From daily routines to workplace operations, artificial intelligence (AI) is reshaping nearly every aspect of our lives. Across industries, including manufacturing, AI is now widely employed for a broad range of functions. According to a report by the Bank of Korea, 63.5% of Korean workers use generative AI, and 51.8% have already adopted it for their work tasks. The adoption of AI has resulted in an average reduction of 3.8% in working hours, signaling a clear improvement in overall efficiency.

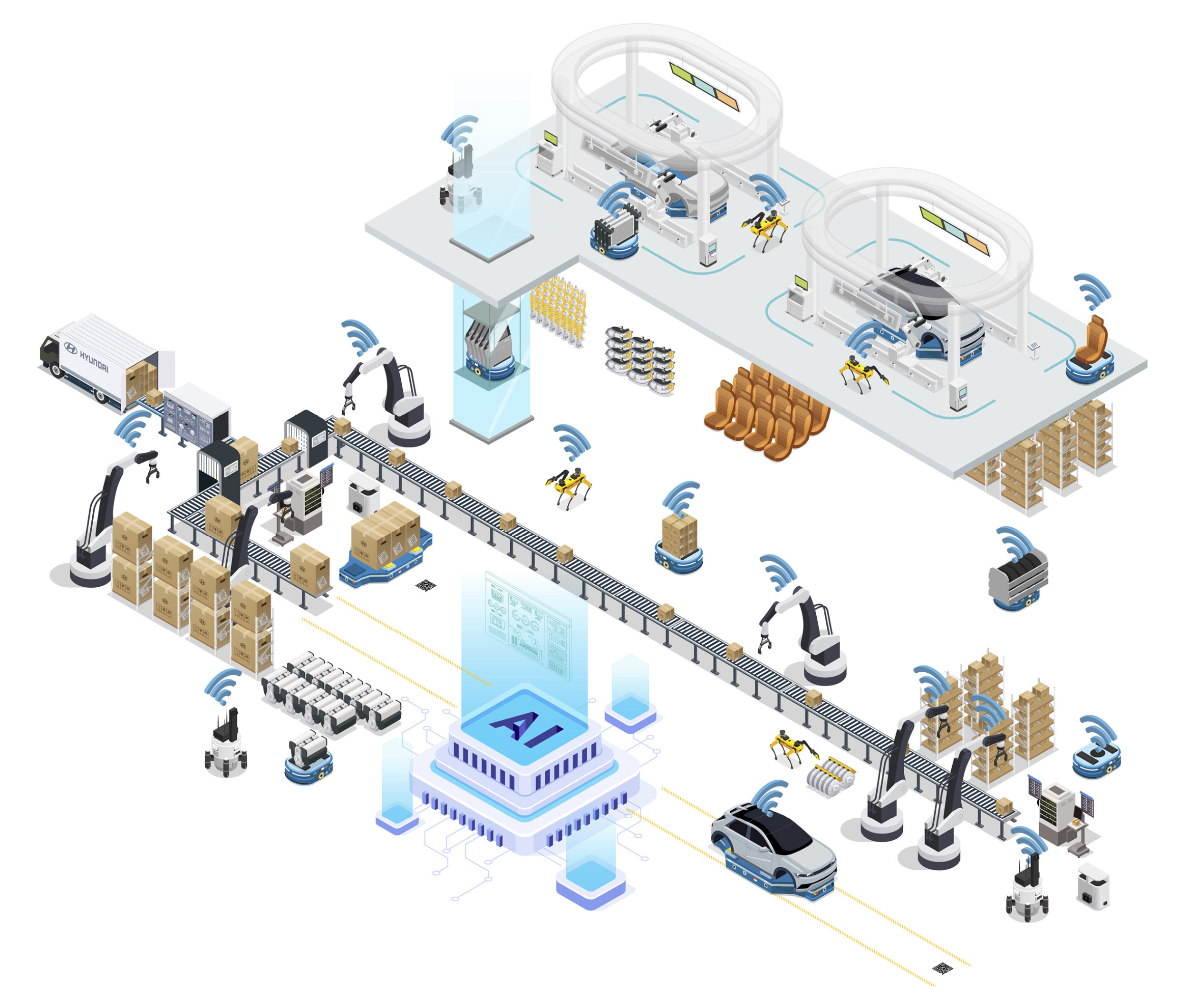

Hyundai Motor Group recognized the potential of artificial intelligence even before the technology began gaining momentum across industries. As early as the mid-2010s, the Group positioned AI as a core pillar of its strategy, and in the 2020s, it began integrating the technology across its entire business through a unified roadmap and large-scale investments. From smart manufacturing and robotics to autonomous driving, personalized services, and marketing, AI now drives HMG’s continuous creation of innovative products and services.

AI technology is reshaping everyday operations across Hyundai Motor Group’s diverse affiliates, spanning parts manufacturing, logistics, construction, steel, and data security. The following examples illustrate how AI is being applied at the core of these operations.

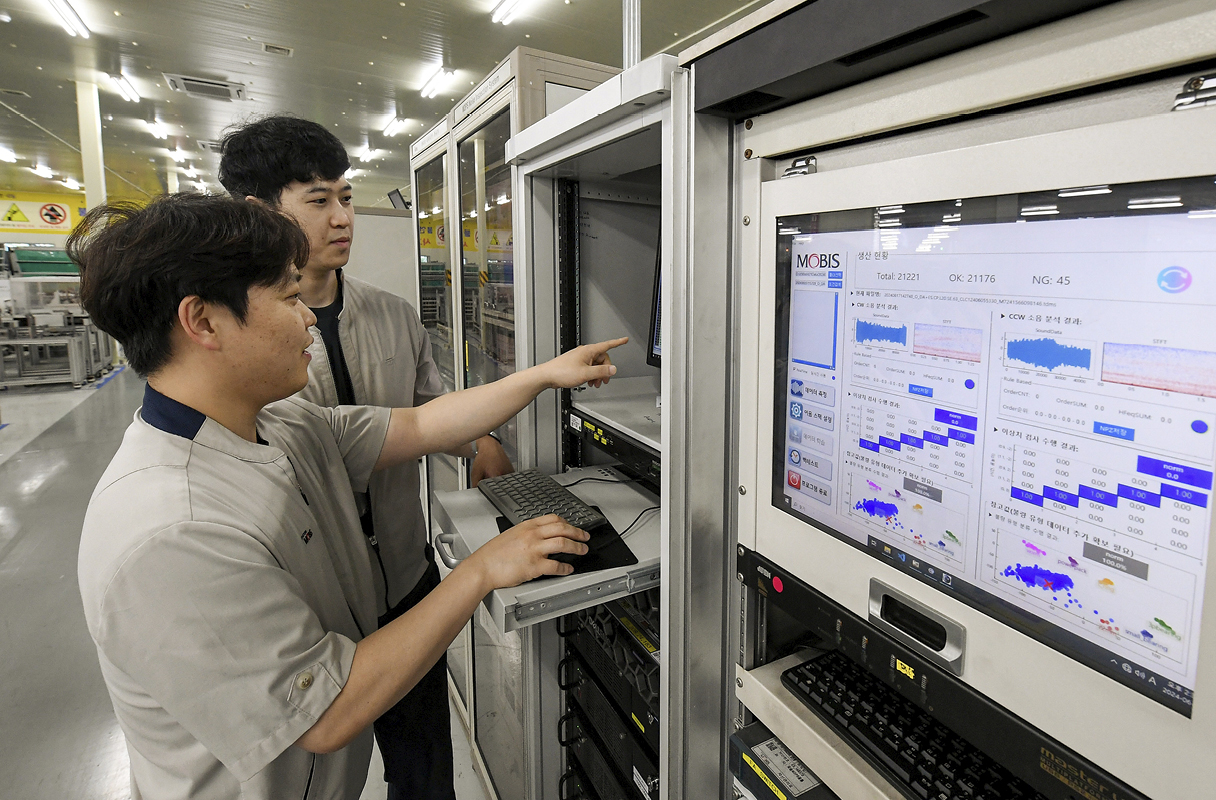

Hyundai Mobis has developed and introduced “Acoustic AI,” an artificial intelligence technology that operates through sound. This in-house system distinguishes itself from conventional AI by learning sound frequencies and wave patterns to perform a wide range of functions. In particular, it stands out as an innovative technology that remains rare within the manufacturing sector.

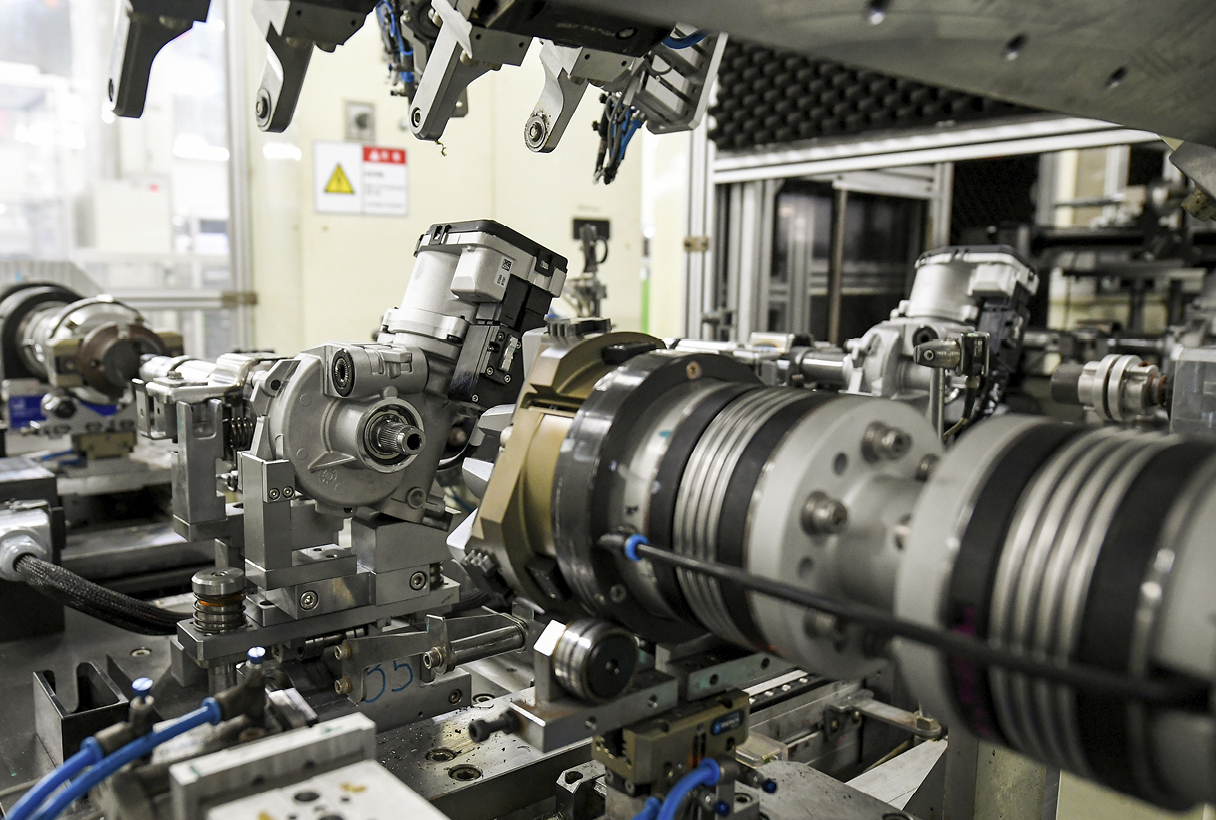

Hyundai Mobis has introduced its Acoustic AI technology at the Changwon Plant, which produces approximately 1.3 million Motor-Driven Power Steering (MDPS) systems annually. The technology was implemented to ensure the highest level of quality control for this critical safety component. By learning the sound waveforms generated during MDPS motor operation, the system can detect even the slightest variations during production to identify potential defects. This enables precise inspection of one unit per second, significantly improving productivity.

Meanwhile, Hyundai Mobis recently unveiled a generative AI model capable of simulating virtual driving environments. The model integrates text and image data to precisely modify visual elements and rapidly generate diverse road conditions. A research paper related to this technology was selected as an outstanding paper at the Conference on Computer Vision and Pattern Recognition (CVPR) held in Tennessee, United States, earlier this year.

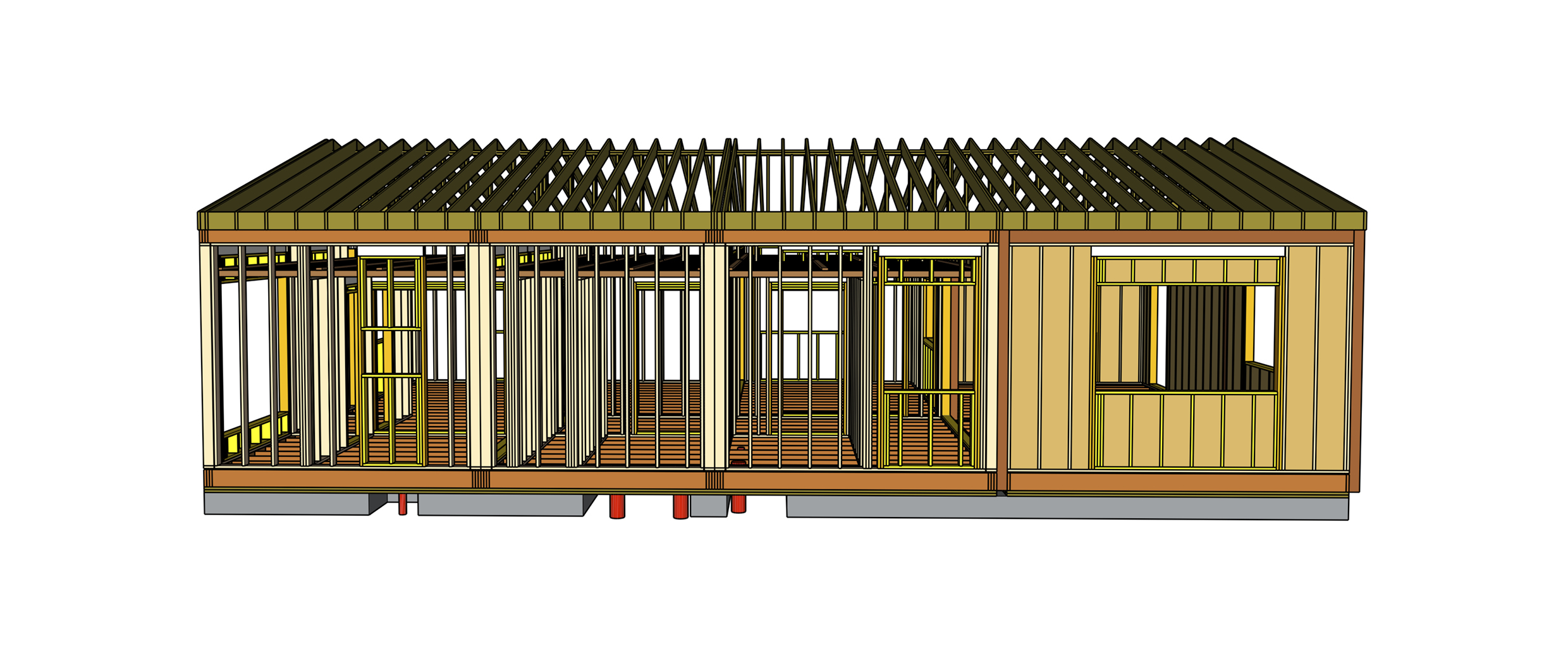

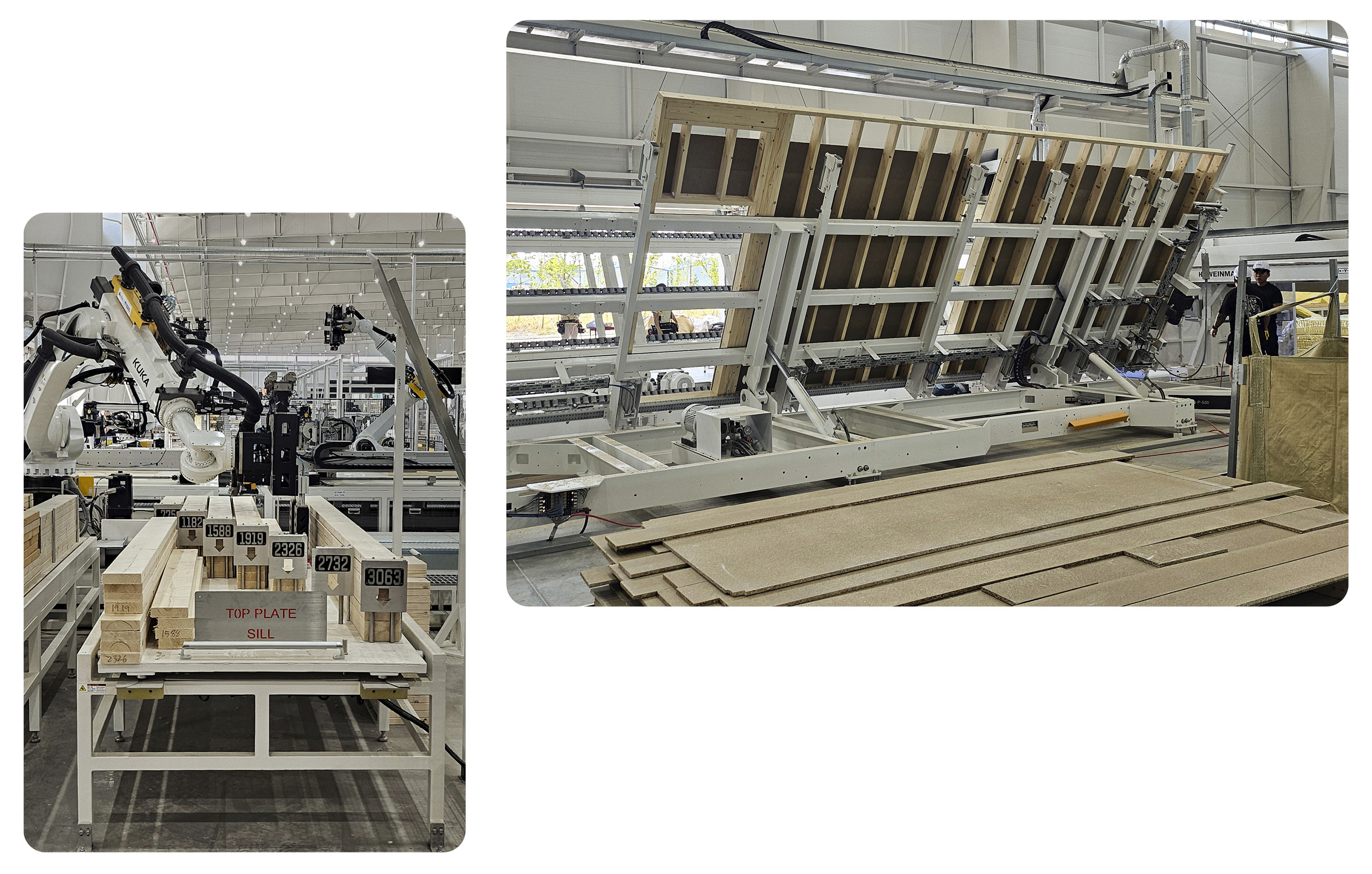

Hyundai E&C is working to improve construction-site efficiency and ensure quality stability while promoting sustainable residential environments through its AI-based, automated wood-modular construction method. In May, the company took a further step by signing a MOU with Space Factory, a modular-housing firm specializing in robotics and AI, to expand the use of Off-Site Construction (OSC)—a process in which housing modules are manufactured in factories and assembled on site.

Through this partnership, Hyundai E&C is advancing the adoption of a construction method that enhances quality while minimizing on-site work. By establishing a smart factory powered by AI and robotic automation, the company aims to improve safety at construction sites, shorten project timelines, and reduce carbon emissions—achieving both environmental and economic benefits.

Key processes such as material cutting, assembly, and inspection are performed automatically, while most of the work takes place indoors, allowing construction components to be completed quickly and unaffected by weather conditions. Data-driven quality control and real-time production monitoring significantly reduce process errors compared to traditional on-site construction. The use of wood as the primary structural material further enhances environmental sustainability and thermal insulation performance.

Hyundai E&C is advancing the first application of its wood modular construction technology at the Hillstate Yongin Mark Valley apartment complex, which is scheduled for occupancy in December 2027. The company plans to begin with smaller auxiliary facilities—such as children’s stations and bicycle storage areas, where design standardization is easier—and later expand the technology to independent structures, including daycare centers and senior community facilities.

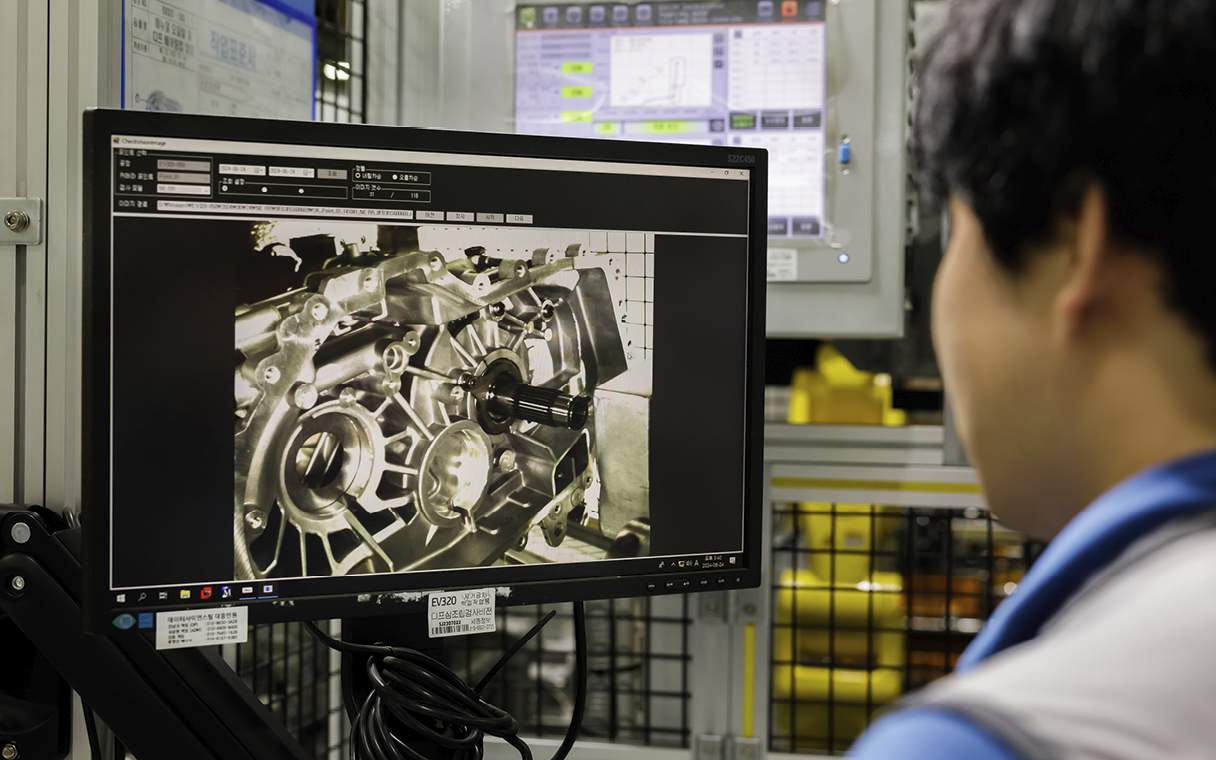

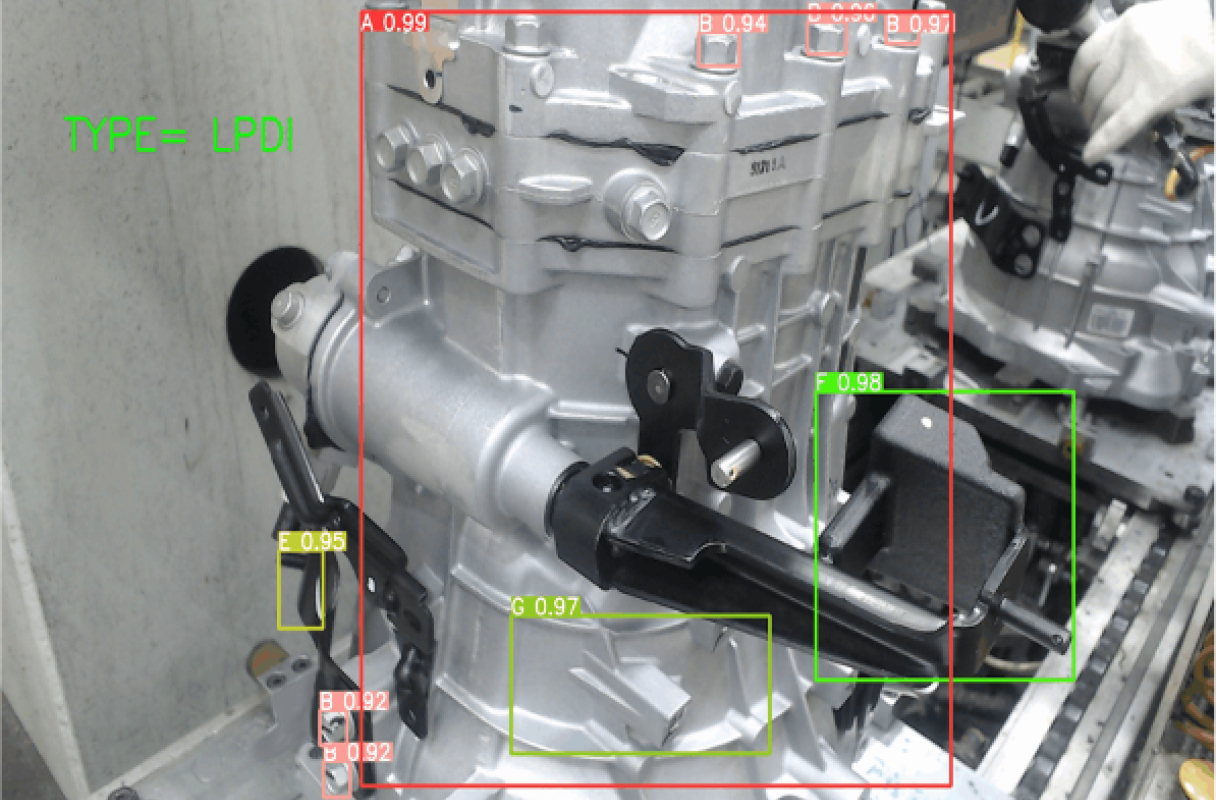

Hyundai Transys has introduced its in-house AI system, TADA (Transys Advanced Data Analytics), to its production sites. TADA functions as a digital platform that drives innovation across multiple areas, including smart manufacturing, big data platform development, and digital transformation training. Building on this system, AI vision inspection* solutions—TADA Smart Solution and TADA Edge Solution—enhance inspection accuracy and significantly improve productivity on the manufacturing line.

*AI Vision Inspection: A technology that uses AI-powered cameras to detect defects and verify whether manufactured products meet their specifications.

TADA Smart Solution enhances production efficiency by inspecting defects through the analysis of pre-trained images of finished products.

First, TADA Smart Solution is an inspection system that applies deep learning*—a core technology in today’s AI. By analyzing pre-trained images of finished products, it detects even the smallest defects—such as internal air bubbles or cracks—within components during production.

*Deep Learning: An AI learning method that uses deep neural networks modeled after the human brain to learn complex patterns from data.

AI verifies whether the ISO-FIX anchoring status of a seat meets the proper quality standards based on pre-trained images.

As production processes grow more complex, the value of TADA Smart Solution becomes even greater. For example, automotive seats often come with various optional specifications, and multiple product types are frequently produced simultaneously on a single assembly line. In such intricate seat manufacturing processes—where components of different specifications are mixed—TADA Smart Solution achieves a 99.9% detection rate for assembly errors that might otherwise go unnoticed by human inspectors, thereby strengthening overall quality competitiveness.

Meanwhile, TADA Edge Solution is a compact inspection system that enables on-site workers to independently build deep learning–based AI models for defect detection. Requiring no additional network infrastructure, the solution significantly reduces both installation and maintenance costs and can be implemented at approximately one-tenth the cost of conventional AI vision inspection systems. Its user-friendly design allows smaller partner companies to adopt it easily without the need for specialized engineers. Through this technology, Hyundai Transys supports its partners in improving quality and strengthening competitiveness across the automotive parts industry.

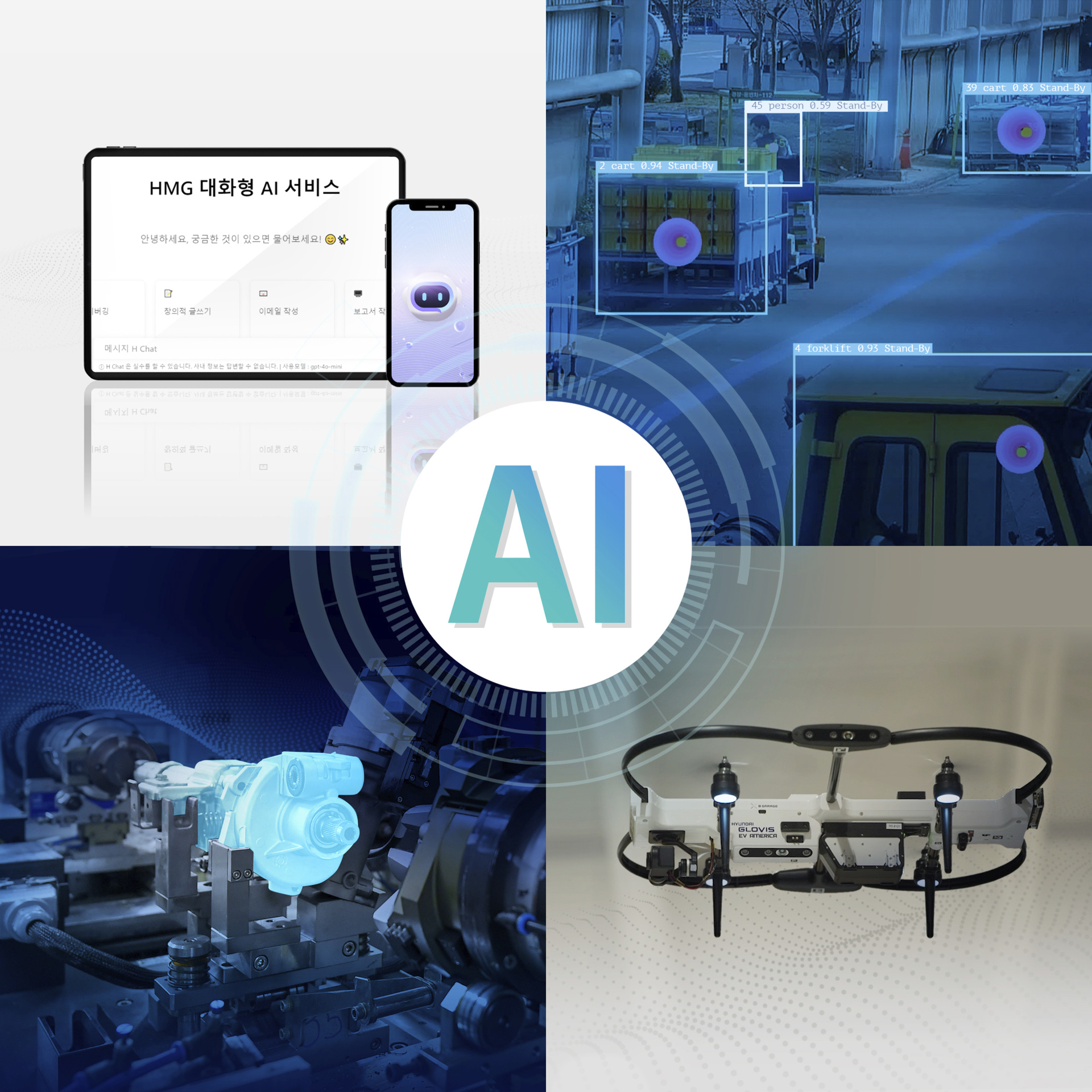

The responsive CCTV system detects abnormalities within the factory and sends a-lerts to workers

TADA’s vision inspection technology is also utilized in component development stages, such as durability testing for powertrain gears

The applications of TADA continue to expand. One notable example is the AI-based responsive CCTV system, which detects approaching logistics vehicles near factory workers and issues a-lerts, and also enables swift responses to waste oil or wastewater leaks caused by equipment damage. In addition, Hyundai Transys is actively applying AI in areas such as powertrain gear durability testing and customer claim analysis to address diverse challenges across its business operations.

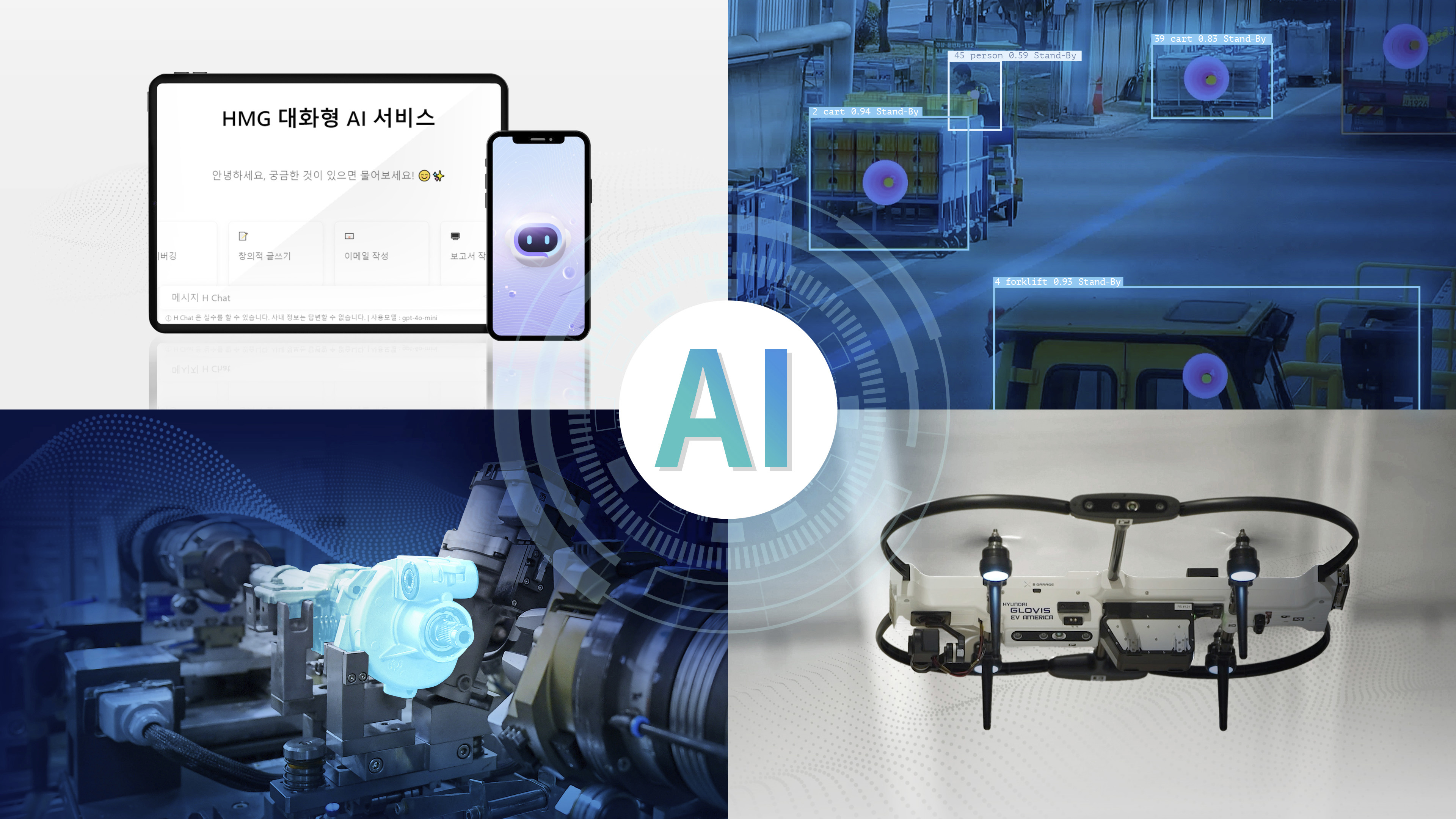

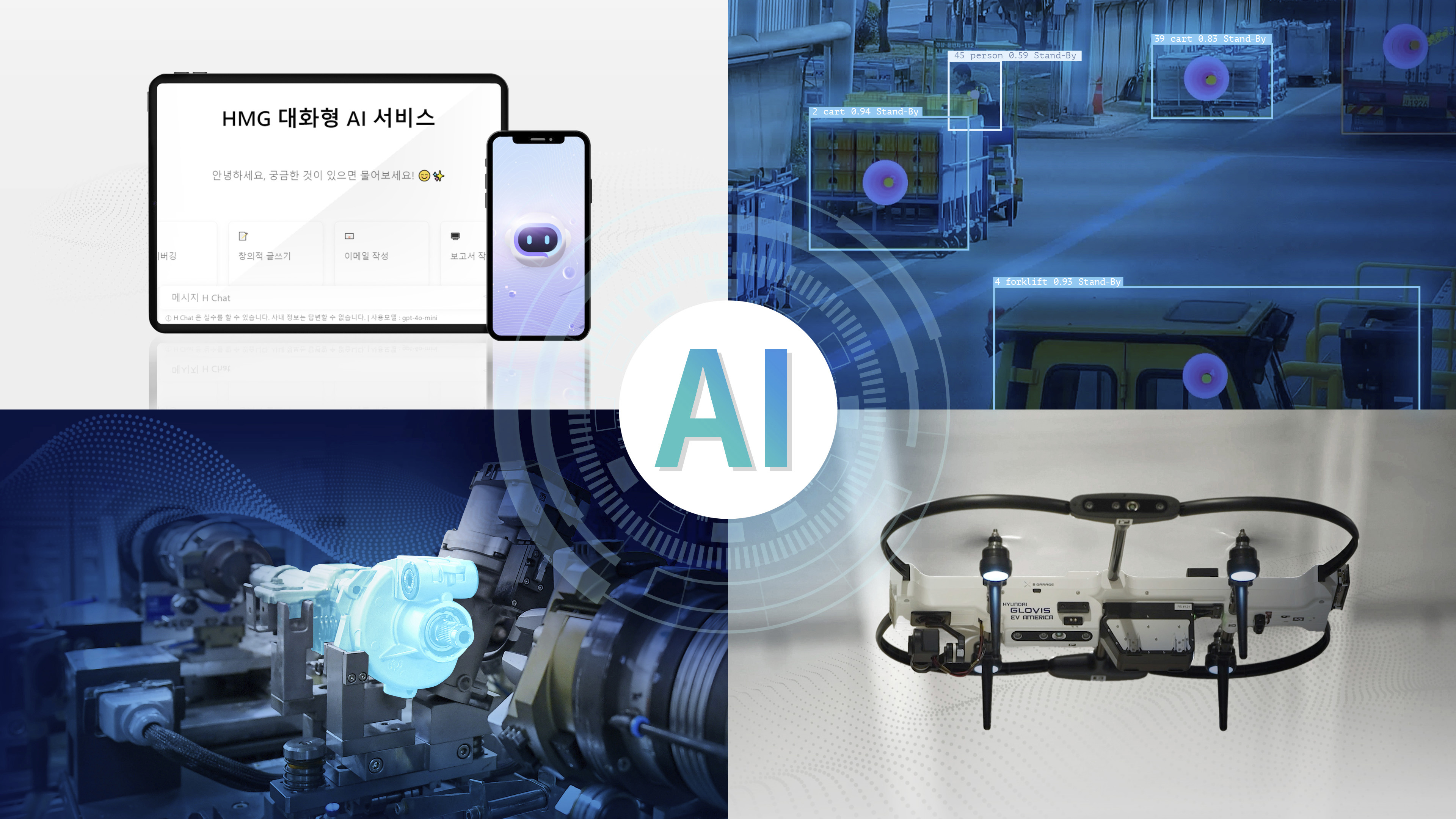

Generative AI tools such as ChatGPT were once considered impractical for corporate use due to security concerns, including the risks of internal data being relearned or leaked. However, as these technologies demonstrate strong potential to enhance efficiency in fields such as software engineering and research and development, many companies are now actively seeking ways to leverage large language models (LLMs)* within their operations.

Hyundai AutoEver, HMG’s software development affiliate, has recently introduced H-Chat, a conversational AI service powered by large language models (LLMs). Designed with enhanced security features, the solution enables safer and more reliable use of AI in corporate environments and is now being utilized by Hyundai AutoEver and most affiliates across entire Group.

*Large Language Model (LLM): An AI model trained on vast amounts of language data, capable of understanding and generating human language.

H-Chat provides a secure channel between corporate networks and external LLMs, ensuring that sensitive information remains protected. It also allows security administrators to easily implement client-specific policies and includes safeguards that prevent corporate data from being relearned. In addition, with compatibility across multiple generative AI models—such as ChatGPT, Claude Opus, and Google Gemini—it enables Group affiliates and partners to safely leverage the latest AI technologies.

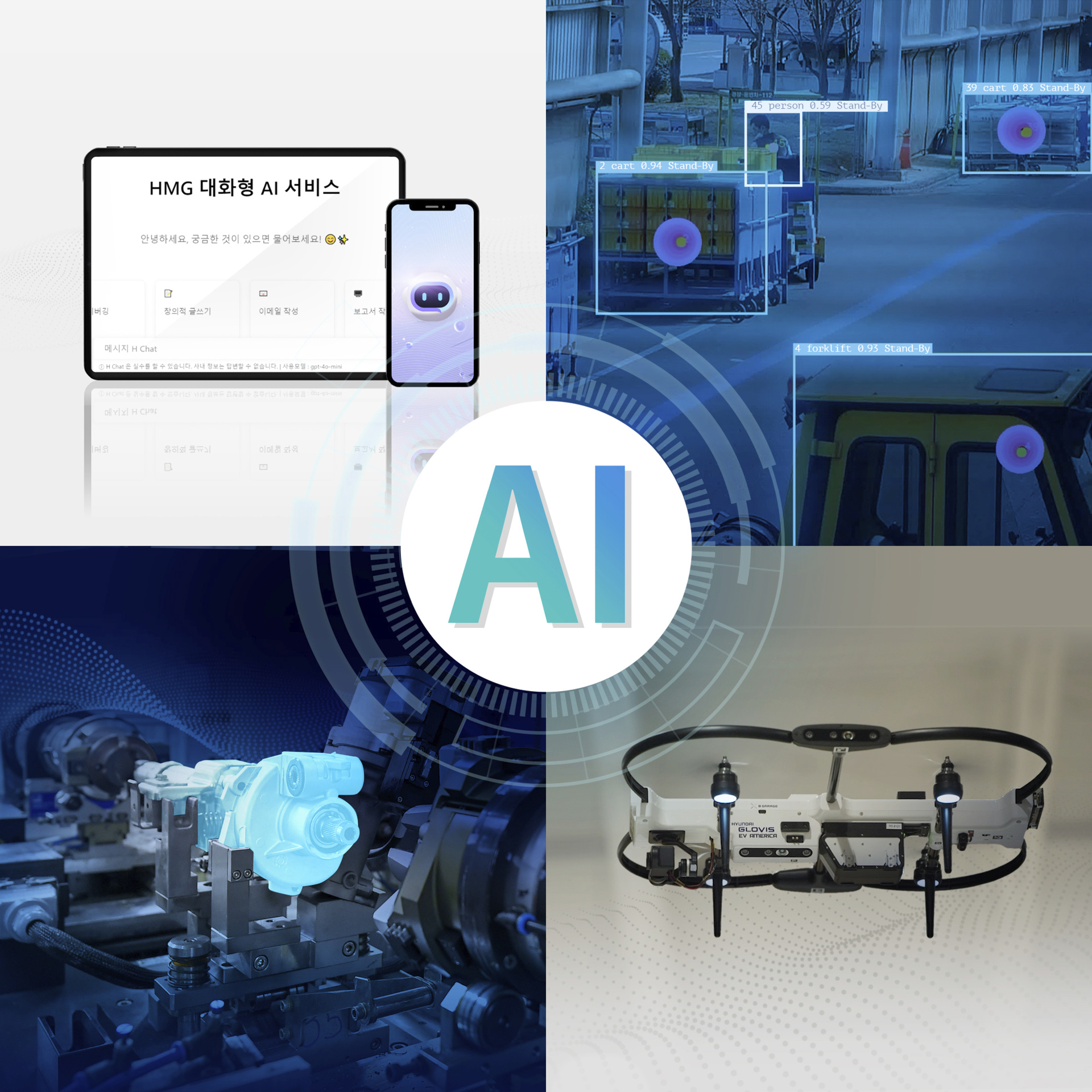

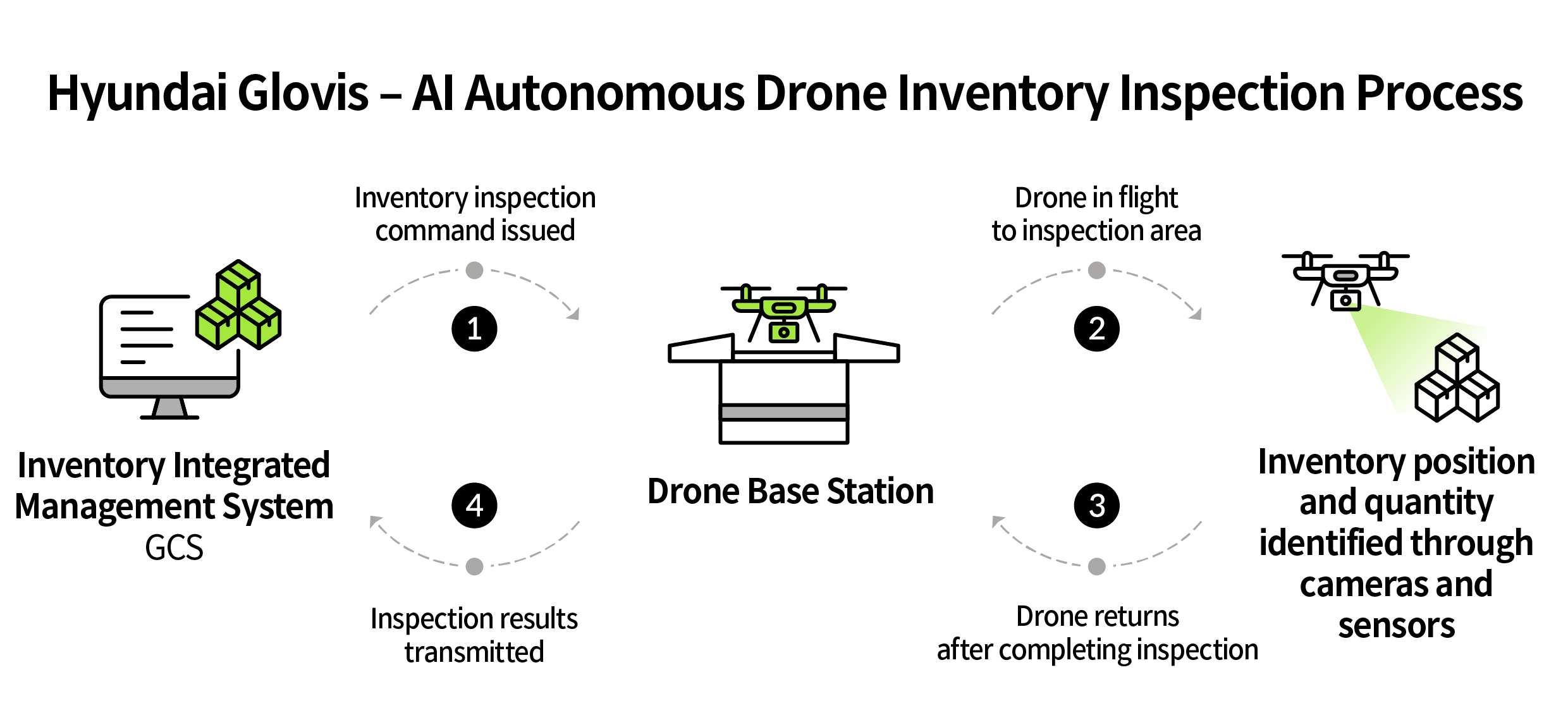

Hyundai Glovis has deployed two AI-powered autonomous drones within HMGMA (Hyundai Motor Group Metaplant America) in the United States. These drones are now responsible for conducting inventory inspections of knock-down (KD) automotive parts—a task that previously required workers to check stock manually.

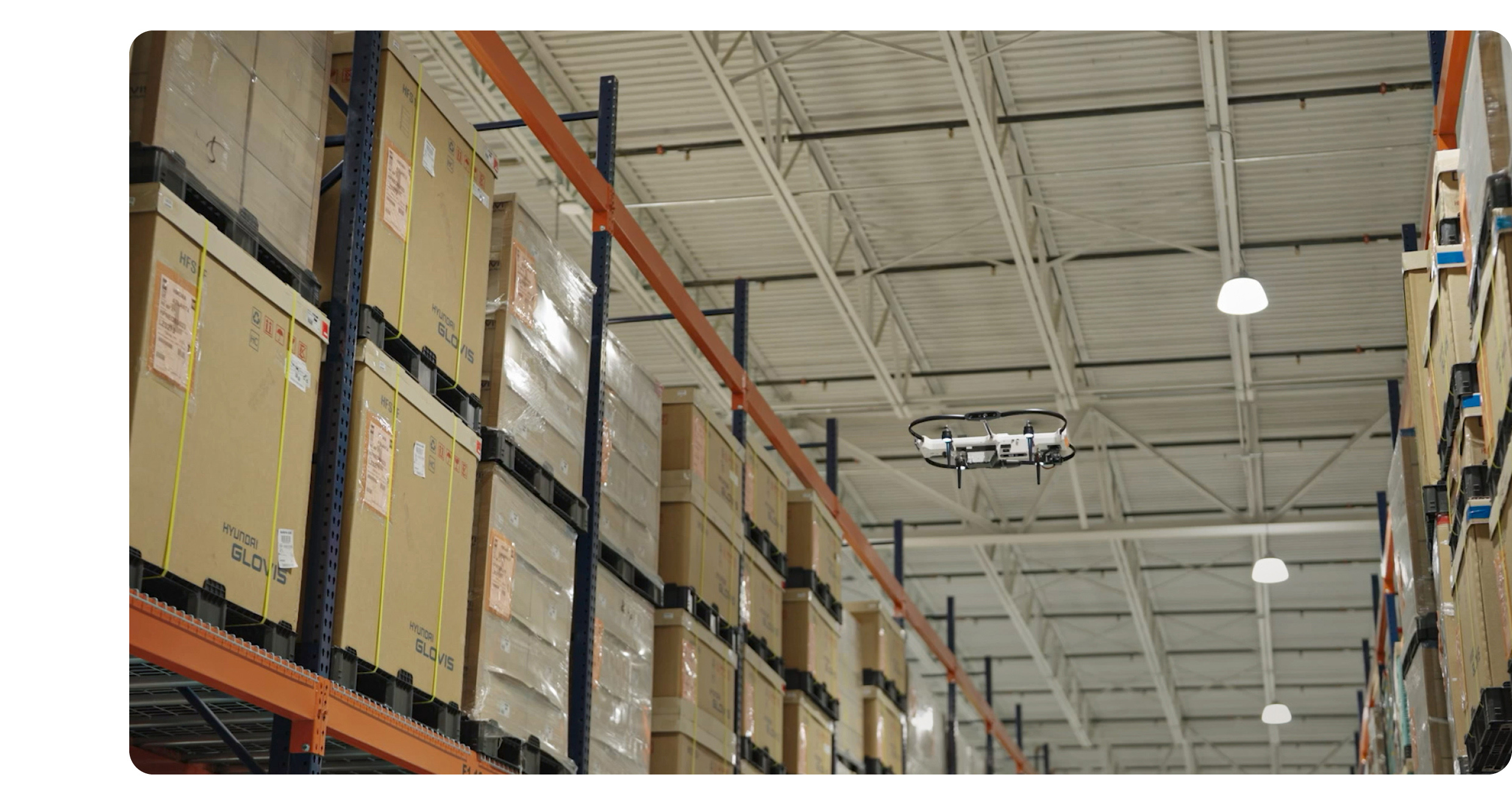

Hyundai Glovis’s drones can quickly identify inventory in areas that are difficult for humans to inspect

In the past, workers had to manually check each bin—the smallest unit used to indicate inventory locations—a process that took more than 300 minutes on average. After the introduction of drones, however, the same task can now be completed in about 30 minutes, reducing work time by roughly 90% and greatly enhancing overall operational efficiency. The drones can also identify items located more than 3.5 meters above ground or hid-den in blind spots behind structures, thereby improving accuracy while reducing workers’ physical strain.

These drones operate in conjunction with GCS (Global Consolidation Center Support System), Hyundai Glovis’s integrated inventory management software for logistics centers. Upon receiving an inspection command, a drone stationed at the Drone Base Station takes off automatically, following a designated flight path to capture images of storage boxes. After completing the task, it returns to the base to transmit the data, and the analyzed results are then shared with GCS.

What makes autonomous drone flight possible even indoors is computer vision–based navigation technology. Each drone is equipped with Visual Inertial Odometry (VIO) and an Inertial Measurement Unit (IMU), allowing it to precisely determine its position. In addition, a range of sensors—including fisheye and stereo cameras, distance sensors, and acceleration and angular velocity sensors—enable the drone to perceive its surroundings, accurately locate objects, and fly safely within confined spaces.

Hyundai Glovis’s drones can fly autonomously indoors without GPS by using their own network system

While most commercial drones rely on GPS—which is often limited in indoor environments—Hyundai Glovis’s drones can fly autonomously indoors without it, using their own internal network system. Their battery levels are continuously monitored, and automatic charging and replacement at the base station enable fully automated operation. Building on the two drones already in service, Hyundai Glovis plans to deploy two additional units at HMGMA and is exploring broader applications of this technology across other logistics centers.

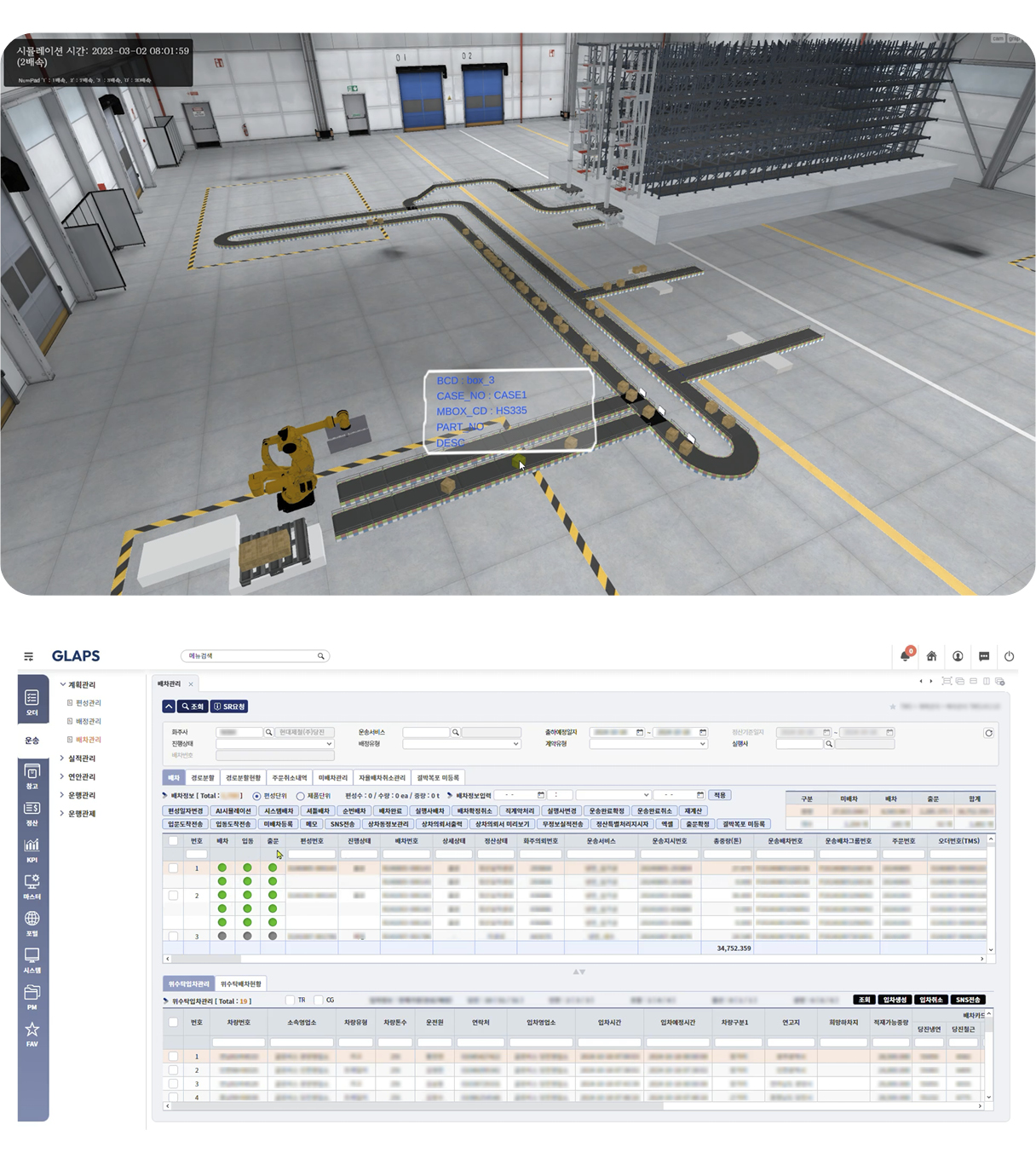

Beyond this, Hyundai Glovis is integrating AI technology across various aspects of its logistics operations. AI-driven simulation tools have been introduced to enhance both fairness and efficiency in dispatch planning, while AI-based optimization technology is applied to maximize loading efficiency for parts in trucks and containers.

Equipped with high-performance GPU resources and a robust MLOps* and LLMOps* infrastructure, the platform offers an advanced environment for research and development, enabling business divisions to expand AI utilization and continuously enhance service quality.

*MLOps: A methodology that automates, integrates, and efficiently manages the entire lifecycle of machine learning models—from development and deployment to monitoring and retraining.

*LLMOps: A methodology that automates and optimizes all stages of large language model (LLM) development, deployment, monitoring, and operation to maximize the stability and performance of LLM-based applications.

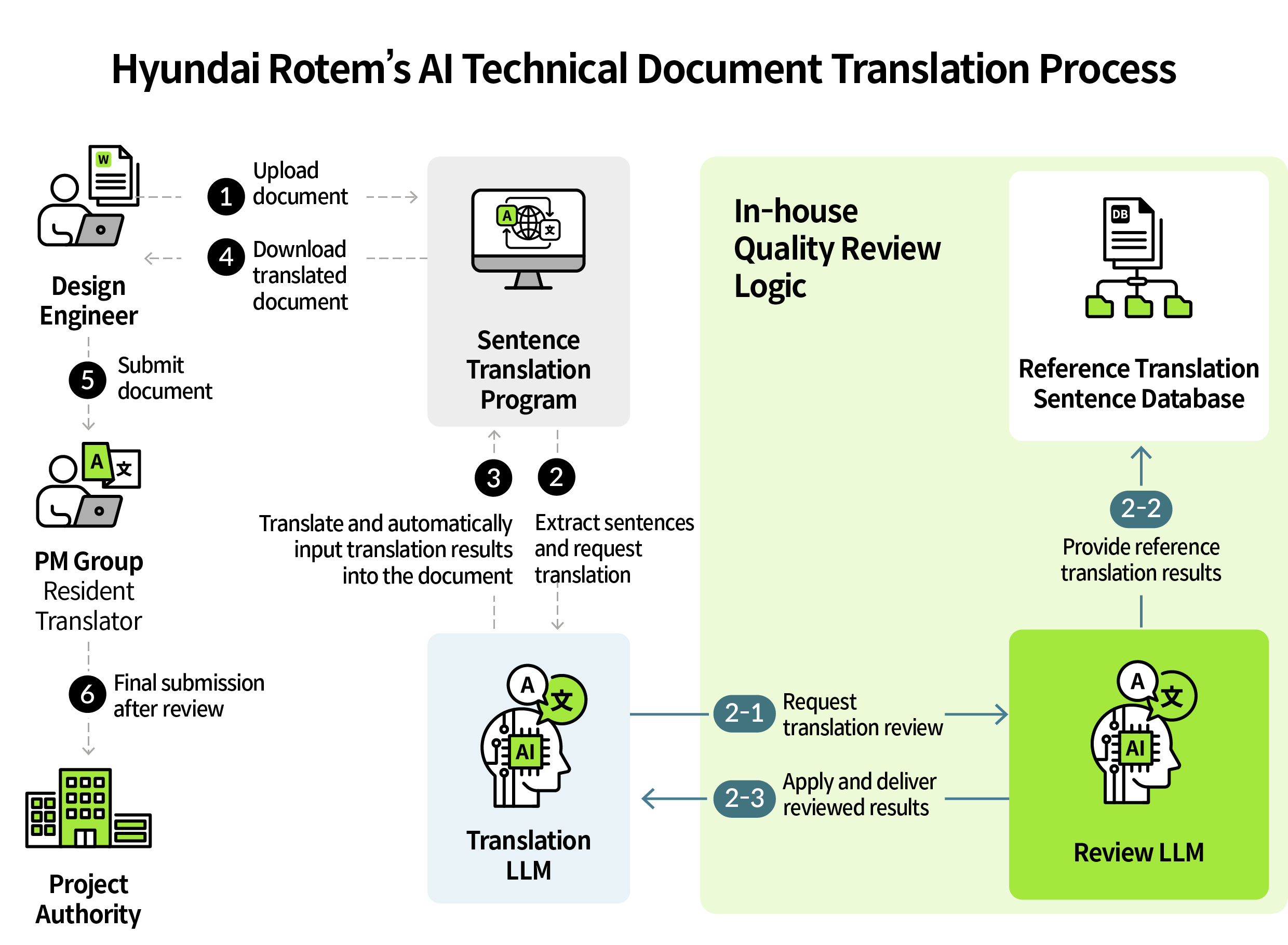

In the defense and railway systems sectors, Hyundai Rotem is leveraging AI technology to enhance product competitiveness and overall operational efficiency. One of the most prominent applications is the translation of technical documents, which are often thousands of pages long and filled with specialized terminology. Previously handled entirely by human translators, this process required extensive time and resources, becoming a significant constraint on project schedules.

To enhance translation efficiency, Hyundai Rotem developed an automated translation program that integrates LLM and RPA (Robotic Process Automation) technologies. The system performs fast and accurate multilingual translation while preserving the original document format, significantly reducing editing workloads and allowing on-site teams to use translated materials immediately.

The program delivered impressive results during a pilot run for the Morocco railway project, cutting costs by approximately KRW 240 million and reducing work hours by more than 80% within just three months of launch. Hyundai Rotem plans to expand the system to future international projects, including those in Taiwan. In the defense sector, AI is also being utilized to enhance Polish translation accuracy and support communication for the recently signed USD 6.5 billion K2 tank export contract with Poland.

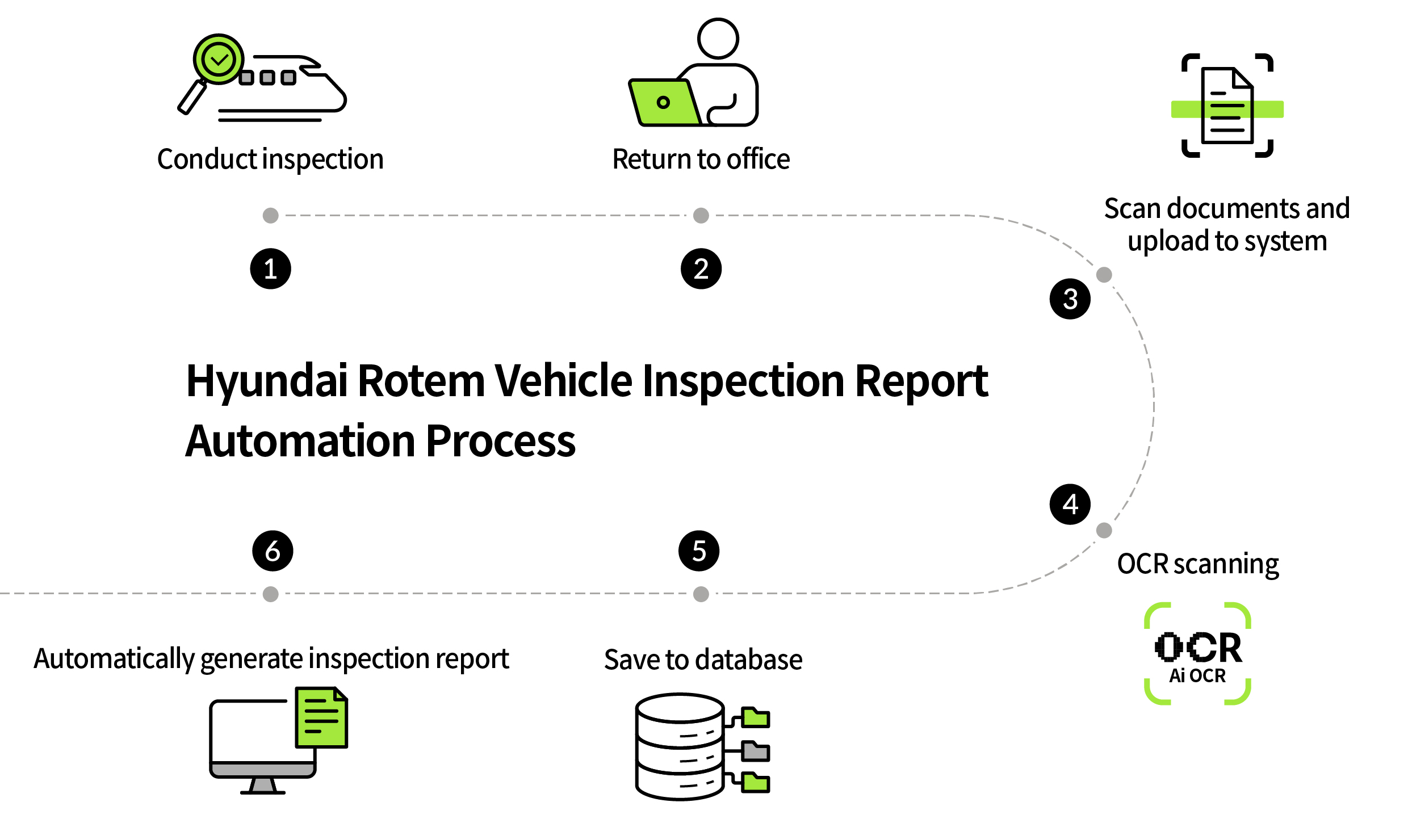

Meanwhile, Hyundai Rotem is developing a system that automatically digitizes handwritten railway vehicle inspection sheets using OCR AI* and Robotic Process Automation (RPA). As hundreds of sheets are generated each day, the system aims to minimize the risk of human error through automation. After completing the technology verification stage, the company is now refining the program for full-scale deployment. Also, similar AI technologies are being applied to blueprint verification systems that automatically recognize text within large-scale technical drawings.

*OCR AI: Optical Character Recognition (OCR) AI — a technology that identifies text contained in images or documents and converts it into machine-readable digital text.

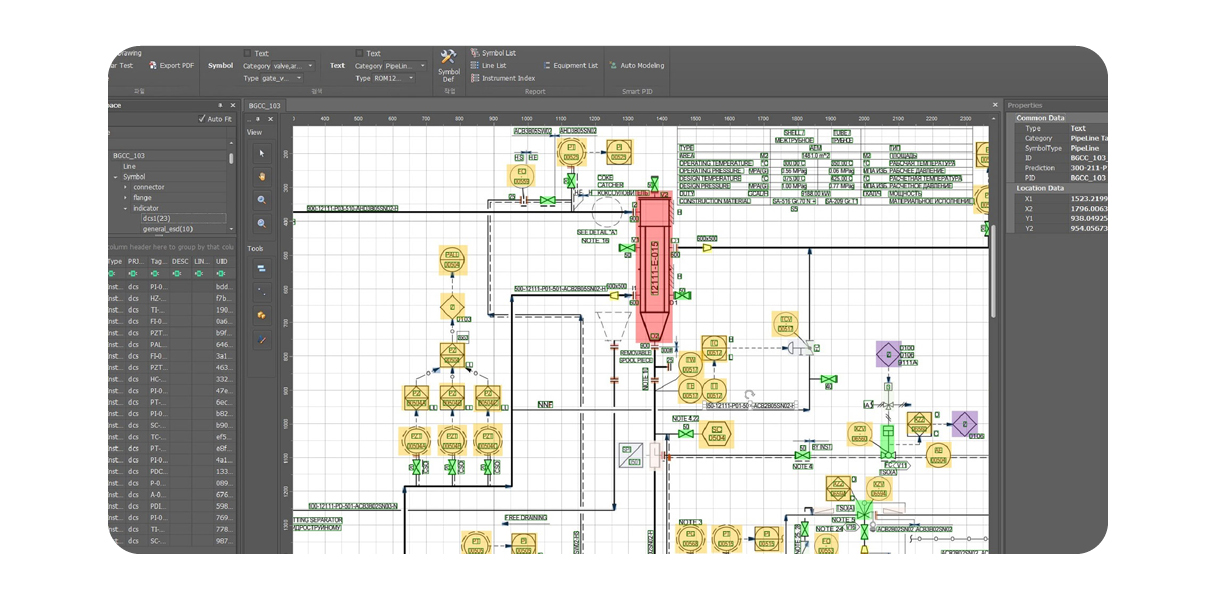

Hyundai Engineering has focused its research and development efforts on identifying areas within the construction industry where design automation can be applied. The company developed its own Piping & Instrumentation Diagram (P&ID) Automatic Recognition System based on AI deep learning and computer vision, which is utilized during the design recognition stage. This technology enables the automatic generation of digital process diagrams that incorporate key process data, including piping and instrumentation lists as well as CAD drawings.

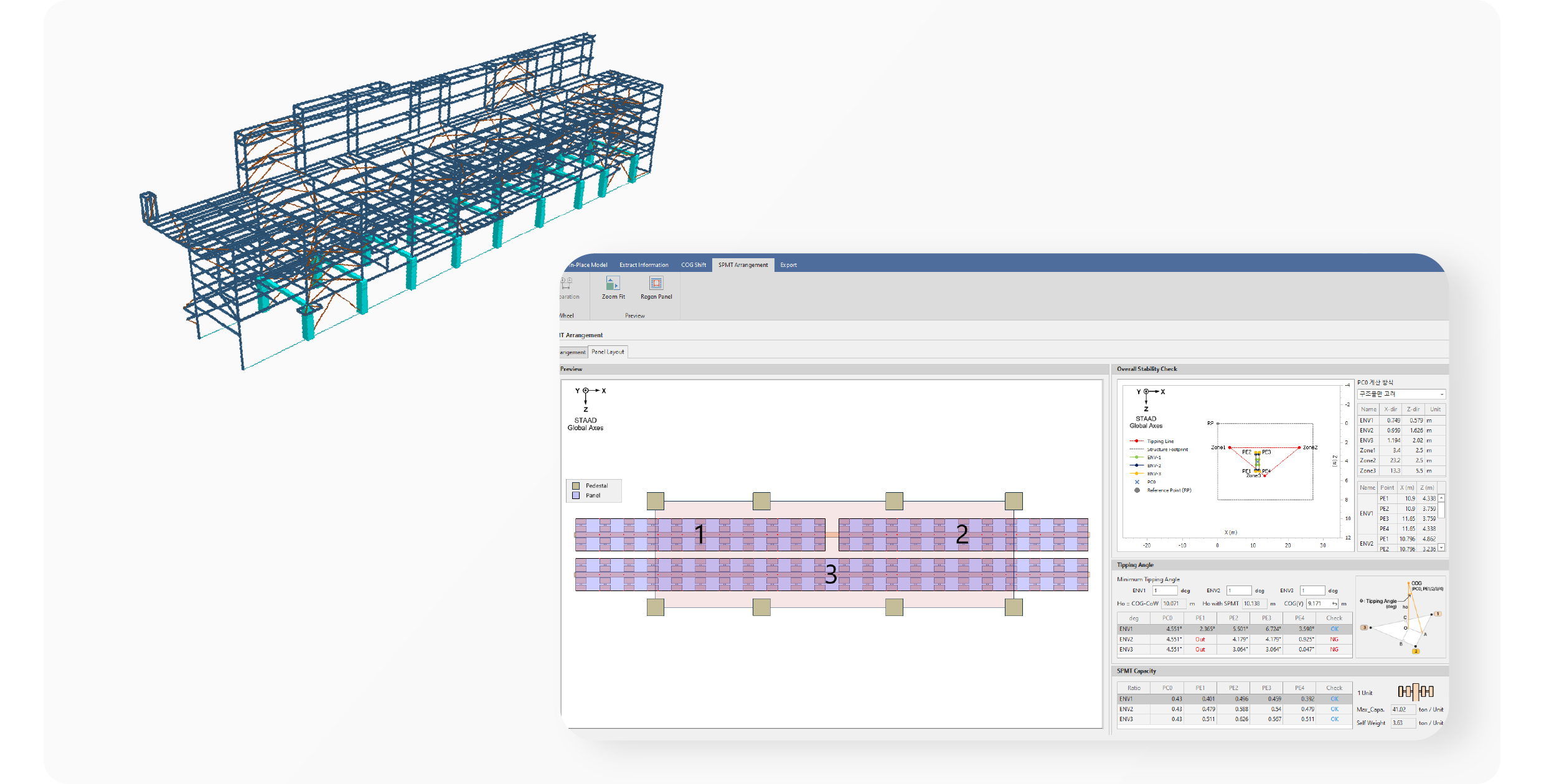

Various automation technologies are also being applied in the detailed design stage. A representative example is the Plant Steel Structure Design Automation System, which uses design data to enable AI to automatically select the most suitable steel members. The system also supports modularization by accounting for transport conditions and verifies structural stability through simulation.

AI is also supporting one of the most challenging on-site operations: installing control valves above fire protection piping. The PIV Layout Optimization System, which utilizes reinforcement learning technology, automatically recommends valve positions to enable safer and more efficient designs. Moving forward, Hyundai Engineering plans to further expand its AI-based design automation to include areas such as automatic structural support calculations and Precast Concrete (PC)* design.

*Precast Concrete (PC): A construction and civil engineering method in which concrete components are manufactured in a factory in advance and then assembled on-site to complete the structure.

Through the active adoption of AI, Hyundai Motor Group is transforming everyday work—driving innovation and enhancing efficiency across all operations. Looking ahead, AI will serve not only as a tool for automation but also as a catalyst for talent development and new value creation. The Group’s vision for an AI-powered workplace will foster smarter, more creative achievements and power the next leap forward in the global mobility industry.