hyundai’s production advancements documented under the theme “The Journey to 100 Million.” This section traces Hyundai’s evolution, from the early days of assembly to today’s cutting-edge smart manufacturing systems. A key highlight here is an assembly process called unitization, where workers moved vehicles along assembly lines, installing components individually. Photos and audio recordings of Hyundai’s employees provide visitors with an immersive look into Hyundai’s production history.

Ahead of Pony production, Hyundai introduced a conveyor belt system at the Ulsan plant, establishing a modern mass-production system that improved assembly speed and efficiency. The second-floor wall displays images of Pony production at Ulsan plant and the diorama of the initial prototype assembly, capturing visitors’ interest.

The 1990s and 2000s marked an era of both qualitative and quantitative growth in Hyundai’s production technology. In 1990, Hyundai incorporated automated processes at Ulsan Plant 3, enhancing worker safety and production efficiency and achieving the milestone of 1 million units per year. Hyundai expanded its reach by constructing additional plants in Jeonju and Asan in Korea and establishing production bases in the U.S., India, the Czech Republic, Turkey, and other global locations.

In Singapore, HMGICS is producing the IONIQ 5 through its smart manufacturing system.

In the 2020s, Hyundai introduced a new vision for automotive manufacturing. The Hyundai Motor Group Innovation Center Singapore (HMGICS), completed in 2023, exemplifies this vision. Here, a smart manufacturing system replaces the traditional conveyor belt, organizing production by “cells.” In this oval-shaped facility, human-robot teams flexibly produce a range of models tailored to customer orders. The advanced technologies—AI, robotics, and smart factory platforms—employed here will enhance production efficiency at Hyundai’s future Georgia-based HMGMA (Hyundai Motor Group Metaplant America) and the dedicated EV plant in Ulsan.

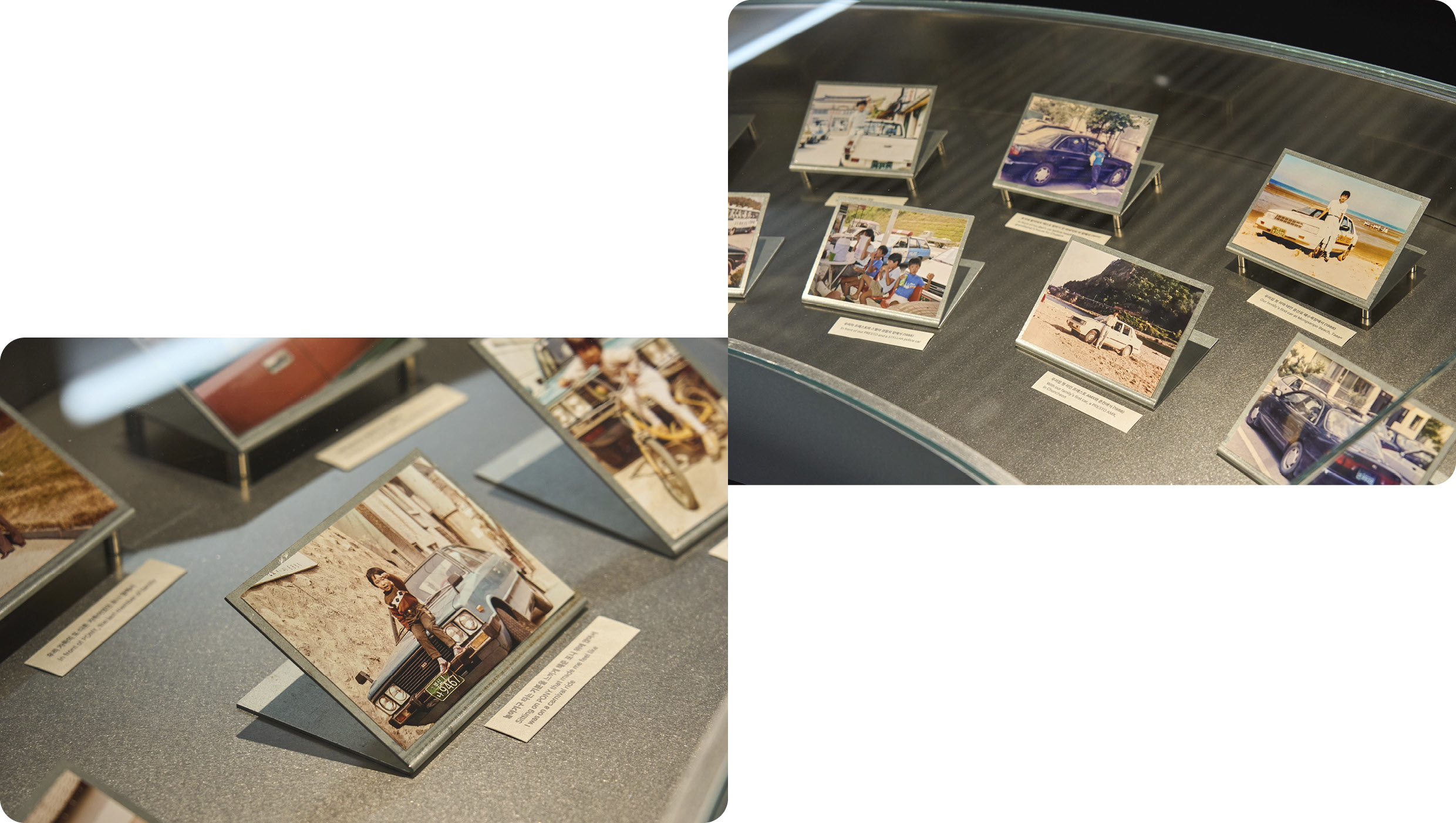

On the right wall of the second floor, visual displays showcased Hyundai’s advanced manufacturing technologies, including a model of HMGICS's cell production system and blueprints for the dedicated EV plant in Ulsan, enriching the exhibit experience. At the center of the floor, a photo gallery highlighted customer memories, underscoring the significance of reaching 100 million vehicles.

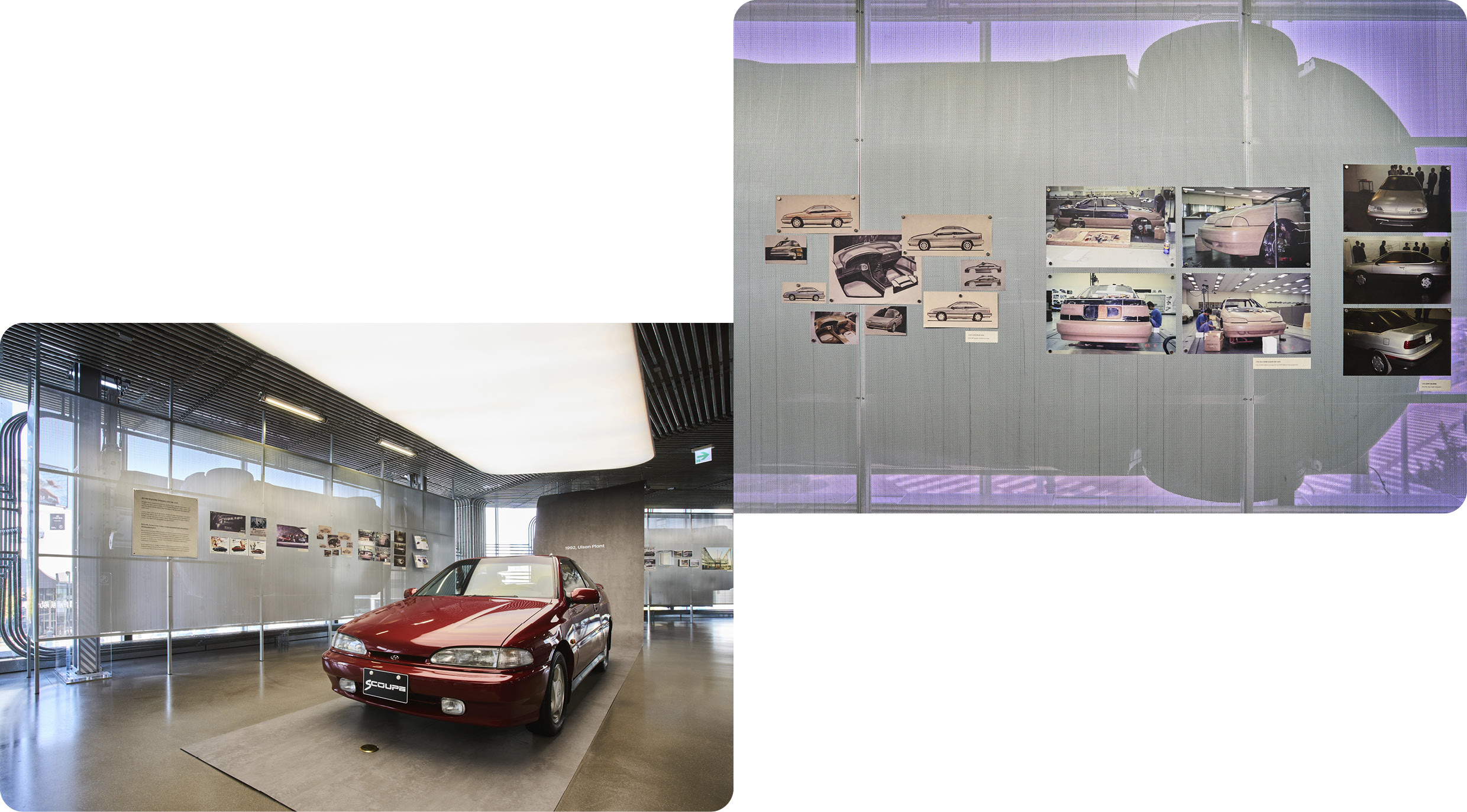

The third floor, themed “The Drive to 100 Million: One Step Further,” displayed heritage models that laid the foundation for Hyundai’s milestone. Featured were meticulously crafted, original designs, including the first-generation Sonata, the two-door Coupe Scoupe with Hyundai’s own first engine, and the Elantra(Avante), produced using advanced automation. The first-generation Sonata, a proud symbol of Korea’s middle class, stood out for its quality, achieved by incorporating domestically produced parts that matched local standards.

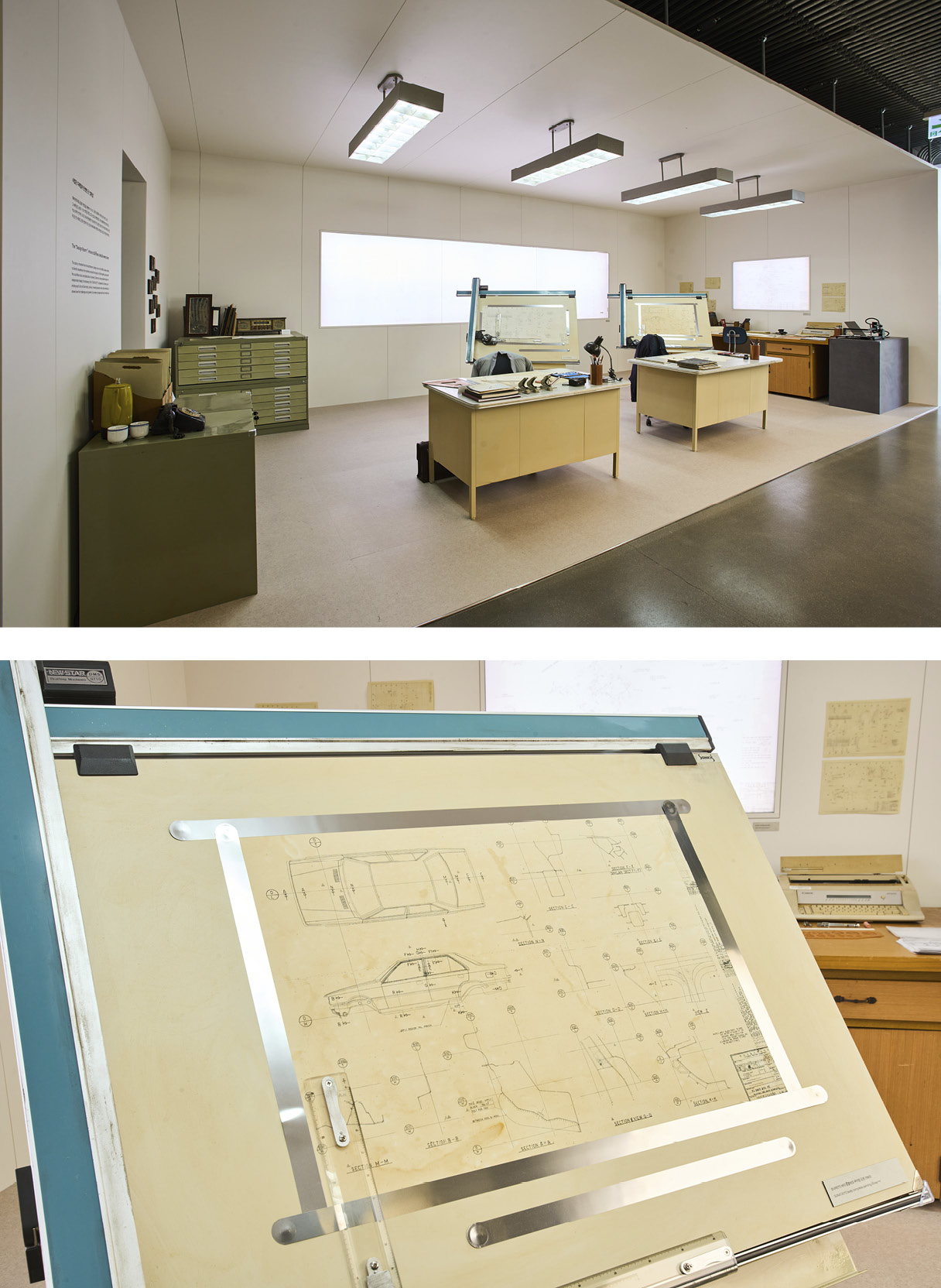

In one corner of the third-floor display area, a recreated 1980s Hyundai design office showcases the development process for the first-generation Sonata’s full-scale and parts blueprints. Outfitted with original tools and furniture used by Hyundai’s draftsmen of the era, the space vividly conveys the dedication and craftsmanship behind each line and dot—values that fueled Hyundai’s journey to 100 million vehicles and the heritage models that made it possible.

The Scoupe stands as a vital milestone in Hyundai’s history. Its streamlined exterior, developed entirely in-house, showcased the latest design trends of its era, marking Hyundai’s shift from relying on Italian studios to establishing its own design capabilities.

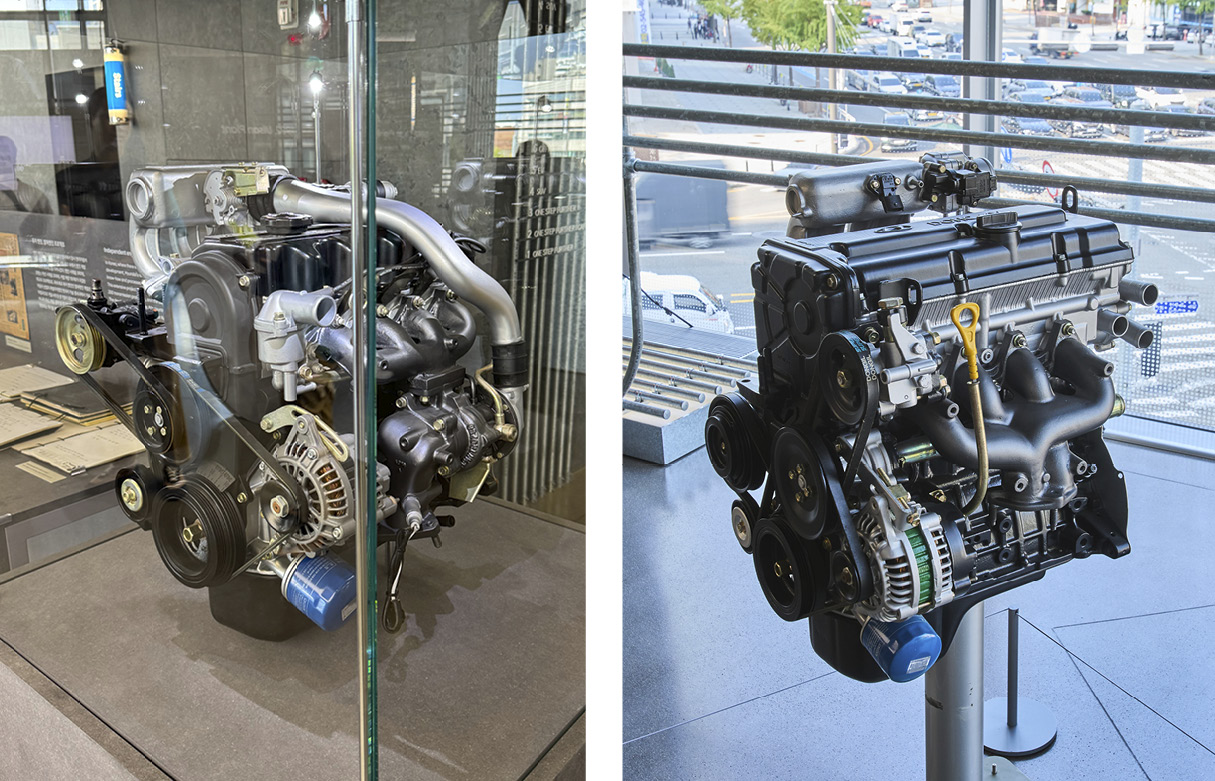

The Scoupe’s most significant technical achievement was the introduction of the Alpha engine, the first engine independently developed by Hyundai. Launched in 1991, the Alpha engine was a cutting-edge 1.5L MPi, representing Hyundai’s historic accomplishment in powertrain technology. The engine’s performance was also impressive: the Scoupe, powered by the Alpha engine, accelerated from 0 to 100 km/h in 10.4 seconds (naturally aspirated), 0.6 seconds faster than comparable Japanese models, and achieved fuel efficiency of 20.2 km/L at 60 km/h, surpassing its competitors’ 19.4 km/L.

The development of the Alpha engine spurred advancements in casting, machining, and manufacturing, furthering Hyundai’s technological capabilities. The exhibit includes Alpha engine samples and related materials beside the Scoupe, emphasizing its significance as Hyundai’s own first engine.

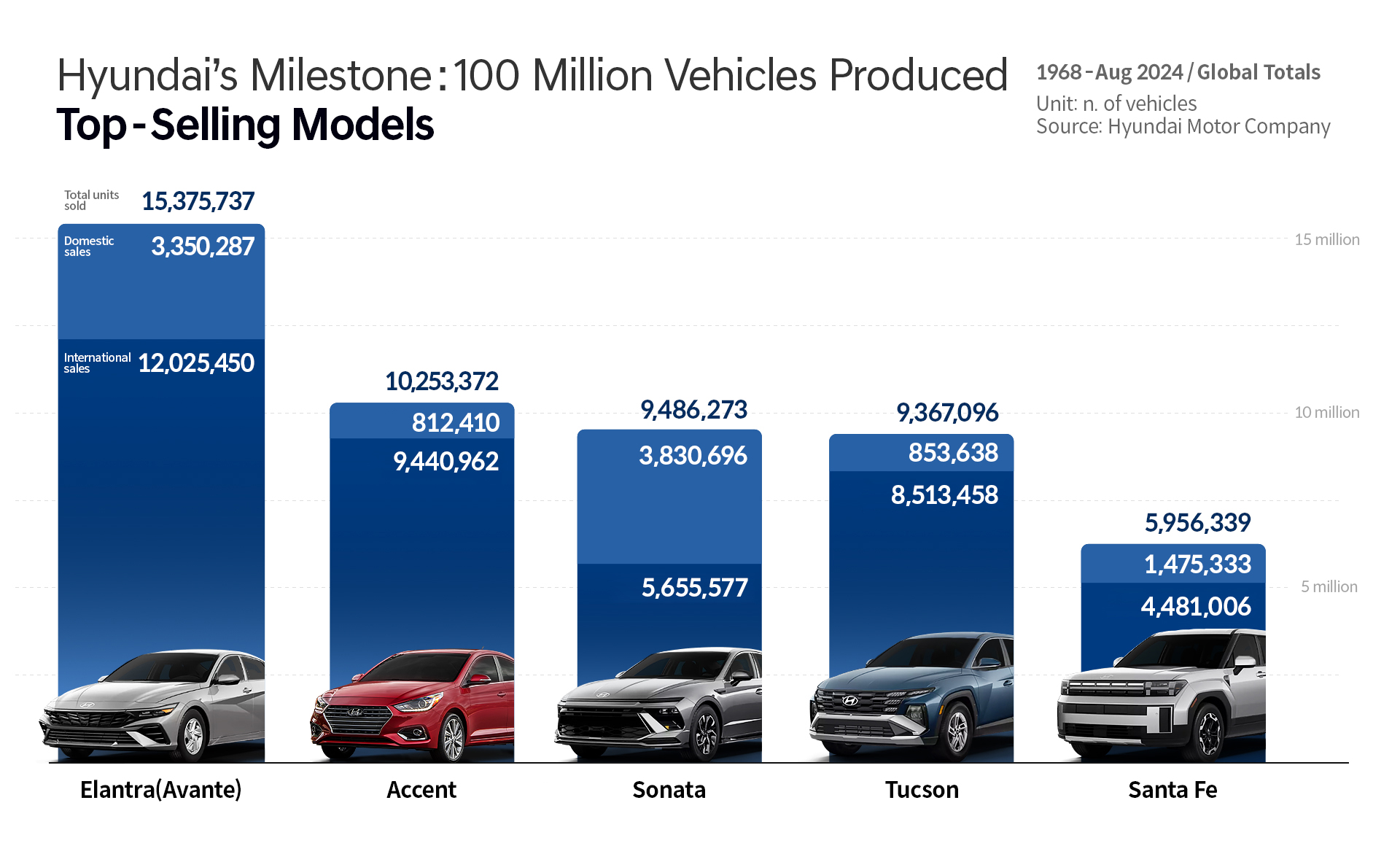

The Elantra holds a historic place in Hyundai’s lineup as a pioneer in the compact sedan segment in Korea. It also marked the first model in Hyundai’s best-selling Elantra series, with over 15.3 million units sold as of August 2024. The Elantra made waves upon its release with powerful performance, featuring a 1.6L DOHC engine with a maximum output of 126 horsepower, and introduced top-notch features like an LCD instrument cluster.

Thanks to its impressive features, the Elantra saw 56,943 units exported in its first year, 1991, with a total of around 370,000 units shipped overseas before it was discontinued. This exhibition not only displays the popular burgundy-colored Elantra, a favorite among customers, but also showcases scenes from its automated production process and vintage newspaper ads, evoking nostalgia for many Elantra enthusiasts.

The fourth and fifth floors focus on Hyundai’s present and future, showcasing its SUV lineup and electric vehicles as it aims for the next 100 million. The fourth floor features the globally popular mid-size SUV Santa Fe, along with the small electric SUVs Kona Electric and Inster(Casper Electric), with the long-standing Santa Fe taking center stage.

Debuting in 2000, the first-generation Santa Fe was Hyundai’s first urban SUV. This model featured a monocoque structure, built on a front-wheel-drive mid-size platform. In Korea’s automotive market, where body-on-frame SUVs were the norm, the Santa Fe successfully combined the driving feel of a passenger car with the practicality of an SUV, quickly gaining popularity with consumers. It also became a bestseller in global markets, including North America, with cumulative sales reaching 5.95 million units from the first through the fifth generation as of August 2024.

*Monocoque: A structure where the body and frame are integrated

*Body-on-frame: A structure where the cabin is placed on a frame that houses the engine, powertrain, and suspension.

The Santa Fe on display is the fifth-generation model, optimized for outdoor lifestyles with enhanced tailgate functionality and maximized interior space. In front of the Santa Fe display features the design development spanning all five generations, while behind the vehicle is a setup recreating auto camping, underscoring the Santa Fe’s versatile character for both urban and outdoor adventures.

This floor features Hyundai’s 30-year legacy of electrification alongside flagship EVs, the IONIQ 5 and IONIQ 6. The electrification heritage section showcases the development of key models like a modified second-generation Sonata EV, the first-generation i10-based production EV BlueOn, and RoboTaxi prototypes, offering visitors a clear view of Hyundai’s progress in electrification technology over the decades.

The IONIQ 5 and IONIQ 6, Hyundai’s flagship EVs embodying its advanced electrification, drew much interest from visitors, especially those intrigued by new models. These vehicles represent major milestones in Hyundai’s shift toward electrified mobility and have driven significant growth in Korea’s EV market. Through this floor, the exhibit highlights that Hyundai’s globally recognized electrification achievements were built on years of steady innovation.

As shown throughout, Hyundai’s journey to 100 million units has been marked by relentless innovation. Each pioneering step forward is remembered as a journey of bold exploration and growth. This exhibit, "One Step Further"

Photography by Hyuk-soo Jo