From January 6–9 in Las Vegas, United States, Hyundai Motor Group brought forward a cross-affiliate collaboration strategy anchored in AI robotics. With Boston Dynamics’ humanoid robot Atlas at the center, technologies spanning logistics, parking and mobility robots, HVAC and Hyundai WIA components, next-generation cockpits and vehicle control solutions, and open innovation were presented not as isolated showcases, but as interconnected elements within a single flow—forming a blueprint for the future of industry.

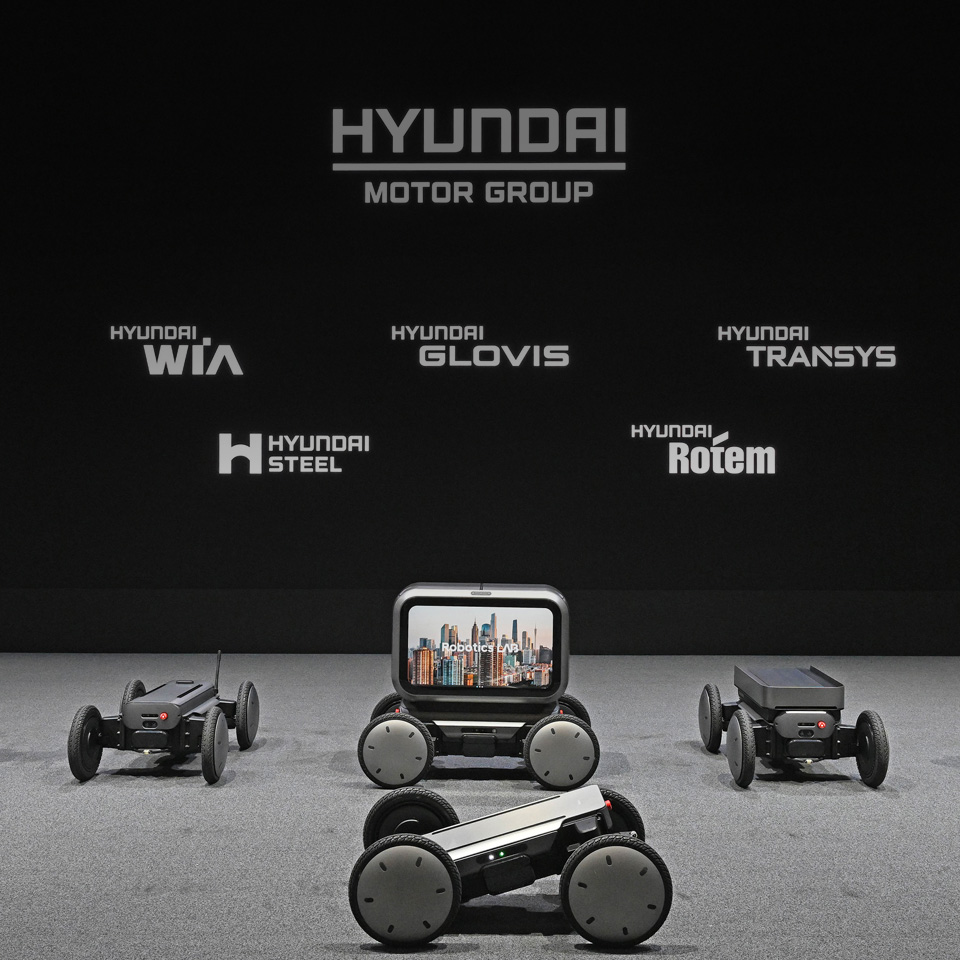

To make its AI robotics collaboration structure intuitive and tangible, Hyundai Motor Group built part of its booth as a scaled-down version of a future industrial site. In the Tech Lab—an exhibition space designed to resemble an AI robotics research environment—the Group showcased not only Atlas, but also Spot performing real operational tasks supported by the Orbit AI software.

Spot moved up and down stairs and navigated between facilities to carry out inspection work—demonstrations that went beyond a simple showcase and instead illustrated specific roles robots are expected to perform in industrial settings. Looking ahead, these capabilities are set to be further advanced through the addition of Hyundai AutoEver’s monitoring and integration solutions.

The Group also demonstrated a coordinated workflow in which Boston Dynamics’ Stretch, Hyundai WIA’s Collaborative Robot (Cobot), and Autonomous Mobile Robot (AMR) operated together to deliver an end-to-end process—from unloading and loading to transport—as a single continuous sequence. This level of organic connection was enabled by close role-sharing and collaboration among the Group’s affiliates, each participating in robotics development and validation by maximizing its specialized expertise.

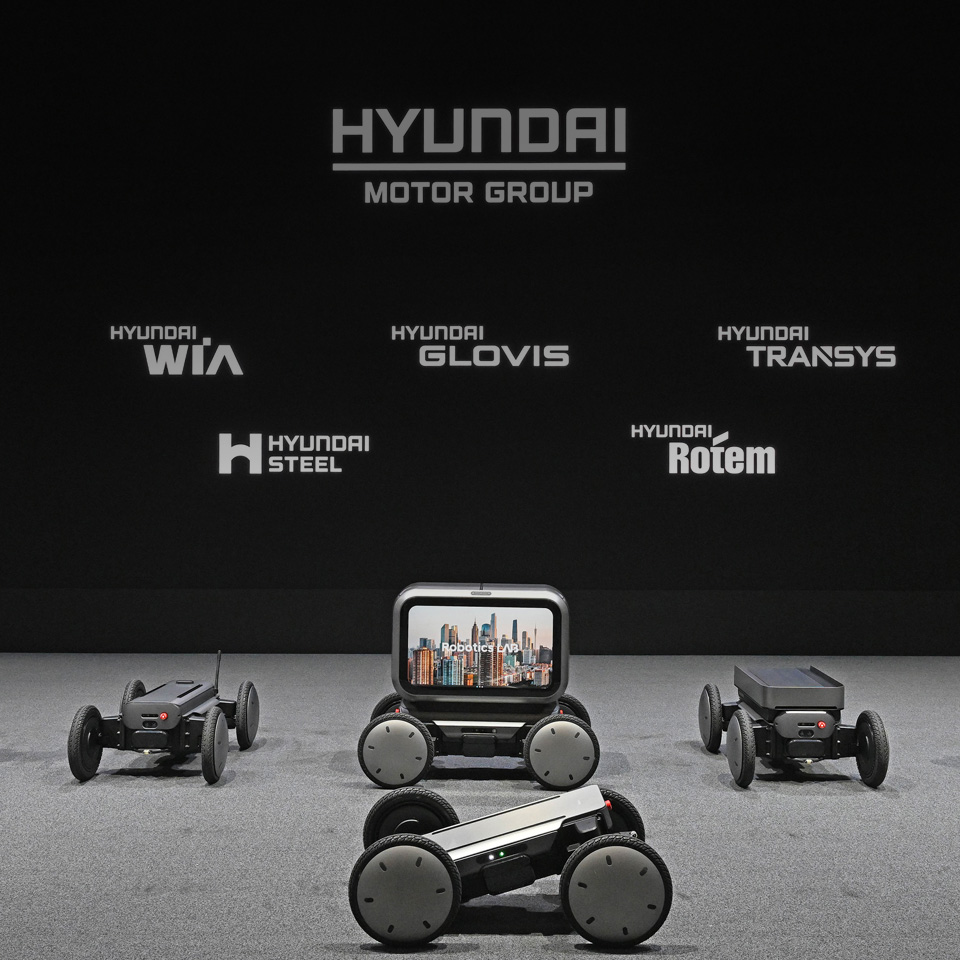

Hyundai Motor Group also conducted exhibits and demonstrations featuring MobED, its next-generation mobility robot platform. The commercial-ready MobED model—Hyundai Motor Group’s first recipient of a CES 2026 Best of Innovation Award—is offered in Basic and Pro lineups, with the Pro model designed as an autonomous-driving-capable platform. It can recognize people and obstacles and is engineered to navigate complex environments safely and reliably.

During the exhibition, Hyundai Motor Group unveiled concept configurations combining a range of top modules, including MobED Pick & Place, MobED Delivery, MobED Golf and MobED Urban Hopper. As MobED demonstrated stable driving even across uneven terrain, visitors were able to experience firsthand the potential of “platform mobility”—a system that can shift roles depending on purpose and operating environment.

The Group also displayed an IONIQ 5 robotaxi Mapping developed with Motional. Beyond the vehicle itself, a demonstration of the Automatic Charging Robot (ACR) charging the robotaxi allowed visitors to see both charging convenience and potential operational scenarios in action, particularly addressing concerns around EV charging. The demonstration was particularly effective in addressing concerns among potential EV customers who remain hesitant due to charging inconvenience.

Hyundai WIA’s Parking Robot also drew attention by demonstrating how it can maneuver a Kia EV6 into a tight parking space—offering a clear look at a technology that is approaching commercialization.

Hyundai WIA participated in CES with a booth for the first time this year. Under the theme “Journey of Connection,” it highlighted thermal management systems, Hyundai WIA components and robot platforms. At the center of the booth, a thermal-management experience vehicle enabled visitors to explore a future climate-control concept based on distributed HVAC (Heating, Ventilation and Air Conditioning).

The distributed HVAC system uses AI and sensors to provide tailored temperature settings for each passenger. A roof-mounted air-conditioning unit delivers cooling and adjusts airflow by detecting occupant movement, while an indirect airflow mode supports those who prefer to avoid direct cold air. Heating is delivered from the lower portion of the vehicle using radiant warmers that emit infrared heat and are positioned beneath the vehicle and under the seats—an approach comparable to Korea’s traditional ondol-style heating.

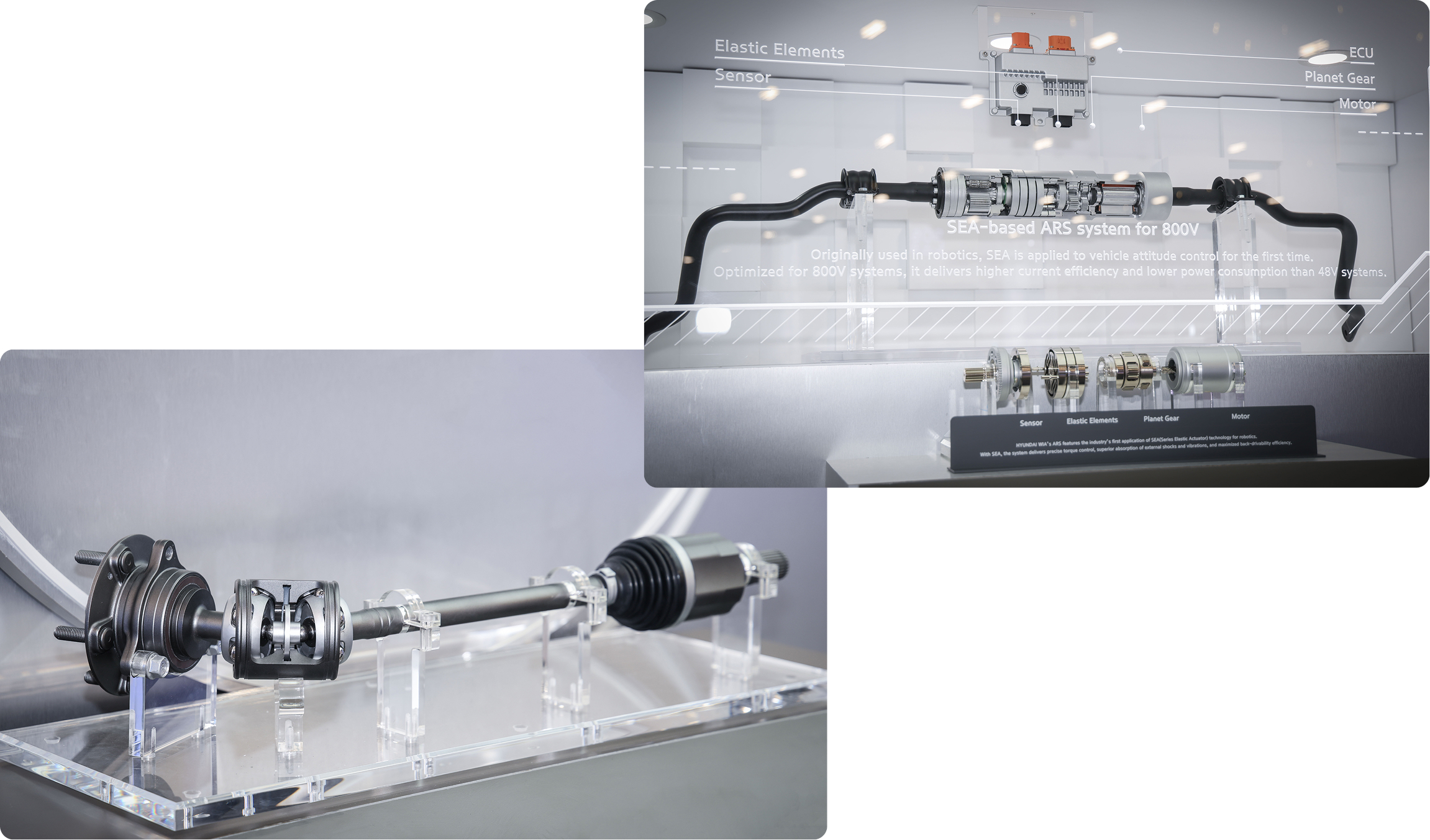

Hyundai WIA also unveiled a range of next-generation Hyundai WIA components. One highlight was the Dual Constant Velocity Joint (Dual CVJ), described by the company as the world’s first. By connecting two constant velocity joints in series, the system significantly expands steering angle range—dramatically reducing turning radius and enabling U-turns in narrow spaces.

Another technology introduced was the Active Roll Stabilizer (ARS), designed to minimize body roll when vehicles navigate uneven or curved roads. Hyundai WIA said the system applies Series Elastic Actuator (SEA) technology—commonly used in robotics—to vehicle control, enabling detection of road-surface changes and vibrations for more precise control. Hyundai WIA displayed the components and used on-screen videos to explain operating principles and illustrate how the technologies perform when applied to a vehicle.

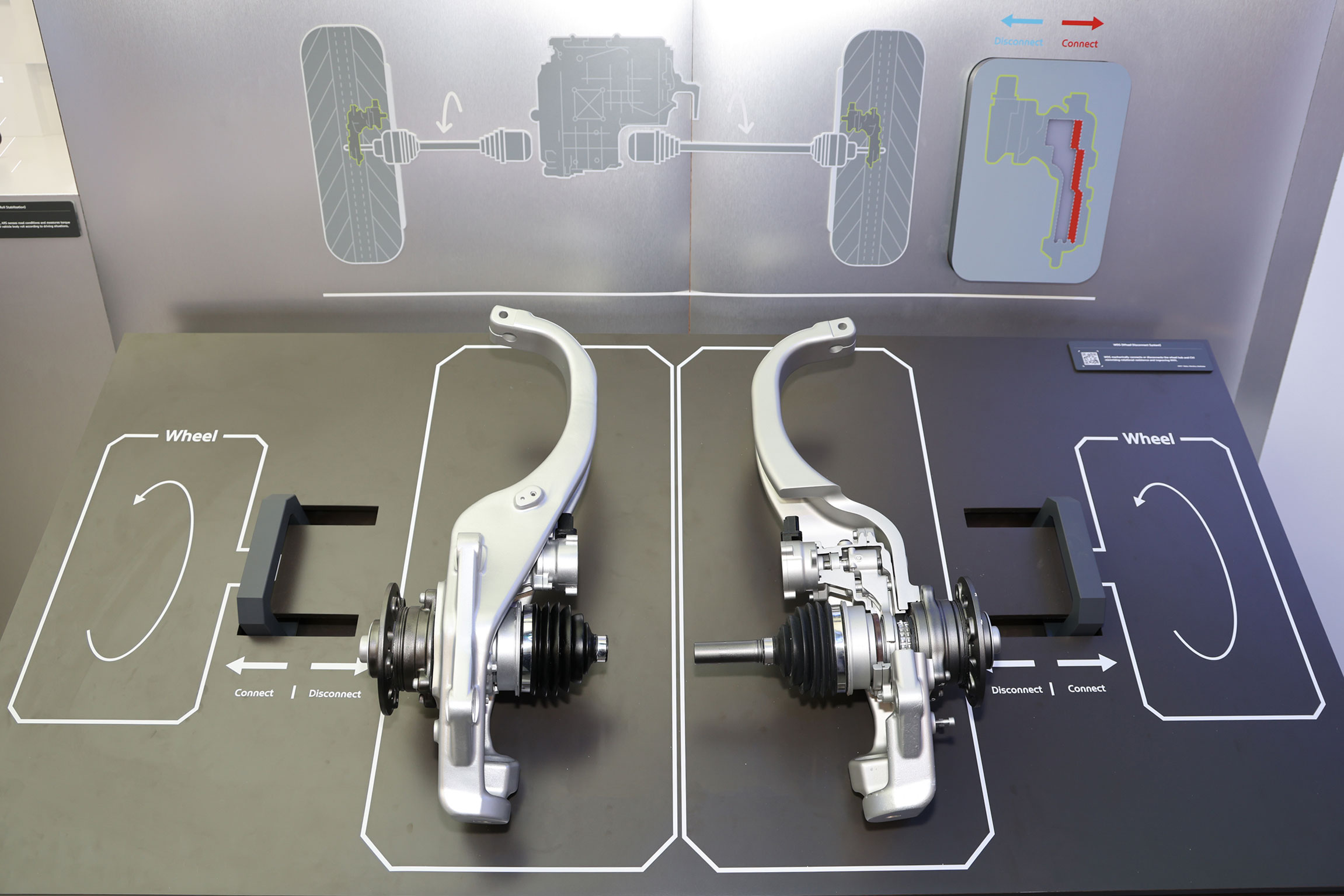

Hyundai WIA also presented the Wheel Disconnect System (WDS), a component that can separate the electric vehicle’s drive shaft and wheels as needed. The system is designed to reduce unnecessary energy losses during driving to improve efficiency and extend range, with a focus on minimizing noise and vibration through precise torque distribution.

Hyundai WIA also introduced H-Motion at CES 2026. H-Motion is Hyundai WIA’s robotics brand and platform, comprising AMR, Parking Robot and Cobot. Its AMR can carry up to 1.5 tons and supports both LiDAR-based autonomous navigation and guided operation using QR-code recognition. The Parking Robot operates in pairs, moving beneath a vehicle to lift the wheels and transport the car, and can carry vehicles weighing up to 3.4 tons at speeds of up to 1.2 meters per second.

Hyundai WIA’s robots were also deployed within Hyundai Motor Group’s booth demonstrations—an on-site illustration of the “partnership” theme emphasized by the Group at CES 2026. If partnerships between humans and robots, as well as between robots themselves, can be achieved in an organic and integrated manner, industrial environments can become safer and more convenient.

Hyundai Mobis also drew attention through a differentiated approach at CES 2026, operating a private booth for invited customer companies. The company used the setting to discuss collaboration plans with global customers and create practical opportunities that can translate into business outcomes.

At a separate technology exhibition space on the third floor of the Convention Center’s West Hall, Hyundai Mobis showcased more than 30 technologies, including M.VICS 7.0, its cockpit integration solution, and X-by-Wire, a next-generation electronic control solution, while engaging with executives from global automakers to explore potential cooperation.

M.VICS 7.0 integrates a holographic windshield display that projects driving information onto the windshield, an 18.1-inch display that can expand vertically, and console controls designed to enhance aesthetics and usability. Hyundai Mobis said the holographic windshield display is being developed in collaboration with German optics company ZEISS, using holographic film technology.

Designed to minimize driver eye movement, the system projects key driving information clearly onto the windshield. Separate content is available for the front passenger, while the display is engineered so passenger content is not visible from the driver’s position, supporting safety.

Hyundai Mobis’ holographic windshield display received a CES 2026 Innovation Award from the Consumer Technology Association (CTA). The company said it is accelerating commercialization with a target of mass production in 2029.

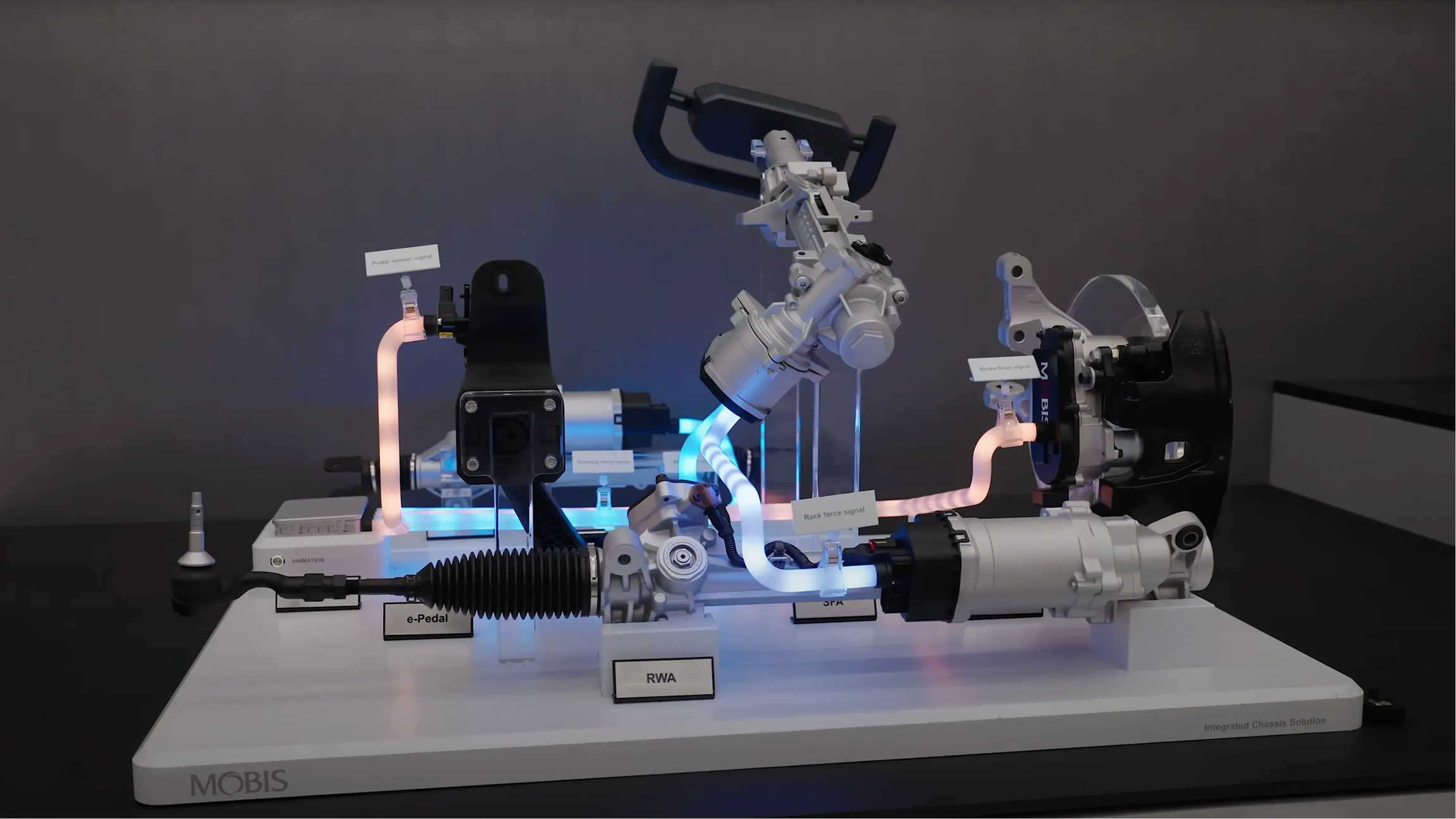

Hyundai Mobis’ X-by-Wire integrated solution combines Brake-by-Wire (BbW), Steer-by-Wire (SbW) and Rear-Wheel Steering (RWS). By controlling steering and braking through electrical signals without mechanical connections, the system increases vehicle design flexibility and is positioned as a core technology for next-generation mobility.

Hyundai Mobis said the integrated approach improves precision and stability by centrally managing key functions such as braking and steering, enabling optimized driving performance. The company also said the system includes redundancy measures so that even in the event of a steering malfunction, braking can help maintain safe vehicle control.

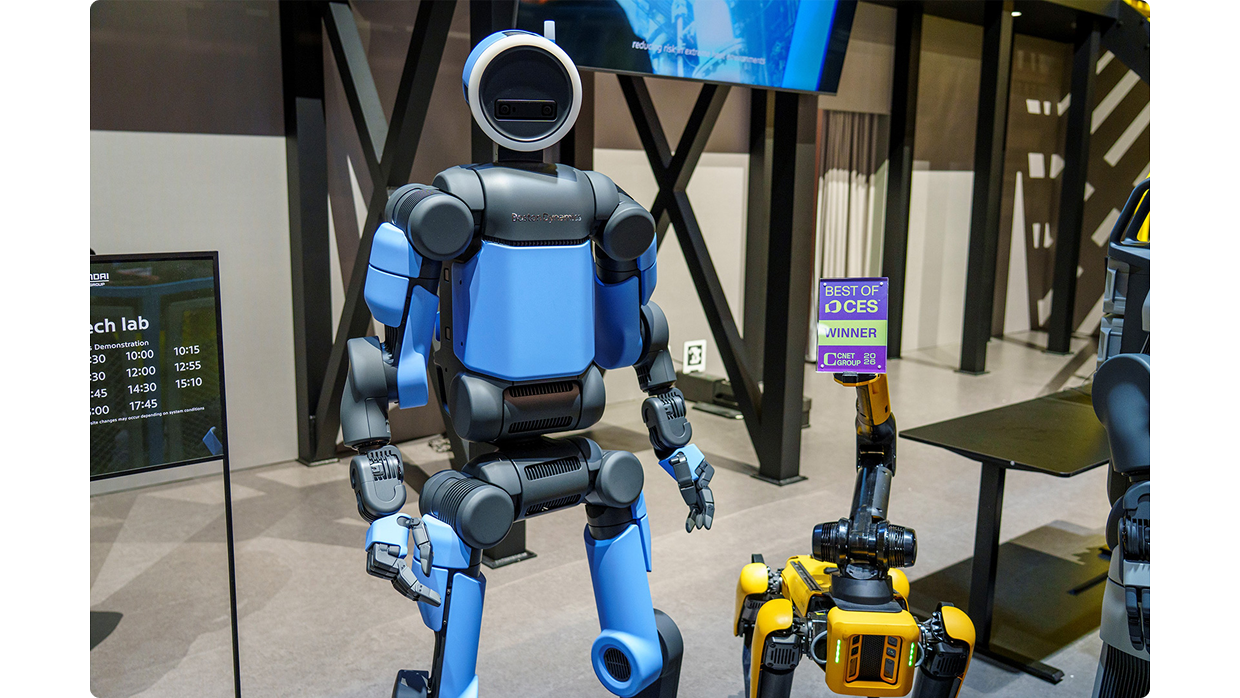

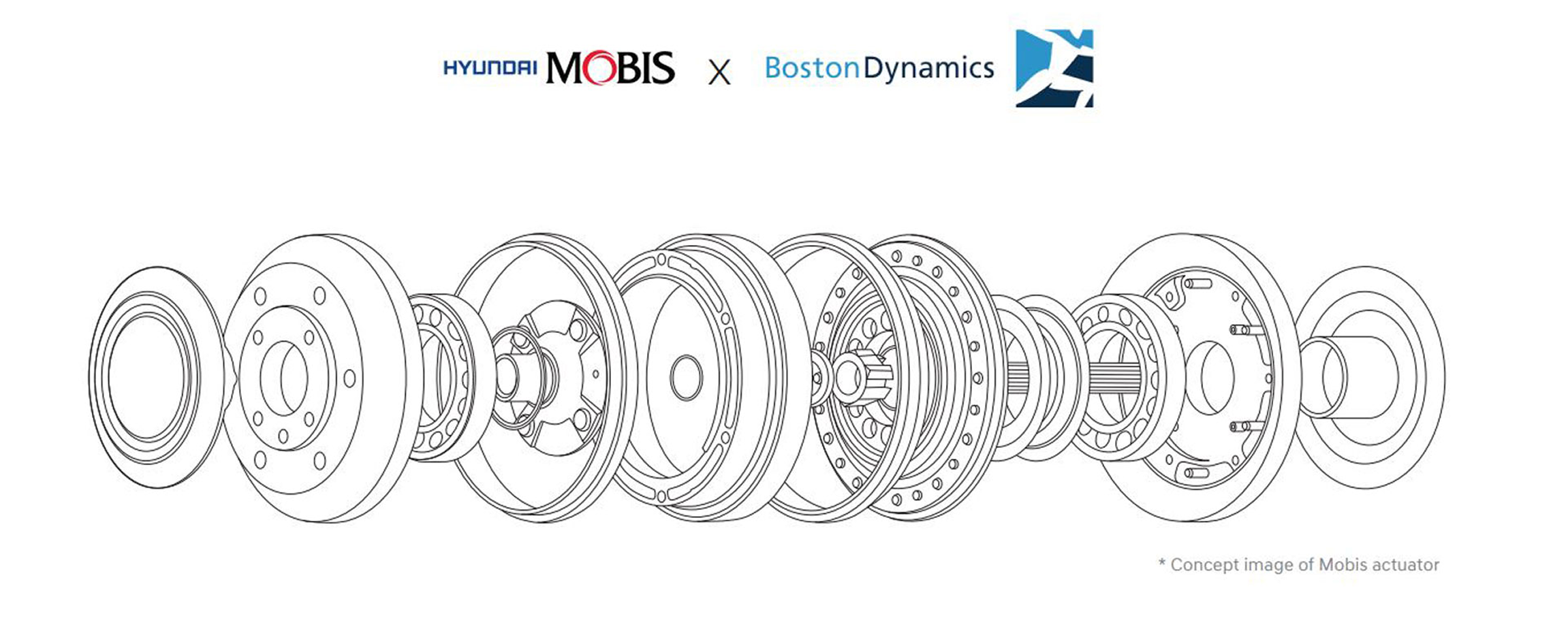

Hyundai Mobis announced at CES 2026 that it has established a cooperation framework with Boston Dynamics and plans to supply actuators when Atlas enters mass production. Actuators serve as critical joint components in robots and can account for a significant share of robot manufacturing costs.

Following Hyundai Motor Group’s August 2025 announcement of plans to establish a new robotics factory in North America, Hyundai Mobis said the collaboration will support the build-out of a mass-production system for robotics. Starting with actuators for Atlas, Hyundai Mobis plans to expand its robotics portfolio to include hand grippers, sensors and controllers.

Hyundai Motor Group’s open innovation platform ZER01NE also participated in CES 2026. The Group said ZER01NE—attending CES for the fourth consecutive year since 2023—supported startup exhibitions across fields including AI, energy, robotics and quantum computing, alongside Hyundai CRADLE, the Group’s global open innovation hub.

A total of 10 startups participated, including Solastic (plastic-packing solar module solutions), Qunova (algorithms and industrial solutions for quantum computing) and IdeaOcean (mechanism autonomous-design software and modular hardware).

Through CES 2026, ZER01NE plans to introduce its open innovation activities and support participating startups as they scale globally.

At CES 2026, Hyundai Motor Group presented an AI robotics ecosystem completed through cross-affiliate collaboration—not a single technology showcased in isolation, but a set of interlocking capabilities designed to operate together across logistics, manufacturing, cities and everyday life.

The ecosystem’s core value lies beyond individual technologies—in the collaboration structure itself. As specialized capabilities connect on site, technologies can be validated faster and their application scope expands naturally. For Hyundai Motor Group, CES 2026 demonstrated that the future is no longer a distant possibility, but an ecosystem already entering the execution phase.