Hyundai Motor Group celebrated the grand opening of Hyundai Motor Group Metaplant America (HMGMA) in Ellabell, Georgia, on March 26. As the Group’s third production hub in the United States, following Hyundai Motor Manufacturing Alabama and Kia Autoland Georgia, HMGMA is poised to become a key growth driver in its core U.S. market and on the global stage.

HMGMA represents more than just a new production site. As a Software Defined Factory (SDF), it brings together Hyundai Motor Group’s advanced manufacturing capabilities, seamlessly integrating AI and robotics-powered automation. It also embodies the Group’s vision for a human-centered future of mobility, where technology and people thrive in harmony.

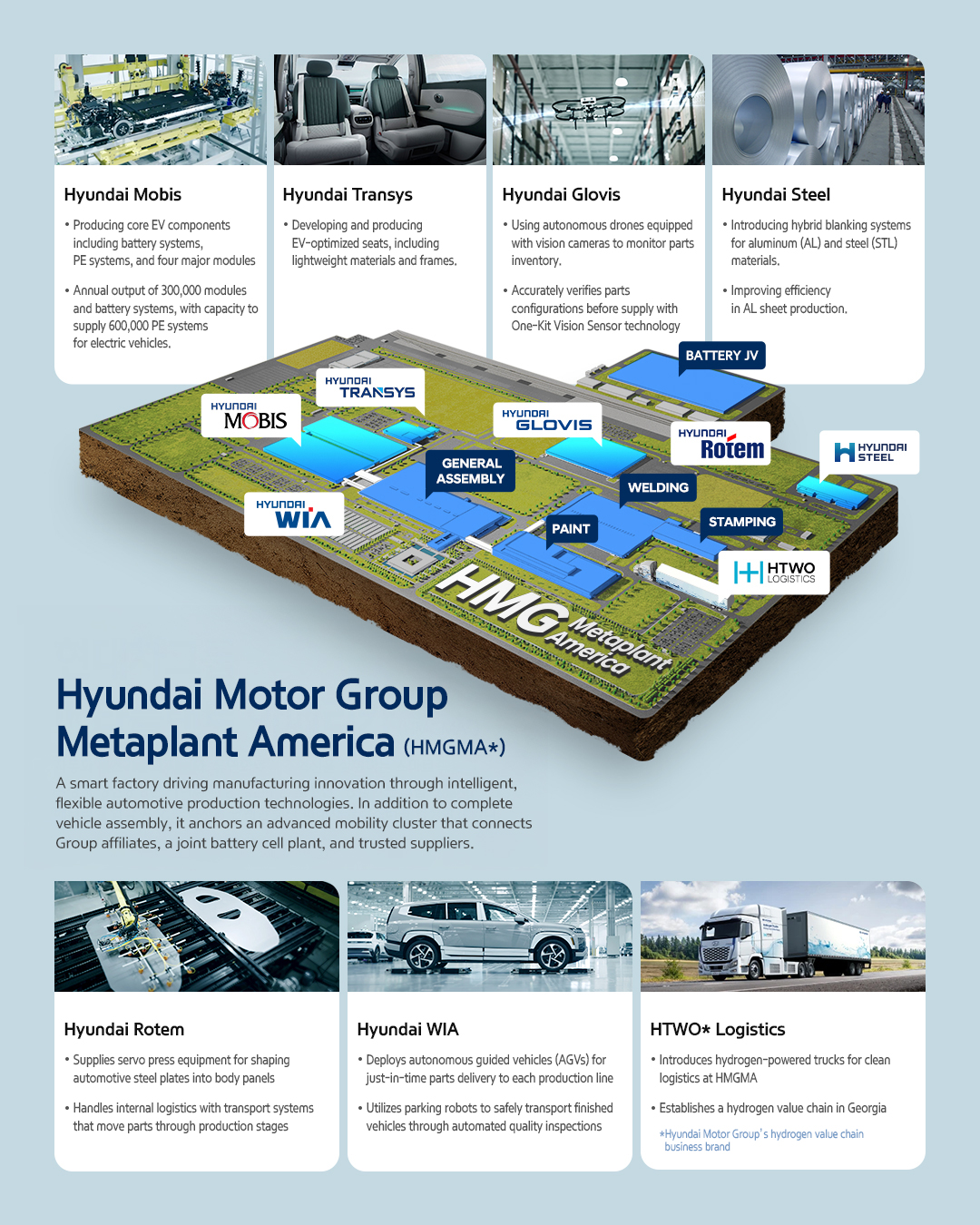

HMGMA is more than just a manufacturing hub for Hyundai, Kia, and Genesis. It serves as a future mobility cluster, bringing together key affiliates such as Hyundai Mobis, Hyundai Glovis, Hyundai Steel, and Hyundai Transys, alongside major joint ventures and partners—creating a powerful springboard for Korea’s automotive industry to expand globally. At the grand opening, we explored this bold new chapter.

The Group's investment in Georgia related to HMGMA and joint battery ventures with LG Energy Solution and SK On is $12.6 billion. This represents the largest single investment in the state's history and includes a total of 8,500 jobs at HMGMA by 2031. The Group’s total investments in Georgia are expected to create nearly 40,000 direct and indirect jobs, and $4.6 billion in individual earnings every year, according to the Center for Automotive Research.

As of the end of 2024, more than $2.5 billion in capital investment and approximately 6,900 jobs have been announced by HMGMA suppliers in 12 counties across the state. This more than doubles the additional $1 billion investment by suppliers that was originally anticipated.Prior to its grand opening, HMGMA began production of the IONIQ 5 in October of last year, and this March, the plant commenced mass production of Hyundai Motor Company’s electrified flagship SUV, the IONIQ 9. Kia models are slated to join the production line next year, with Genesis vehicles expected to follow in the near future. Leveraging its integrated mixed-model production system, the plant is also equipped to manufacture hybrid vehicles, ensuring it can meet the evolving needs of the U.S. market.

To commemorate the grand opening of HMGMA, Euisun Chung, Executive Chair of Hyundai Motor Group; Jaehoon Chang, VICE Chair of Hyundai Motor Group; José Muñoz, PRESIDENT and CEO of Hyundai Motor Company; Ho Sung Song, PRESIDENT and CEO of Kia; and HMGMA employees were joined by distinguished guests, including Brian P. Kemp, Governor of Georgia; U.S. Representative Buddy Carter; Ángel Cabrera, President of the Georgia Institute of Technology; and Hyundong Cho, Ambassador of the Republic of Korea to the United States. Ahead of the event, CHAIRMAN Chung, Governor Kemp, and other honored attendees toured the production line, gaining firsthand insight into HMGMA’s human-centered manufacturing processes that seamlessly integrate people, AI, and robotics.

During the ceremony, Executive Chair Euisun Chung emphasized that HMGMA represents more than just advanced manufacturing, declaring, “With HMGMA, we are building the future of mobility together with America, in America.”

Governor Brian P. Kemp delivered his congratulatory address, stating, “Hyundai Motor Group Metaplant America is a once-in-a-generation opportunity, made possible by our commitment to working with job creators to build fruitful partnerships for decades. Collaborations between HMGMA and Georgia’s universities and technical colleges, including Georgia Quick Start’s on-site training facility, are preparing Georgians for high-quality jobs of today and tomorrow, while our award-winning infrastructure, such as our ports, connects companies to markets around the nation and globe.” To commemorate the occasion, Executive Chair Chung and Governor P. Kemp personally signed the hood of the first IONIQ 5 to roll off the HMGMA production line.

HMGMA is a large-scale smart plant with an annual production capacity of 300,000 units. The plant has scaled up advanced manufacturing technologies originally developed and validated at the Hyundai Motor Group Innovation Center Singapore (HMGICS) for mass production. By integrating AI, IT, robotics, and data technologies, HMGMA has established an automated production system where all processes — from order collection and procurement to logistics and assembly — are seamlessly connected.

This is a prime example of how advanced technology can take on tasks that are too heavy, hazardous, or difficult for human workers to perform or inspect with the naked eye. True to its brand philosophy of Progress for Humanity, HMG is designing its manufacturing environment to place people at the center. HMGMA’s open layout, abundant natural light, and the creation of a 41-acre ecological park—with walking trails, sports fields, and picnic areas—perfectly embody this human-centered approach. Looking ahead, the plant will also pilot Boston Dynamics’ humanoid robot, ‘All-New Atlas,’ to support its workforce.

Another key reason HMGMA stands out is its integration with Hyundai Motor Group’s core affiliates, which are responsible for the development and production of key vehicle components, along with its on-site joint battery cell venture with LG Energy Solution. Additionally, domestic suppliers supporting HMGMA have established operations nearby, forming a large-scale cluster. This strategic setup enables fast and efficient parts supply while allowing for agile responses to evolving market demands.

Hyundai Mobis has established its largest global production facility at HMGMA, manufacturing 300,000 battery systems annually along with four key component modules—cockpit, front-end, chassis, and PE systems. By connecting the plant directly to HMGMA and implementing an integrated logistics system, the company ensures immediate parts supply, enhanced production efficiency, improved inventory management, and reduced logistics costs.

Hyundai Glovis operates both the Consolidation Center (CC) and the Vehicle Processing Center (VPC) within HMGMA. At the Consolidation Center, autonomous drones equipped with demand-driven data analysis and AI-powered forecasting capabilities continuously monitor inventory levels in real time and anticipate supply needs—ensuring just-in-time parts delivery to support HMGMA operations.

Hyundai Steel processes ultra-high-strength automotive steel plates at the Georgia Steel Service Center (SSC) within HMGMA, providing materials that deliver both lightweight construction and exceptional collision safety. The facility also marks Hyundai Steel’s first use of aluminum-steel hybrid processing equipment, further enhancing productivity.

Hyundai Transys has established a high-capacity seat production facility with an annual output of 420,000 units. Utilizing advanced automation technologies, including an auto docking system and mold release application robots, the plant efficiently manufactures seats for electric vehicles, incorporating innovative features and materials that reflect global trends. Hyundai WIA further supports HMGMA by deploying autonomous robots to enhance logistics automation, while Hyundai Rotem has supplied equipment for the press shop—demonstrating the full strength of the Group’s integrated capabilities.

Construction is nearing completion on the joint battery cell plant between Hyundai Motor Group and LG Energy Solution, which is targeting an annual capacity of 30 GWh and is scheduled to open next year. This output is enough to supply batteries for approximately 360,000 vehicles per year, based on the 84 kWh battery pack used in the IONIQ 5. The battery cells will be processed at Hyundai Mobis before being supplied to HMGMA, Hyundai Motor Manufacturing Alabama, and Kia Autoland Georgia.

This localized battery production strategy is poised to significantly enhance Hyundai Motor Group’s EV competitiveness in the U.S. market. By sourcing optimized batteries locally, the Group can deliver high-performance, high-safety electric vehicles to market on time. Additionally, 17 key suppliers are either expanding or establishing new operations near HMGMA, further strengthening the Group’s global competitiveness.

The completion of HMGMA, with an annual production capacity of 300,000 vehicles, has enabled Hyundai Motor Group to establish a formidable U.S. production network totaling 1 million units. Together with Hyundai Motor Manufacturing Alabama, completed in 2005 with a capacity of 360,000 units, and Kia Autoland Georgia, completed in 2010 with a capacity of 340,000 units, the Group has achieved this remarkable milestone in just two decades since launching local production in the United States.

HMG is expected to surpass 30 million cumulative vehicle sales in the U.S. this year—a historic milestone nearly 40 years after first launching the Hyundai Excel in 1986. Having previously reached 5 million units in 2004, 10 million in 2011, and 20 million in 2018, the Group had already exceeded 29.3 million units as of February, placing this landmark goal well within reach.

HMG is advancing beyond its current achievements, with plans to expand HMGMA’s annual production capacity to 500,000 units and establish an integrated U.S. production system capable of manufacturing 1.2 million vehicles annually. During his visit to the White House on March 24, Executive Chair Euisun Chung announced the Group’s bold commitment to invest $21 billion in the U.S. over the next four years—the largest investment in its history in the country.

In addition to expanding production capacity at HMGMA, Hyundai Motor Group plans to invest in critical sectors such as parts and logistics, steelmaking, and future industries. In Louisiana, the Group is preparing to establish an Electric Arc Furnace-based integrated steel mill with an annual production capacity of 2.7 million tons, aiming to localize the supply of high-quality automotive steel. HMG will also accelerate the commercialization of its U.S.-based affiliates, including Boston Dynamics, Supernal, and Motional, while strengthening collaboration in future technologies such as autonomous driving, robotics, artificial intelligence (AI), and advanced air mobility (AAM). Additional investments will also support nuclear and renewable energy, as well as the expansion of EV charging infrastructure.

HMGMA sits at the center of Hyundai Motor Group’s long-term plan to strengthen its U.S. competitiveness. More than just a facility to increase production, it serves as a strategic foundation to seize new business opportunities across multiple sectors and reinforce the Group’s presence in the world’s largest automotive market. The establishment of HMGMA opens new avenues for global growth not only for HMG but also for its affiliates and trusted suppliers. This milestone creates a vital platform for Korean enterprises to sharpen their global competitiveness. Furthermore, these investments will drive talent development and job creation, helping to strengthen the industry and secure the long-term position of Korean companies in the global automotive sector.

Ultimately, HMGMA will serve as a cornerstone not only for Hyundai Motor Group, but also for enhancing the global competitiveness of Korean industry as a whole, helping it take a bold step forward on the world stage. We look forward to continued interest in the transformative changes and far-reaching impact that HMGMA will bring.