The electrification business platform 'ST1' introduced by Hyundai combines a chassis* cab-based expandable hardware with diverse software technologies, creating a new genre of mobility. The first lineup under ST1 includes 'Cargo' and 'Refrigerated Cargo' models, optimized for logistics and delivery, offering several innovative specifications that revolutionize the concept of traditional fulfillment* vehicles. Hyundai's ST1 models, Cargo and Refrigerated Cargo, lead to a more convenient and safer business life.

*Chassis cab refers to a vehicle that consists of only a chassis (vehicle frame) and cab (passenger compartment) and does not have a cargo compartment behind the cab.

*Fulfillment refers to a service that handles the entire logistics process, from product ordering to delivery.

Starting with the cargo model, ST1 is poised to delve into the domestic and international business mobility markets. One of the core values of ST1 is its infinite scalability. The chassis cab model features a 'Plug & Play' technology, allowing various expansions by connecting power and communication data of specialized vehicle equipment through connectors inside and outside the vehicle. Such a flexible hardware design of the chassis cab model paves the way for various specialized ST1 models in the future, such as campers optimized for outdoor activities or open-bed trucks with maximized load capacity through technological partnerships.

ST1's scalability is more than just a hardware level; Hyundai has introduced a 'Data Open API (Application Programming Interface)' for the first time, allowing customers and partners to freely communicate data. With the data open API, standardized vehicle-related data can be shared externally, facilitating the development of associated applications.

The reason for equipping with an Android OS-based infotainment system also lies in such scalability, providing an environment where applications or services developed by customer companies can be easily implemented. In the future, Hyundai plans to enhance the value of customer businesses by providing various data and functionalities through such software features of ST1 and developing applications that reflect vehicle information.

Unlike common logistics vehicles, the ST1 Cargo adopts a semi-bonnet type like European LCVs (Light Commercial Vehicles). This structure allows for a wider area to absorb impacts in the event of a frontal collision, benefiting passenger safety. Add-on protectors have also been added to the frequently damaged bumpers and lower side panels to enhance durability. Moreover, pixel pattern details have been engraved on the bumpers and grilles, and parametric pixel designs applied to the tail lamps incorporate Hyundai's EV identity and futuristic sensibility.

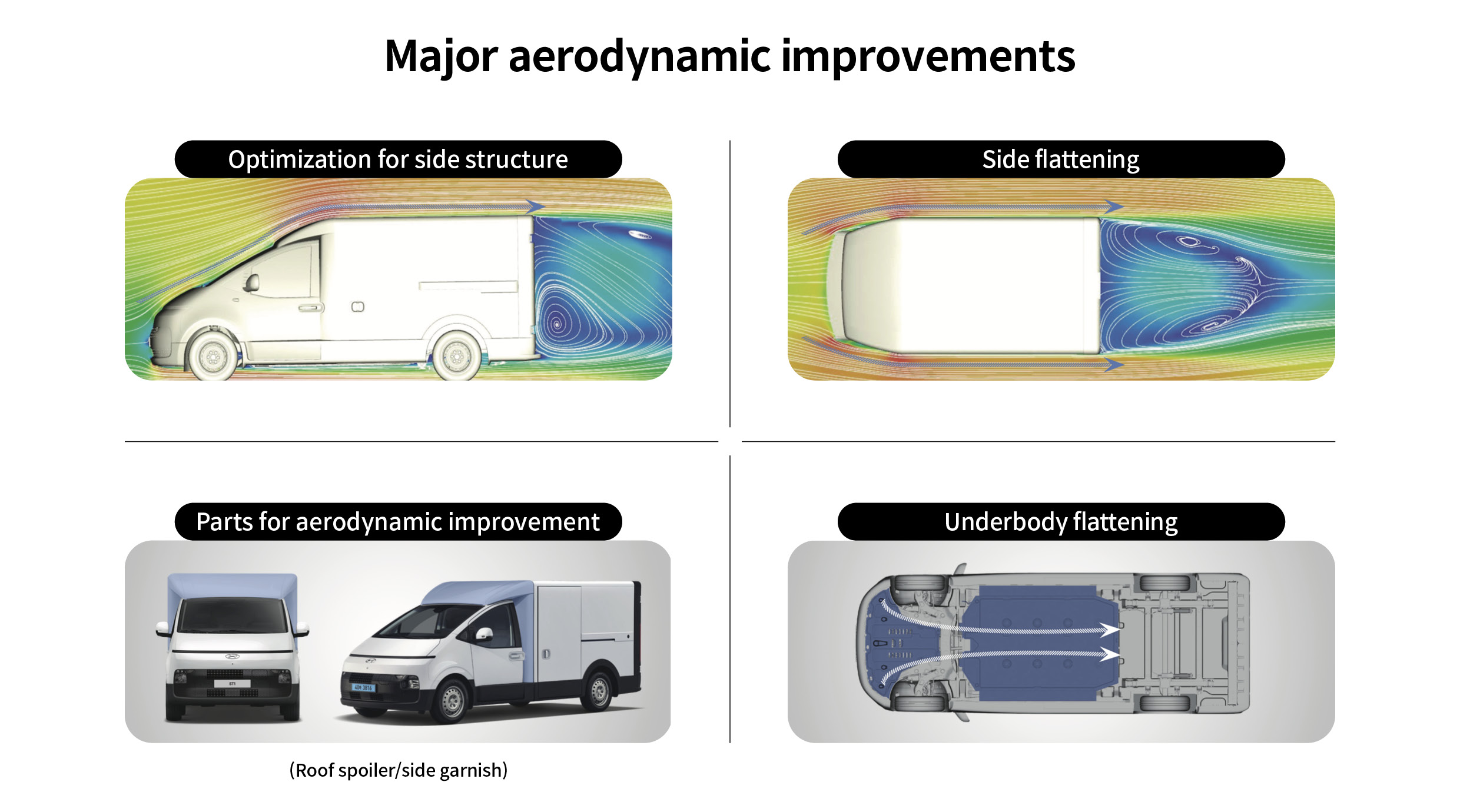

The ST1 Cargo achieves an impressive drag coefficient (Cd 0.290, for the Cargo model), comparable to passenger cars, reflecting several designs that enhance aerodynamic performance to improve fuel efficiency. For example, the ST1 Cargo features a front-end structure with maximized forward angles, and the roof spoiler and side garnishes connecting the body and cargo box are designed in the smoothest shape possible to minimize drag. Furthermore, most elements, such as the underbody panels and the locking mechanism of the cargo box, are designed flat to achieve excellent aerodynamic performance.

The ST1 Cargo is based on a new low-floor electrified platform optimized for cargo loading. Hyundai has designed a new platform with the floor as low as possible for ease of loading, based on the third-generation platform. For example, the step height of the cargo bay was reduced to 38 cm, reducing physical strain and fatigue for delivery workers who repetitively load and unload hundreds of times a day.

Moreover, Hyundai maximized the internal width to accommodate large cargo easily, creating a spacious loading space of 8.3 m³ (7.2 m³ for Refrigerated Cargo). Despite this, the ST1 Cargo's low-floor design keeps the total height of the vehicle including the cargo bay to just 2.2 m (2,230 mm), making it possible to enter most underground parking lots previously inaccessible to small logistics vehicles due to the 2.3 m height restriction.

The electric motor produces a maximum output of 160kW and a maximum torque of 350Nm, allowing the ST1 Cargo to travel comfortably in urban and highway settings. It also features a 76.1kWh battery, achieving a driving range of 317km (Cargo Refrigerated at 298km). Considering the average daily driving distance of 42km for delivery vehicles (according to the Korea Transport Institute), the ST1 Cargo’s range is sufficient for a week's travel without the need for recharging.

The benefits of the latest EV platform continues; The ST1 Cargo supports the Vehicle-to-Load (V2L) function, which allows the vehicle battery to be used as an external power source. Additionally, its 350kW ultra-fast charging system can recharge the battery from 10% to 80% in just 20 minutes. Given the logistics industry's emphasis on time equating to business value, the ST1 Cargo's rapid charging capability is expected to significantly influence consumer choice.

The ST1 Cargo, equipped with a large cargo bay, requires particular attention to safety due to its long and tall structure. Especially given the frequency of navigating narrow alleys in delivery operations, damage to the vehicle body is common. The ST1 Cargo addresses these concerns of logistics and delivery workers with specialized features to aid in more comfortable operations.

For instance, ultrasonic sensors located at the upper rear of the cargo bay help prevent collisions during slow reversals. The linked "Cargo Rear Collision Warning System" a-lerts the driver of collision risks through warning sounds and messages on the cluster. Additionally, the cargo bay’s side sliding door is electrically operated for one-touch control, and features a 'Smart Walk Away' function that automatically locks the doors when the key fob* is moved away from the vehicle, preventing theft.

*key fob: A small remote control device that controls a remote keyless entry system

Moreover, 'Smart Drive Ready' is a specialized feature designed for delivery drivers who frequently enter and exit the driver's seat. This system automatically starts and stops the engine without pressing the ignition button based on various sensors, including a seating sensor (the Cargo Refrigerated model can only auto-start considering the freshness of the cargo). ST1 Cargo also introduces remote smart parking assistance, surround view monitors, blind-spot monitors, and safe exit warnings among other advanced technologies to ensure safe disembarking and parking.

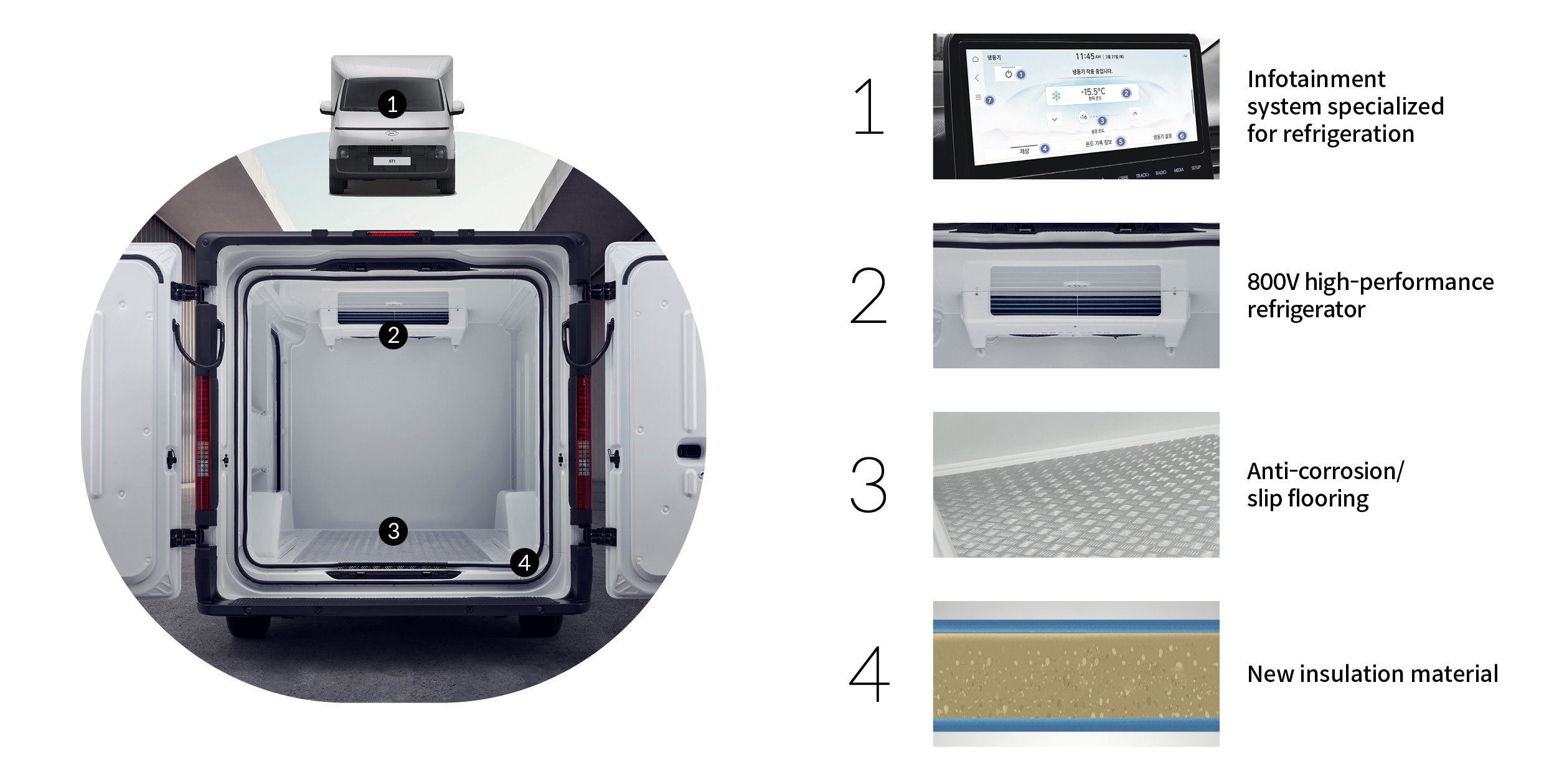

The ST1 Cargo Refrigerated model includes dedicated technologies to maintain optimal storage conditions for the cargo. The refrigeration unit uses the vehicle's high-voltage battery directly, reducing the hassle of charging a separate battery. The cargo bay is insulated with new materials that minimize thermal conductivity, ensuring minimal cold air escape. Furthermore, integration with the infotainment system allows easy control of the refrigeration unit from the driver's seat and monitoring of the cargo bay’s temperature records.

The ST1 Cargo moves away from the rough aesthetics typical of logistics and delivery vehicles, offering a comfortable travel experience with a modern interior layout. For instance, an intuitive electronic shift button, a large 12.3-inch digital cluster, and a 10.25-inch cargo model-specific infotainment system provide a high-tech image with excellent visibility and operability.

The vehicle also features a large center console and overhead console roof trays, providing ample storage space. Additional premium convenience features include a built-in cam, after-blow system, ventilated seats, and wireless smartphone charging, offering value comparable to that of MPV passenger cars.

ST1 Cargo includes a comprehensive intelligent safety technology (ADAS) package as a standard feature, enhancing safety and convenience. It incorporates smart cruise control with stop-and-go functionality, high beam assist, and various forward collision avoidance assist technologies that recognize and prevent collisions with multiple types of obstacles (vehicles, pedestrians, cyclists, oncoming vehicles at intersections). It also features driver attention warnings, leading vehicle departure a-lerts, lane departure prevention, and lane keeping assist, meticulously ensuring the driver's safety from all angles.

Hyundai's ability to create the innovative ST1 Cargo was made possible by actively incorporating feedback from actual logistics service workers. Incorporating customer voices into products lays the foundation for building a business vehicle ecosystem. Hyundai continues to lead in mobility innovation, listening to customer feedback and constantly striving to enhance the business value for its clients.