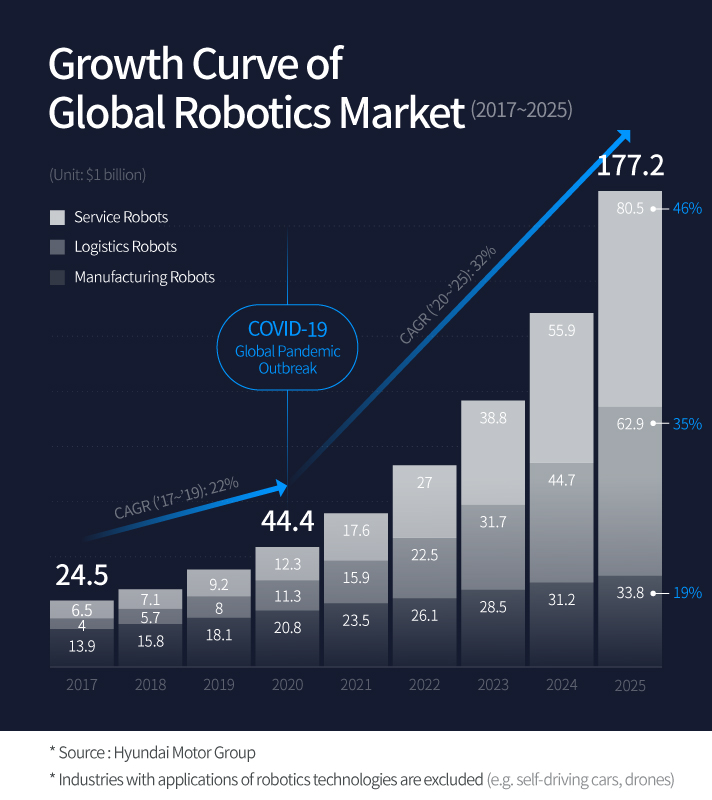

Nearing the advent of the ‘Robot Everywhere’ Age―the age in which robots will have a ubiquitous commercialized presence―the robotics industry is on a meteoric rise. According to Hyundai Motor Group, the global robotics market, which was valued at $24.5 billion in 2017, has recorded a 22% annual growth rate since and was valued at $44.4 billion in 2020. With the shifting economic and social paradigms amid the Covid-19 pandemic, the growth rate is expected to rise further to 32% by 2025, when the market will be worth an estimated $177.2 billion. This figure excludes fields in which robotics technologies are merely applied, such as autonomous vehicle and drone industries, and encompasses only robots produced for service, logistics, and manufacturing; nonetheless, it is still nearly triple the predicted 2030 market size of self-driving cars, which the global market research firm Research and Markets estimates at $60 billion.

The global rise of the ‘Mobility as a Service’ industry―including such services as micro-mobility and shared mobility―is also noteworthy. According to the U.S.-based market research firm Markets and Markets, the industry, which in 2020 was worth $4.7 billion, is expected to grow at 31.1% per year to reach $70.4 billion in 2030. Once the industry begins to seriously incorporate self-driving cars and Urban Air Mobility (UAM), which will increase the demand for hardware, the growth rate may even exceed those expectations.

These predictions stand as the backdrop of Hyundai Motor Group’s acquisition of Boston Dynamics, the world’s leading robotics company. Many car manufacturers are developing robots and/or are partnering with outside robotics companies, but it is rare to find a precedent for a full M&A like Hyundai’s. What accounts for this move? The answer is likely found in the fact that the boundary between robotics and mobility has, in large part, been blurred―we now call autonomous vehicle services ‘Robotaxi’ and autonomous grocery deliveries ‘Robomart.’ Below, let us further review the implications of Hyundai’s Boston Dynamics acquisition.

Robots are increasingly becoming a playing field of global car manufacturers. While revealing its self-driving car concept e-Palette in the 2019 Tokyo Motor Show, for example, Toyota simultaneously unveiled its 6-wheel delivery robot, ‘Micro Palette.’ Likewise, Ford drew attention by revealing Agility Robotics’s legged delivery robot ‘Digit’ at the 2020 CES. There, Digit traveled the 50-ft distance between the autonomous car and the customer to make routine deliveries.

As demonstrated by Digit, the main area of robotics application for self-driving cars is short-distance delivery―such as delivery within doors or from vehicle to doorstep―otherwise known as “last mile” delivery. Of course, the courier vehicle in this scenario must be a connected car that shares with the delivery robot a real-time, cloud-based map; it must also be able to respond to orders and demands from the courier center and the customer and send feedback in the event of unexpected contingencies.

According to Markets and Markets, the delivery robot market will grow from $11.9 million in 2018 to $34 million in 2024, showing an average growth rate of 19.15% per year. The demand for delivery robots will be driven by its ability to cut labor costs―according to a global manufacturing company Honeywell, 53% of logistics costs is incurred by last-mile delivery, dwarfing the cost for line haul (37%), sorting (6%), and collection (4%). Using delivery robots for the last mile can thus potentially decrease one of the largest sources of cost for commerce companies.

The benefits of delivery robots extend also to misdelivery handling; in the U.S., a study found that delivery robots can reduce costs incurred by misdelivery by about $335 million per year. It is also notable that the pandemic has increased the demand for untact deliveries while reducing the supply of delivery labor, accelerating the expansion of the robot delivery service market.

Delivery robots come with lots of potential for expansion, as they will continue to be useful―imagine having one port your shopping cart around―even after mobility paradigms shift and new disruptive technologies like autonomous vehicles and UAM come to the fore. In addition, robots are increasingly becoming a means of not just delivery but of transport of people and goods on larger scales, which means that the trends for car manufacturers entering or partnering with the robotics industry will only accelerate in the future.

“Since 2018, we’ve shifted to becoming a commercial organization,” said Michael Perry, Vice President of Business Development at Boston Dynamics, in an interview with the U.S. based electrical engineering journal IEEE Spectrum. The company had been just announced as having been acquired by Hyundai Motor Group.

Boston Dynamics was founded in 1992 by Marc Raibert, who had been a professor at Carnegie Mellon University and MIT. Starting with its 2004 co-work with NASA and Harvard that produced the four-legged delivery robot Big Dog, the company unveiled a series of robots like Little Dog, Cheetah, and Spot, to garner attention in the emerging robotics industry.

The bipedal robot Atlas, unveiled in 2016, particularly wowed the crowd by performing parkour, handstand, and even backflips, demonstrating the company’s capability to produce “the world’s most dynamic humanoid robot.” Humanlike in shape, Atlas is 1.5 meters tall and weighs 80 kilograms, and it moves at a brisk 1.5 meters per second. Popular Mechanics, an over century-old stalwart magazine in the field, dubbed Atlas’s backflips as “10-out-of-10” on the gymnastic scale.

Last December, the company made headlines yet again by revealing a viral video on YouTube featuring its robots―Atlas, Spot, Pick, and Handle―dancing to the tune of Do You Love Me by the Contours. More than just entertainment, though, this lineup of dancers has propelled Boston Dynamics to the top of the robotics industry, unequivocally strong in both hardware and software.

Spot, the four-legged robotic dog, is Boston Dynamic’s first commercialized robot. The price is $74,500, and the company has sold about 400 units in the last six months, generating over $30 million in revenue. Equipped with LIDAR, a 360-degree camera, and IoT sensors, Spot can serve as a mobile surveillance or monitoring unit that simultaneously compiles data. Spot’s four legs move in a fluid motion that evades obstacles and traverses rough surfaces far better than wheels can, and they are also sturdy enough to withstand a maximum of 13.6 kg of cargo.

Spot’s ability to mount diverse IoT sensors and to navigate through rough surfaces sets it apart from wheeled robots. That’s why it is being used in extreme terrains unfit for human presence―for example, Spot was recently deployed in Chernobyl, Ukraine, where the radiation from the nuclear disaster in 1986 still prohibits safe human entry. Spot measured the radiation and EMF levels throughout the site and generated a 3D map, successfully demonstrating its ability to replace human labor in an unsafe environment.

In a similar vein, NASA has recently unveiled Au-Spot, Spot’s reconfigured version for exploring Mars. Au-Spot will be deployed to Mars to assist in establishing a manned base camp, providing the astronauts a virtual map of the area and underground caves. NASA’s Rover, which has been responsible for those tasks, can only move well on even surfaces and weighs 12 times as much as Spot. Spot is also faster―the Curiosity Rover currently on Mars moves at the speed of 0.14km/hr, whereas Spot moves at a much more efficient 5 km/hr.

Swinerton, an American construction company, uses Spot in its many Texas construction sites. There, Spot is used for construction data collection (e.g. number studs and electrical conduits), for creating a “digital twin” of the construction site in virtual reality, and for verifying the real site’s match with the building information modeling.

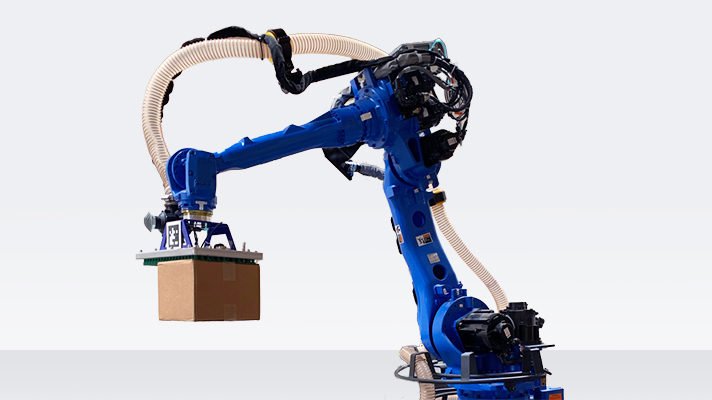

Other Boston Dynamics products drawing the market’s attention are Pick, which has now commercialized, and Handle, which will be made available in 2022. Pick is a vision processing solution that uses deep learning to move boxes of various sizes and shapes from a mixed stock-keeping unit onto a conveyor belt. It uses high-res 2D and 3D object detection to discern the boxes in view and optimizes the processing route for each box. Compatible with most industrial robotic arms in use, Pick functions well even under poor lighting conditions and processes as many as 720 boxes per hour.

Handle is essentially Pick on wheels―resembling an ostrich, it is sometimes called the “Ostrich Robot.” Thanks to its mobility, it can be deployed onto trucks and containers where standard industrial robotic arms are not easy to install. Handle can discern various locations of boxes in a warehouse and bring them together on a pallet, or “palletize” for short. It can also distribute boxes on a conveyor belt to various production lines. Handle has a reach of 3 meters and moves on two wheels. It moves a 15-kg box at a speed of 4 m/s, which makes it capable of handling over 360 boxes per hour.

So what’s behind the Hyundai Motor Group’s acquisition of Boston Dynamics? First, the acquisition jump-starts the group’s announced transition to a “Smart Mobility Solution Provider,” during which the core areas like vehicle electrification, autonomous driving, mobility as a service, and UAM will require capabilities in robotics. In an age in which low birth rates and extending life span reverses the population pyramid and makes active labor scarce, and especially in an age in which the Covid-19 pandemic is accelerating society’s transformation to the untact and the digital, the rising demand for robots in both manufacturing and service (e.g. health care, delivery, disaster relief, personal secretary) can be said to have prompted this move.

Combining the robotics expertise of Boston Dynamics with the Hyundai Motor Group’s world-class capacity for mass production will allow the group to effectively enter the global robot market. From the intra-group perspective, Hyundai Mobis and Hyundai Glovis may stand to expand their business areas by incorporating robots into Smart logistics solutions.

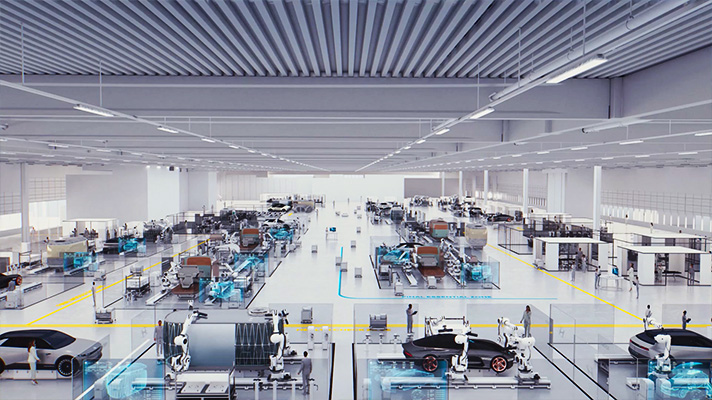

Second, the acquisition should produce synergy by adding robots to some of the group’s existing projects. The group’s new “growth engines,” like eco-cars, self-driving cars, and UAM, must be envisioned in a way that is different from the past in all aspects―not limited to just service, but also manufacture, production, R&D, and logistics. Consider Hyundai Motor Company’s goal to electrify all lineups for global major markets by 2040 and to achieve 8 to 10% global EV market share. Doing so will require the cost-competitiveness that innovating the production platform can definitely deliver. Hyundai Motor Company has already launched AI- and robotics-based Smart Factory brand e-Forest, in which robots like Pick and Handle will surely serve essential roles.

Third, robots share many base technologies with autonomous vehicles, UAM, and PBV, all focal areas of the Hyundai Motor Group. Using various sensors and AI to discern and respond to the surroundings and developing precision parts and system controls are as important to realizing future mobility in general as they are to robots. Hyundai’s expertise in this area has so far been in sensor fusion technology, for collecting and processing data from cameras, radars, and LIDAR, and in developing and improving the electronic control unit for various autonomous driving features. Adding the expertise of Boston Dynamics here is sure to produce many synergies.

Finally, it adds to the group’s long-term potential. Humanoid robot Atlas is still at a research platform stage, and much time will be needed before it can be commercialized and mass-produced. But the potential for a humanoid robot―or even a robot with just human arms and hands―that can replace human labor, particularly in dangerous situations like disaster relief or patient care, is obviously great. The humanoid robot industry can thus be an area of expansion for the group in the future. Just as Spot is already transcending human limitations on Mars, future Hyundai robots might not only bring efficient labor but deliver on the end of corporate social responsibility.

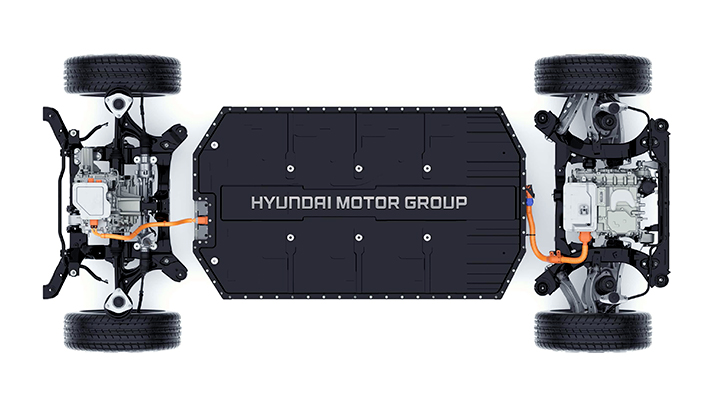

Hyundai Motor Group is moving fast. Announcing its plans for UAM, investing in the British smart-EV firm Arrival, partnering with Kanu for developing Purpose-Built Vehicles (PBV), founding a joint autonomous driving venture Motional with APTIV, launching the AI- and robotics-based Smart Factory brand e-Forest, and unveiling the group’s first BEV-exclusive platform E-GMP―all are important steps toward the group’s declared transition to a “Smart Mobility Solution Provider,” propelling the group to the leadership role in the future mobility industry.

Currently, 20% of Boston Dynamics is owned by Softbank Group Corp, which is the largest shareholder of Uber and owns a diverse group of global mobility service providers. In June 2020, it invested $500 million to Didi Woya, Didi Chuxing’s self-driving affiliate. The Softbank Vision Fund portfolio includes robotics companies Brain and Cloudmind, mobility service providers Tier, Grab, Getaround, and Ola, and self-driving technology developers Cruise and Nuro. This diverse lineup should also provide meaningful synergy if Hyundai Motor Group opts to collaborate with the Softbank Group.

Global attention to the mobility industry’s development and evolution is at an all-time high. The direction of the industry’s future can be summarized into four aspects: (1) diversifying the means of transport beyond automobiles, (2) ensuring easy access, particularly for the transportation-disadvantaged, by establishing on-demand type services, (3) providing new user experiences (UX) beyond just physical movement from one point to another, and (4) expanding the definition of safety to concern not only car accidents but also viruses and air quality.

Following this vision, cars themselves and the philosophy behind their designs are increasingly changing from “an efficient means of transport” to “an interactive, value-added UX provider.” As technology frees the driver from the physical maneuver of the vehicle, cars are expected to become spaces for rest, leisure, and work. Hyundai Motor Group’s acquisition of Boston Dynamics makes sense in this regard: not only will it help the group gain a foothold in the robotics industry, but it will also help the group create new services and values in the mobility area―indeed, the group’s transition to a Smart Mobility Solution Provider just got a lot faster.

by Cha Doo-Won

Having majored in human machine interface and technology management, Cha now runs the Cha Doo-Won Mobility Research Institute. He has worked for Hyundai Mobis, Korea Institute of Science & Technology Evaluation and Planning, and 42dot, and currently chairs the Office for Government Policy Coordination’s New Industry Regulation Committee, Ministry of Land, Transport, and Maritime Affairs’ Mobility Innovation Committee, and Autonomous Vehicle’s Convergence Future Forum. He’s authored such books as <Future of Mobility>, <Job Killer>, and <Shared Economy and the Future of IoT>, and is interested in the domestic/global policies on the mobility industry, future technology, and companies’ strategic and alliance evolutions in those contexts. He personally aspires to contribute to Korea’s mobility ecosystem by helping envision more human-centered and safe mobility devices and services as well as by helping lift regulations.

*This op-ed presents the subjective opinion of the author and does not necessarily represent the editorial direction of the HMG Journal.