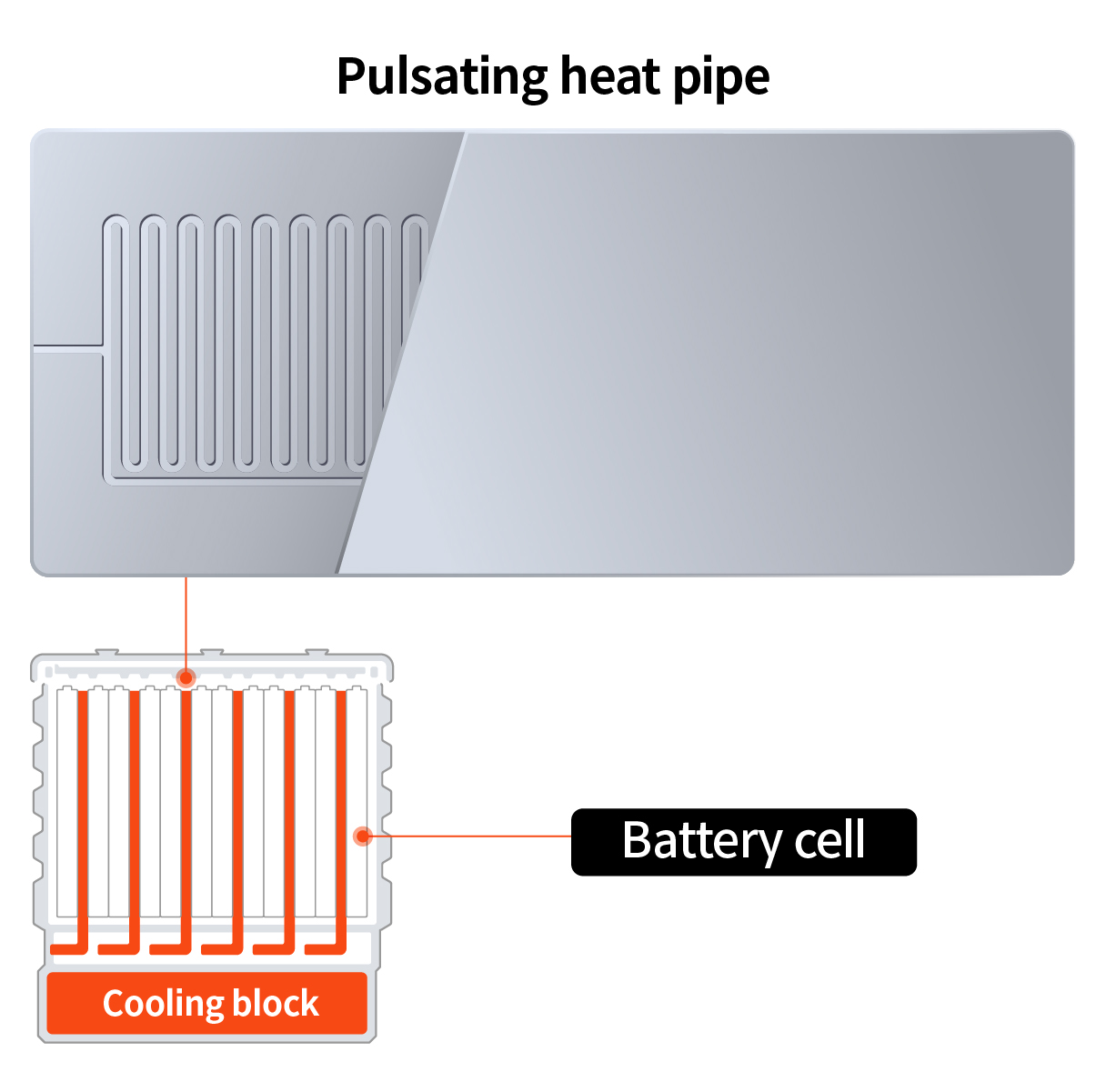

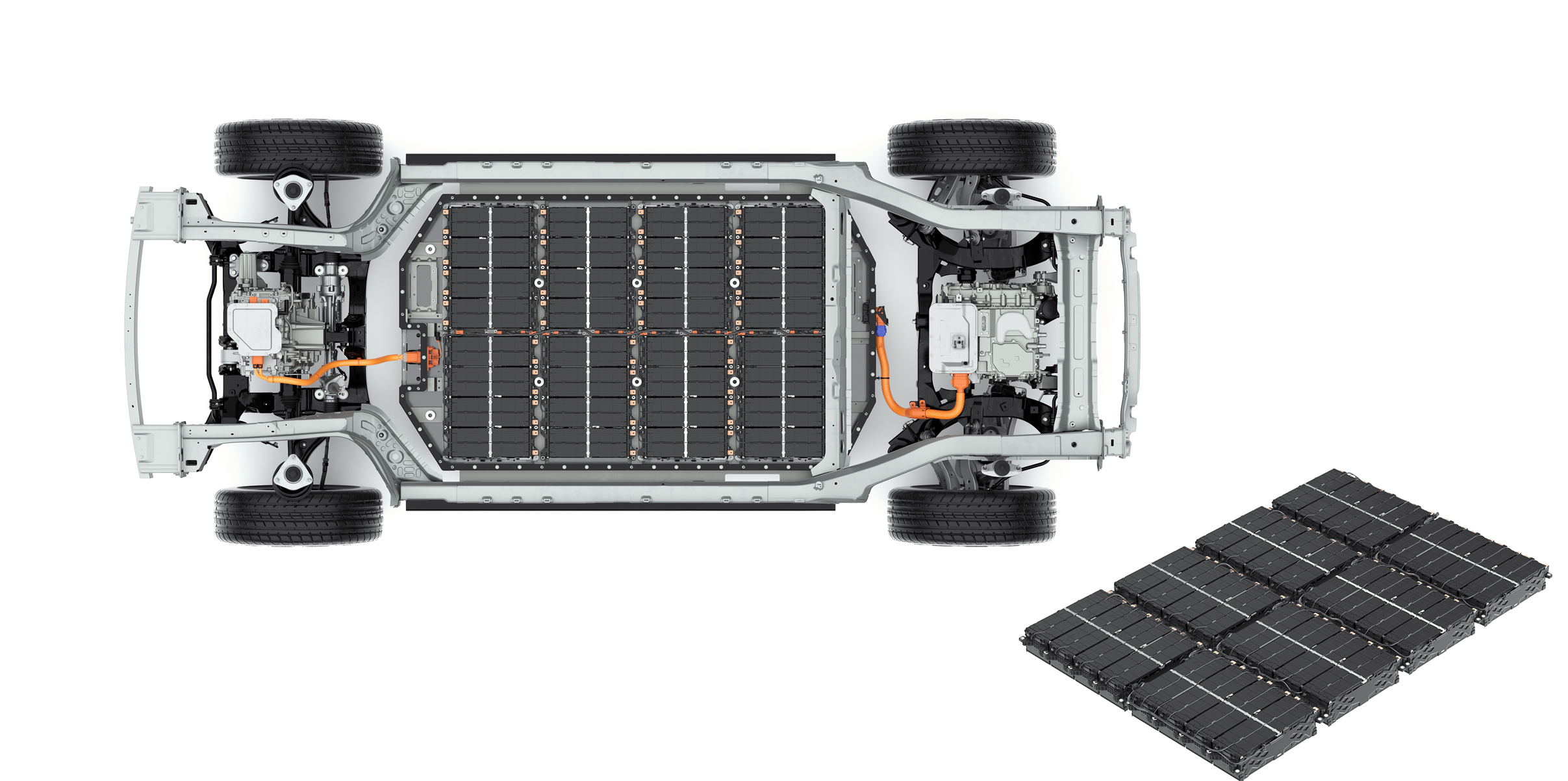

Recently, Hyundai Mobis introduced a new cooling material for battery cells called the “Pulsating Heat Pipe (PHP).” This technology rapidly and evenly disperses the heat generated within a battery cell during fast charging, thanks to its high thermal conductivity. By placing a pulsating heat pipe—known for its exceptional heat transfer performance—between individual battery cells, this system helps lower cell temperatures. As a result, it can greatly enhance battery performance and extend battery life.

By maximizing battery performance through pulsating heat pipe technology, battery temperatures can be maintained at more stable levels, which increases an electric vehicle’s driving range. Shorter charging times also improve user convenience and provide a more comfortable experience for EV drivers. Let’s take a closer look at Hyundai Mobis’s pulsating heat pipe, a cutting-edge cooling solution set to elevate the future competitiveness of mobility.

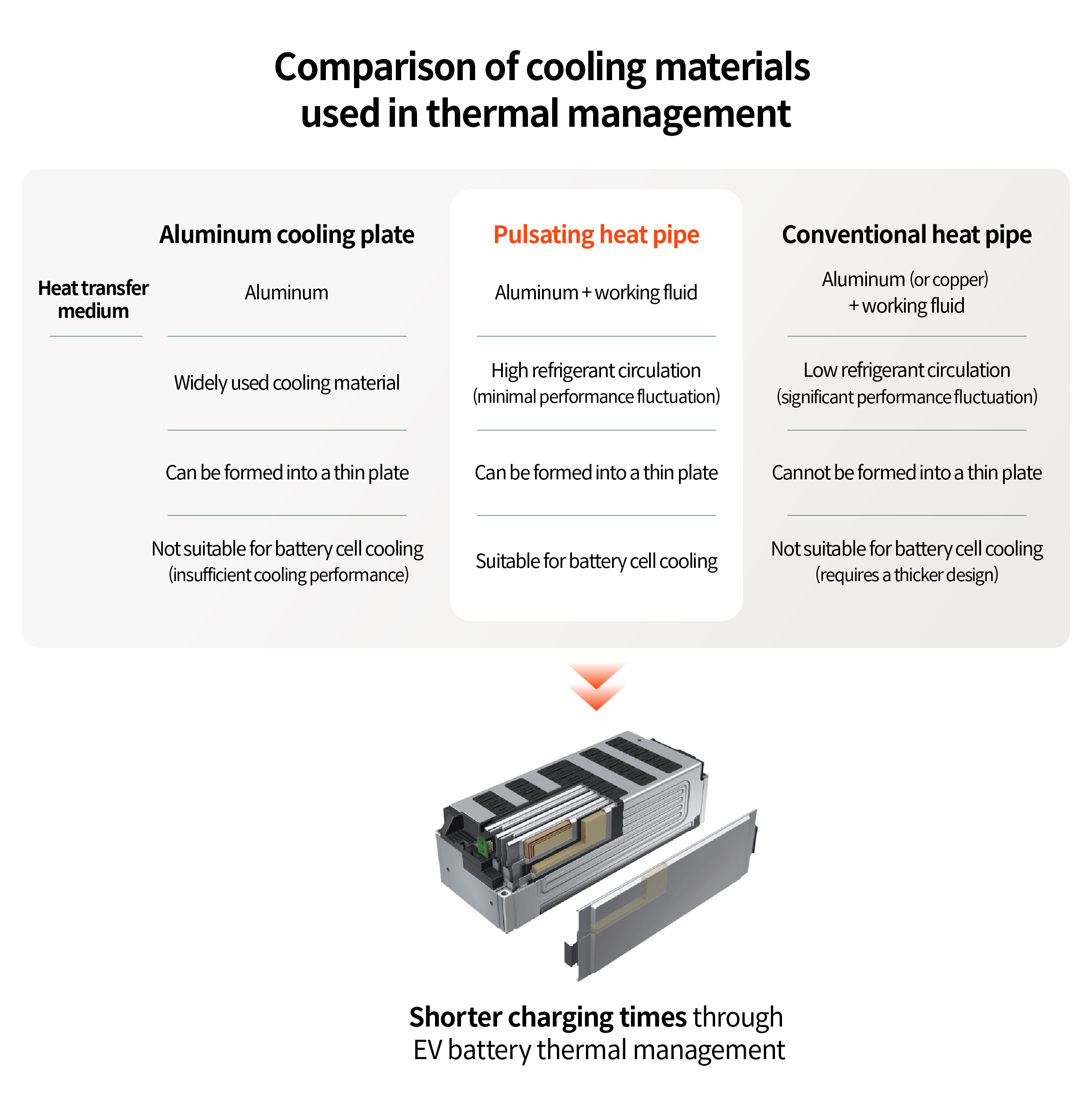

Hyundai Mobis developed the pulsating heat pipe specifically to manage the heat produced in a battery cell during ultra-fast charging. Traditional cooling methods have struggled to fit effectively into the narrow space between cells. For instance, aluminum cooling plates are popular in various applications due to their easy fabrication into thin, flat plates, but their heat dissipation performance is only about 10% that of a standard heat pipe—making them insufficient for use with battery cells. Meanwhile, conventional heat pipes offer higher performance than aluminum cooling plates but are typically too thick for battery cell applications.

Hyundai Mobis’s pulsating heat pipe overcomes these drawbacks. Like an aluminum cooling plate, it can be formed into a thin, broad plate, allowing it to fit between battery cells. Moreover, the pulsation of its refrigerant ensures smoother circulation compared to a conventional heat pipe, delivering superior heat transfer capabilities. The result is a new heat pipe optimized for battery cell applications.

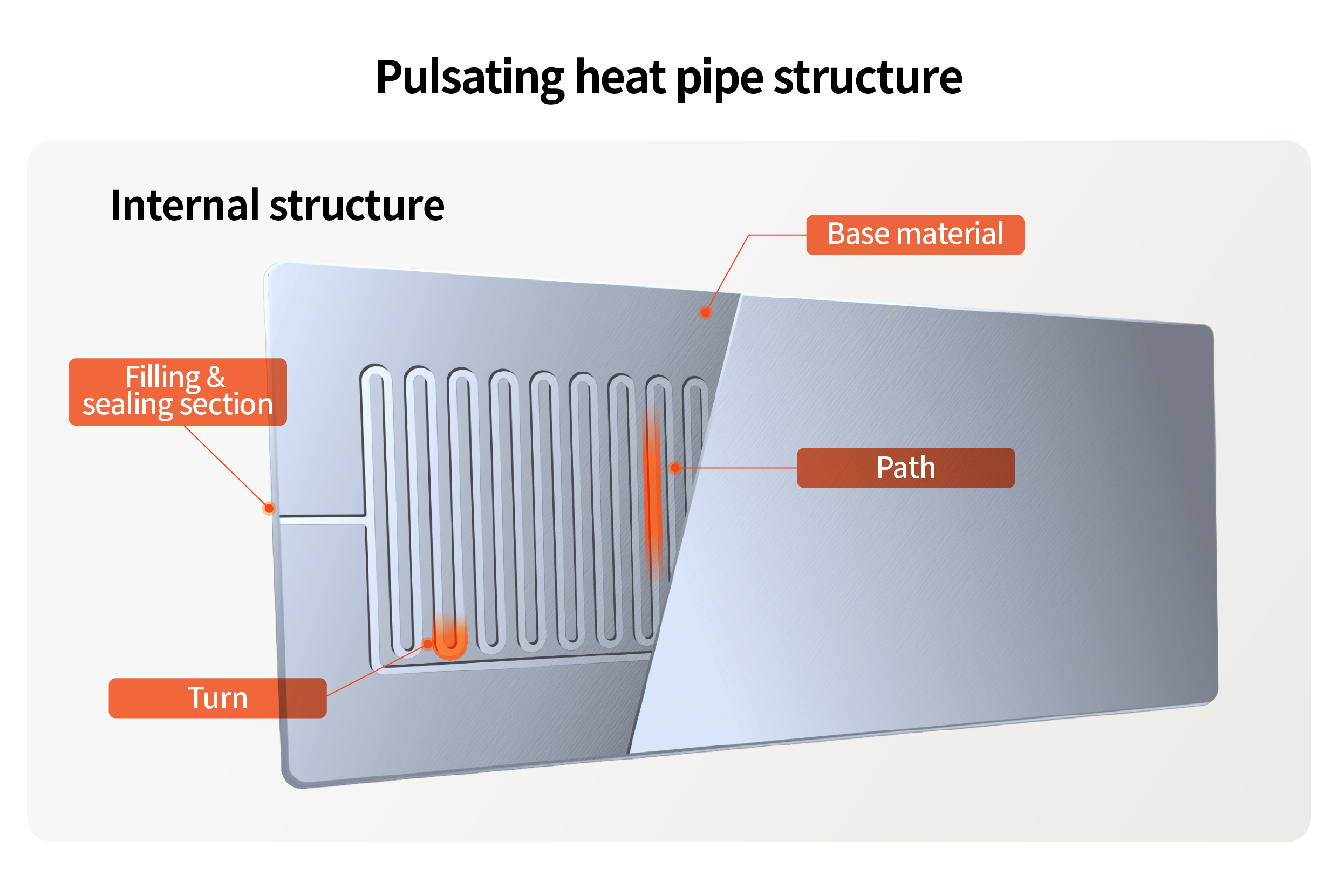

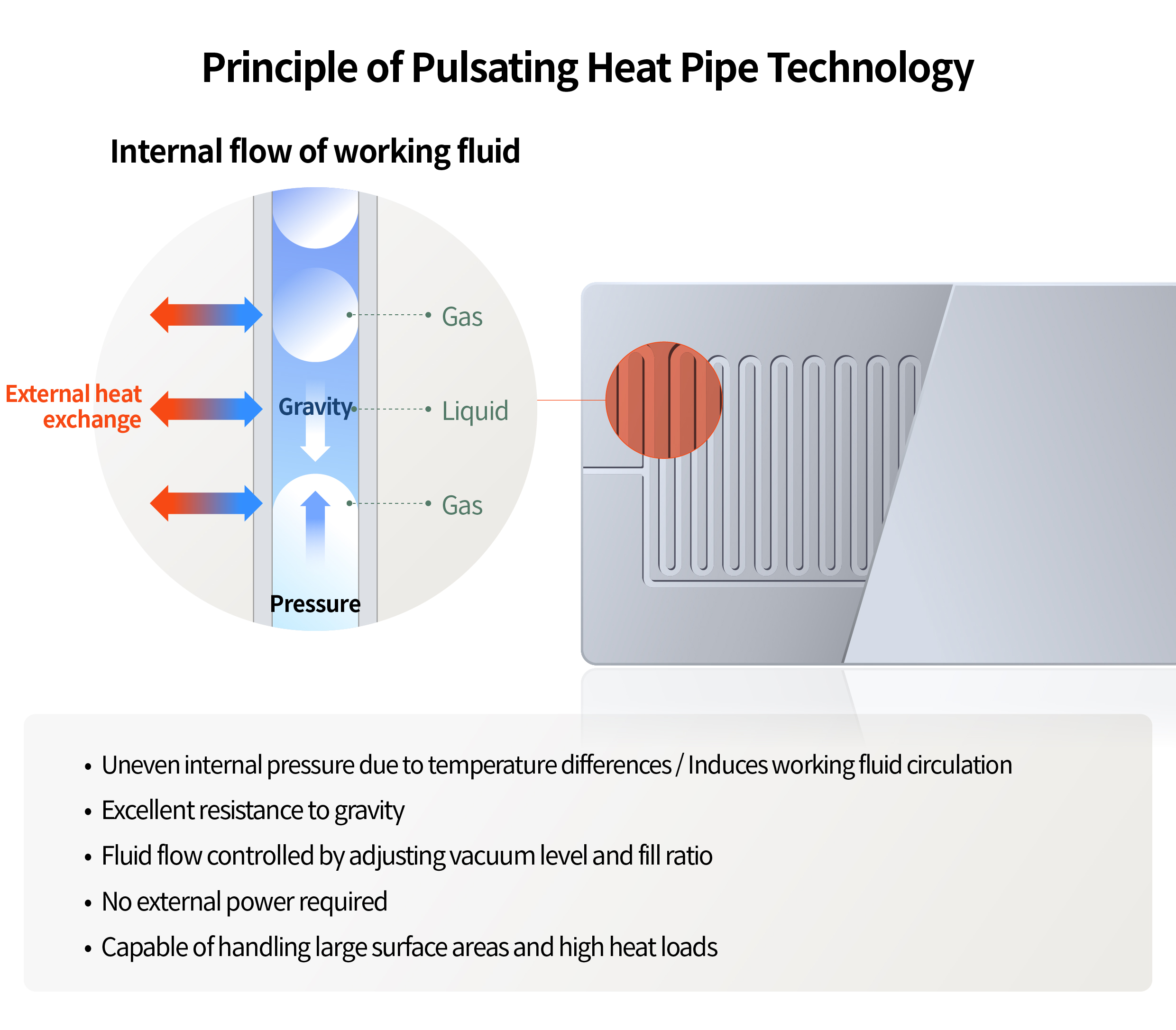

How exactly does the refrigerant in the pulsating heat pipe vibrate and circulate? The pulsating heat pipe uses an air-conditioning refrigerant as its working fluid. Placed inside a vacuum-sealed heat pipe, the refrigerant is enclosed under low pressure—similar to how bubbles form when water boils. As the refrigerant vaporizes, the resulting vapor pressure causes it to vibrate within the sealed interior, traveling through the internal channels.

The refrigerant vibrating and expanding inside the pulsating heat pipe

Notably, the pulsating heat pipe doesn’t require the high temperatures needed to boil water. Like water boiling at lower temperatures at high altitudes due to reduced atmospheric pressure, lowering the pressure inside the system decreases the boiling point. The pulsating heat pipe leverages this principle by creating a vacuum environment that encourages the refrigerant to vaporize and circulate more efficiently. This key difference sets the pulsating heat pipe apart from conventional heat pipes.

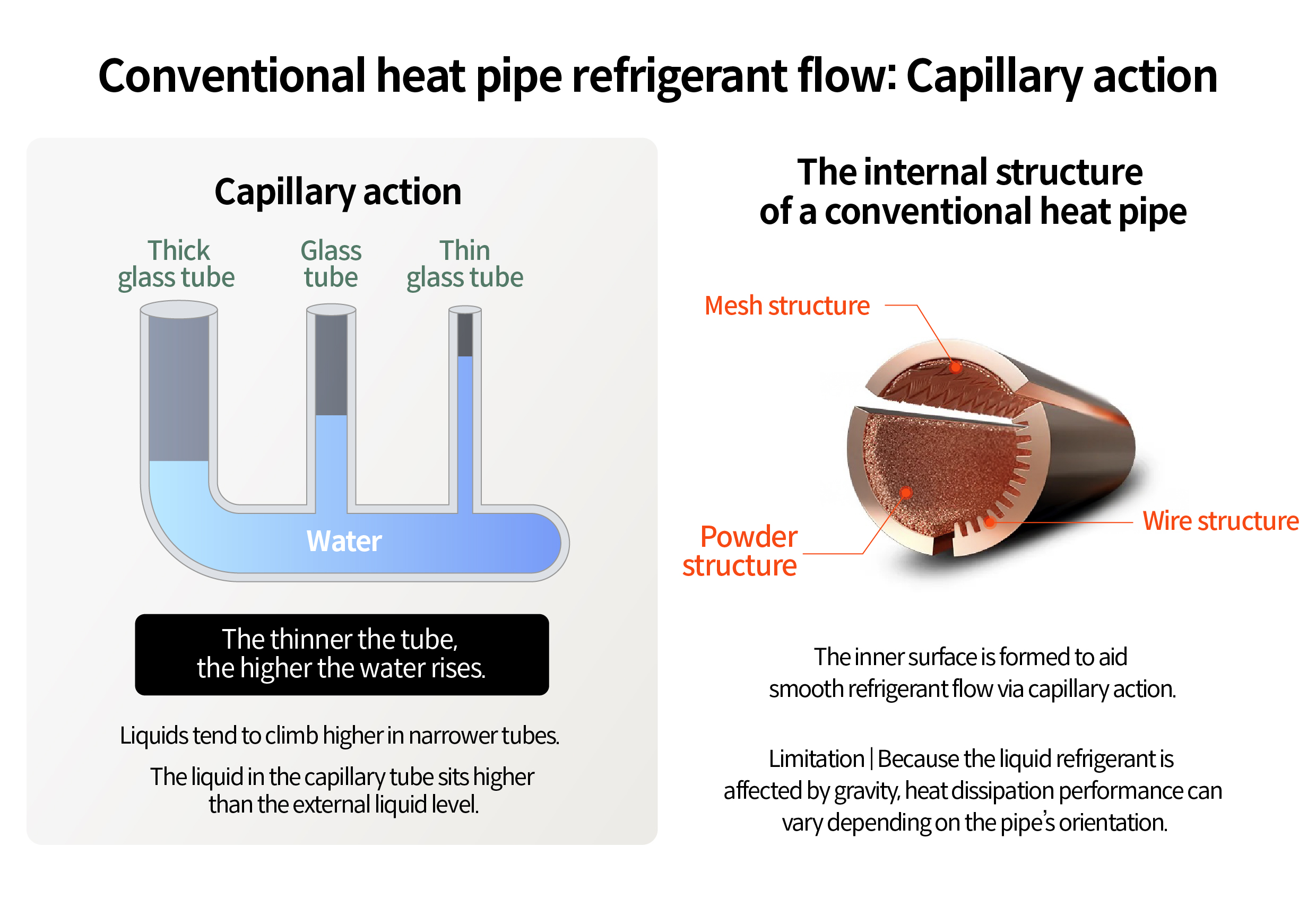

First, let’s look at how a conventional heat pipe works. Much like an air conditioner, the refrigerant inside a typical heat pipe absorbs heat from its surroundings when it changes from a liquid to a gas, thereby lowering the local temperature. Once in its gaseous form, the refrigerant releases heat at the condenser section as it returns to a liquid state—similar to how an air conditioner’s outdoor unit expels hot air. In simple terms, the refrigerant repeatedly transitions between liquid and gas phases, absorbing and releasing heat in the process.

However, conventional heat pipes have structural limitations. Typically, the evaporator section (where the refrigerant vaporizes) must be located at the top, and the condenser section (where the vaporized refrigerant returns to liquid) must be at the bottom. This is because the refrigerant travels via capillary action, the same principle that causes the surface of a drink in a thin straw to sit higher than the liquid in the cup, or that draws perfume up a diffuser stick to spread its scent. But the downside of relying on capillary action is that liquid refrigerant is heavily influenced by gravity, causing differences in performance depending on how the evaporator and condenser are positioned.

In contrast, the pulsating heat pipe doesn’t rely on capillary action. Instead, its internal environment is set up so the refrigerant vaporizes and vibrates easily, allowing the fluid to circulate more freely. The force generated by the refrigerant’s expansion far exceeds gravity, so there is virtually no drop in performance due to gravitational effects. Meanwhile, the repeated vibration and circulation help distribute heat evenly, leading to outstanding thermal conductivity. As a result, this high refrigerant flow rate enables stable cooling when placed between battery cells—even in vehicles traveling at high speeds—because gravity plays an almost negligible role.

Compared to an aluminum cooling plate (left), the pulsating heat pipe (right) delivers superior heat transfer performance.

“We developed the pulsating heat pipe to address overheating during rapid charging and slash EV charging times. In an aluminum cooling plate, heat transfer depends on electron movement and molecular vibration, whereas heat pipes rely on the flow of refrigerant—which can handle a lot more heat overall. In other words, it’s way more effective at pulling heat away from battery cells. For reference, you can pair roughly one pulsating heat pipe with every one or two battery cells,” senior research engineer Dohyun Koo from Hyundai Mobis Metallic Electronics Materials Team explains.

Hyundai Mobis is taking the lead by bringing heat pipe technology to EV battery cooling—and prepping it for mass production. An EV battery system includes multiple modules, each containing layered battery cells, plus things like a battery management system and cooling gear. Since these cells generate a lot of heat, nailing the perfect cooling setup is essential to prevent performance dips or failures.

Under the same conditions, the pulsating heat pipe (center) dissipates heat much more efficiently than an aluminum cooling plate (left). In heat-dissipation tests, it recorded a temperature a full 19°C (about 34°F) lower.

As seen in the demo, pulsating heat pipes spread heat faster and more evenly than an aluminum cooling plate—thanks to that refrigerant moving heat from the battery cell straight to the cooling system.

Hyundai Mobis tested this by layering pulsating heat pipes between individual cells, and the results soared past their target for thermal conductivity. Getting there, though, was no cakewalk. According to Senior Research Engineer Dohyun Koo, “The main challenges were space within the battery system and cost. There’s been lots of research on using heat pipes for battery cooling, but no one’s actually mass-produced it.”

So how do you wedge a heat pipe into the tight space between battery cells? Hyundai Mobis made theirs incredibly thin. While standard heat pipes usually measure around 6 mm thick, these new pulsating ones are just 0.8 mm—perfect for slipping in between battery cells without hogging precious room.

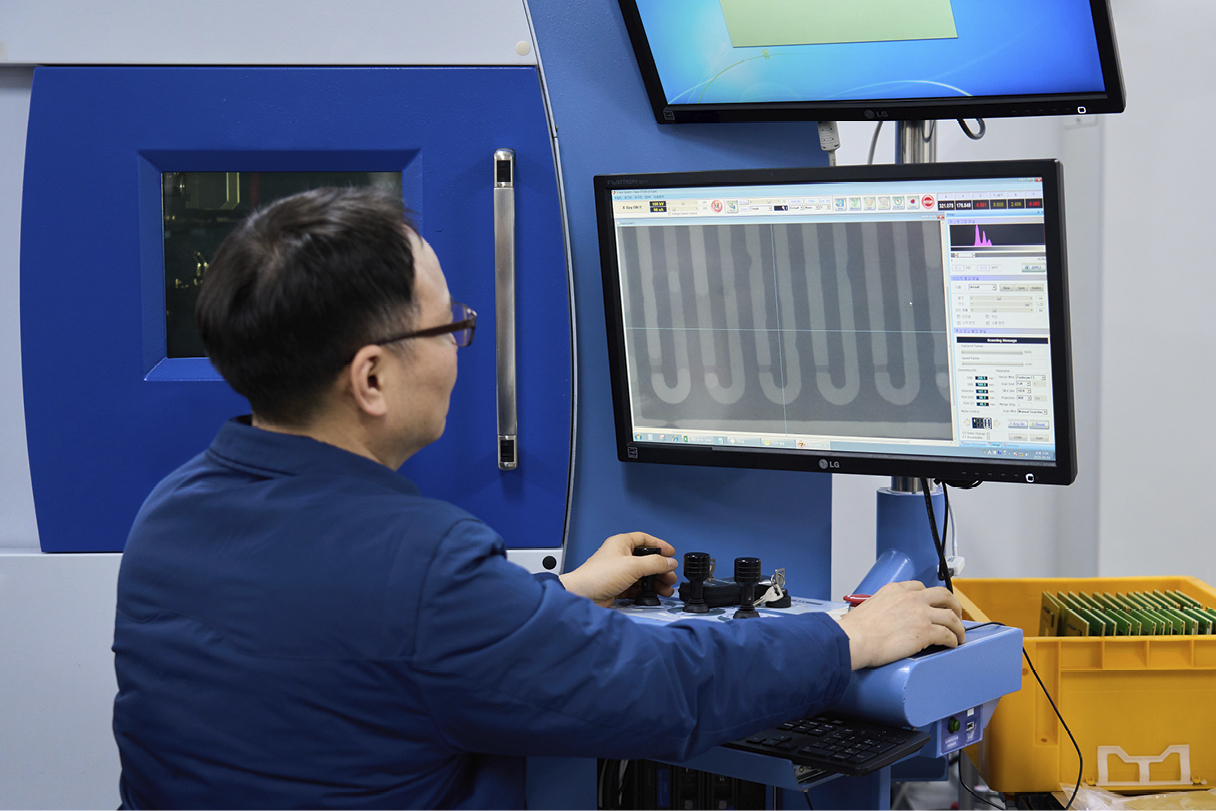

“Most standard heat pipes use copper tubes with a 6mm diameter, so shrinking them wasn’t easy. Pulsating heat pipes, however, are super thin—which can pose challenges for performance and reliability. To overcome that, we poured time into simulations and testing under all sorts of conditions to make sure everything worked flawlessly,” explains Senior Research Engineer Dohyun Koo.

On top of that, Hyundai Mobis chose a press-based manufacturing method for high-volume production, slashing costs by pressing three layers of aluminum alloy together and brazing them. It’s a low-cost route to achieving an ultra-thin design with a wide cooling surface—making it way easier on the wallet than regular heat pipes.

Hyundai Mobis expects its pulsating heat pipe to make its first splash in premium EVs, where ultra-fast charging is critical. More research is in the pipeline to fully integrate this technology into complete battery systems. “We’ll stay in close contact to keep pushing EV performance forward,” says Koo, adding:

“It takes a huge collaborative effort for a technology like this to go from concept to mass production. Our next step is to verify and optimize it, and we’re committed to developing breakthrough innovations that make EV driving more convenient.”

As a self-styled “mobility solutions provider,” Hyundai Mobis is always on the lookout for ways to enhance every inch of your car. Drawing on top-tier engineering skills, the company finds fresh solutions in areas long thought settled or impossible to improve. Many are looking forward to Hyundai Mobis shaping the ever-evolving world of future mobility.