The compact electric SUV EV3 has garnered significant interest. While there is a perception that the electric vehicle market has hit a "chasm"—a period of stagnant demand before widespread market adoption—practical and reasonably priced compact electric SUVs like the EV3 remain highly competitive.

Electric vehicles offer futuristic styling that allows owners to express their individuality. Their structure, with batteries placed on the floor and wheels pushed to the corners, maximizes interior space, a significant advantage for SUVs. Electric powertrains are easy to operate, contribute positively to sustainability, and are more cost-effective to maintain than internal combustion engines. Combining these benefits with an attractive price makes for a compelling proposition.

The EV3 embodies all these advantages. It focuses on critical aspects such as driving range, efficiency, and charging performance, aiming to enhance the nimble driving characteristics of electric vehicles, ensuring a smooth and enjoyable driving experience. Kia aims to let more consumers experience the joy and comfort of driving a Kia electric vehicle. Before delving into the key features contributing to the EV3's superior driving performance, here are the results of Kia's long-distance driving test for the EV3.

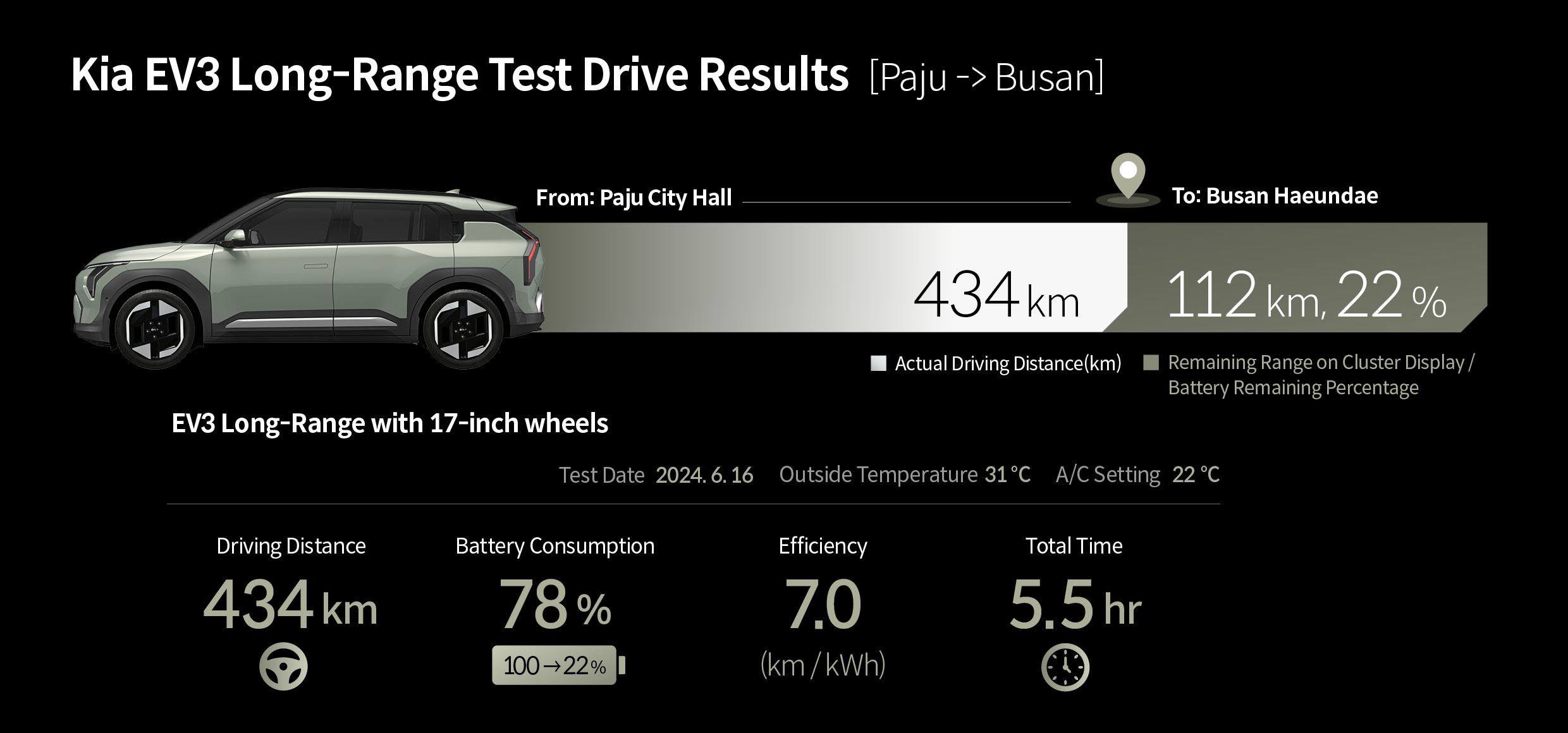

For starters, here is the evidence of the EV3’s impressive range and efficiency. In June, Kia engineers conducted a long-distance driving test from Paju in Gyeonggi Province to Busan. Using the long-range model equipped with 17-inch wheels, the test was conducted in hot weather, with the air conditioning set to 22°C.

The EV3 covered 434 km in approximately 5 hours and 30 minutes, finishing with 22% battery remaining and 112 km of range left. Despite the long highway drive, which is typically less favorable for electric vehicles, the EV3 achieved an efficiency of 7.0 km/kWh, exceeding the official combined efficiency rating of 5.4 km/kWh. Below are the features that enable the EV3 to achieve such excellent range and efficiency.

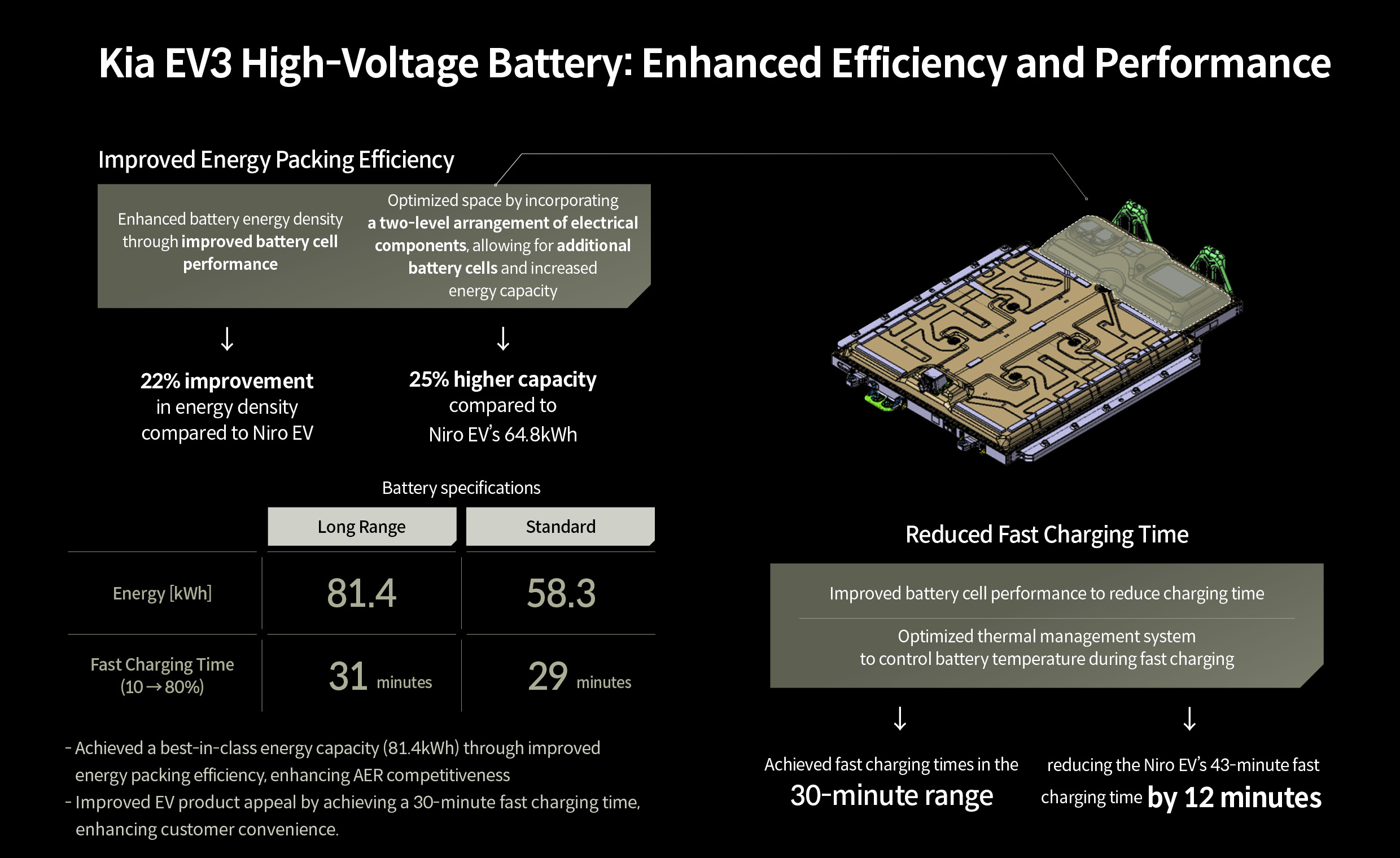

The EV3 comes in two versions based on battery capacity: Standard (58.3 kWh) and Long Range (81.4 kWh), with respective ranges of up to 350 km and 501 km. For those who primarily drive in urban areas, the Standard model offers sufficient performance with just one weekly charge. For frequent long-distance drivers, the Long Range model is the optimal choice. According to the Korea Transportation Safety Authority, the average daily driving distance per vehicle in South Korea last year was 33.9 km. Data from Seoul's Open Data Plaza indicates that the average daily driving distance for passenger cars in Seoul was 29.9 km in 2022.

The EV3's battery capacity surpasses that of similar models like the Kia Niro EV (64.8 kWh), Hyundai Kona Electric (48.6 kWh/64.8 kWh), and Volvo EX30 (66 kWh). While increasing battery capacity helps extend range, it also adds weight, which can reduce efficiency. Therefore, it’s essential to enhance aerodynamic performance and improve the efficiency of the powertrain components (battery, motor, inverter, and reducer). The EV3 has undergone this thorough process to become a highly refined electric vehicle.

The driving range of an electric vehicle is directly influenced by its high-voltage battery. To ensure a generous driving range, Kia improved the smallest unit—the cell—of the EV3’s battery. As a result, the EV3’s high-voltage battery boasts 22% higher energy density compared to previously developed electric vehicles in the same class.

he battery structure to fit more cells. Previously, components like the Battery Management Unit (BMU), Cell Monitoring Unit (CMU), and Power Relay Assembly (PRA) were placed at the front of the battery pack. In the fourth-generation battery used in the EV3, these components are positioned at the top rear of the battery pack, allowing for more cells in the same space.

As battery capacity increases, so must charging performance. Without improved charging capabilities, an enlarged battery and extended range wouldn’t provide an optimal electric vehicle experience. The EV3’s battery has enhanced cell-level performance to reduce fast-charging times. Its water-cooled battery thermal management system has also been upgraded to better control battery temperature during rapid charging. Consequently, the EV3 can charge from 10% to 80% in just 31 minutes for the Long Range model and 29 minutes for the Standard model, using a 350 kW charger.

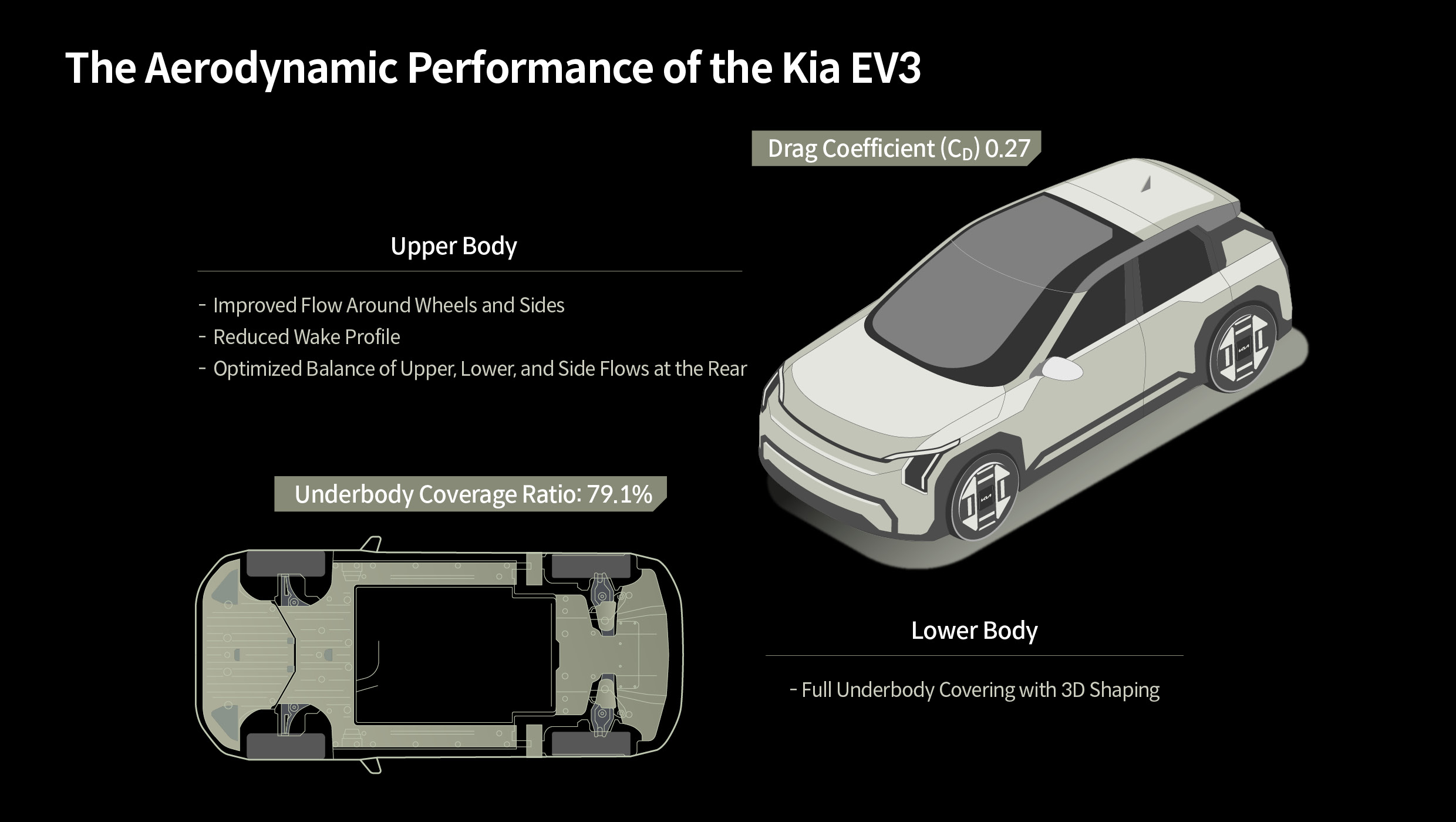

Aerodynamic performance is crucial in enhancing the energy efficiency of electric vehicles and extending their driving range. While increasing the capacity, energy density, and efficiency of high-voltage batteries is one approach, there are limits to balancing these factors with the vehicle's weight, interior space, and driving performance. Improving aerodynamic performance reduces energy consumption by minimizing air resistance during driving, and it also contributes to driving stability.

The EV3 was designed with Kia's ‘Joy for Reason’ philosophy in mind, balancing and harmonizing its exterior design concept with meticulous aerodynamic refinements. The underbody was carefully sealed and sculpted with 3D shapes to optimize airflow, achieving top-level aerodynamic performance among compact EVs.

As a vehicle moves forward, it encounters air resistance, which increases with speed. Therefore, it's essential to design the front of the vehicle to guide the air smoothly along the body without causing turbulence. If the airflow detaches from the body, it can destabilize the vehicle.

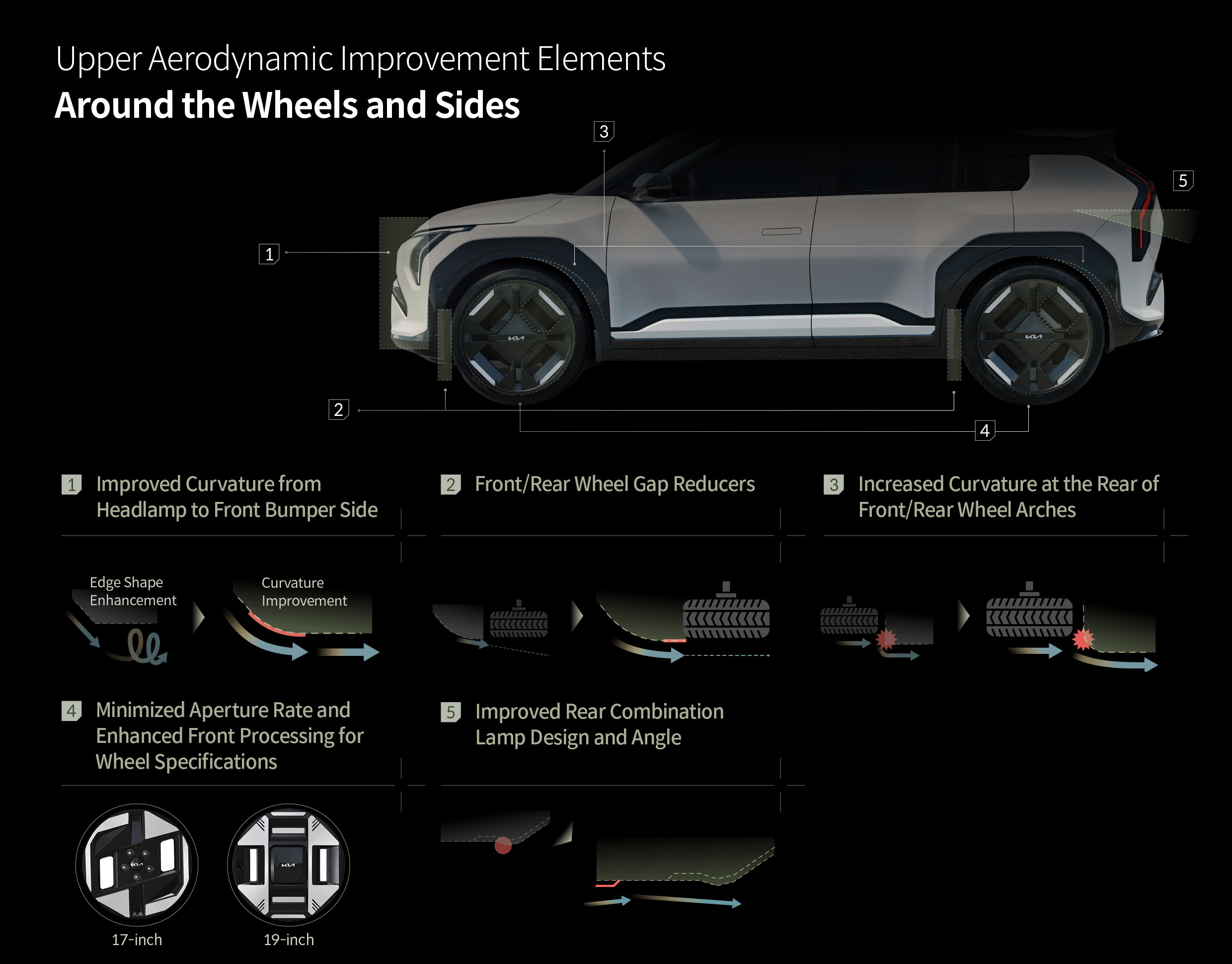

The EV3's body is meticulously designed to enhance aerodynamic efficiency. The sides of the headlights and front bumper are rounded to guide the airflow smoothly, preventing disruption. Wheel gap reducers are placed between the wheel arches and the wheels to keep the air flowing close to the body. The shape behind the wheel arches is refined to minimize sharp edges, allowing the air to flow more smoothly past the tires and rearward. Additionally, the 17- and 19-inch wheels incorporate aerodynamic features to minimize openings, and the shape and angle of the protruding rear lamps are carefully adjusted to improve the rear airflow.

The vehicle’s rear design is equally important for aerodynamic efficiency. Turbulence at the rear can drag the car, impacting both efficiency and stability. To counter this, the rear design narrows towards the back, resembling a teardrop shape, which is ideal for aerodynamics.

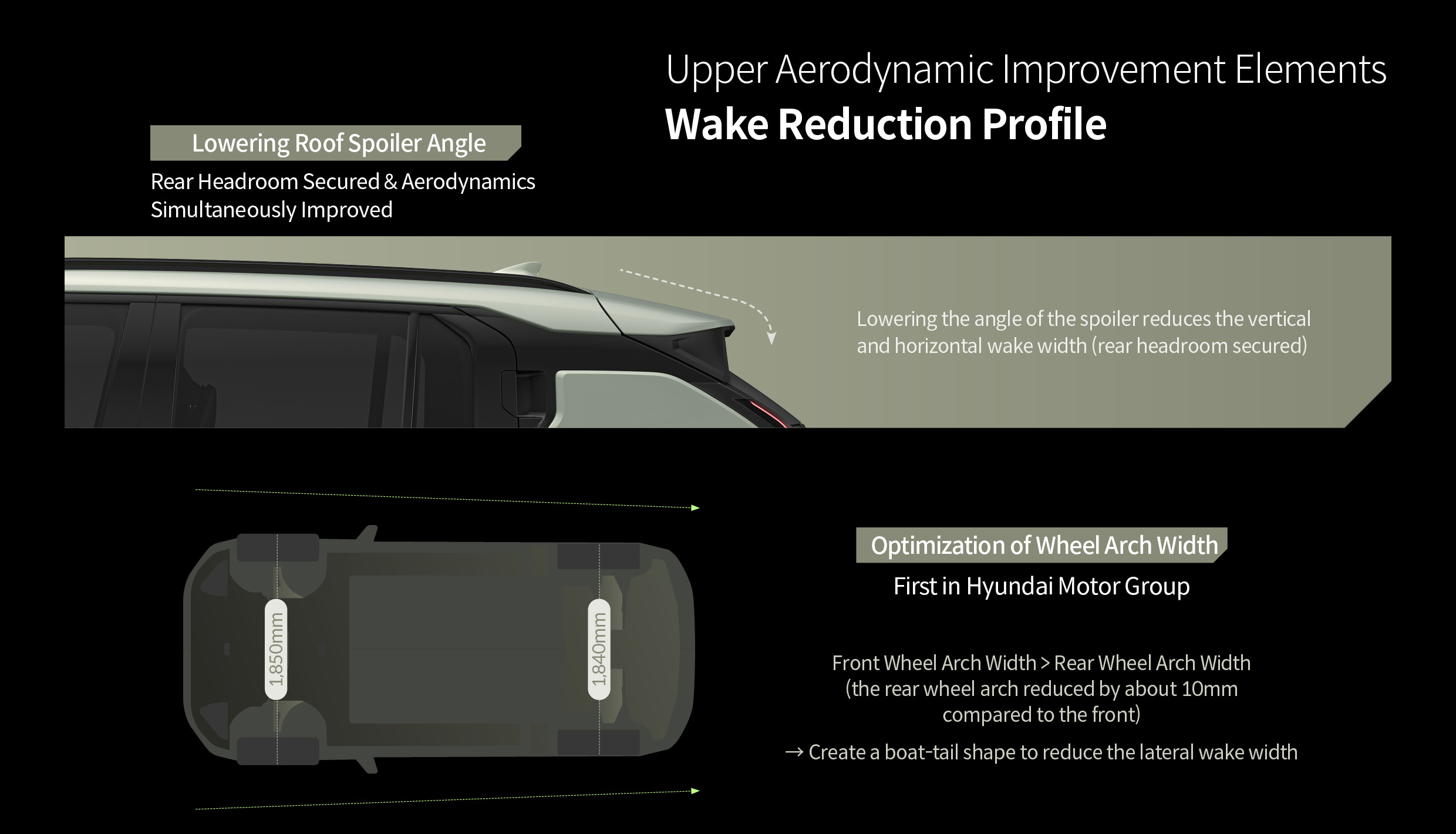

The EV3 features a roof spoiler with an optimized downward angle to maintain rear passenger space while enhancing aerodynamics. The vehicle is designed with a boat-tail shape, narrowing the rear wheel arches by 10mm compared to the front, a first for Hyundai Motor Group.

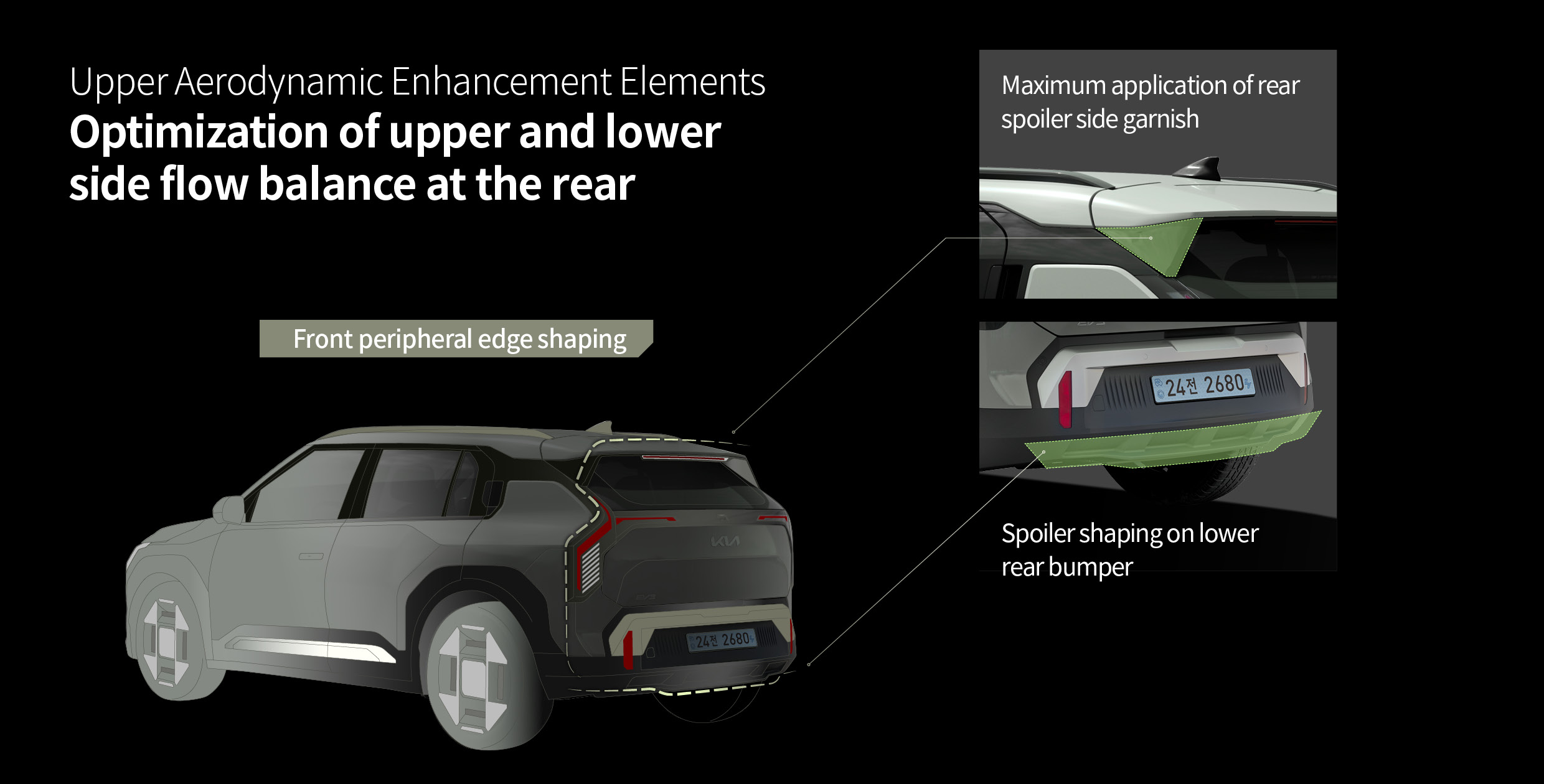

Furthermore, the side garnish areas on the left and right of the rear spoiler were widened, and a spoiler shape was applied to the lower part of the rear bumper. Additionally, the upper, lower, and lateral parts of the body, as well as the rear end, were refined into angular shapes to optimize airflow. This design ensures that the point where the air detaches from the body and creates vortices is moved further away, minimizing the impact of the pressure formed by the air gathering behind the vehicle.

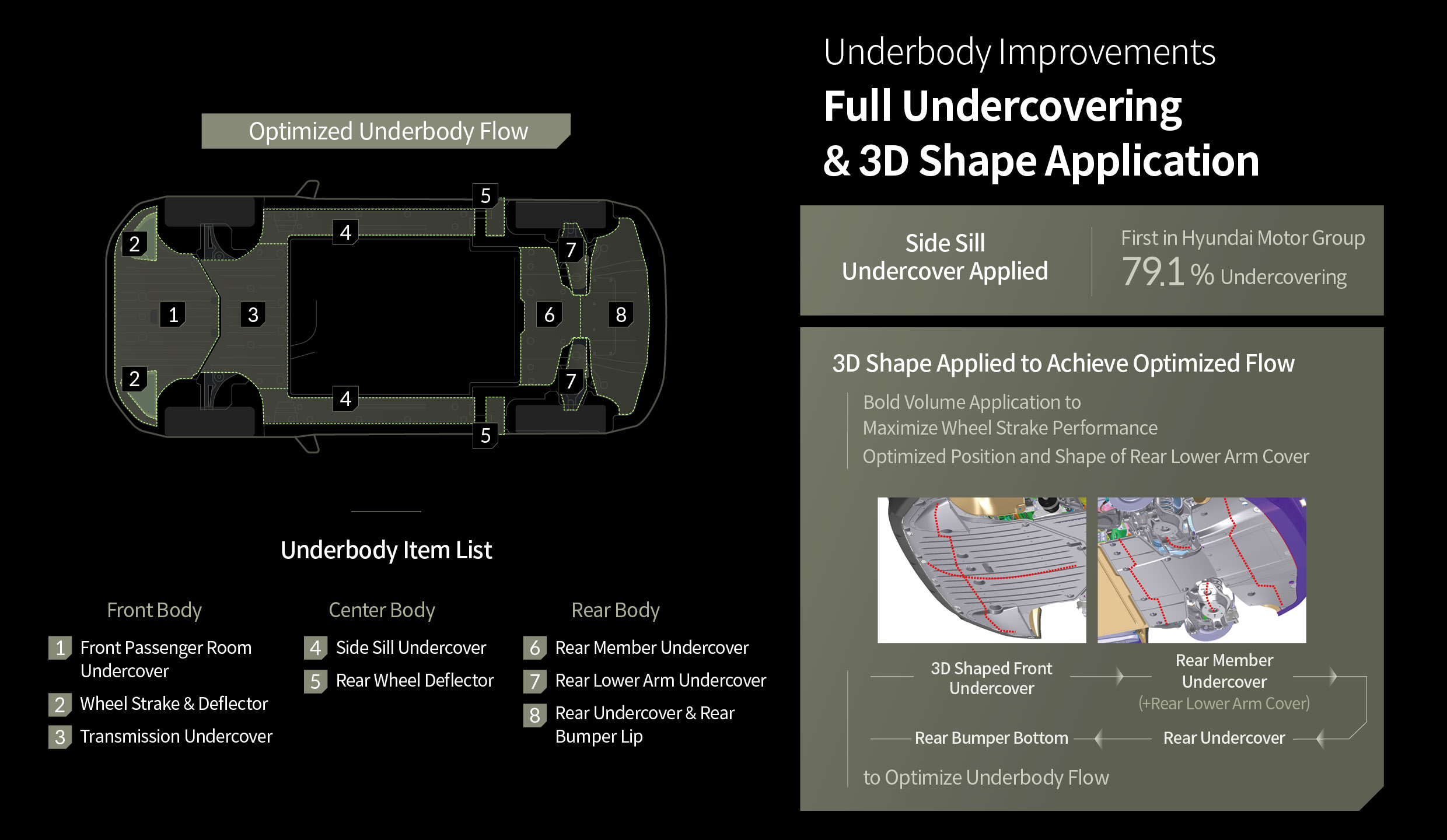

Aerodynamic design has been meticulously applied to the underbody of the vehicle. The undercarriage is equipped with covers that guide the airflow smoothly from the front to the rear. For the first time in the Hyundai Motor Group, side sill undercovers have been installed around the high-voltage battery, achieving a coverage ratio of 79.1%. Additionally, the size of the wheel strakes, which are mounted in front of the wheels, has been increased to ensure that the air flowing underneath the car meets less resistance and smoothly flows towards the rear. The vehicle also features a 3D-shaped underbody, with a convex front undercover and a concave rear undercover. The location and shape of the rear lower arm cover have been optimized, significantly improving the airflow under the car.

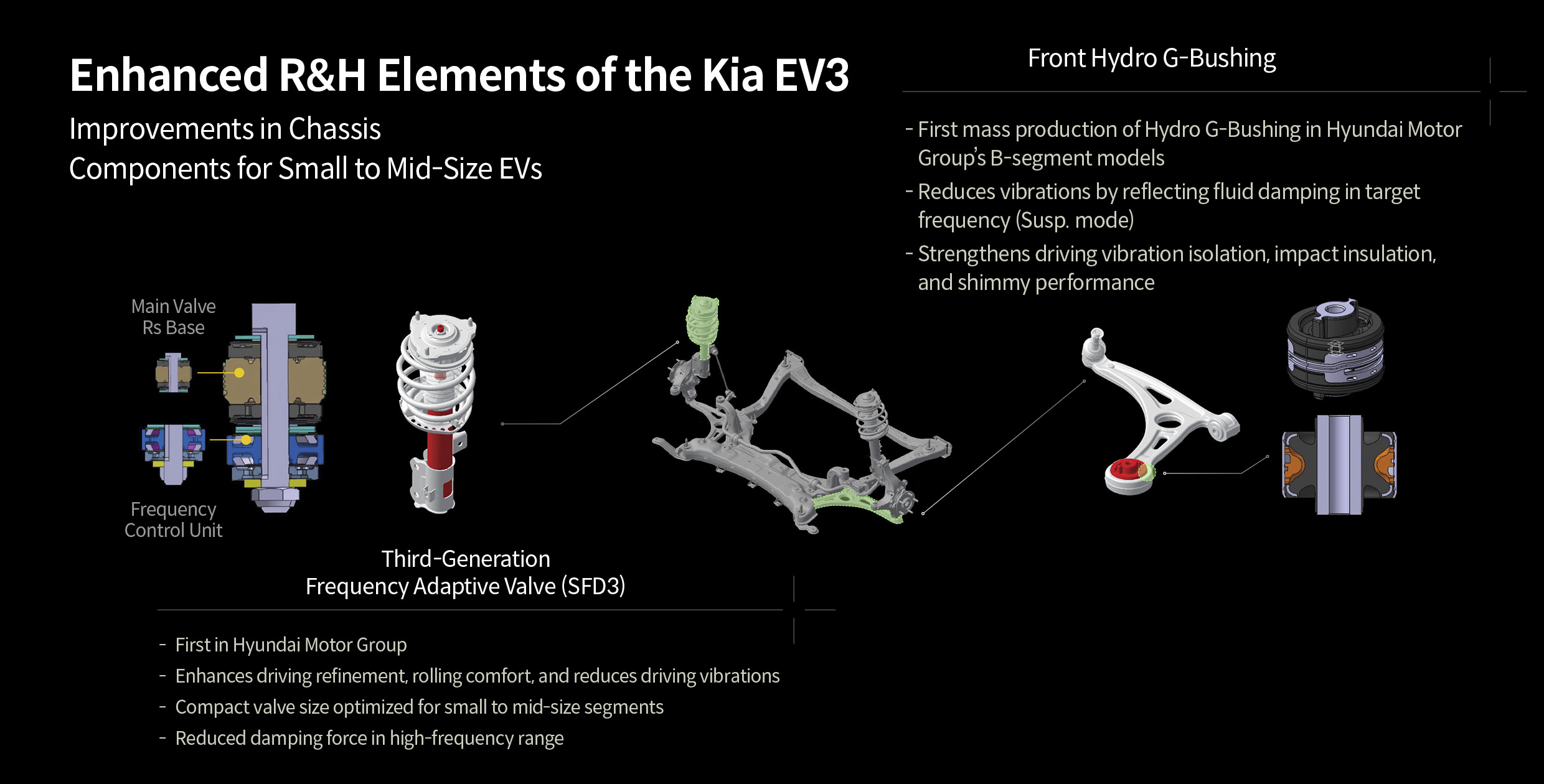

The EV3 not only ensures a substantial driving range but also delivers high levels of driving performance. This is achieved through improved suspension and reinforced body rigidity. The EV3 features the Smart Frequency Control Damper 3 (SFD3), a first for Hyundai Motor Group.

The SFD3 system cancels out high-frequency vibrations from the road. While it filters out large, low-frequency impacts like those from speed bumps using traditional damping, it also reduces minor vibrations during normal driving by lowering the damping force of the shock absorbers, resulting in a smoother ride. Operating similarly to the SFD2 system found in the Hyundai IONIQ 5 and Kia EV6, SFD3 features a more compact valve packaging within the shock absorber, making it suitable for smaller vehicles.

To improve ride comfort, the Hyundai Group has incorporated a hydro G bushing in the front lower arm of the EV3, a first for its B-segment models. Unlike conventional rubber bushings, hydro G bushings contain fluid to reduce vibrations significantly, contributing to a smoother ride. These bushings are approximately ten times more effective than standard bushings and have primarily been used in larger vehicles. However, due to the weight and larger wheels of electric vehicles, they were first applied in the IONIQ 6 for improved ride comfort.

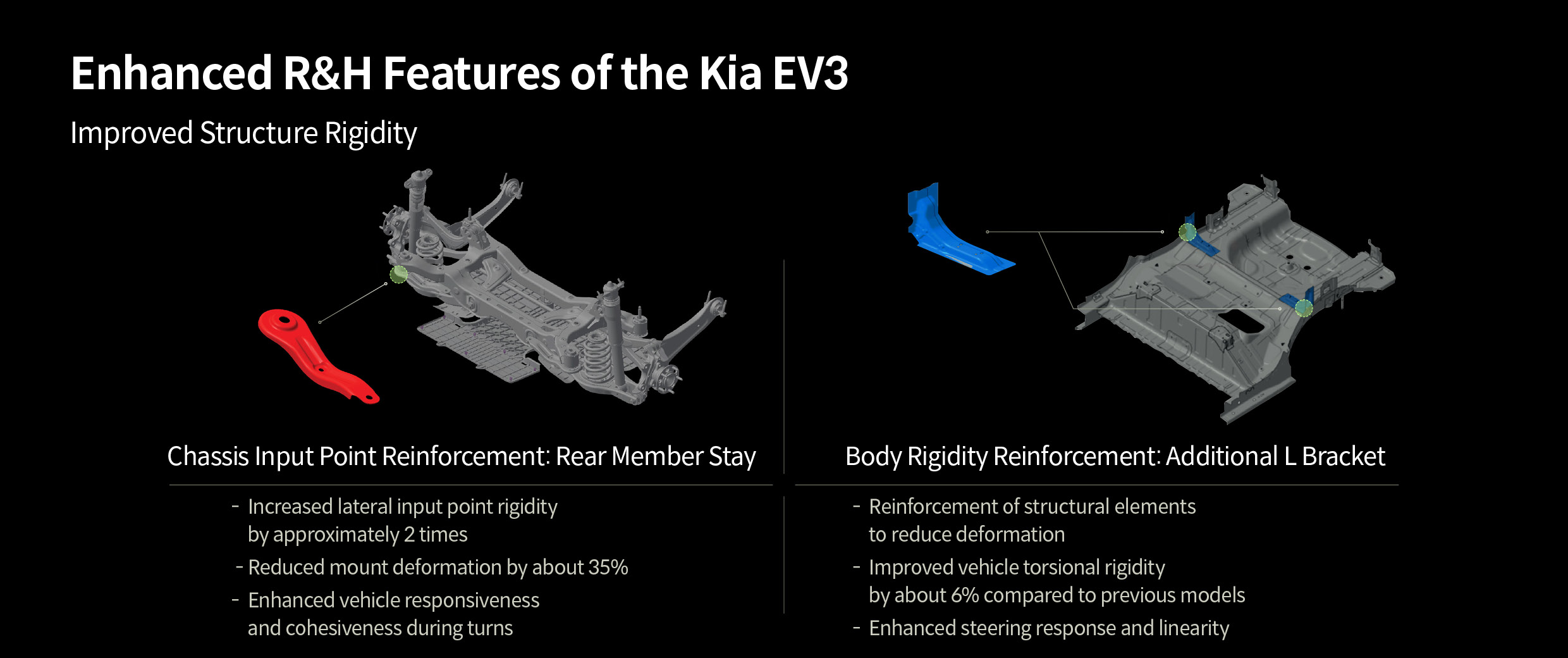

The EV3 has been developed to enhance handling response, unity, and stability in corners, increasing driving pleasure. For this purpose, the Hyundai Group has implemented member stay components, connecting the rear cross member to the body, in its C-segment and smaller models for the first time. This area endures substantial forces during cornering, and reinforcing it with member stays improves steering response.

Furthermore, an additional L-bracket, a type of body connection component, has been applied to the rear wheel section, enhancing the vehicle's torsional rigidity by 6.4%. Cars can experience slight twisting and deformation when passing over large bumps or during cornering. By reinforcing the connection structure to increase torsional rigidity, such occurrences can be minimized. This effort to make the EV3 sturdier and more robust, thereby enhancing handling performance, is evident throughout the vehicle.

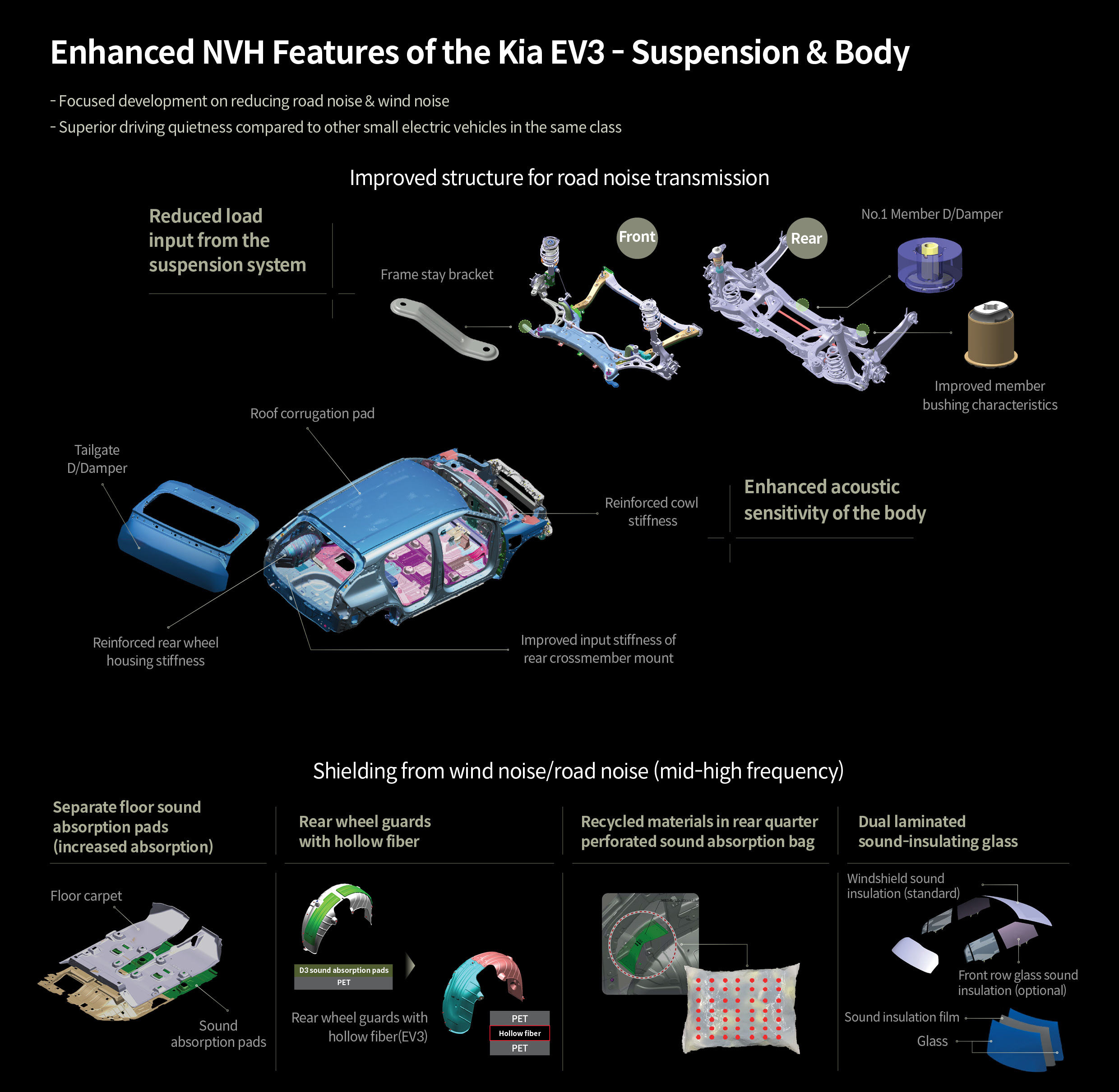

As a compact electric SUV, the EV3 benefits from the absence of an internal combustion engine, which reduces noise and vibrations. However, this makes road and wind noise more noticeable. To address this, the development team reinforced NVH (Noise, Vibration, Harshness) elements throughout the EV3, from the underbody to the roof. For instance, they attached stay brackets to the rear of the front member to reduce road noise and applied dynamic dampers to the front of the rear member, while also improving the rear member's bushings.

Additionally, considering that road vibrations transmitted to the car body can cause noise, the rail of the sunroof area has been reinforced. For models without a sunroof, the rail has been removed and a corrugated pad added to enhance NVH (noise, vibration, harshness) performance. Furthermore, reinforcements have been added to various parts of the car body to increase rigidity, while vibration-damping materials have been extensively applied. To reduce the loud wind noise heard during driving, double-laminated acoustic glass has been used, creating a more pleasant interior environment.

In addition, the IONIQ 6 features floor-split sound-absorbing pads to reduce road noise and perforated sound-absorbing bags made from recycled materials in the rear quarter panel behind the C-pillar to decrease noise from the rear. Sound-absorbing pads were also applied inside the rear wheel housings to minimize tire noise, and hollow fiber sound-absorbing pads were installed to prevent contamination from exposure.

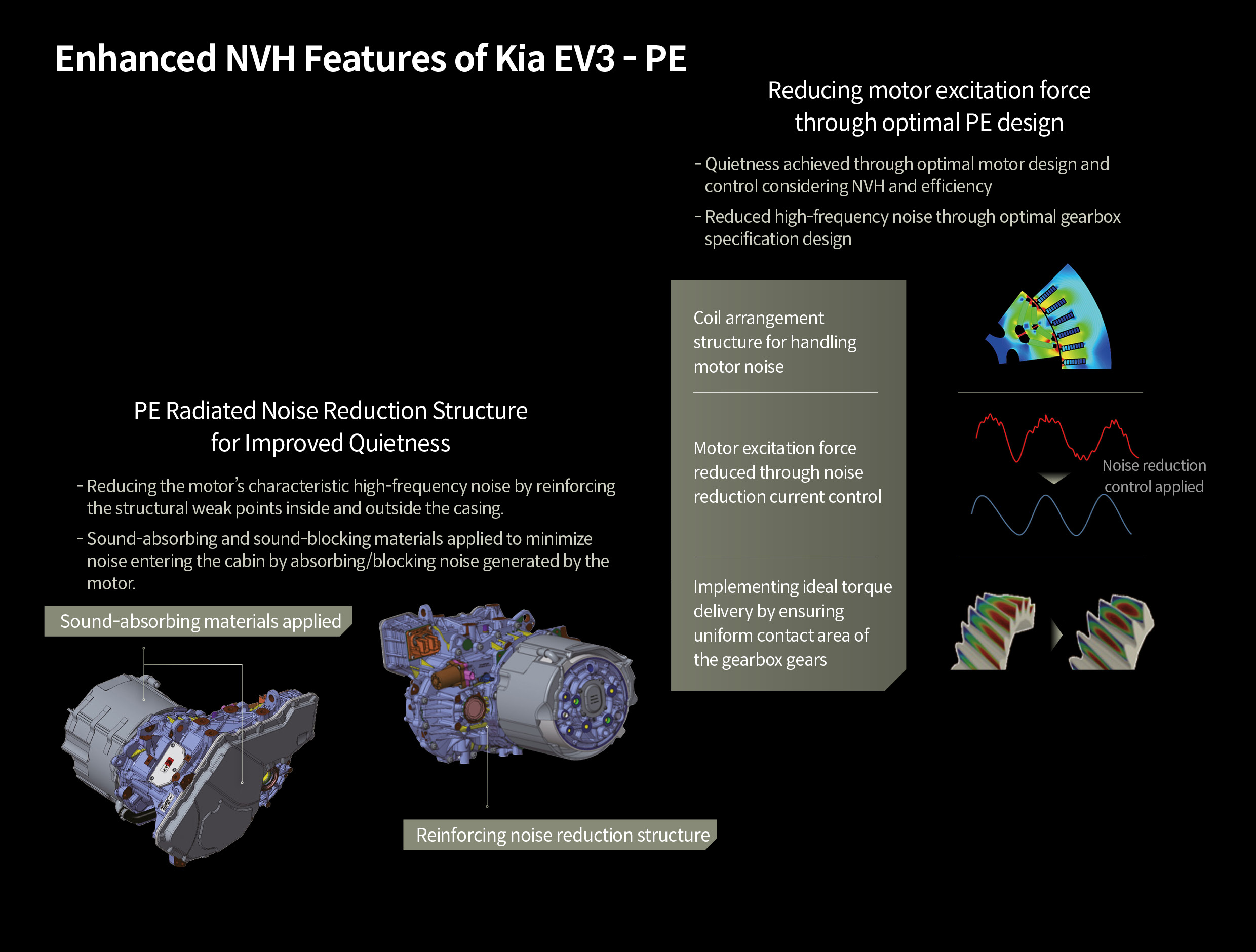

Meanwhile, the EV3 goes beyond just reducing external vibrations and noise; it also focuses on minimizing the operational noise from the PE system that generates power. The PE system in the EV3 features a coil structure designed to reduce motor noise from the initial design phase and improved current control methods to lessen vibration-inducing forces. Additionally, the reduction gears are designed to ensure uniform contact and ideal torque transmission, reducing vibrational forces.

Furthermore, sound-absorbing materials are attached directly to the PE system to fundamentally minimize noise. The EV3's PE system includes thick sound-absorbing materials that wrap around the front of the motor and inverter, and structural reinforcements inside and out to reduce the high-frequency noise characteristic of electric motors.

As we have seen, the EV3 embodies meticulous efforts by the development team to deliver ample driving range, high energy efficiency, advanced battery technology, precise aerodynamics, and a lively yet comfortable driving experience. With the high-quality, well-rounded EV3, drivers can enjoy an EV life free from worries about driving range and efficiency.

By Lee Se-hwan

Photography by: Choi Dae-il and Kim Bum-seok