Zero to 100km/h in 3.5 seconds, maximum speed of 260km/h - these records symbolize the powerful performance of the Kia EV6 GT. With a maximum output of 430 kW (585 horsepower) and a maximum torque of 740 Nm (75.5 kgf ·m), the EV6 GT boasts specifications that suit the title of ‘the fastest car in Korean automobile history’. As such, the EV6 GT plays a role in promoting Kia’s excellent electrification technology to the world based on its explosive power performance.

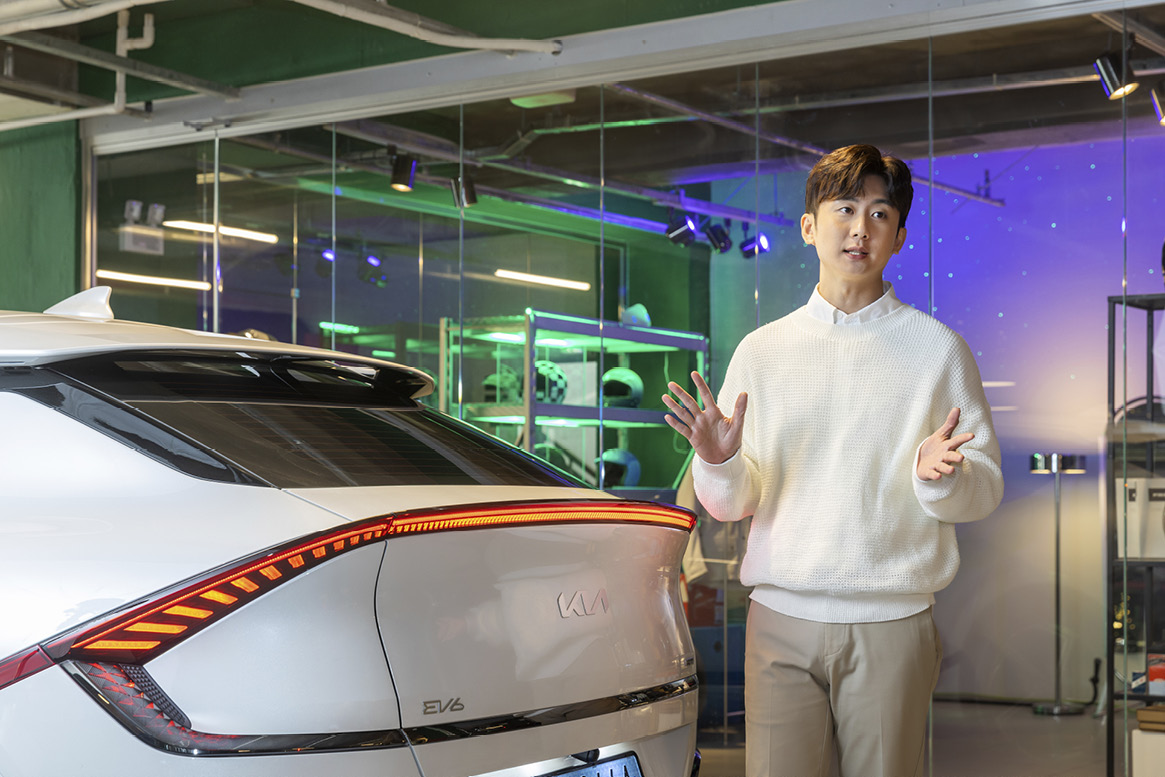

Here, senior researcher Gangho Jung of the inverter design team and researcher Seongwon Jung of the EV drive design team 1, who developed the high-performance motor system of the Kia EV6 GT, explained the secret to the EV6 GT’s overwhelming performance comparable to that of a sports car.

Q. The EV6 GT, the top-of-the-line EV6 model and high-performance electric vehicle, was recently released. What is the reason for developing such a powerful electric vehicle?

As the center of the global automobile market rapidly shifts from internal combustion engines to electric vehicles, high-performance electric vehicles are becoming an indicator of the automaker’s electric vehicle technology. In addition, consumer demand for high-performance electric vehicles is also rapidly increasing, which is because they have experienced the exciting acceleration performance and quick response unique to high-performance electric vehicles. Therefore, Kia developed the EV6 GT, a high-performance version of the EV6 in line with the trend of the electric vehicle market. The EV6 GT succeeded in demonstrating unprecedented power performance by combining a greatly improved motor system - motor and inverter - with a high-output battery.

Q. The rear wheel motor with a maximum output of 270kW is a unique feature of the EV6 GT. What technologies are used in motor systems to achieve high power?

The key to the Kia EV6 GT’s explosive power performance is its rear-wheel motor system. A rear-wheel motor system using 2-stage motor system technology has been newly developed for high output that suits high-performance models. Through this, the rear wheel motor system of the EV6 GT realized the maximum output of 270kW, about 170% of the current EV6. The EV6 GT has a total system output of 430 kW (585 hp) and boasts overwhelming acceleration performance from 0 to 60 mph in just 3.5 seconds.

Q. What are the ways to increase the output of electric vehicle motors?

In general, there are two ways to increase the output of an electric vehicle motor. The first is to increase the voltage supplied to the motor, and the other is to reduce the motor’s inductance (the amount of torque generated per current). Since the voltage is determined by the battery capacity, cell voltage, series/parallel structure, and vehicle layout, it is not easy to simply increase the voltage. On the other hand, reducing the inductance of the motor increases the current of the motor and the current capacity of the inverter, which causes power conversion loss and reduces efficiency.

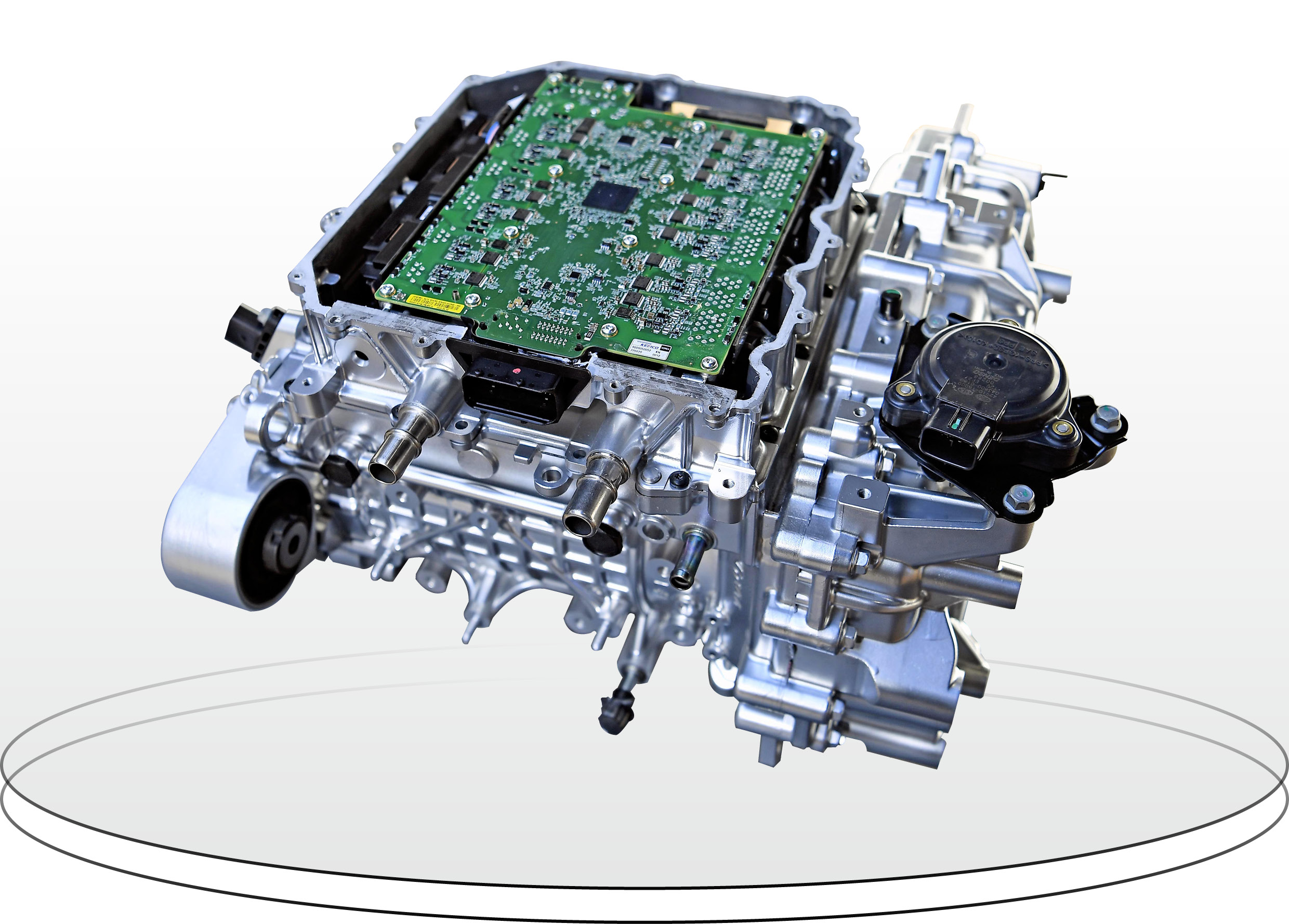

To overcome these technical limitations, a two-stage motor system was developed. The EV6 GT’s two-stage motor system has two inverters, so a larger voltage can be applied to the motor without changing the battery voltage or motor inductance; This would be the key to the EV6 GT’s high output.

Q. What kind of technology is the 2-stage motor system topology?

First of all, topology is a term meaning an electrical structure between a motor and an inverter. Depending on the topology configuration, the output and fuel efficiency of the electric vehicle vary greatly, and the 2-stage motor system topology operates through 2-stage modes using dual inverters, unlike general electric vehicles. For example, when the driver drives daily, one inverter is operated to maximize efficiency, and when the driver wants fast acceleration, two inverters are used to maximize the output of the motor system.

Q. Under what conditions does the high-efficiency mode and high-output mode (2-stage) switch?

The high-efficiency mode operates in normal driving situations - low to medium speed - and uses only one inverter to drive the EV6 GT. In high-output mode, when driving at high speed or when high torque is required, two inverters are operated to exert maximum output. Conversion between these two modes is determined by the motor control unit (MCU) itself according to the torque, speed, and battery voltage of the motor system. In addition, the mode is switched according to how hard the driver presses the accelerator pedal, that is, the demand for acceleration, and the state of charge (SoC) of the battery.

Q. When switching from high efficiency mode to high power mode or vice versa, do drivers feel a sense of difference in driving?

The control of driving heterogeneity between modes was the most important in the process of developing the 2-stage motor system. If the torque changes when switching from single inverter mode to dual inverter mode, it can startle the driver or cause awkwardness. Torque fluctuations occur when there is a difference or discontinuity in motor current, and the 2-stage motor system houses a mode switching control algorithm that considers this. In other words, the 2-stage motor system naturally switches modes without the impact of motor current, and the driver can seamlessly enjoy the excellent driving performance of the EV6 GT.

Q. The volume of the motor system may increase as much as it exerts powerful output. Were there any difficulties in utilizing a high-output motor system on the same E-GMP platform?

If a high-powered motor and an inverter were used as the design method of the existing motor system, the size of the motor system would have become the same because the volume of the inverter was increased. However, since the EV6 GT must use the same platform as the existing EV6, it was necessary to develop a high-performance motor system suitable for the limited vehicle structure. The two-stage motor system minimizes the volume of the inverter. This effectively reduced the volume compared to the output by utilizing the power module (power semiconductor) developed by Hyundai Motor Group without significantly increasing the current of the inverter. In addition, the 2-stage motor system can be easily utilized on the same platform through modularization. This will be used in other high-performance electric vehicles that Hyundai Motor Group will introduce in the future.

Q. The EV6 GT is widely known for its overwhelming top speed record. What is the secret to reaching 260 km/h?

Unlike an internal combustion engine, an electric vehicle is driven through a reduction gear, so it must reach the maximum speed without a separate shift; This means that the rotational speed of the motor must be increased. Hyundai Motor Group developed a top-notch, high-revving electric motor to ensure the highest speed driving capability befitting the EV6 GT, a high-performance model. The rotational speed of the rear-wheel electric motor, which is the main drive motor, has been greatly improved from 15,000rpm to 21,000rpm, and the rotational speed of the front-wheel electric motor is also at the same level.

Q. What were the technical difficulties in developing high-revving electric motors?

It is easier said than done to improve the rotational speed of an electric motor; In order to increase the rotational speed of an electric motor, not only durability, but also various issues such as cooling and NVH (Noise Vibration Harshness) must be considered, and a high level of design is required for this. In addition, dedicated technology suitable for high-speed motors is needed to solve the increase in centrifugal force and increase in heat loss that inevitably occur as electric motors increase in speed. For this reason, many global automakers are making high-performance electric vehicles, but it is not easy to use high-revving electric motors.

Q. What are the characteristics of the high-revving electric motor housed in the EV6 GT?

To ensure durability of high-revving electric motors, Hyundai Motor Group optimized the shape of the bearing cage and refined the arrangement of permanent magnets and the shape of the rotor core to greatly improve *stress distribution. In addition, the bearing type was changed to an oil lubrication method, and the cooling efficiency was improved by directly cooling the rotor. In addition, overlapping frictional parts are minimized through an integrated structure of an electric motor, inverter, and reducer. In addition, in order to cope with the amount of heat generated by the high-speed electric motor, the design was designed to minimize losses and focused on increasing durability and efficiency by improving oil lubrication.

*Stress is the measure of what the material feels from externally applied forces such as compression, tension, bending, and torsion.

Meanwhile, the rotor shaft has also been improved to solve the noise and vibration problems caused by high rotation. In order to respond to high-speed rotation, the shape and design method of the rotor were optimized, and the rotor shaft was designed in a two-piece method to secure high quality. In addition, excellent high-speed rotation performance was secured through stabilization throughout the electric motor, minimization of unbalance, and design to reduce vibration/noise at high frequencies.

Q. As it is equipped with a high-revving electric motor, there will be a lot of heat in high-speed driving. Was a specific technology used for cooling?

Reliability is just as important as strong power performance in high-performance electric vehicles; The ability to maintain high performance over a long period of time is very important for high-performance electric vehicles. The electric motor of the EV6 GT uses a cooling technology specialized for high performance. Unlike current electric motors in which cooling water only flows through the housing, the EV6 GT’s motor system greatly improves its cooling performance by injecting cooling oil directly into the motor’s coils and interior through cooling pipes. In particular, the EV6 GT uses a cooling design specialized for high performance along with the basic motor cooling structure of the existing E-GMP, enabling effective cooling even in extreme situations where the electric motor rotates up to 21,000 rpm.

Q. As the ones who developed a high-performance motor system, what do you want to emphasize to EV6 GT owners?

With the world’s first 2-stage motor system topology technology, the Kia EV6 GT has become the car with the strongest acceleration performance in Korea. In addition, the top speed of 260 km/h boasted by the world’s best high-revving electric motor is an indispensable attraction of the EV6 GT. The EV6 GT, created with such excellent power performance and dynamic driving quality, is a high-performance electric vehicle that thrills car enthusiasts. Through the Kia EV6 GT, we hope that not only car enthusiasts but also many customers can fully enjoy the excellent performance of high-performance electric vehicles.

Photography by Geunjae Lee